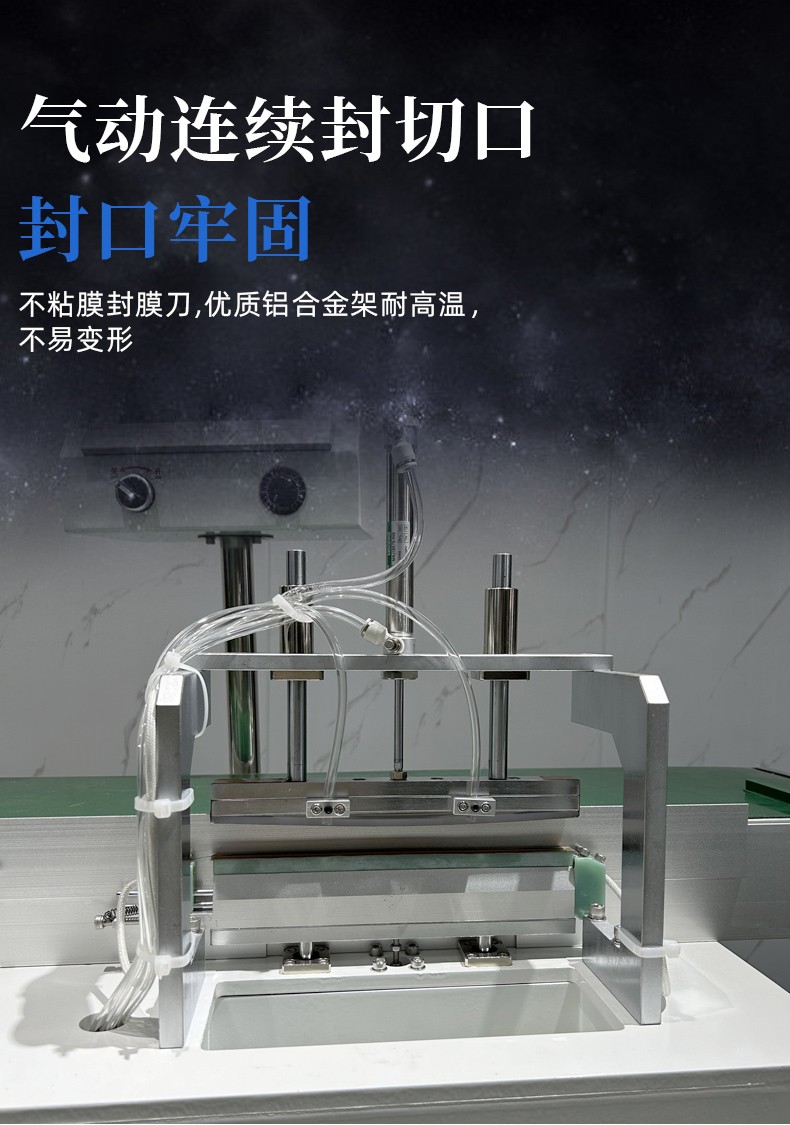

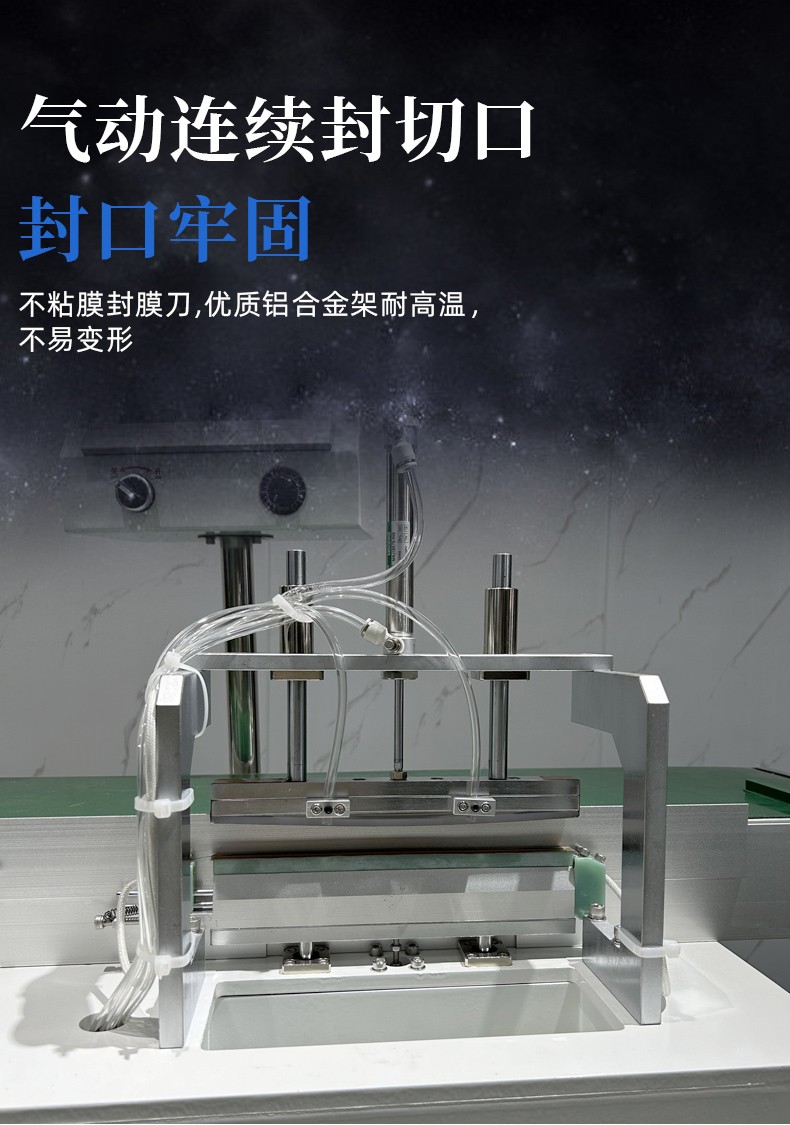

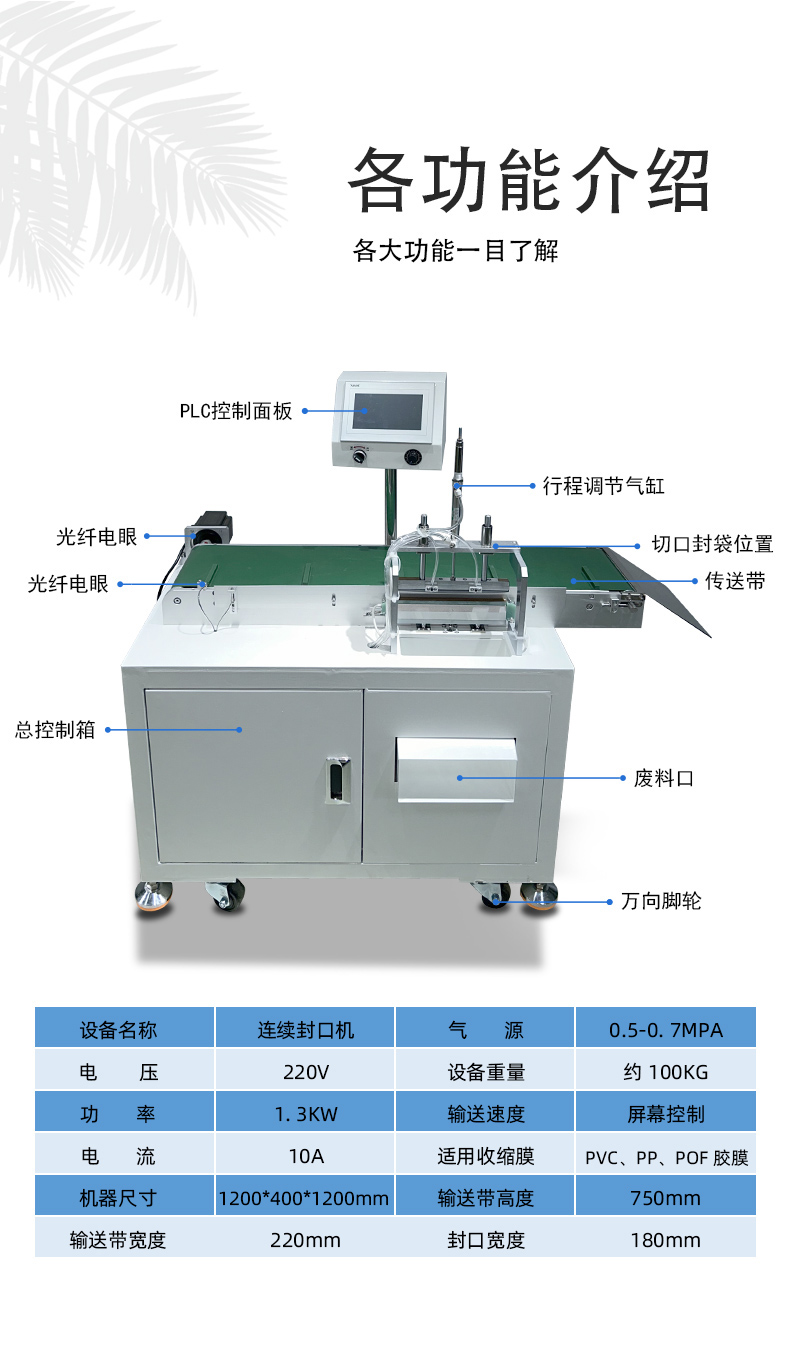

Unlike intermittent sealing and cutting equipment, continuous sealing and cutting machines achieve uninterrupted feeding of packaging materials through the transmission system. The sealing and cutting action is synchronized with the conveying process, eliminating the need for frequent starts and stops. For example, in the packaging of biscuits in the food industry, it can complete dozens to hundreds of sealing and cutting operations per minute, significantly outperforming the processing speed of traditional manual or intermittent equipment, and meeting the high throughput requirements of production lines.

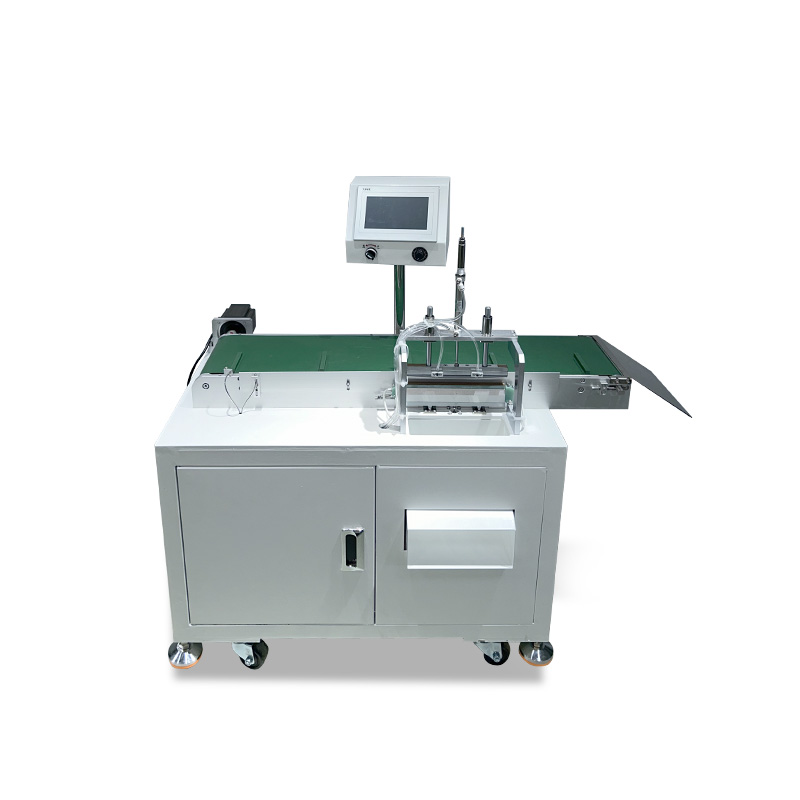

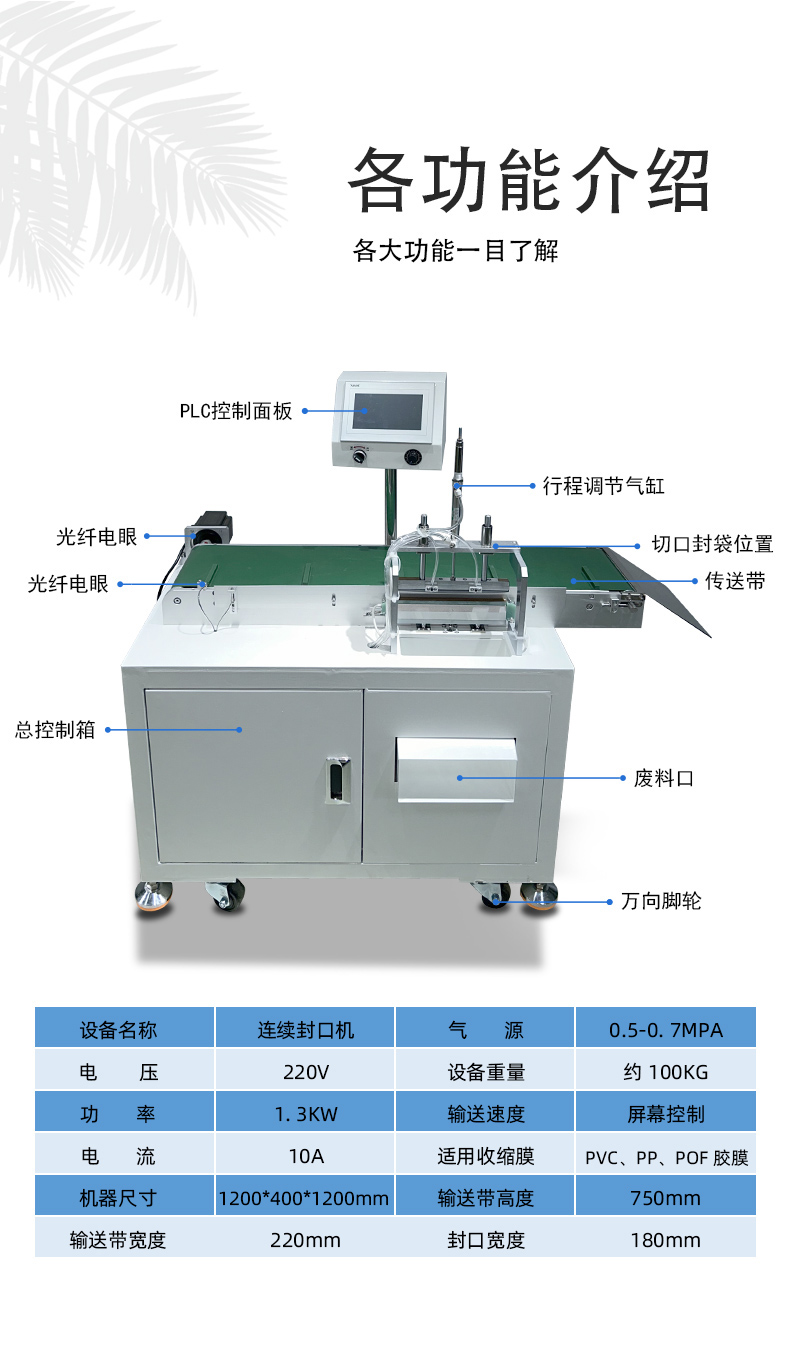

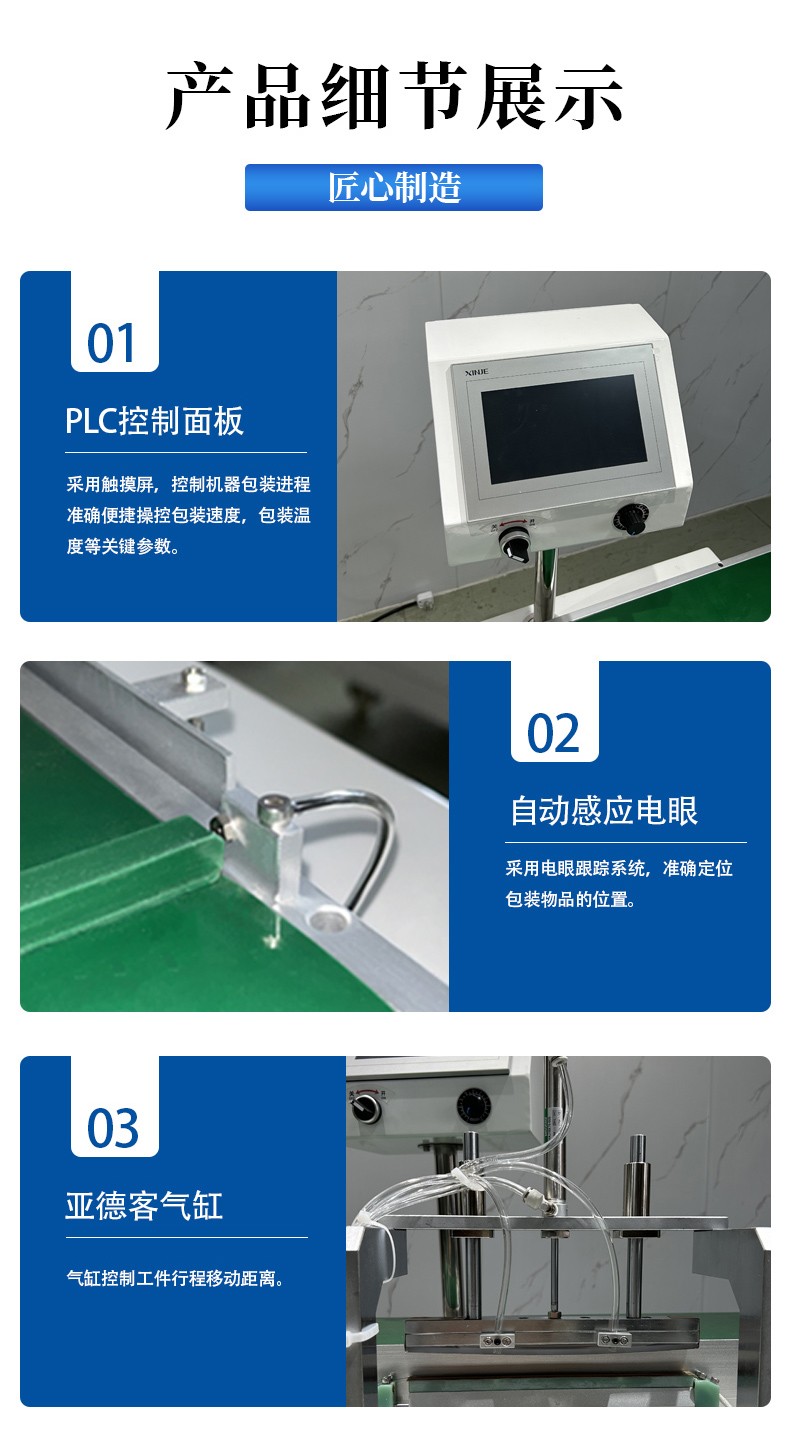

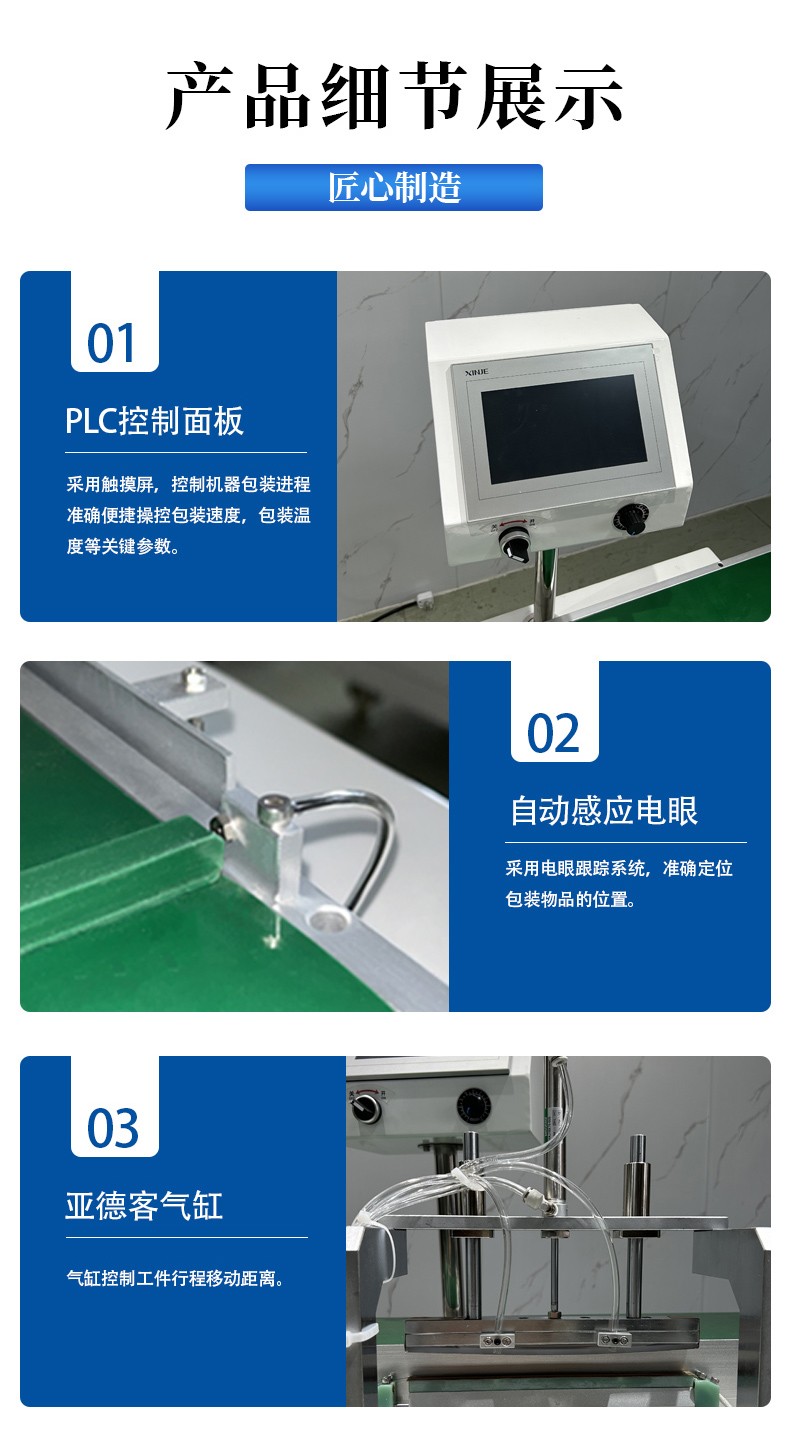

Equipped with an automated control system (such as parameter setting via a touch screen), the equipment enables one-click startup and automatic adjustment of sealing and cutting temperature and speed, reducing reliance on manual operations. A production line equipped with a continuous sealing and cutting machine typically requires only 1-2 workers to be responsible for loading and monitoring. Compared with manual packaging or semi-automatic equipment, it can significantly reduce labor input, making it particularly suitable for large-scale mass production scenarios.

Most continuous sealing and cutting machines can seamlessly connect with front-end conveying lines and back-end heat shrink ovens, forming a complete automated packaging line. For instance, in the packaging of bottled water in the beverage industry, the equipment can continuously complete processes such as film wrapping, sealing and cutting, and shrink shaping. This avoids efficiency losses caused by disjointed processes and improves the collaborative efficiency of the entire production line.

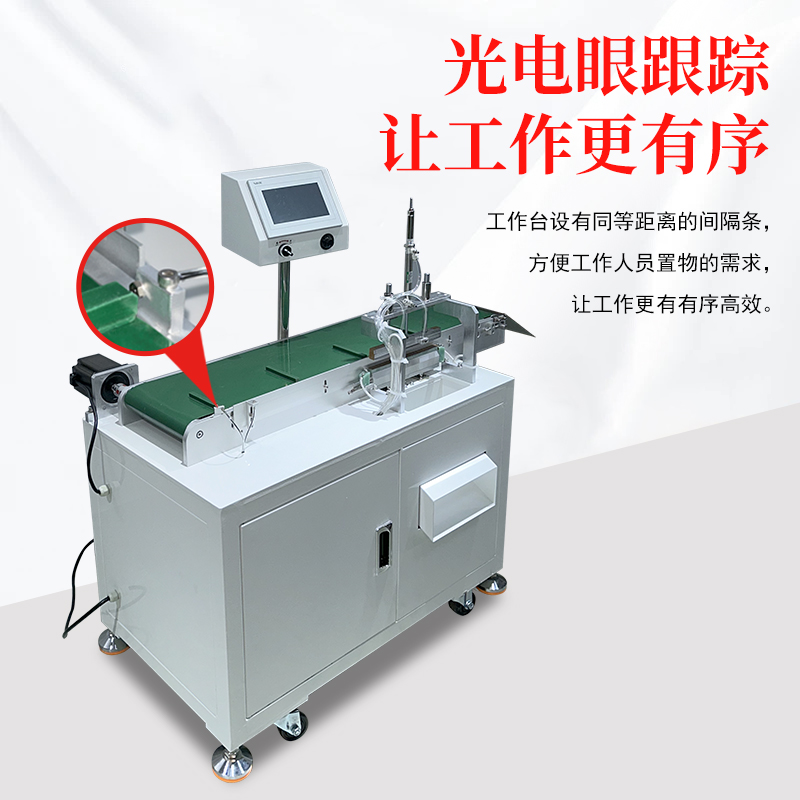

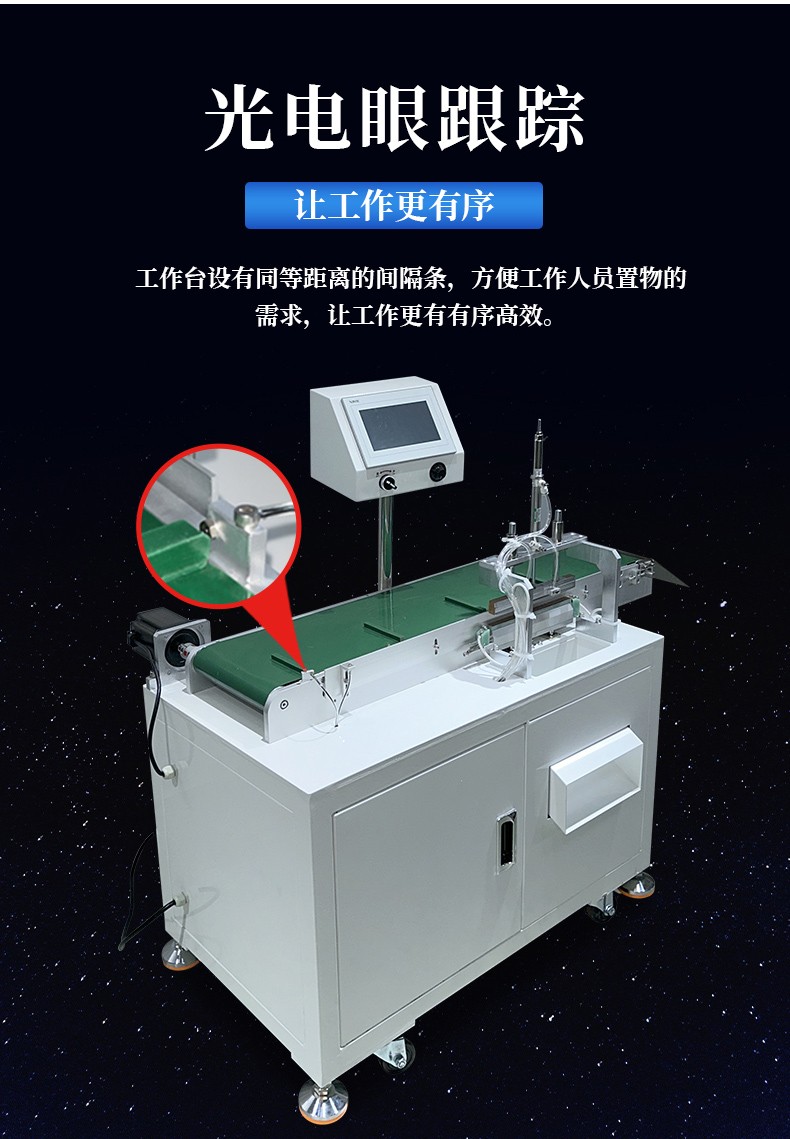

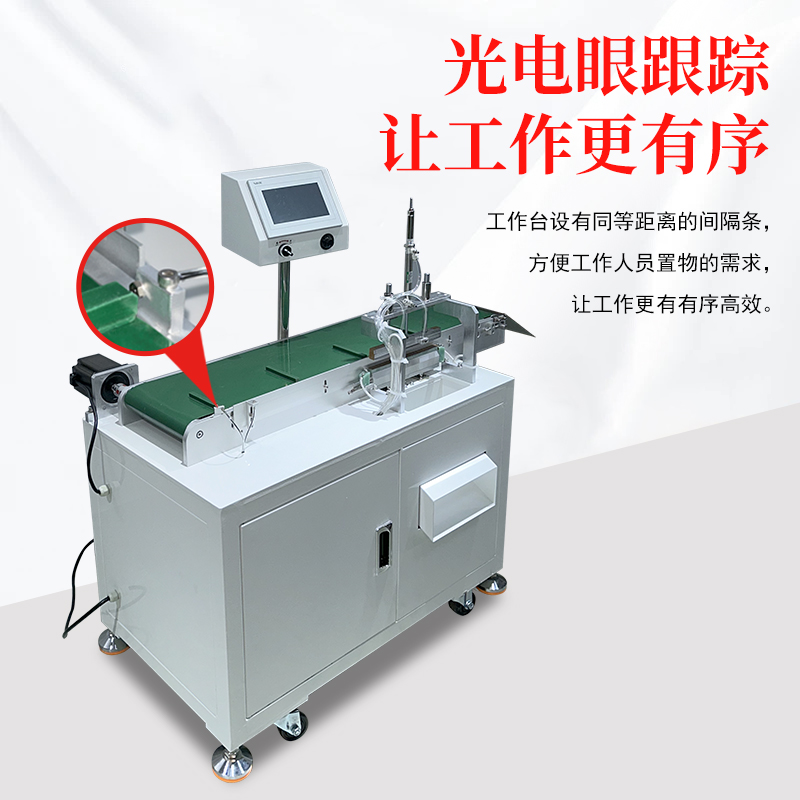

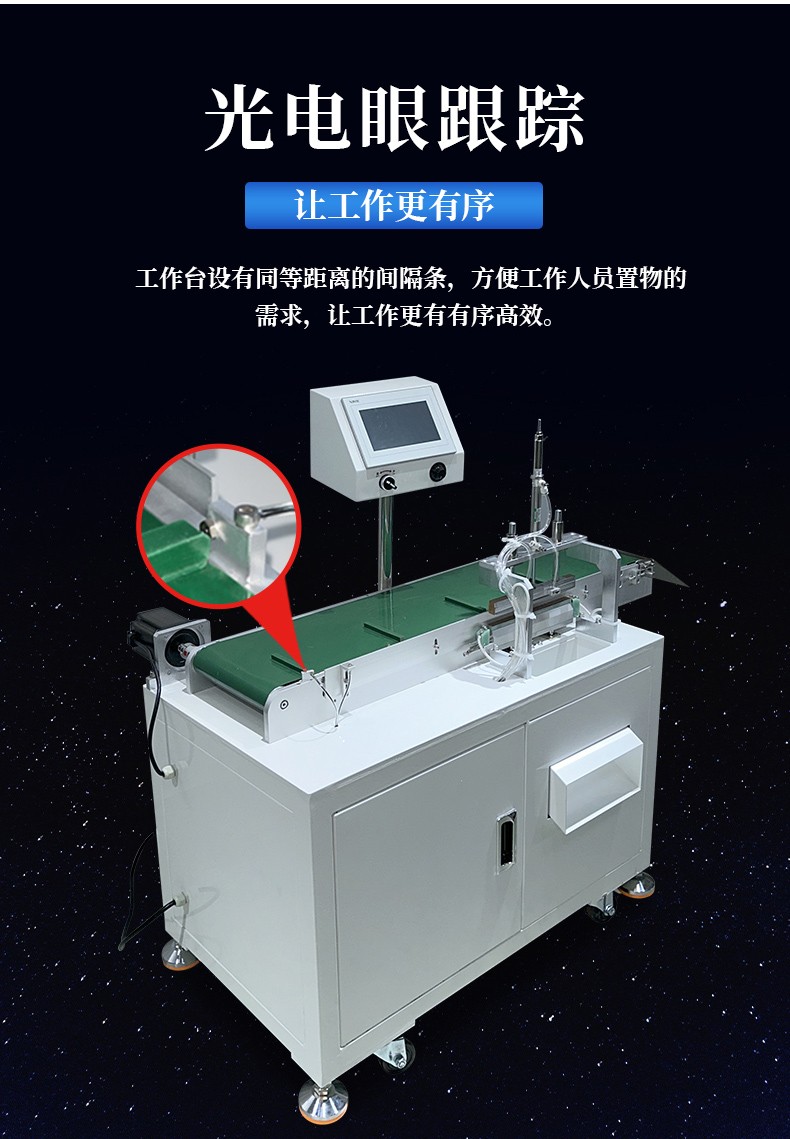

Advanced models are equipped with a photoelectric positioning system, which can accurately identify printing marks on packaging materials, ensuring precise sealing and cutting positions and reducing film waste. Meanwhile, stable sealing and cutting quality lowers the rework rate caused by substandard packaging, indirectly improving production efficiency.

In short, the "efficiency" of continuous sealing and cutting machines is not just about the high-speed operation of a single device, but more about achieving efficient operation throughout the entire chain from material processing to finished product output through automation, continuity, and process optimization. Especially in large-scale production, it can significantly shorten the production cycle and reduce the packaging cost per unit product.