The efficiency of tape winding machines is mainly reflected in processing speed, stability, continuity, and comparative advantages over manual operations. Specifically, it varies depending on factors such as equipment type (for packaging/wire harnesses), degree of automation, and specifications of the objects being wrapped. The core can be analyzed from the following aspects:

- Processing speed: Far exceeding manual operation, suitable for mass production

The efficiency of tape winding machines is first reflected in the processing volume per unit time.

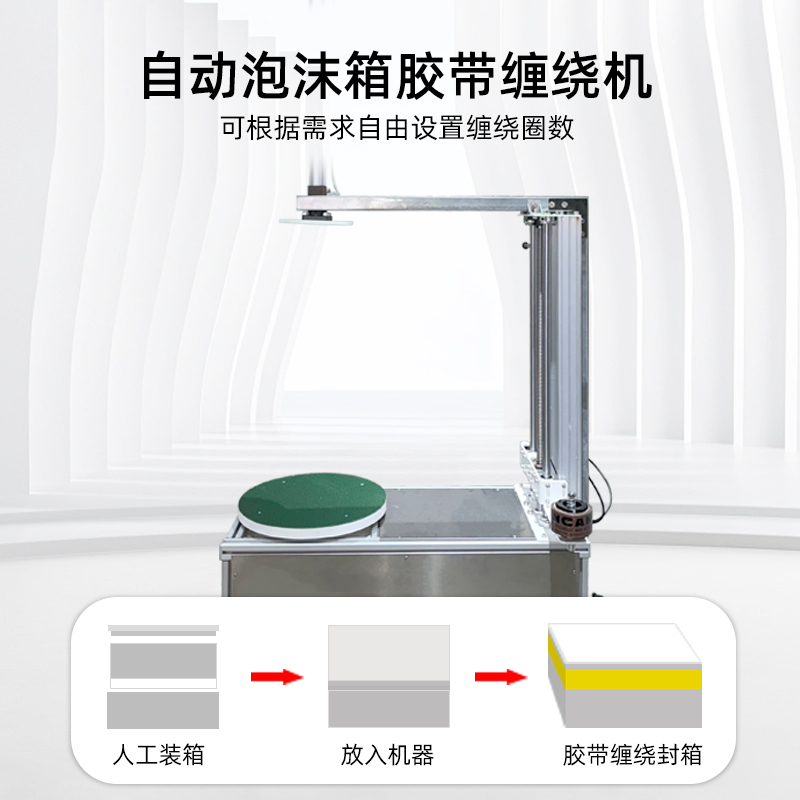

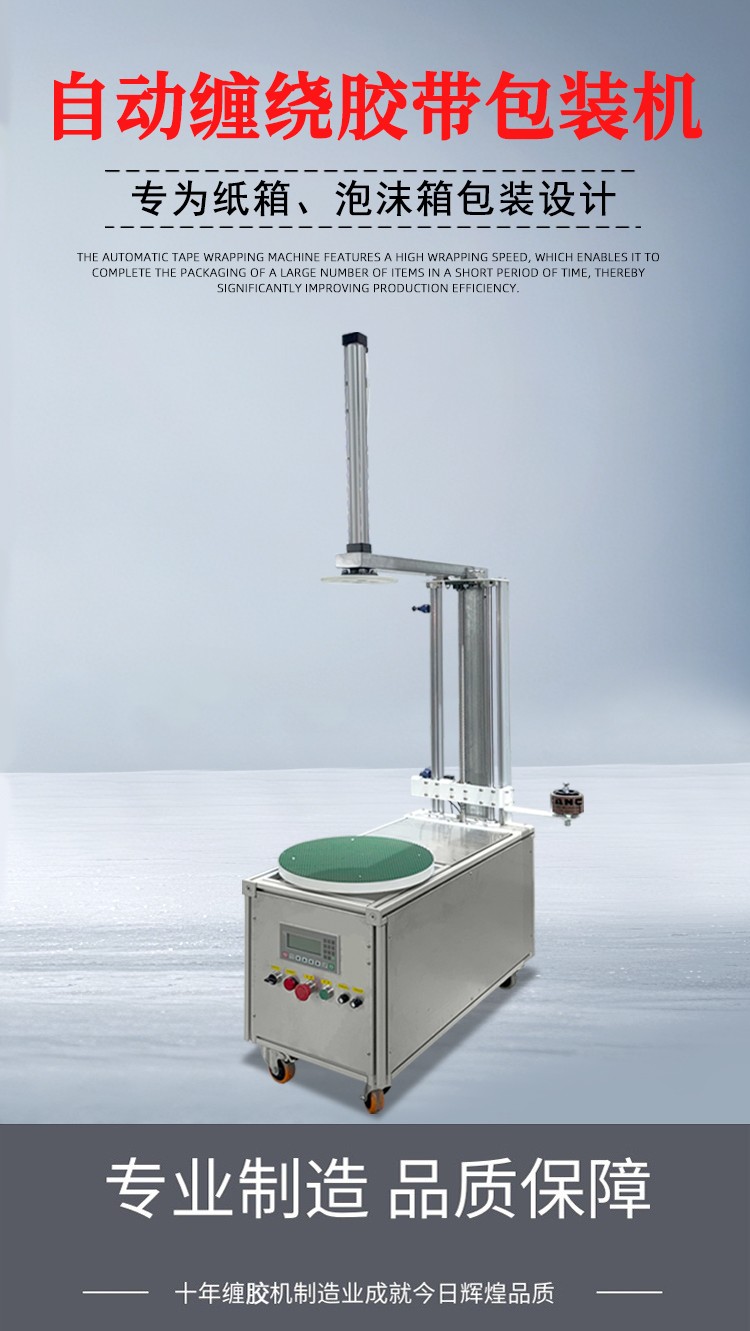

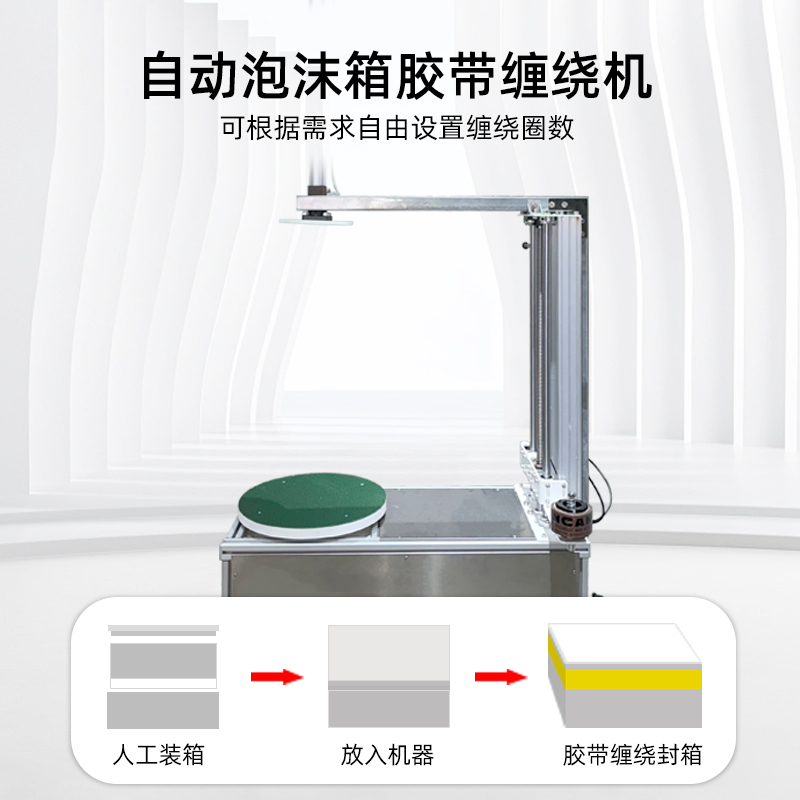

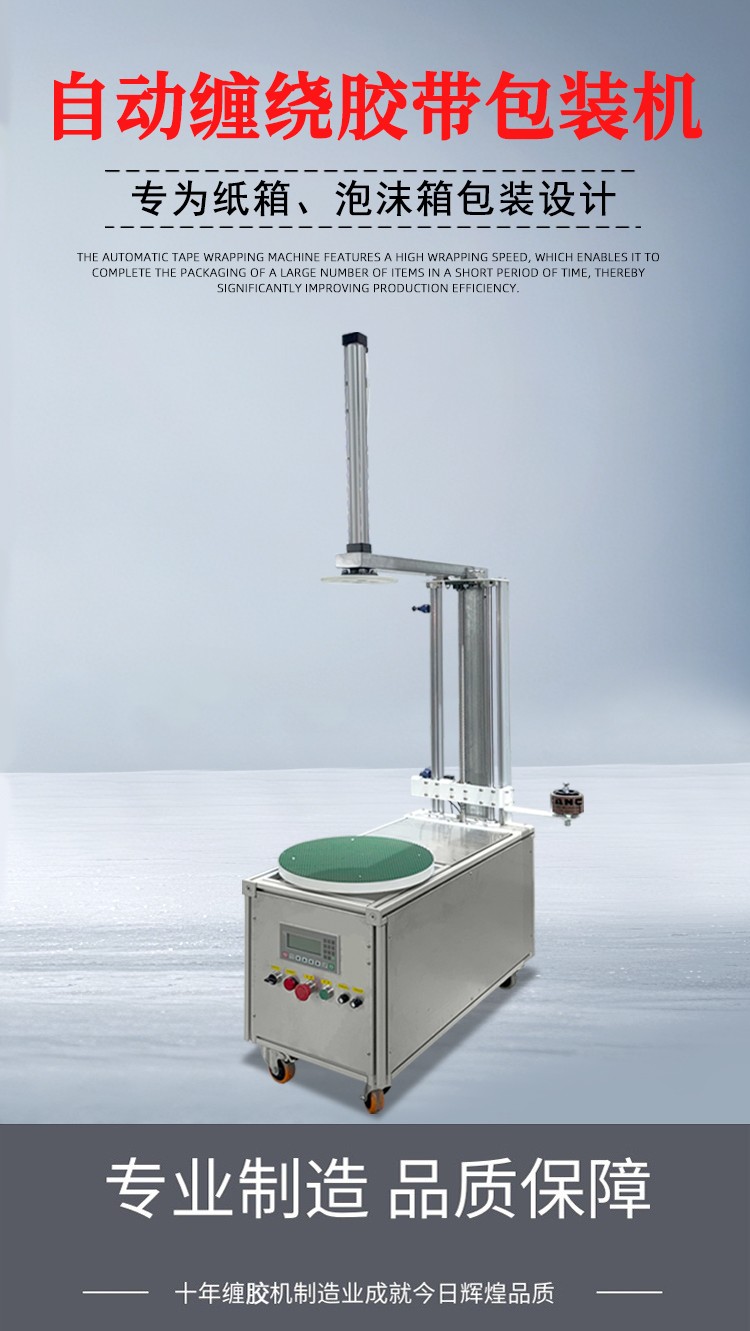

Packaging scenarios: For large objects such as pallets and boxes, fully automatic winding machines can handle 20-40 pallets (or objects of equivalent specifications) per hour; some high-speed models can even reach over 50 per hour. In contrast, manual winding of objects of the same specification, which requires manual adjustment of tape and handling/positioning, can usually only complete 5-10 per hour, resulting in an efficiency gap of 4-8 times.

Wire harness processing scenarios: For wire harnesses in fields such as automotive and electronics (with diameters ranging from a few millimeters to dozens of millimeters), automatic winding machines can process 3-8 meters of wire harnesses per minute (adjusted according to the number of winding turns and overlap rate); some precision models can even reach 10 meters per minute. However, manual winding, limited by hand movement speed and endurance, can only complete 0.5-2 meters per minute, with efficiency increased by 3-10 times.

- Stability: Reducing rework and lowering hidden costs

Manual winding is easily affected by operational proficiency, physical strength, and attention, often leading to problems such as uneven tape overlap, looseness, and wrinkles, resulting in about 5%-15% of products requiring rework, which indirectly reduces overall efficiency.

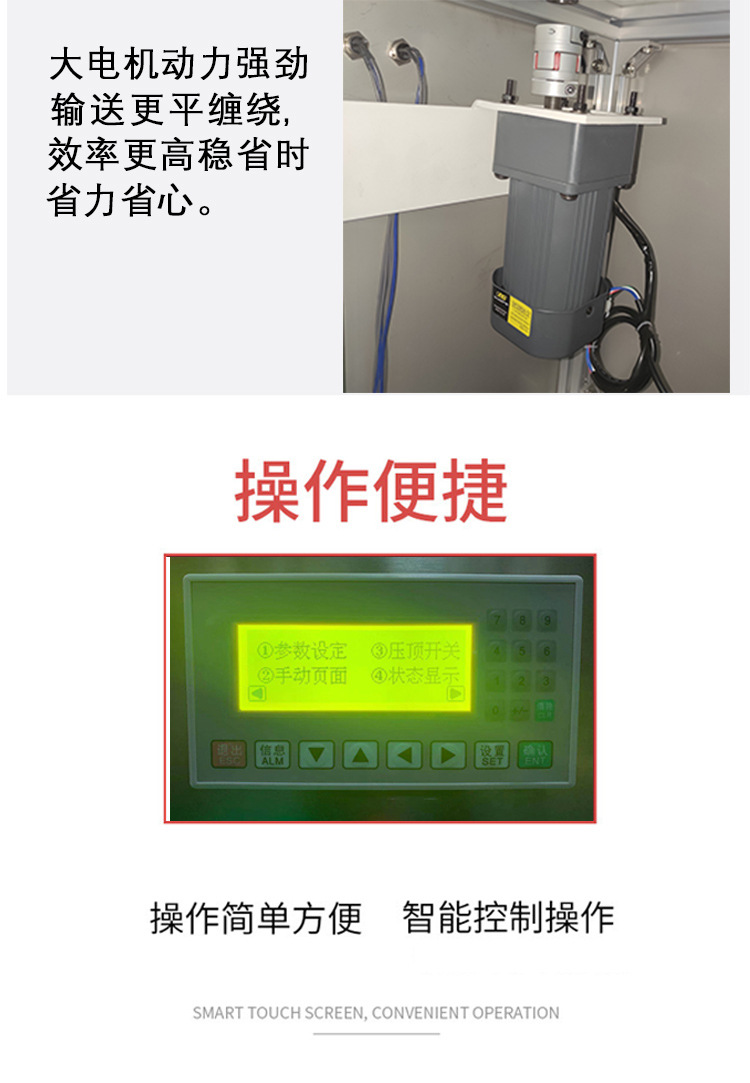

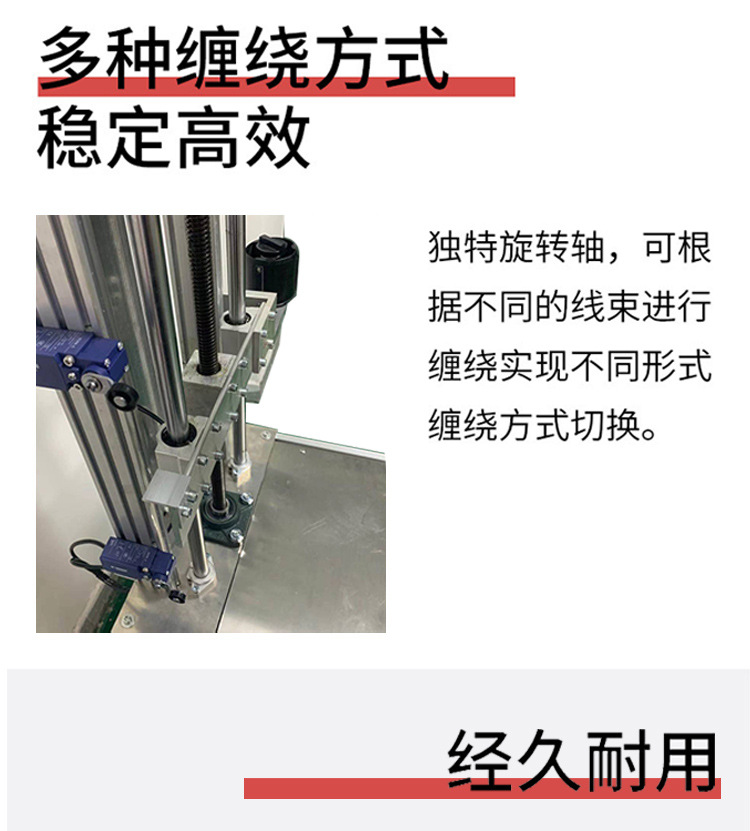

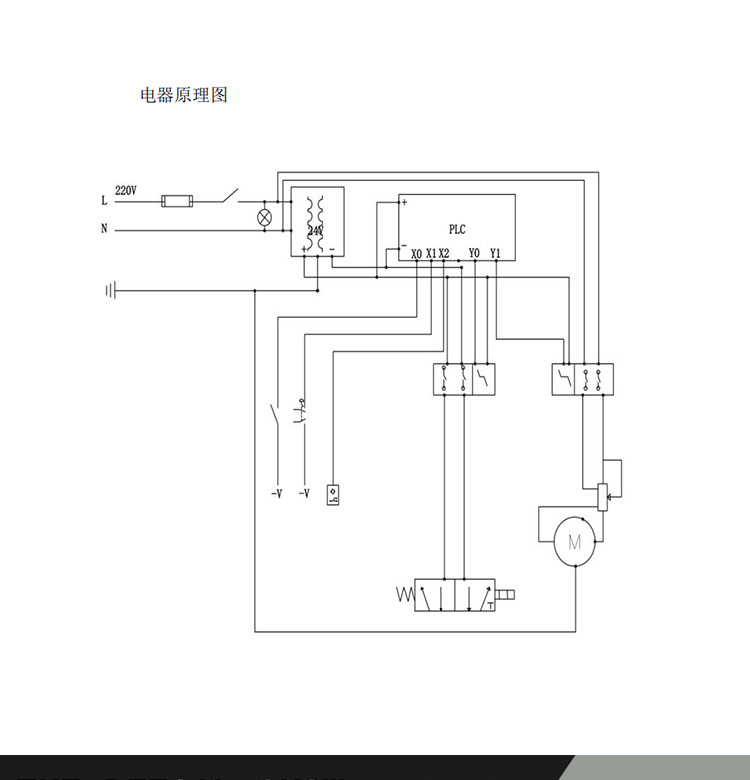

In contrast, automatic winding machines precisely control winding speed, number of turns, tension (tape pulling force), and overlap rate (usually settable between 5%-50%) through programs. The product qualification rate can reach over 99%, with almost no rework, further improving actual production efficiency from the perspective of "one-time qualification."

- Continuity: Breaking through the limitations of manual fatigue

Manual operations have physical limits, with daily effective working time usually being 6-8 hours (including breaks), and efficiency decreases over time (for example, speed may decrease by 20%-30% in the afternoon).

Automatic winding machines can work with production lines to achieve 24-hour continuous operation (only requiring regular tape replenishment and daily maintenance). Especially in mass, continuous production scenarios (such as logistics sorting centers and automotive wire harness factories), the daily processing volume can reach 3-4 times that of manual operation.

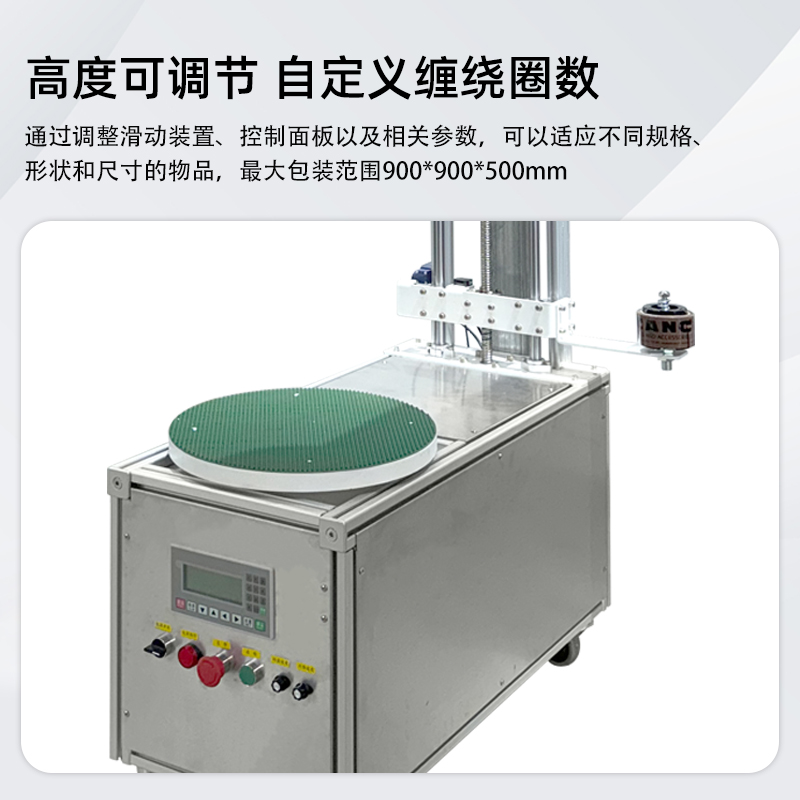

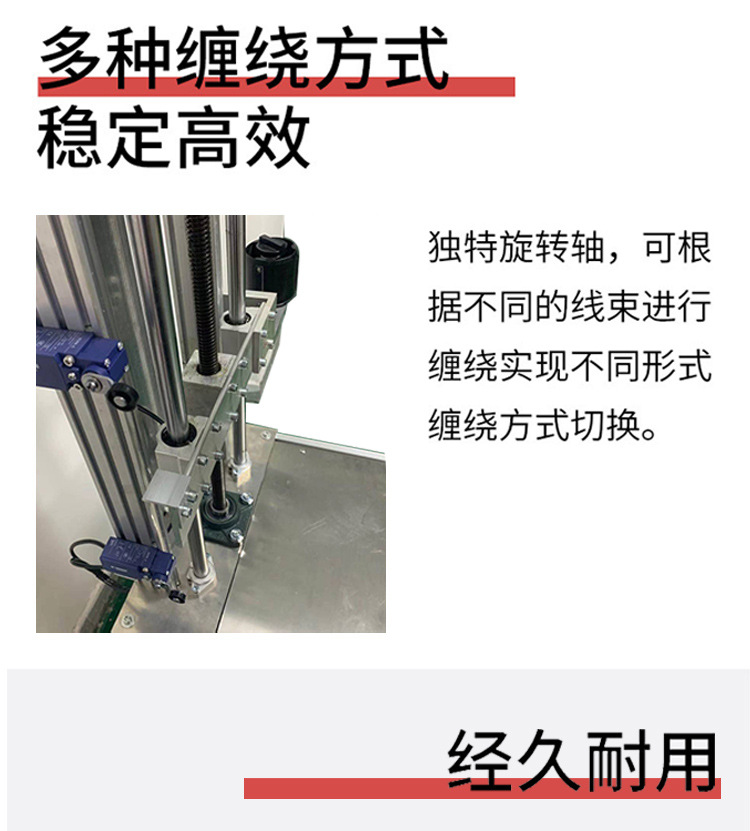

- Adaptability: Flexibly responding to diverse needs and reducing switching time

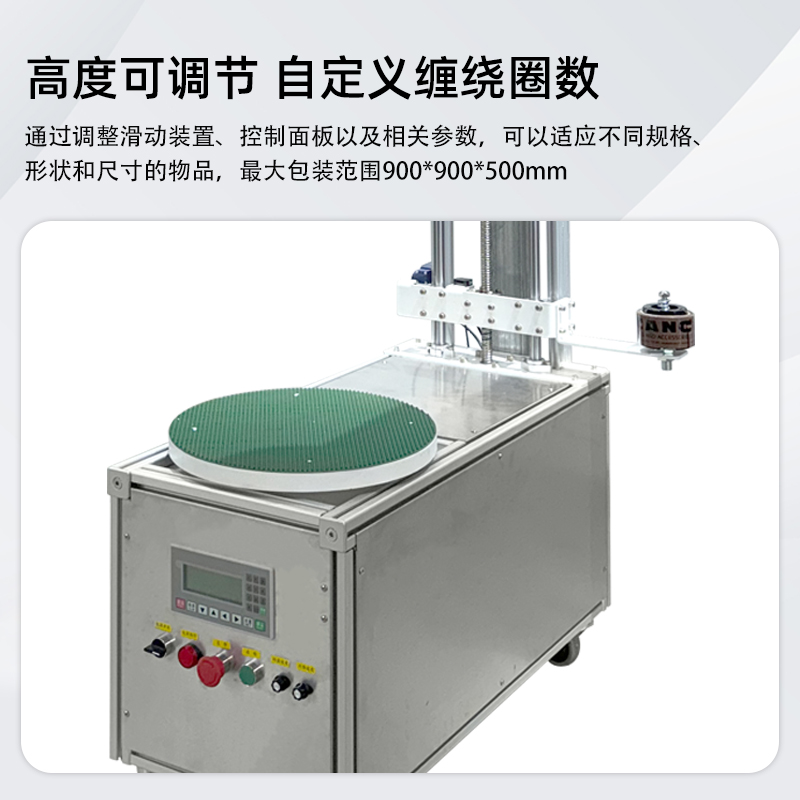

Modern automatic winding machines mostly support parameterized settings (adjusting winding mode, speed, number of turns, etc., through touch screens). For wrapped objects of different sizes (such as objects with a diameter of 5cm to 1m) and shapes (cylindrical, square, irregular), the switching time only takes 1-5 minutes. In contrast, when manual operation handles products of different specifications, operators need to re-adapt to the operation method, with switching time usually being 10-30 minutes, further widening the efficiency gap.