The maintenance and upkeep of air compressors significantly and multidimensionally impact their operational efficiency. Regular and standardized maintenance can enhance efficiency by 10%–30% and reduce energy consumption by 10%–20%. In contrast, inadequate or improper maintenance leads to 逐年 declining efficiency and frequent breakdowns. Below is a detailed analysis of specific maintenance components and their practical impacts:

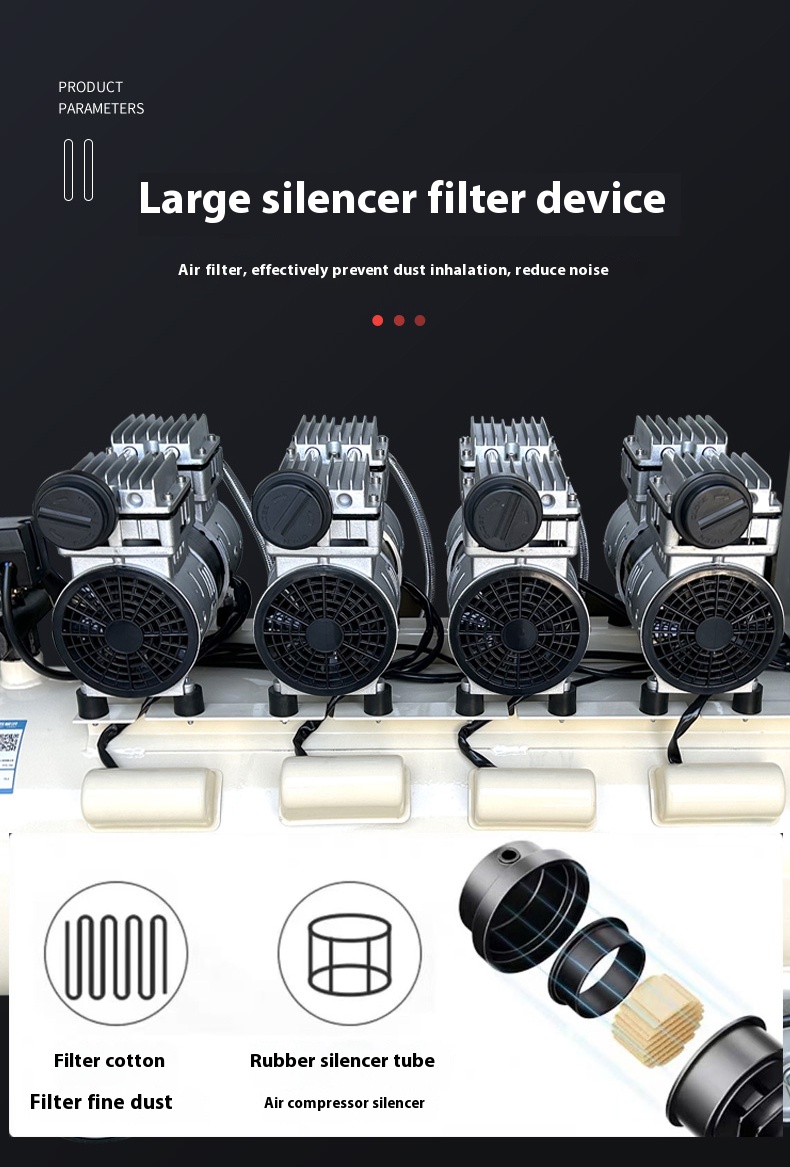

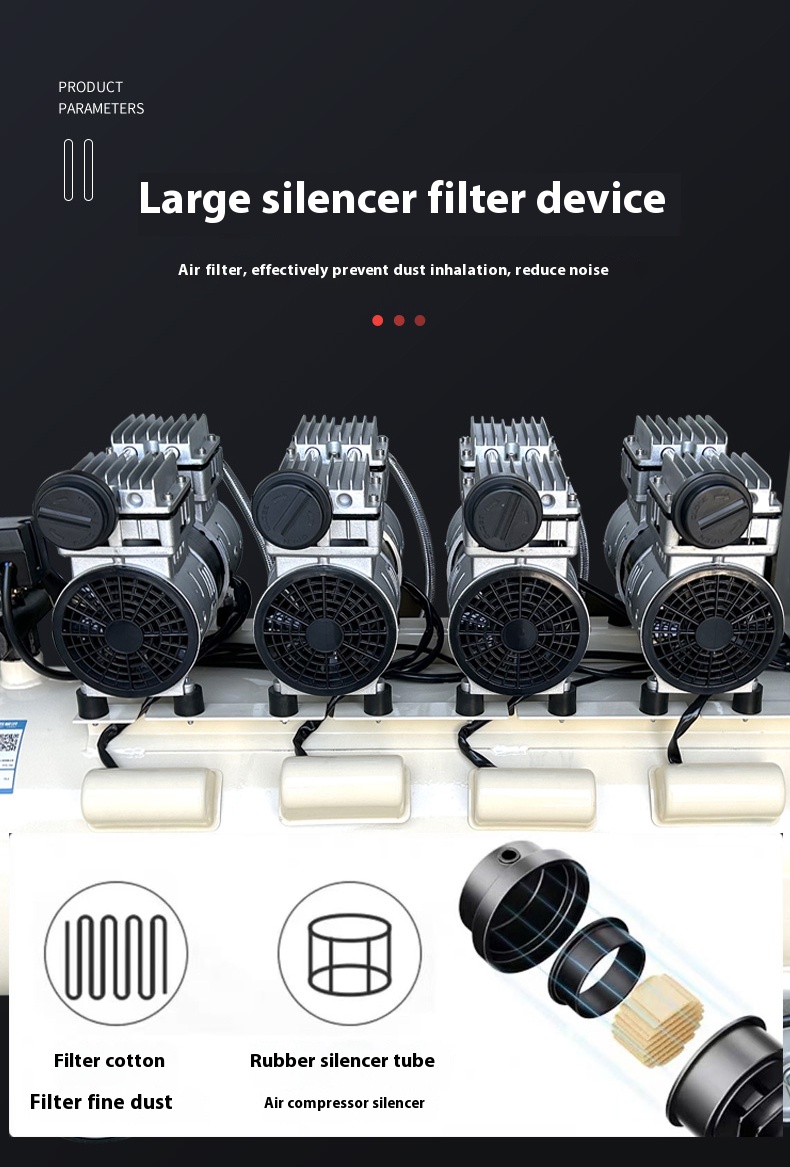

- Air Filter Clogging:

Dust accumulation in the air filter increases intake resistance. Studies show that every 0.01MPa increase in resistance raises energy consumption by approximately 1%. For example, a 100kW compressor with a 0.05MPa resistance increase from a clogged air filter would consume ~40,000 extra kWh/year (based on 8,000 operating hours), costing over ¥20,000.- In extreme cases (e.g., completely blocked filters), insufficient air intake can cause frequent "surges" or shutdowns, nearly eliminating efficiency.

- Oil Filter/Oil-Gas Separator Failure:

- Clogged oil filters restrict lubricant flow, leading to insufficient component lubrication, frictional heating, and a 5%–10% increase in power consumption.

- Failed oil-gas separators cause excessive oil content in compressed air, contaminating equipment and potentially triggering high-temperature shutdowns due to abnormal oil circulation.

- Oil Degradation:

Oxidized, emulsified, or carbonized oil reduces lubrication performance and increases friction. Research indicates that degraded oil can raise internal friction power consumption by 15%–20% and reduce volumetric efficiency by 8%–12% due to poor sealing in screw rotors or piston rings.- Example: A factory’s screw compressor experienced 12% efficiency decline and 15% higher energy consumption after one year of delayed oil changes. Efficiency recovered to 95% of initial levels after oil replacement.

- Abnormal Oil Levels:

- Low oil levels accelerate bearing wear (e.g., increased clearances in rolling bearings reduce mechanical efficiency by 3%–5%).

- Excessive oil levels may cause "oil carryover," increasing resistance.

- Moving Component Wear:

- Wear in piston rings, screw rotor coatings, and bearings increases internal leakage. For screw compressors, rotor wear can reduce volumetric efficiency by 1%–3% annually, with a 8%–10% decline after three years of neglected maintenance.

- In piston compressors, cylinder wear exceeding allowable tolerances (e.g., cylindricity error >0.05mm) can reduce air delivery by 10%–20%.

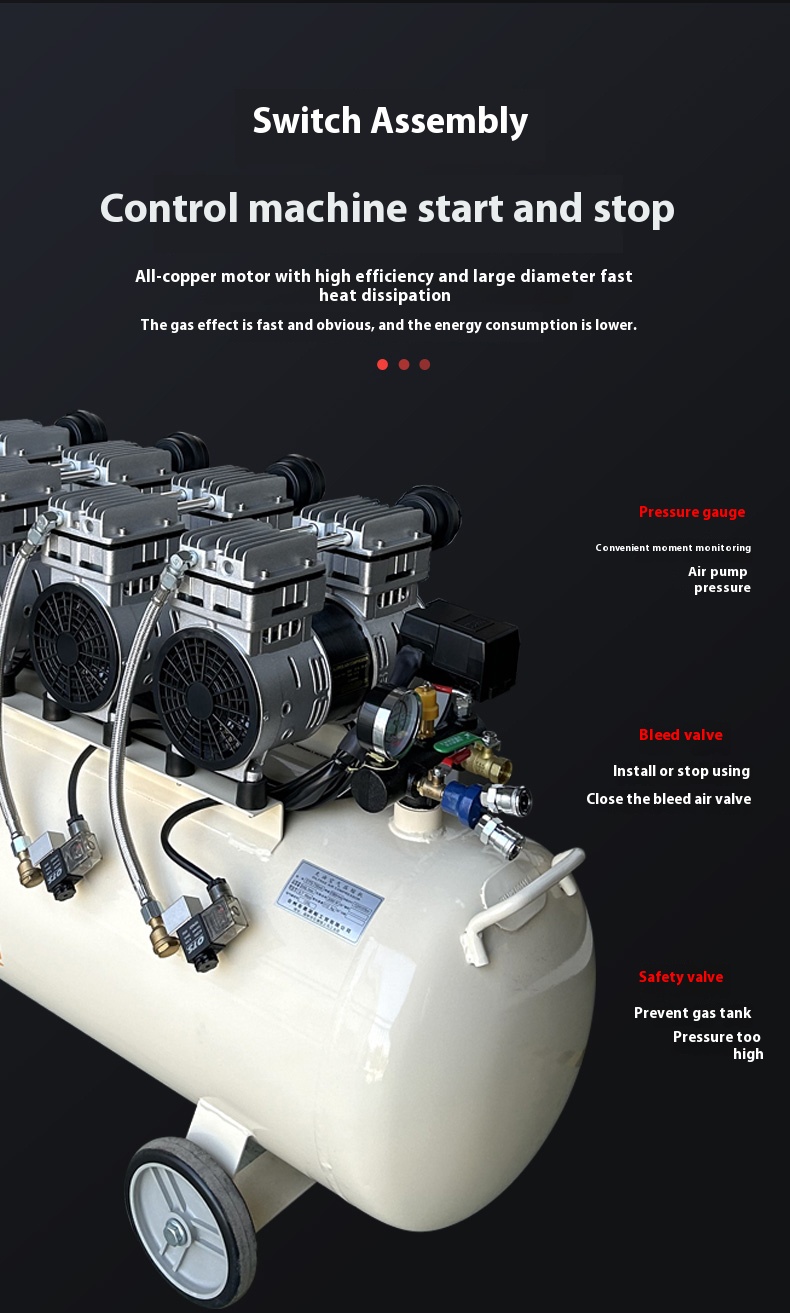

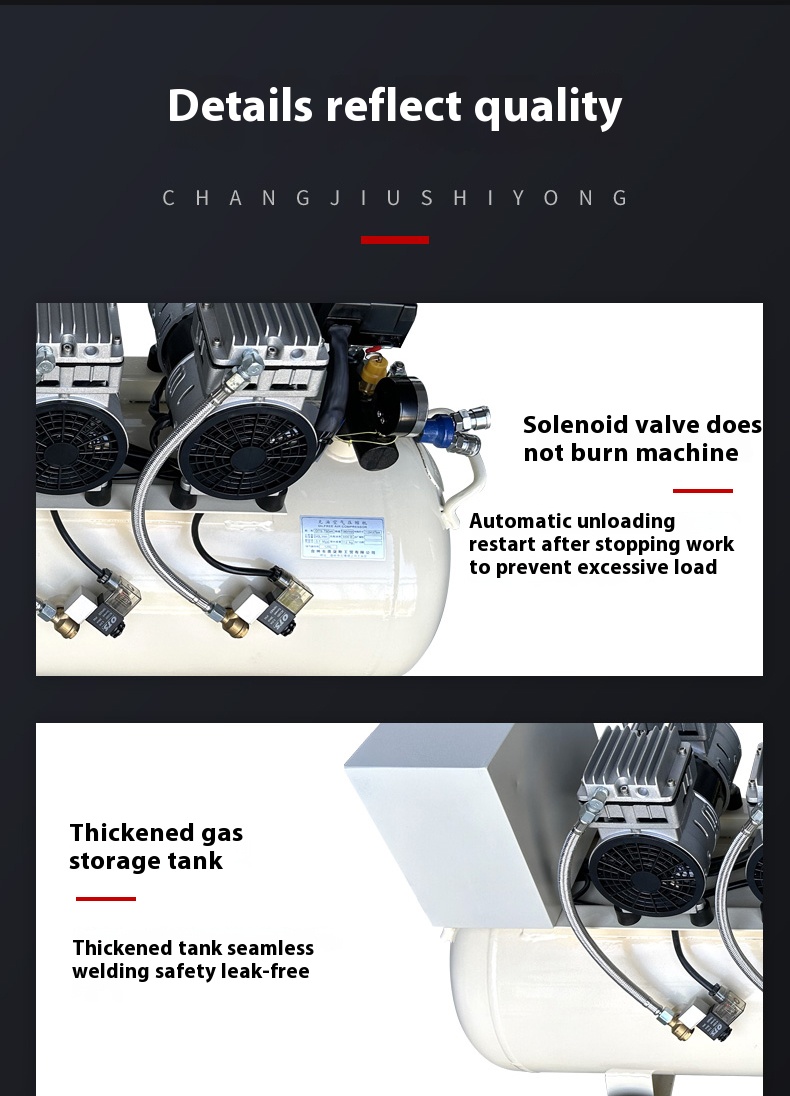

- System Leakage Control:

Leaks at pipe joints, valves, and traps are common. A 1mm-diameter leak point at 0.7MPa pressure leaks ~35,000 m³/year, equivalent to the compressor running an extra 500 hours—a significant energy waste. Regular leak detection (e.g., ultrasonic 检漏) can increase effective air delivery by 5%–10%.

- Cooler Fouling/Clogging:

- In water-cooled coolers, 1mm of scale reduces heat transfer efficiency by >30%, raising discharge temperatures. A 10°C overdesign temperature may force frequency reduction (e.g., from 50Hz to 45Hz), cutting air delivery by ~10% and accelerating oil aging.

- In air-cooled coolers, severe dust accumulation on fins reduces heat dissipation by 20%–40%, similarly degrading efficiency.

This analysis underscores the critical role of proactive maintenance in sustaining air compressor performance, energy efficiency, and operational reliability.