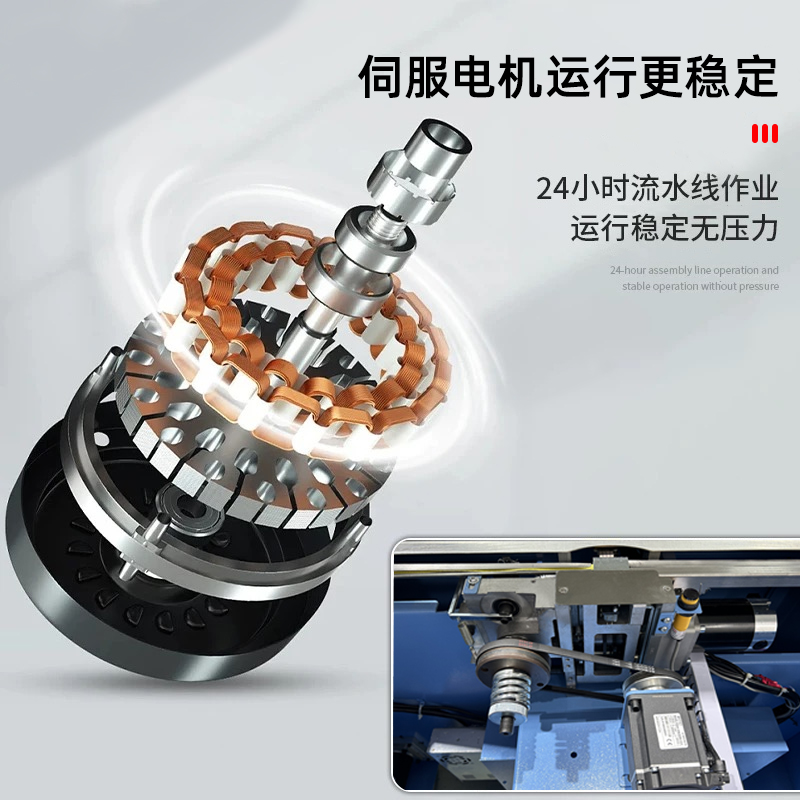

The role of servo motors in automatic strapping machines.

Release date:2025-07-03

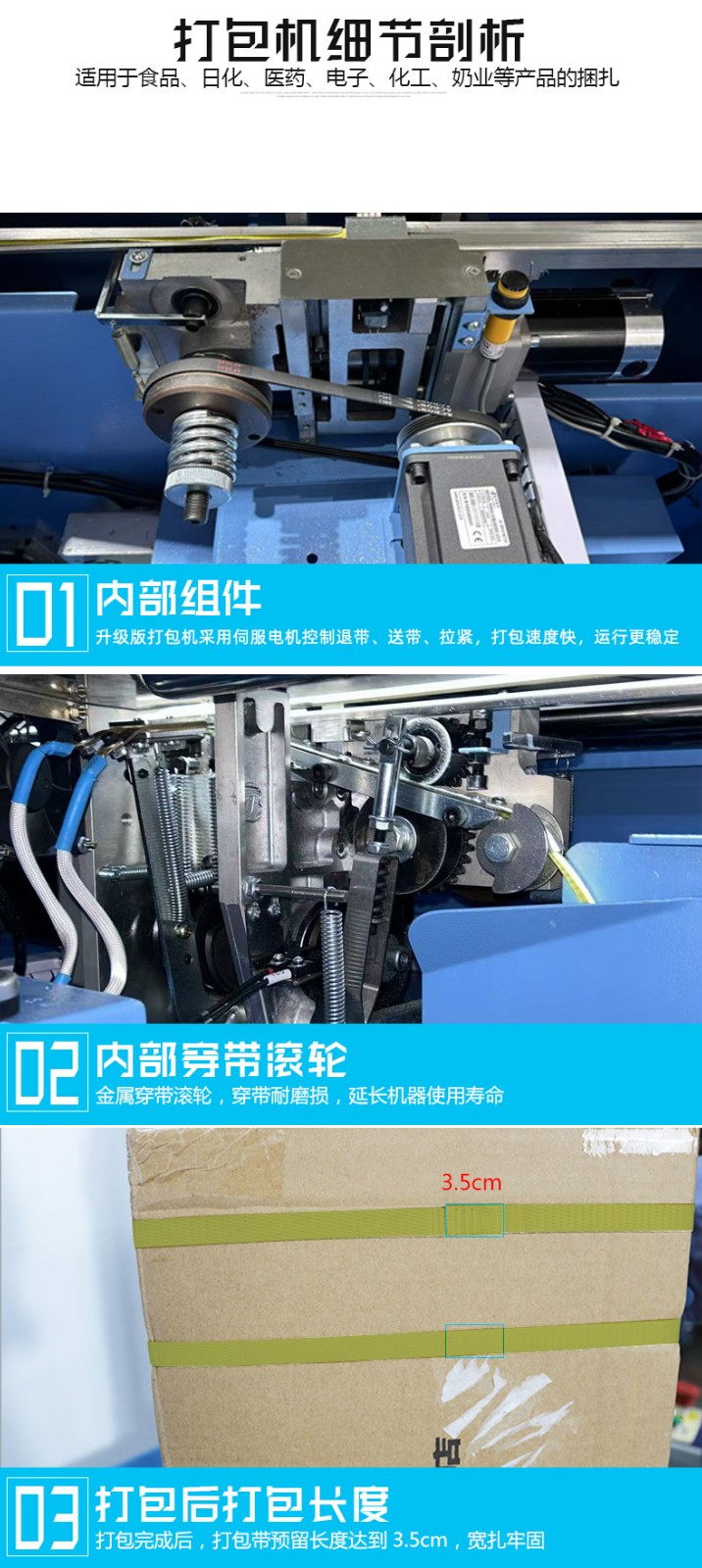

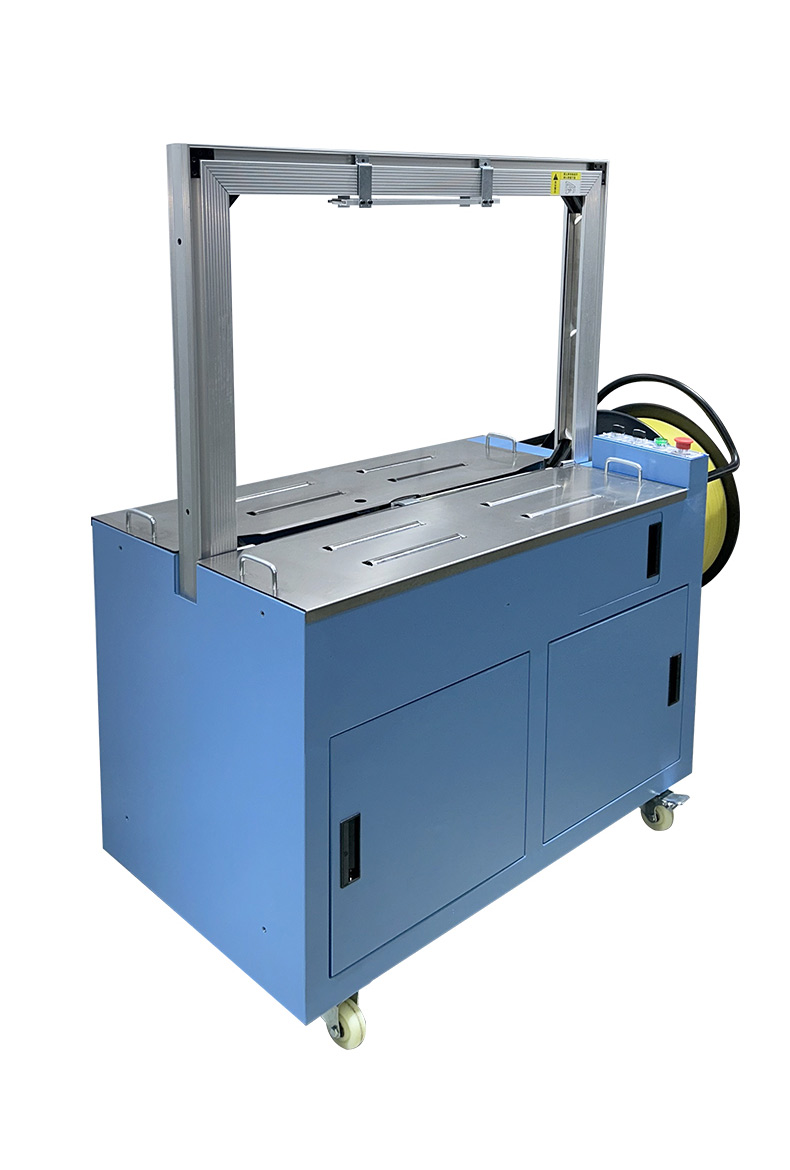

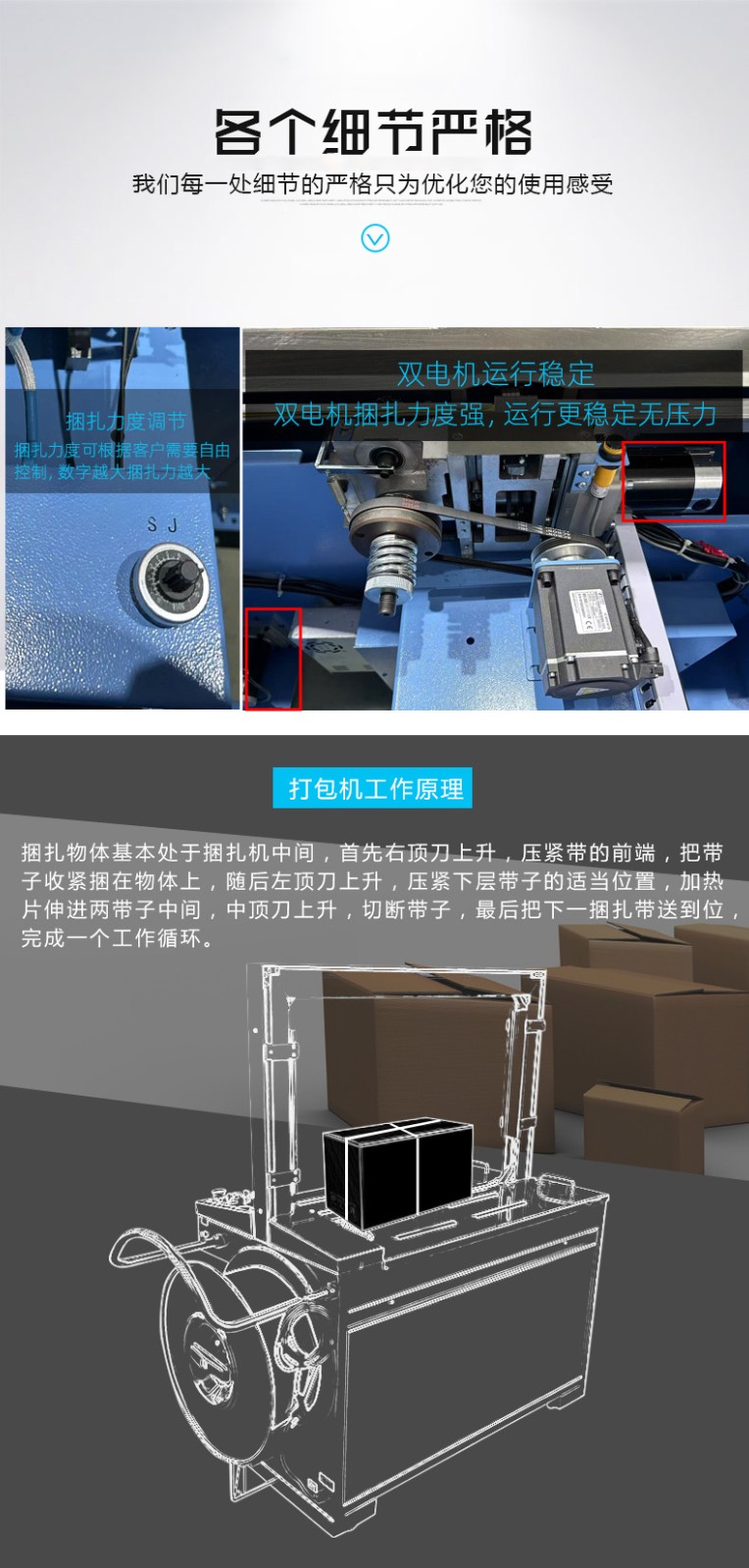

- The servo motor precisely adjusts the rotation speed and angle to control the length of the strapping belt pulled from the storage device (with an error controlled within ±1mm), avoiding waste caused by excessive feeding or affecting the strapping effect due to insufficient feeding.

- Example: When strapping cartons of different specifications, the servo motor can quickly adjust the belt feeding amount according to preset parameters, eliminating the need for manual adjustment of mechanical structures.

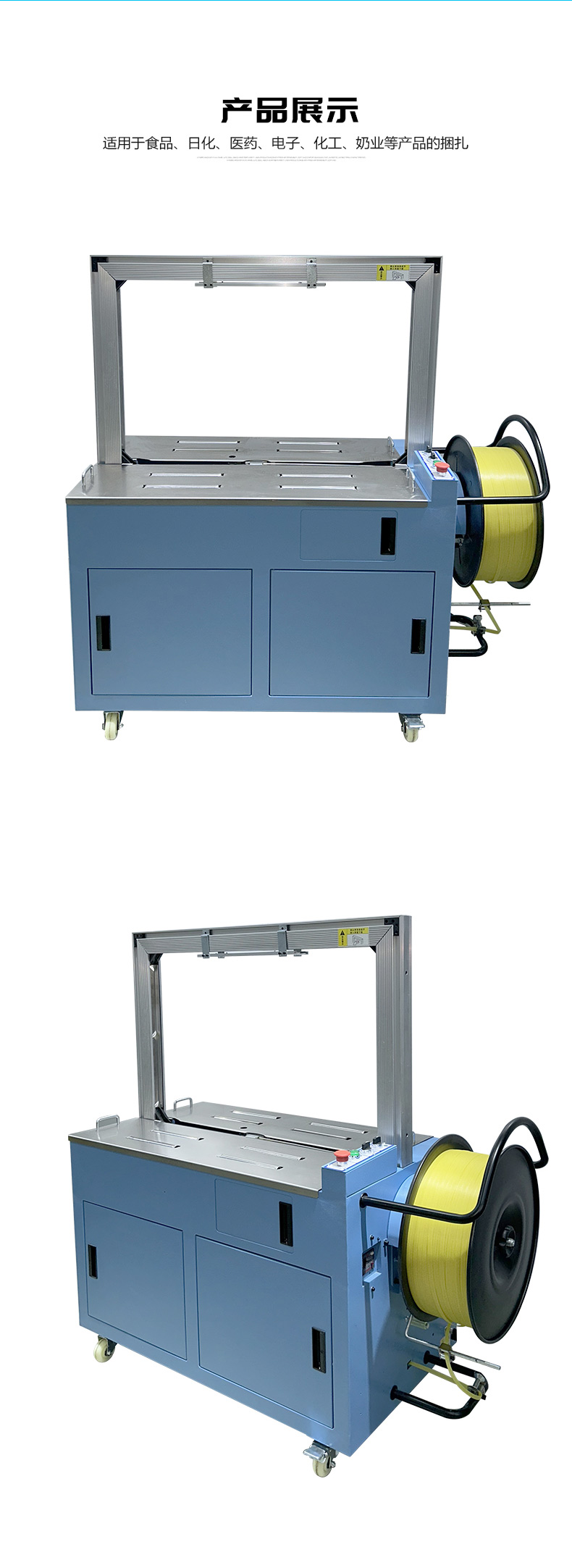

- When the strapping head drives the strapping belt to form a loop and thread around the product, the servo motor ensures the strapping belt accurately wraps around the preset position of the product through real-time feedback of position signals (such as encoder feedback), preventing loose strapping caused by offset.

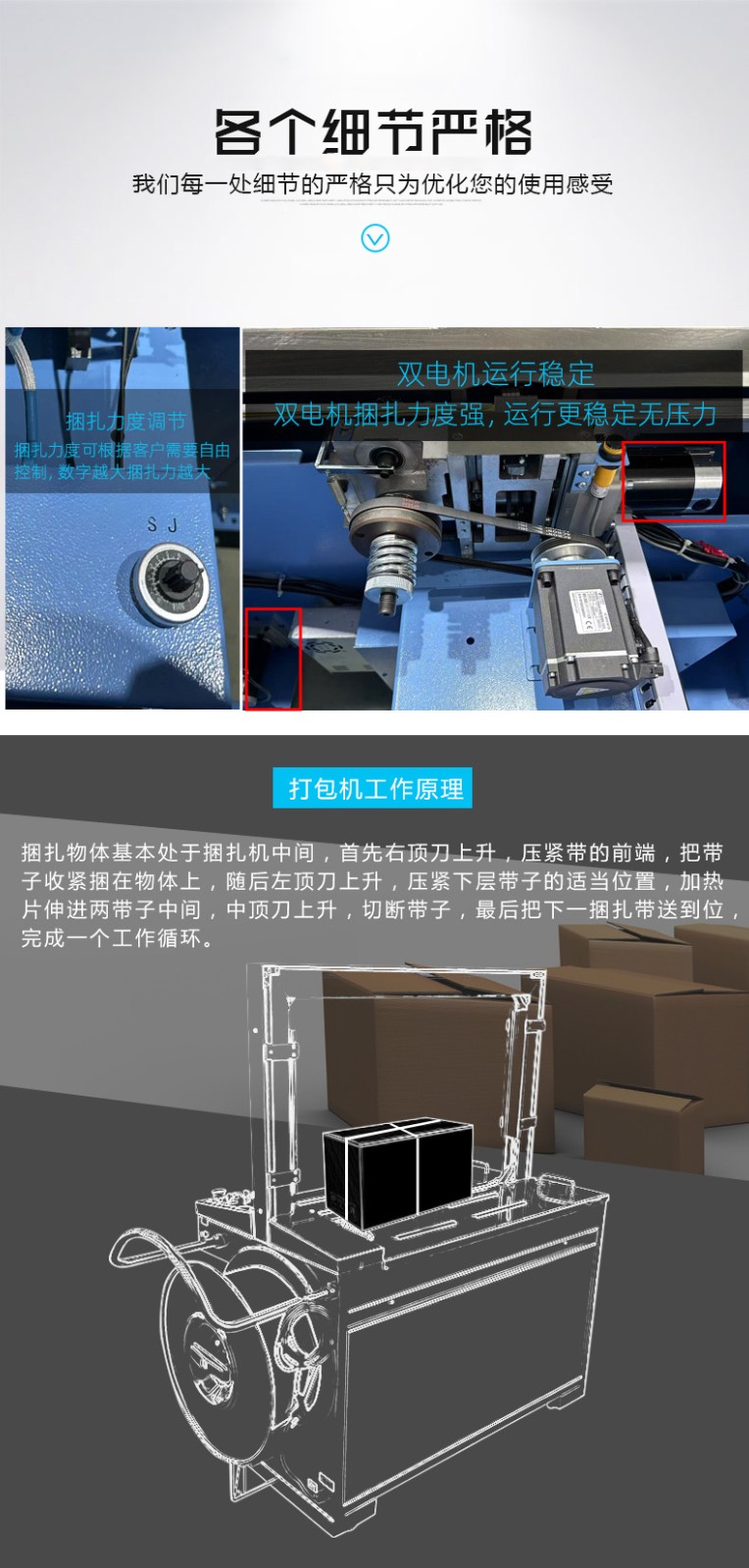

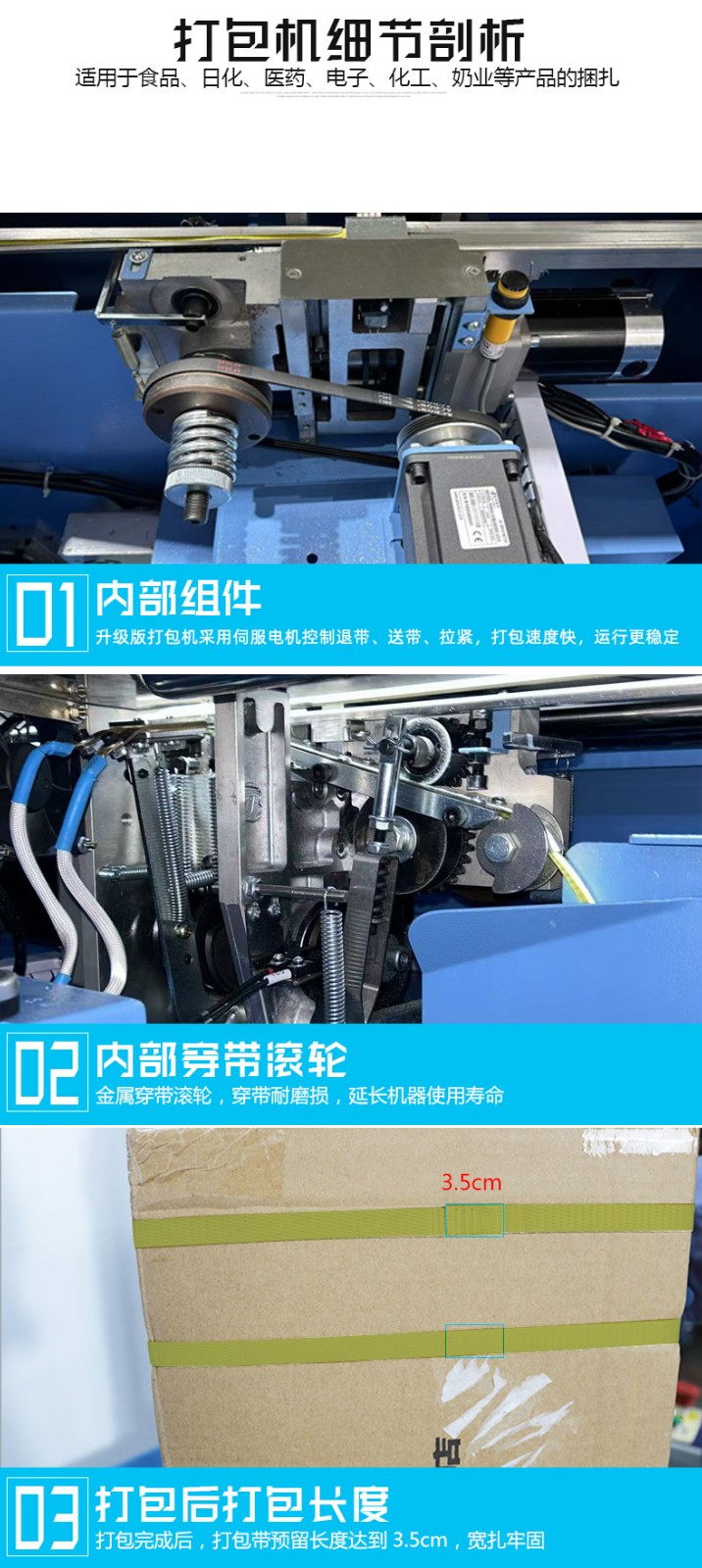

- The servo motor can precisely control the tension of the strapping belt (typically adjustable from 5-100N) according to the product material (e.g., fragile items, hard products).

- Example: When packaging electronic products, the servo motor tightens with low tension (10-20N) to avoid damage to the products; when packaging building materials, it uses high tension (50-80N) to ensure the stability of the goods.

- During belt cutting, the servo motor drives the cutter device to act quickly, ensuring a flat cutting position while controlling the length of the new belt fed out, preparing for the next strapping. The entire process is rhythm-controlled (e.g., the cutting time for each strapping can be controlled within 0.5 seconds).

- The servo motor in the conveying system controls the speed of the conveyor belt (e.g., adjustable from 0.5-2m/s) and the start/stop timing, accurately delivering the products to be strapped into the strapping area.

- Example: When the product is detected to reach the photoelectric sensor position, the servo motor immediately adjusts the conveyor belt speed, making the product stop directly below the strapping head with an error of no more than ±5mm, ensuring precise strapping position.

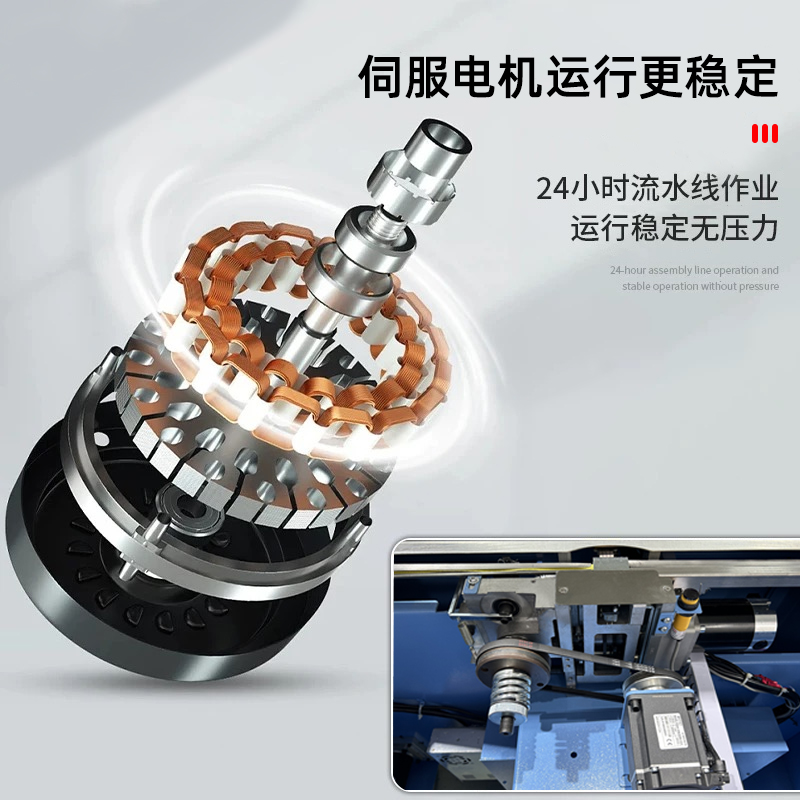

- The servo motor has a short acceleration/deceleration time (e.g., it can accelerate from 0 to the rated speed within 0.1 seconds), shortening the cycle period of the strapping machine (traditional mechanical strapping machines can perform about 20 cycles per minute, while servo strapping machines can reach 40-60 cycles per minute), suitable for high-speed production lines.

- Compared with traditional mechanical transmissions (such as belts and gears), the servo motor is directly driven by electric control, reducing friction loss of mechanical components, lowering the failure rate (e.g., the annual maintenance times are reduced from 5-6 times to 1-2 times), and extending the equipment life to 8-10 years.

- When strapping products of different weights, the servo motor can real-time adjust the output torque (e.g., automatically increasing from 0.5N·m to 2N·m), ensuring constant tightening force and avoiding unstable strapping effects caused by load changes.