The "high efficiency" of fully automatic label sleeving machines does not merely refer to "fast speed"; instead, it is a combination of "high speed + stability + low loss", directly addressing the "production capacity bottleneck" in the industry:

- Speed Aspect: Mainstream models can achieve a labeling efficiency of 600-1000 bottles per minute (BPM) (e.g., Zhongbao Intelligent’s i-Sleeve Pro II reaches 1000 BPM/180mm), far exceeding the manual labeling speed of 10-20 bottles per minute. This meets the demand for "24/7 continuous production" in the food and beverage industry.

- Stability Aspect: Adopting a mechanical structure made of aluminum alloy and stainless steel, along with servo motor drive, the machines feature low failure rates during continuous operation (average monthly downtime due to faults is usually less than 2 hours), preventing frequent equipment shutdowns from hindering the entire production line.

- Loss Aspect: Through the precise control of label feeding and cutting rhythms by the PLC (Programmable Logic Controller), the label waste rate can be controlled within 0.5% (the waste rate of manual labeling often reaches 5%-8%), indirectly reducing production costs.

"High precision" is the "lifeline" of label sleeving machines, especially for scenarios involving special-shaped packaging and small-sized labels—its precision directly determines the uniformity of product appearance:

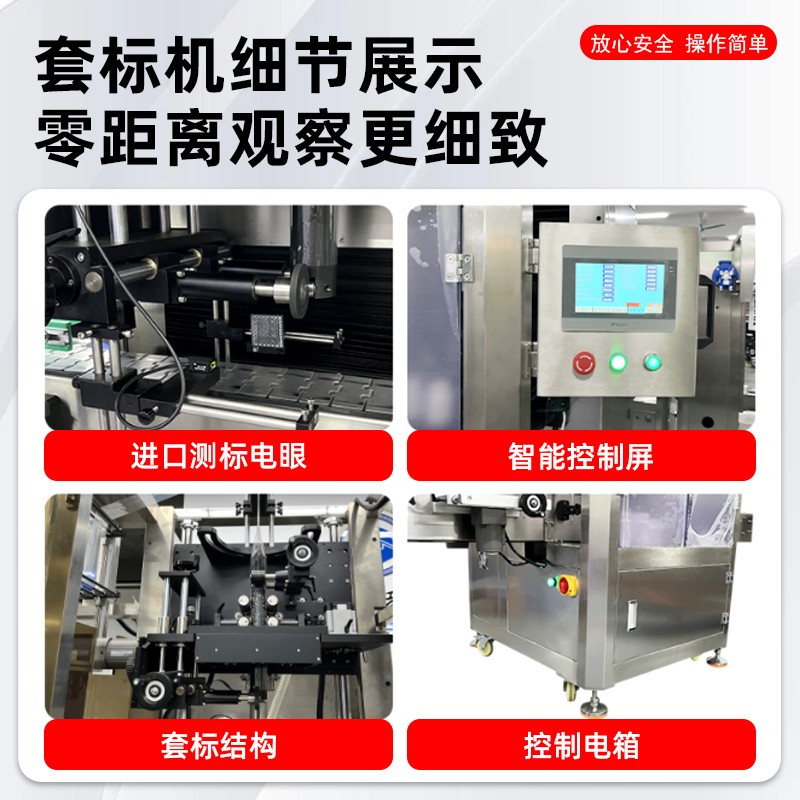

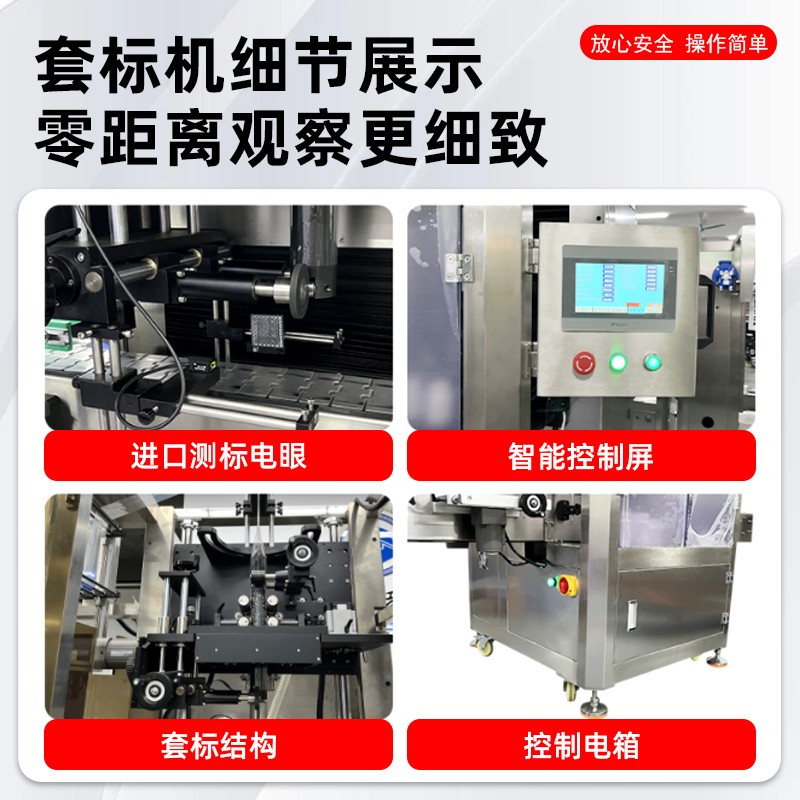

- Positioning Precision: Relying on dual calibration by a "color mark photoelectric sensor + visual inspection system", the vertical/horizontal offset error of labels can be controlled within 0.1 mm. For example, in the pharmaceutical industry, for oral liquid bottles (diameter < 20 mm) and in the cosmetics industry, for essence tubes (length < 50 mm), the machine can still achieve full centered bonding of labels.

- Adaptation Precision: Equipped with an adjustable bottle-separating screw and replaceable label guide channels, the machine can be compatible with packaging of different diameters (20-150 mm) and heights (50-300 mm) (e.g., from 500 ml mineral water bottles to 2 L laundry detergent buckets). There is no need to frequently replace entire machine accessories, and parameter adjustment can be completed in only 10-15 minutes.

For industries with strict requirements on "safety and compliance" (such as pharmaceuticals and food), the design of fully automatic label sleeving machines directly aligns with industry regulations to avoid compliance risks:

- Material Compliance: Components in contact with labels and products (e.g., label guide channels, conveyor belts) are all made of stainless steel and food-contact-grade silica gel, complying with standards such as GMP (Good Manufacturing Practice) and preventing material migration and contamination.

- Information Compliance: The machine supports "tamper-proof label sleeving" (e.g., "void if torn" labels for pharmaceutical bottles) and "traceable information label sleeving" (e.g., one-to-one correspondence between the production date, batch number of food and labels). Moreover, the content printed on labels is locked by the PLC, preventing information errors caused by manual operations and meeting the traceability requirements of the industry.

Against the backdrop of consumption upgrading, "aesthetics" has become a key factor in product differentiation competition. Label sleeving machines realize "packaging is marketing" through process optimization:

- Adhesion Degree: When matched with a hot air shrinking tunnel, labels can fully adhere to the curved surfaces of packaging (e.g., the curved body of PET bottles, the conical top of cans) after being shrunk at high temperature, with no bubbles or wrinkles, presenting an "integrated visual effect".

- Decorativeness: The machine supports adaptation to various label processes, such as gold-stamped labels, hollowed-out labels, and matte/glossy labels. It can even realize "partial labeling" (e.g., decorative bands in the middle of bottle bodies, seal labels for bottle mouths). For example, in the sleeving of cosmetic lipstick tubes, label colors can be used to distinguish shades, enhancing the high-end texture of products.