The working efficiency of external vacuum packaging machines is generally high, and their efficiency advantages are particularly prominent when adapting to various scenarios and types of items. The specific performance and influencing factors can be analyzed from the following aspects:

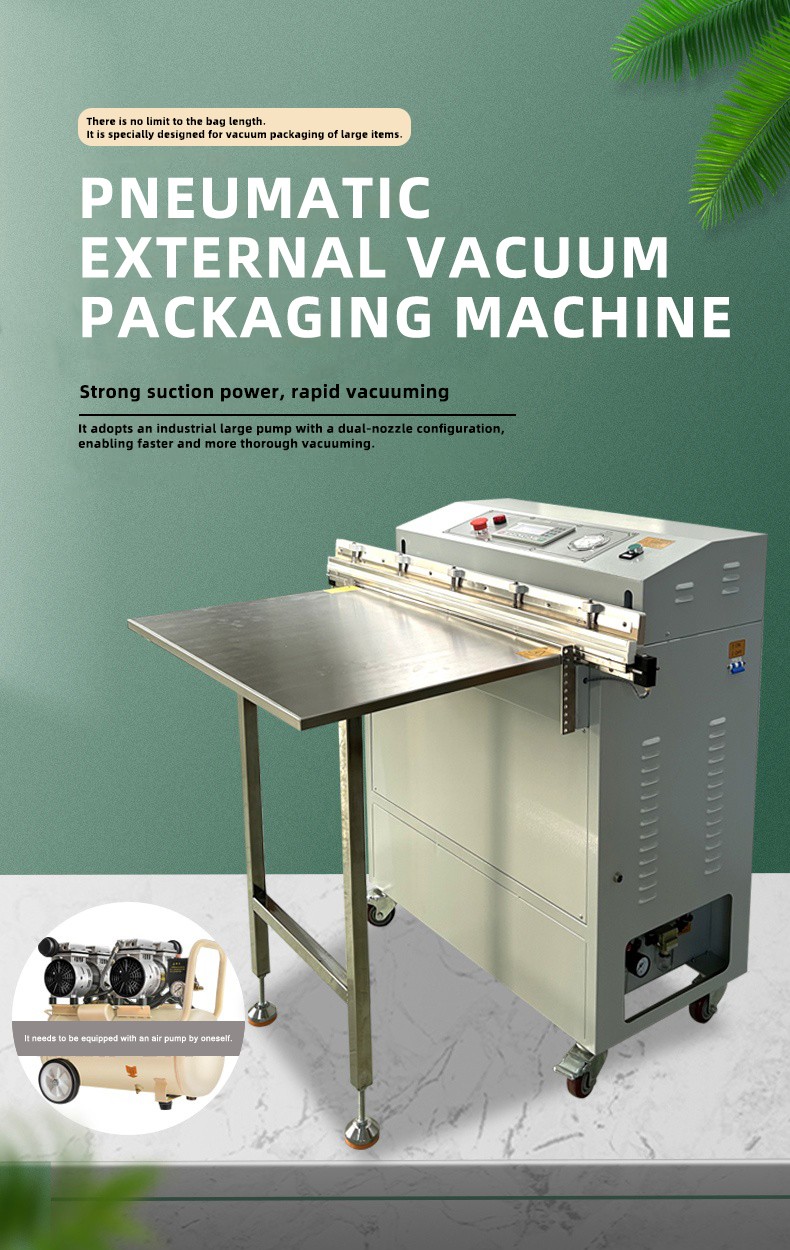

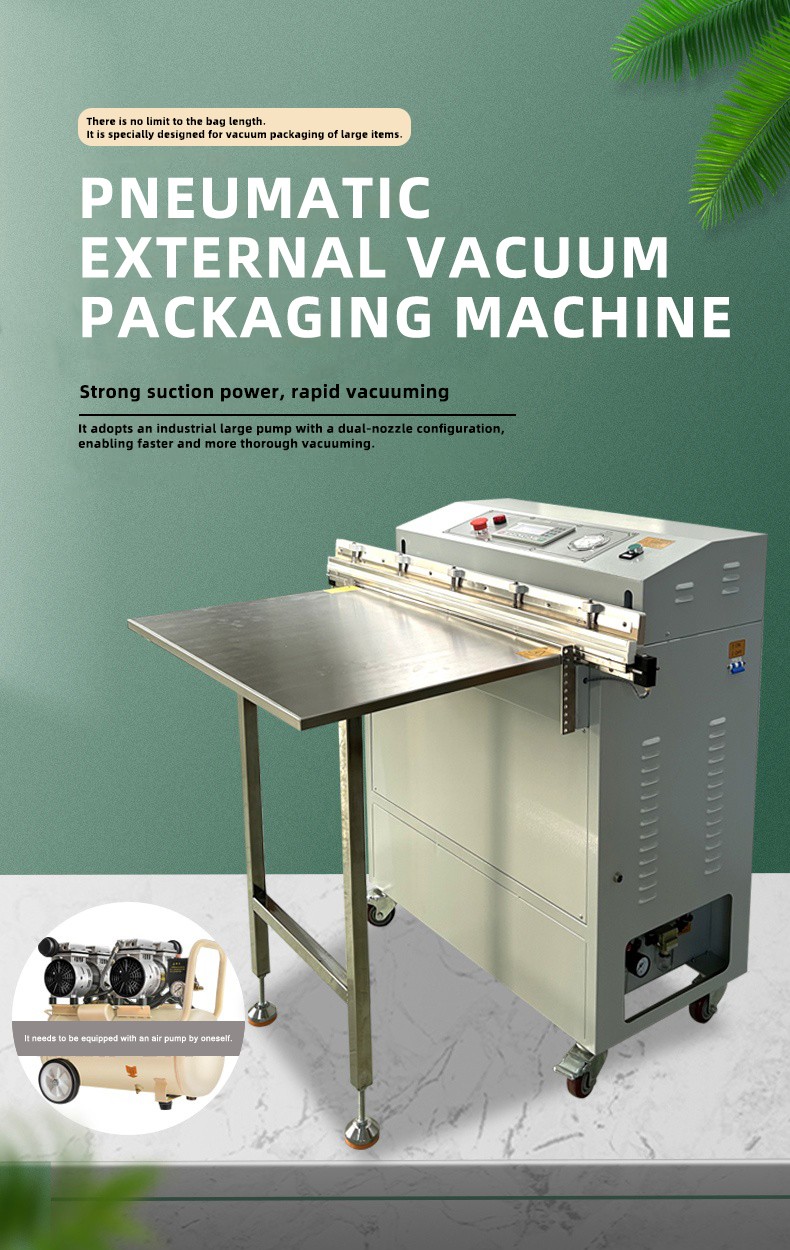

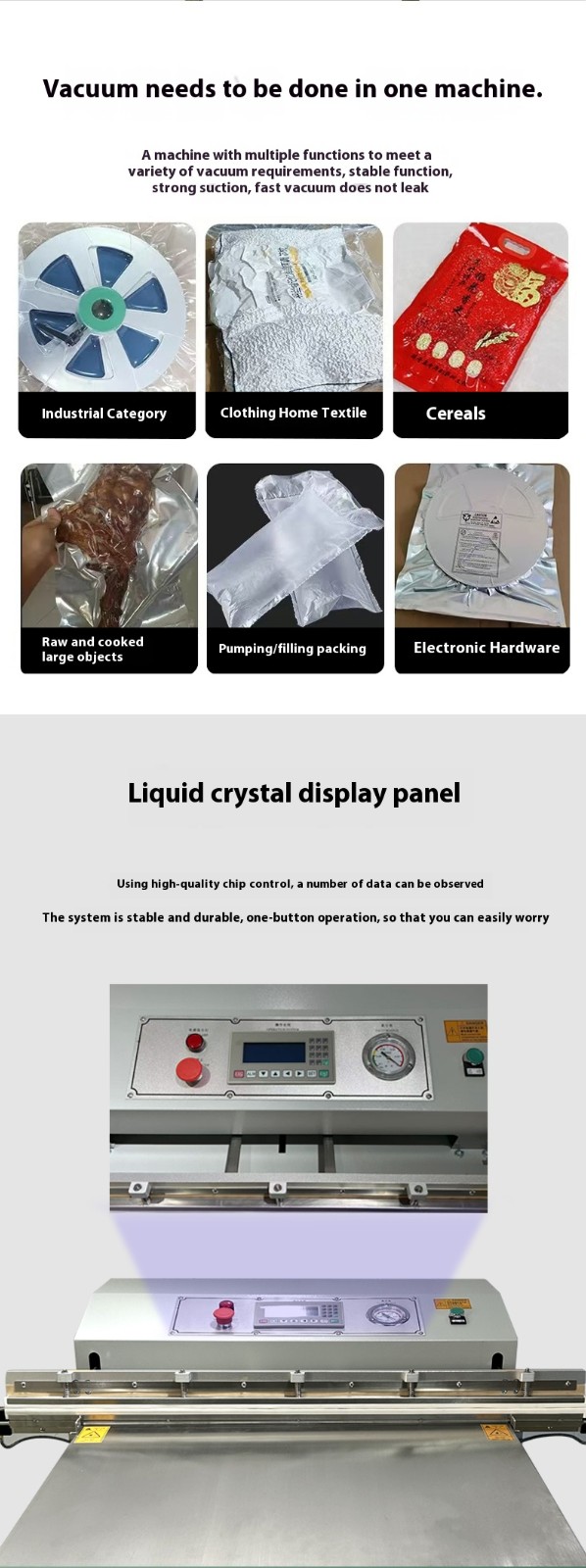

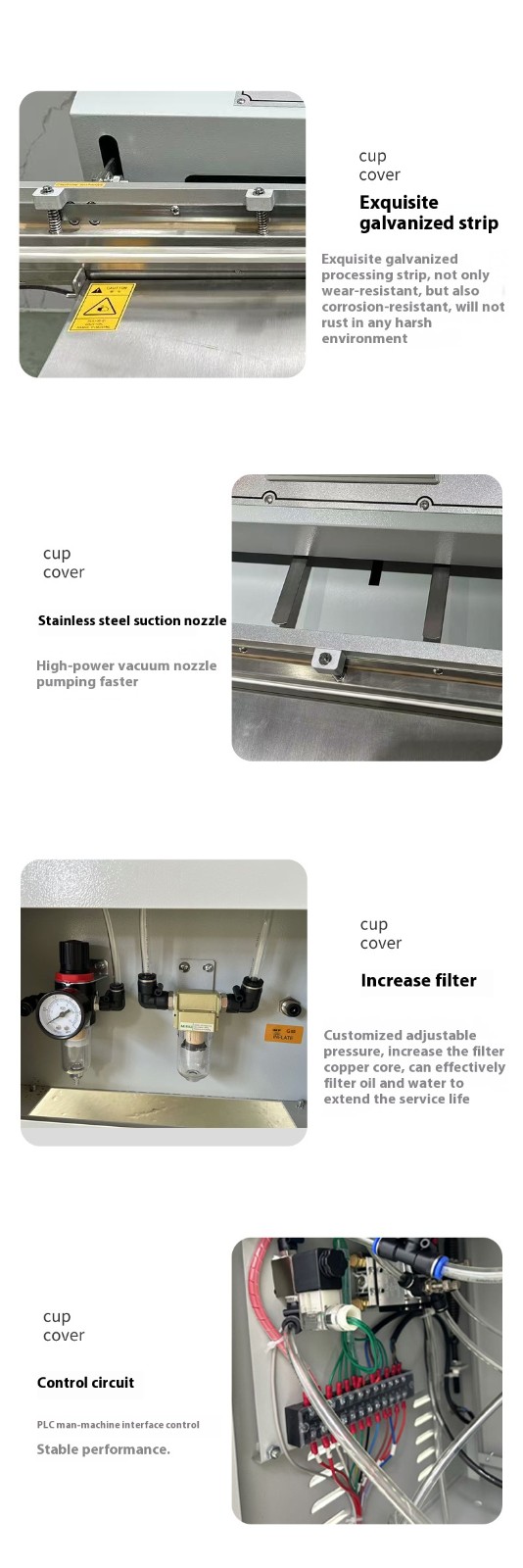

One of the core advantages of the external type is its targeted air extraction – it does not need to extract air from the entire vacuum chamber, but directly extracts air from the packaging bag through the air extraction nozzle, so the air extraction stage takes extremely little time.

For small and medium-sized packaging bags (such as food bags, electronic component bags), the air extraction time is usually only 2-5 seconds;

Adding heat sealing (1-3 seconds) and mechanism reset (1-2 seconds), the total time for a single cycle can be controlled within 5-10 seconds, which means 6-12 packages can be completed per minute.

For large items (such as whole rolls of fabric, large mechanical parts), although the packaging bag has a large volume and the air extraction time will be slightly longer (usually 5-10 seconds), compared with the internal vacuum type, which requires moving large items into the vacuum chamber and then extracting air from the entire vacuum chamber (which may take 15-30 seconds), the external type still saves more than 50% of the time.

The structural design of the external type is more suitable for continuous operation:

The workbench height is adjustable, and there are casters at the bottom, allowing flexible connection to production lines;

Most models support foot switches or photoelectric induction automatic start, so operators do not need to bend down or press buttons frequently, making loading and unloading smoother;

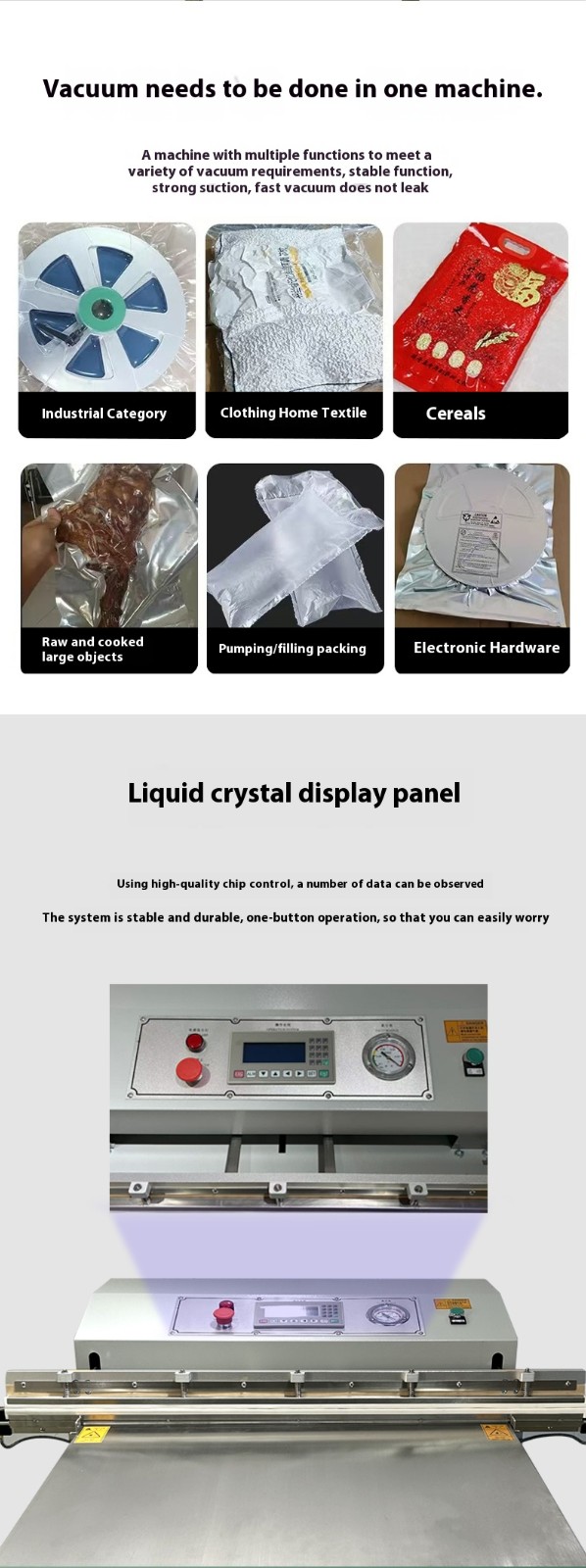

Some high-end models (such as fully automatic external vacuum types) can integrate conveyor belts to realize full automation of "feeding - air extraction - sealing - discharging". During continuous operation, there is almost no downtime, and the hourly output can reach 300-600 pieces (depending on the size of the items).

Compared with the internal vacuum type:

When handling small items, the single-cycle efficiency of both is similar (the internal type may take slightly less time due to faster sealing of the vacuum chamber);

When handling large or irregularly shaped items, the external type is far more efficient than the internal type (usually 2-3 times faster) because it does not need to move items into the vacuum chamber and its air extraction does not depend on the volume of the vacuum chamber.

Compared with manual packaging:

The external type avoids the time-consuming process of manual pressing for air exhaust and manual sealing through automated air extraction and sealing (manual packaging may take 20-30 seconds per piece). Its efficiency is increased by more than 3-5 times, and the vacuum degree and sealing performance are more stable.

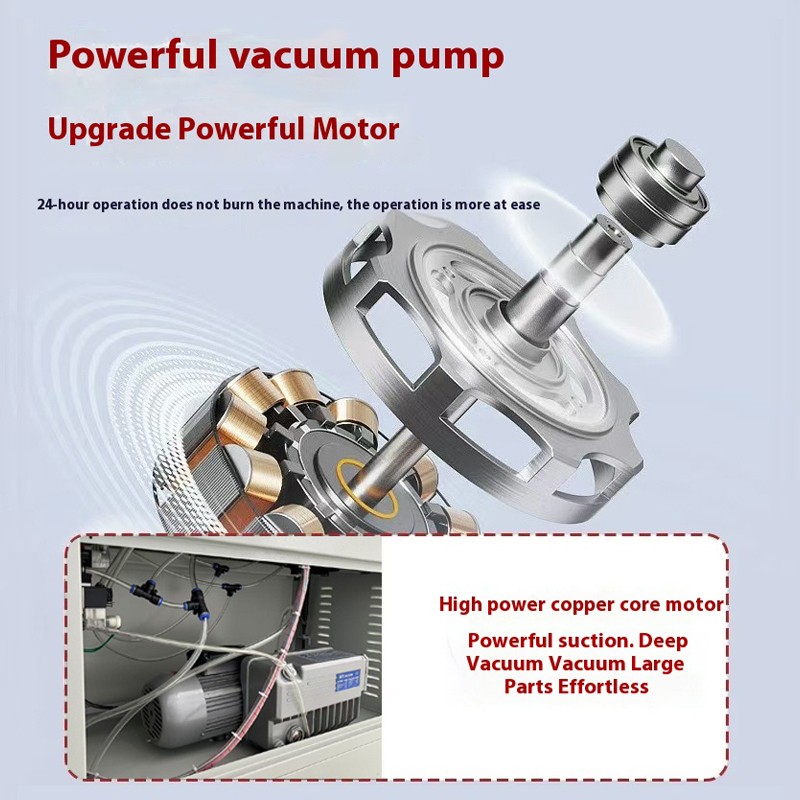

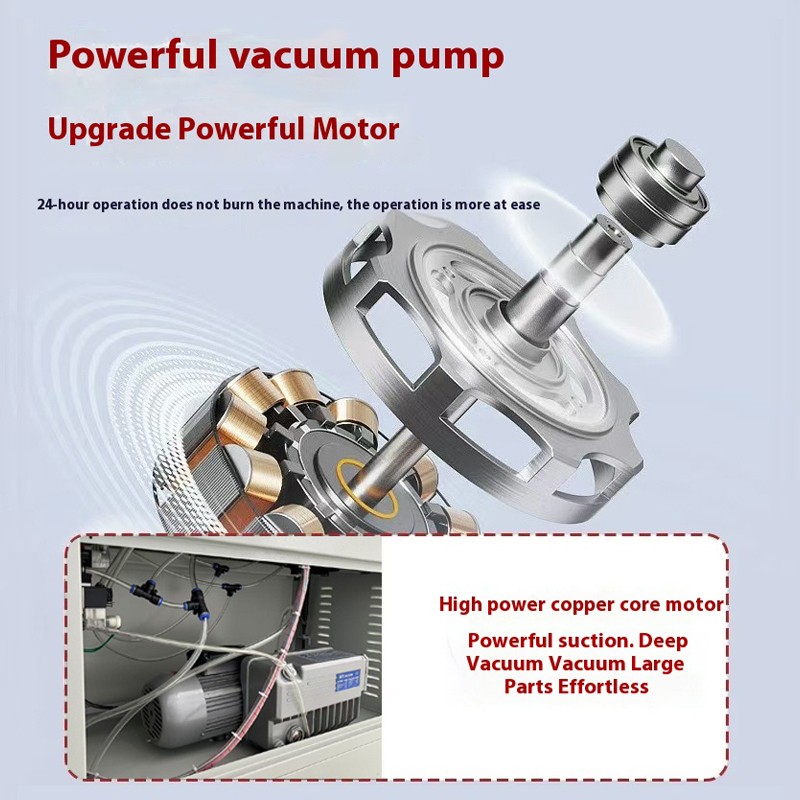

Air extraction rate: The vacuum pump power determines the air extraction speed (unit: m³/h). The higher the power (e.g., 20-50 m³/h), the faster the air extraction for large packaging bags;

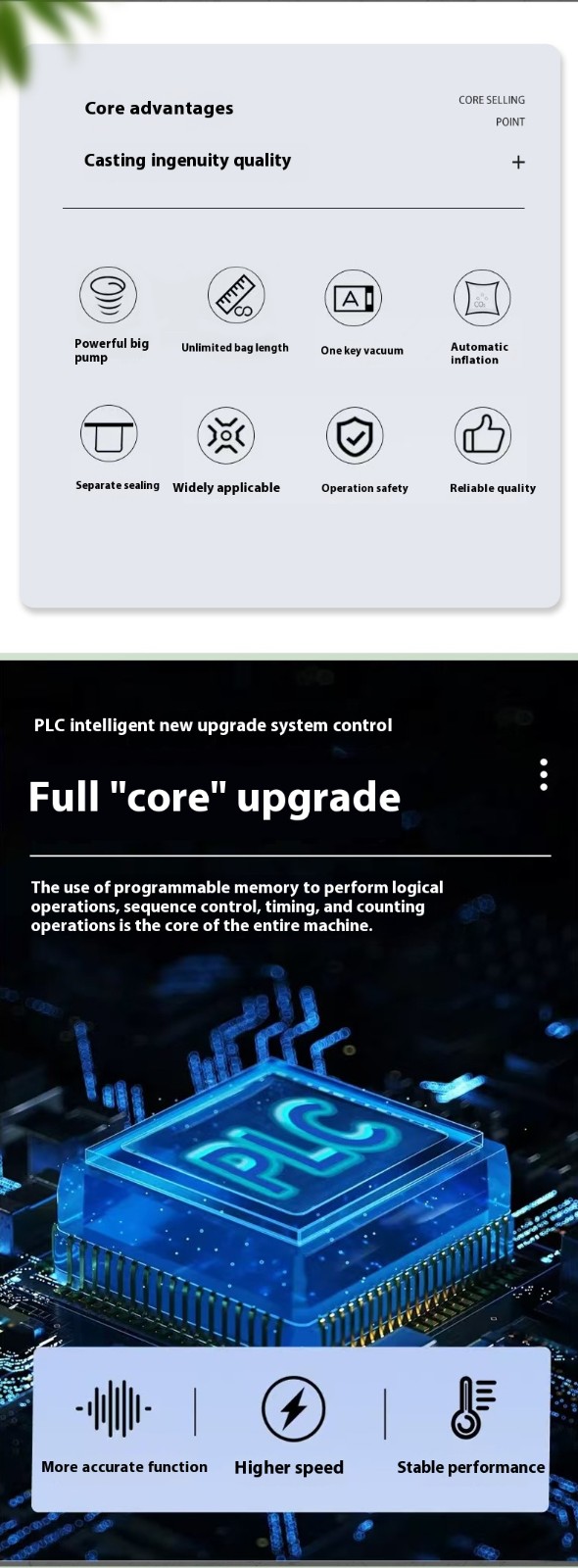

Degree of automation: Manual models require manual operation of switches, and their efficiency is affected by operator proficiency; Fully automatic models (with automatic feeding and multiple sets of air extraction nozzles) can significantly improve batch processing efficiency;

Item characteristics: Fluffy items (such as fabric, cotton) need to discharge more air during extraction, taking slightly longer; Liquid or soup-containing items need to be matched with anti-splash designs, which may increase the waiting time before sealing (to prevent liquid spillage).