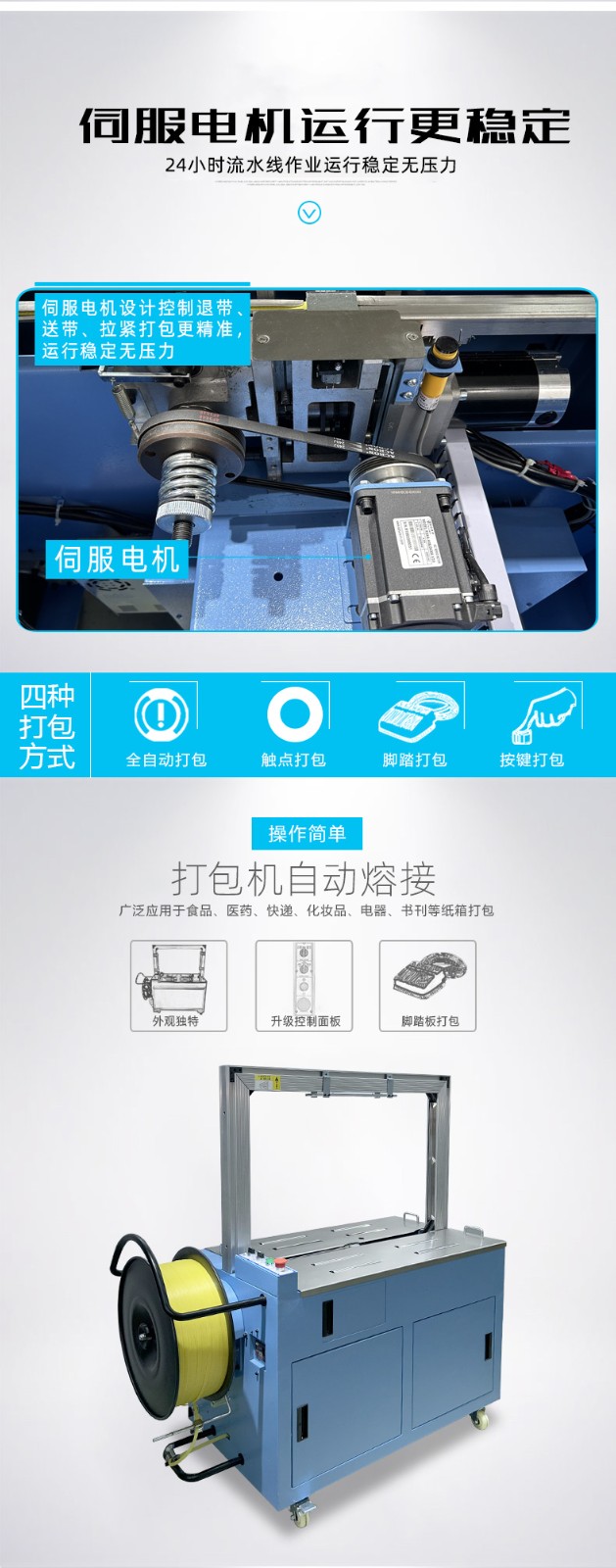

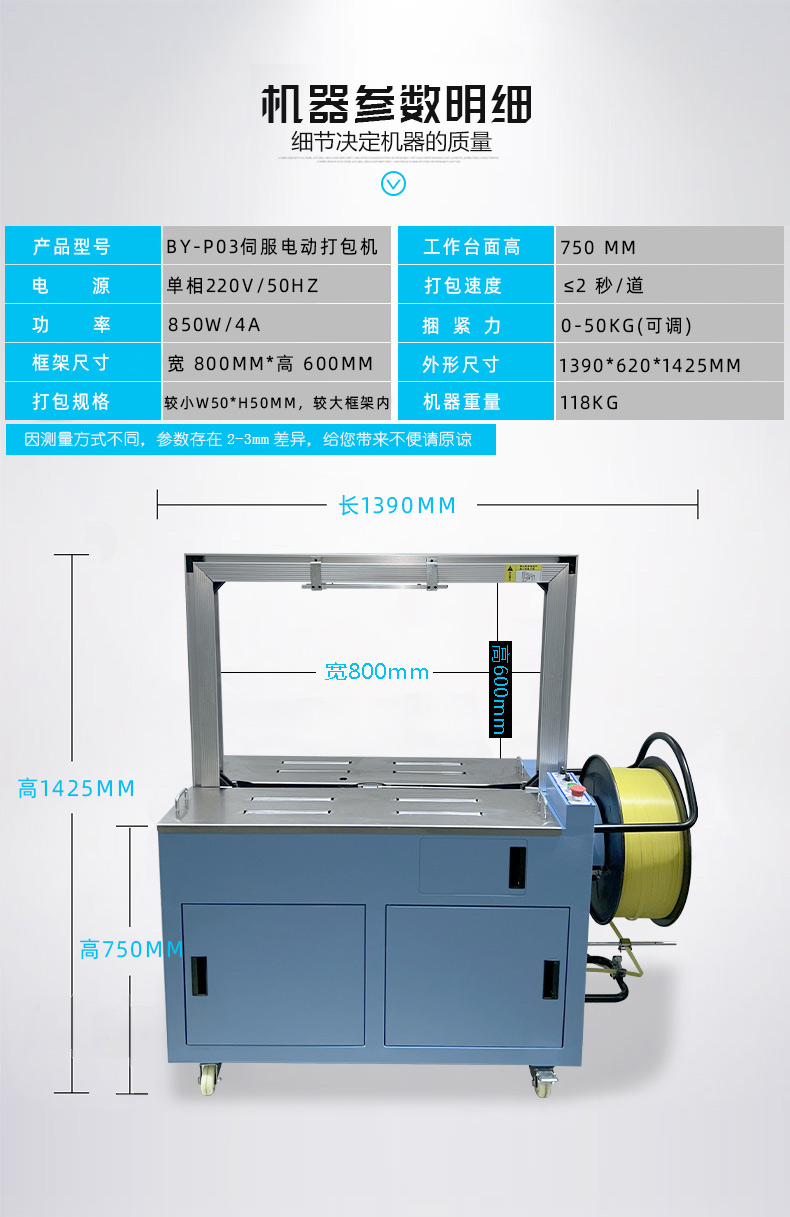

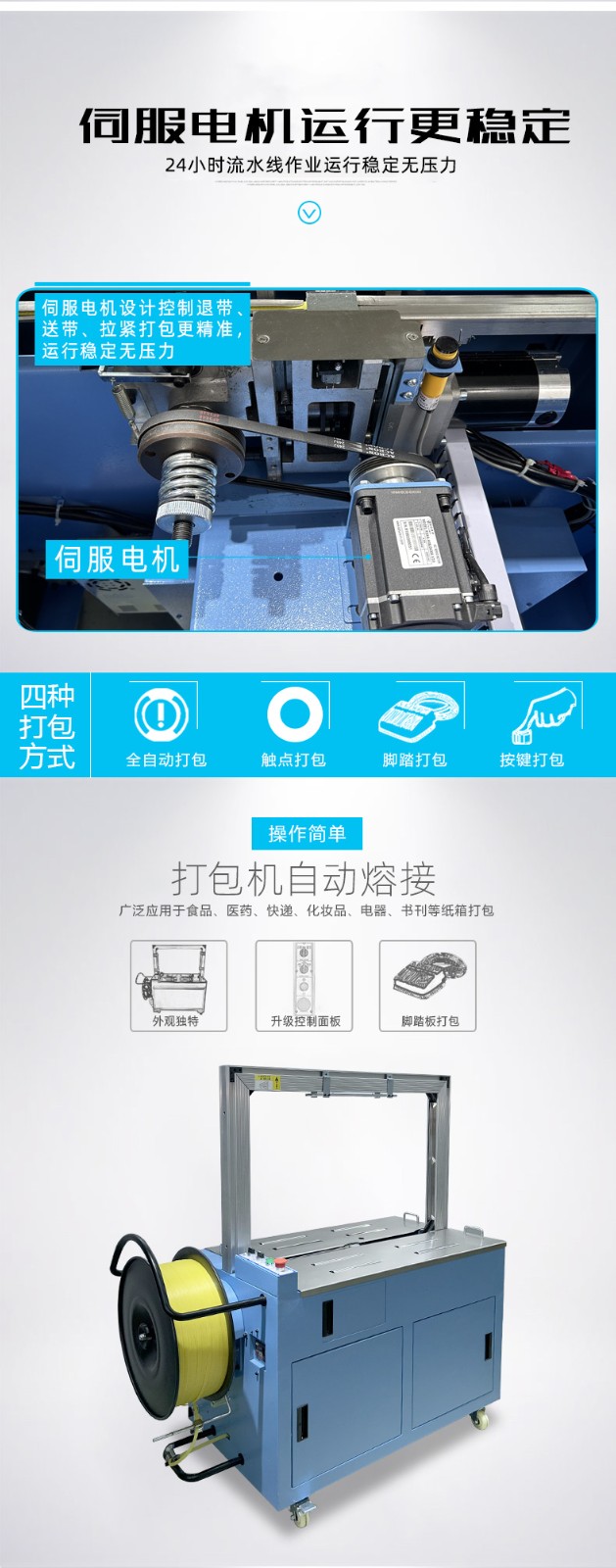

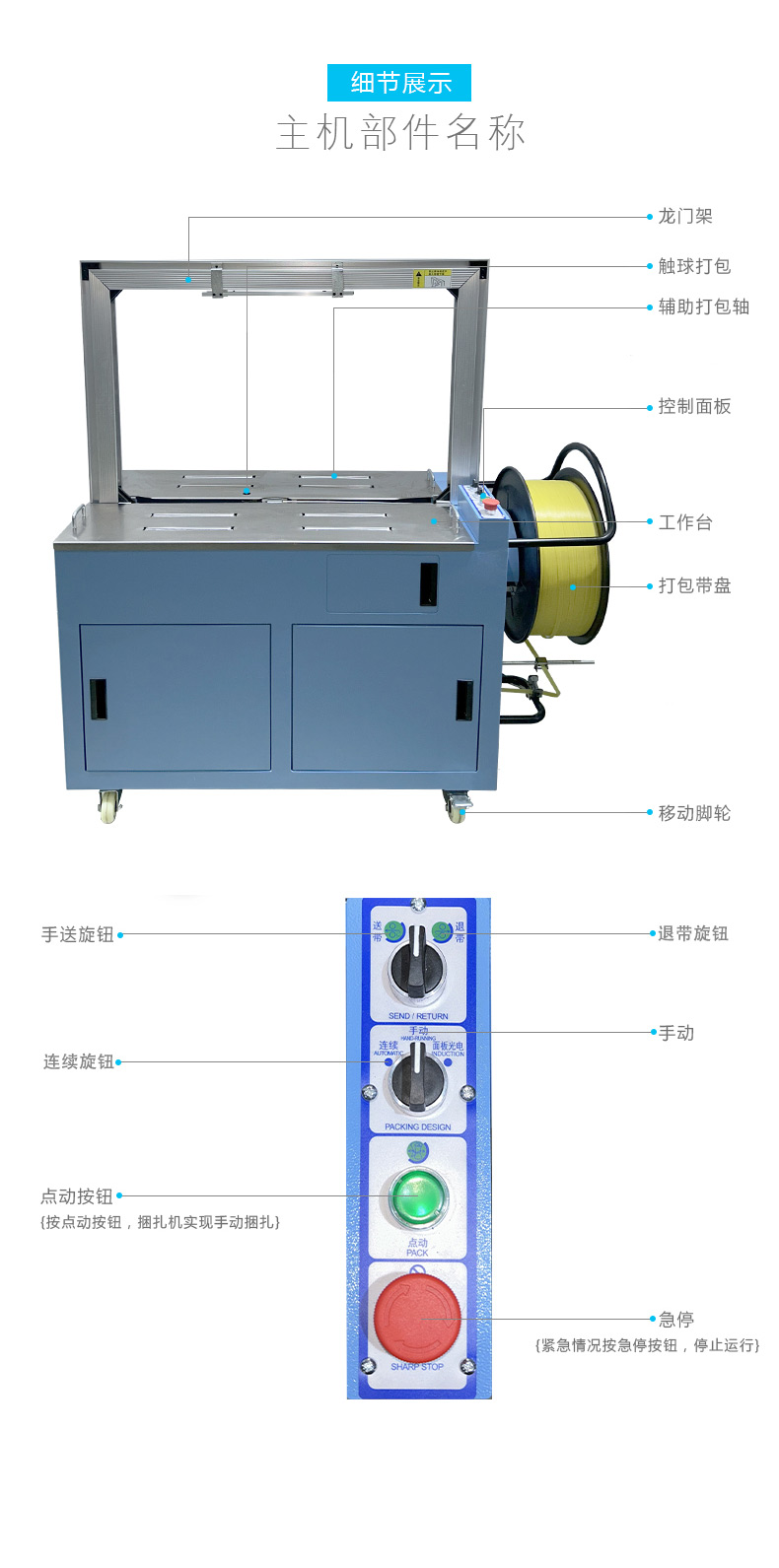

The high control precision of the full-automatic servo strapping machine stems from the application of servo motor + high-precision encoder + intelligent control system, which realizes millisecond-level response and millimeter-level positioning in the entire strapping process, effectively avoiding common problems such as loose strapping, uneven tension, and offset sealing.

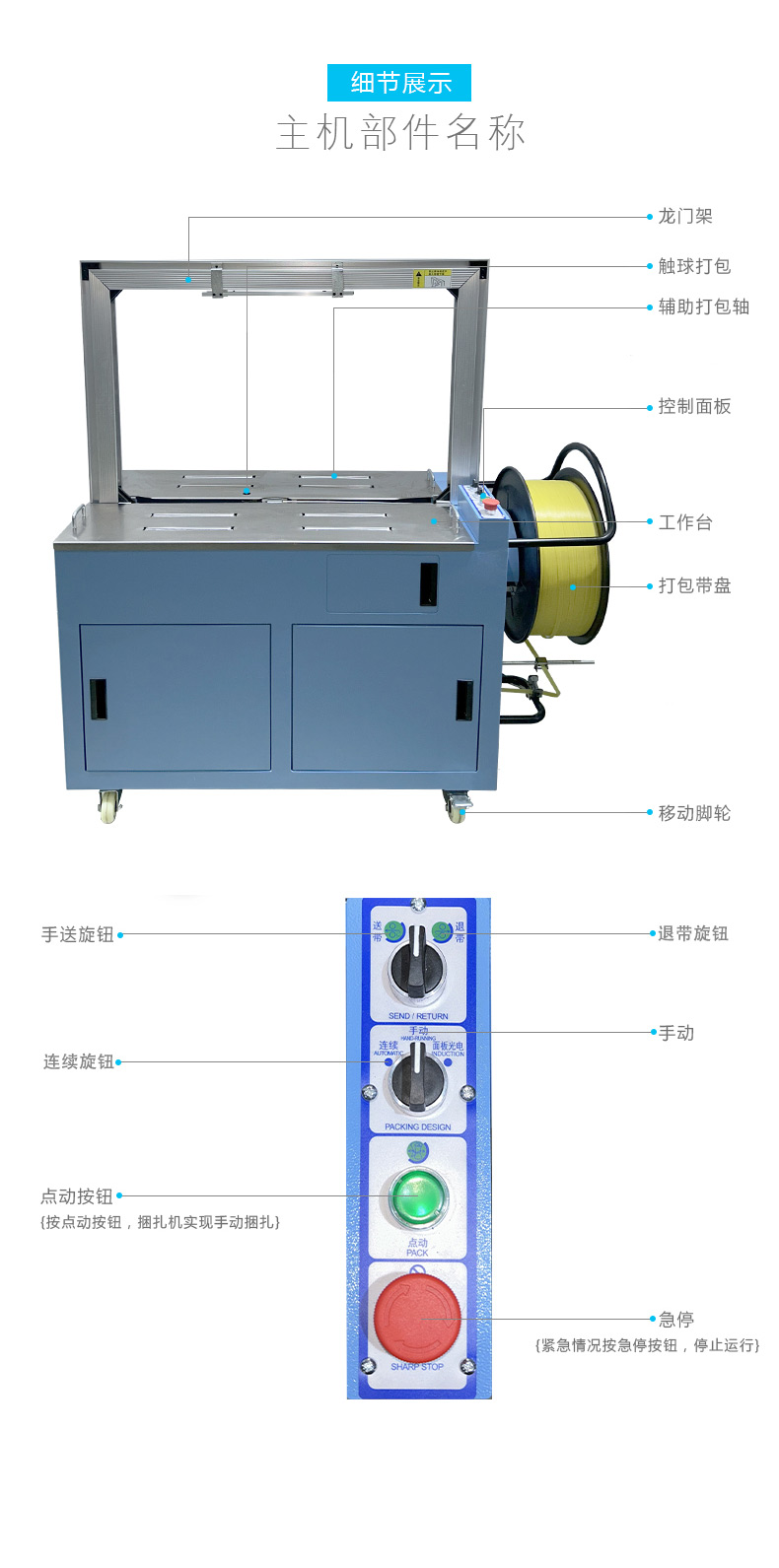

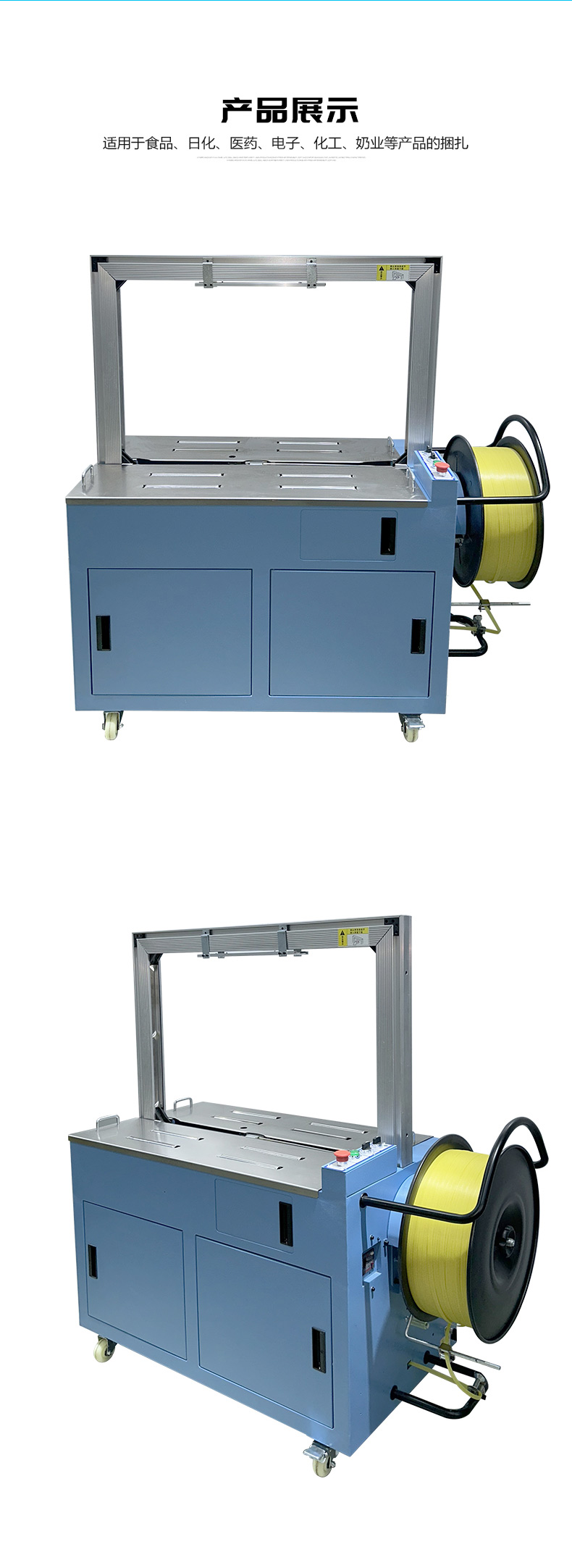

- Precise Material Positioning: Equipped with photoelectric or laser sensors, the servo motor can accurately adjust the speed and stop position of the conveyor belt according to the size and shape of the material. The positioning error is controlled within ±1mm, ensuring that even irregular items (such as 异形 hardware, irregularly packaged food boxes) can be stably sent to the strapping station without deviation.

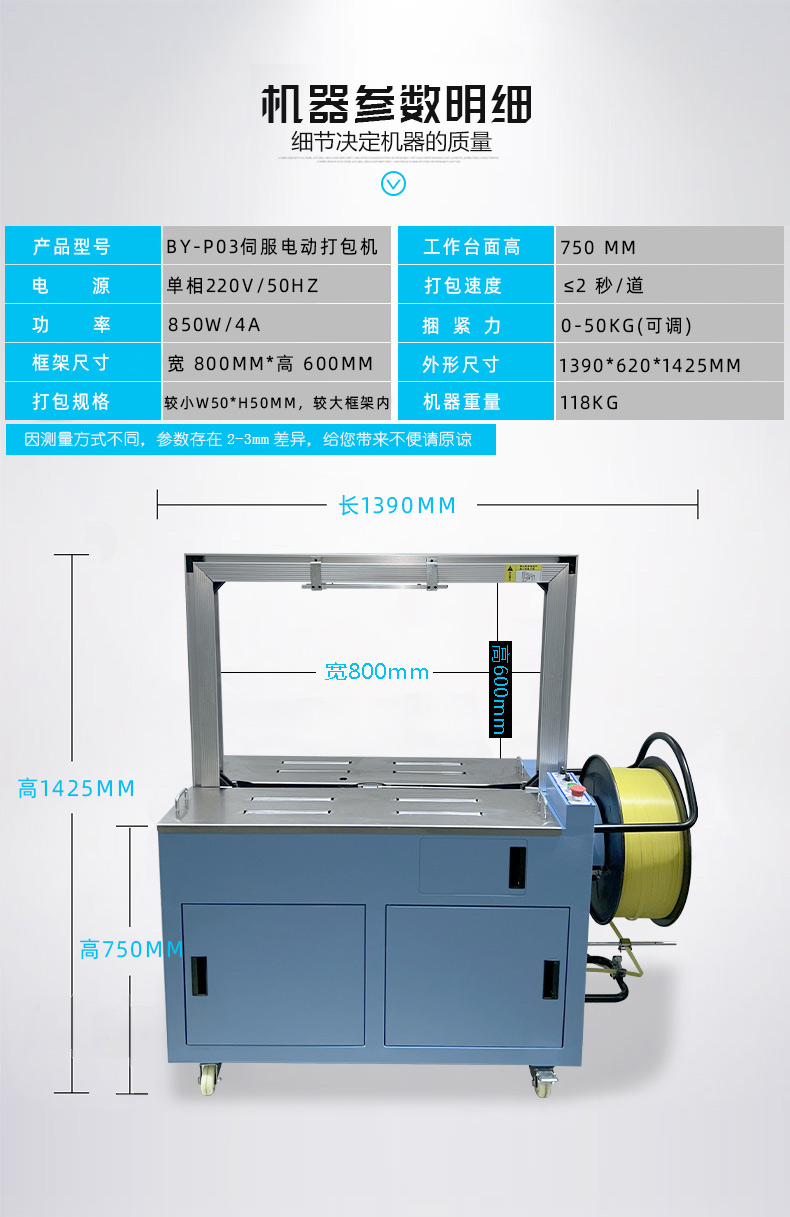

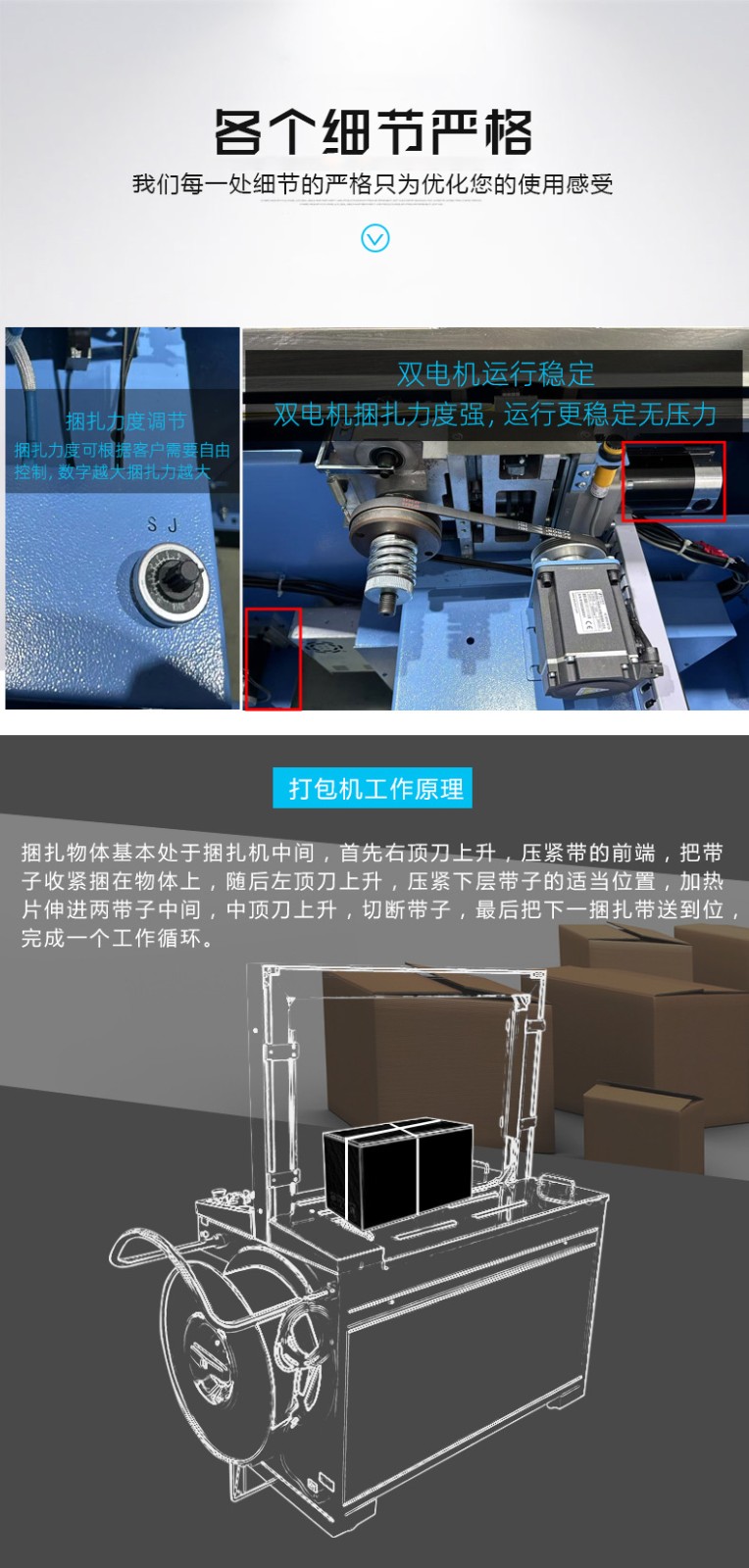

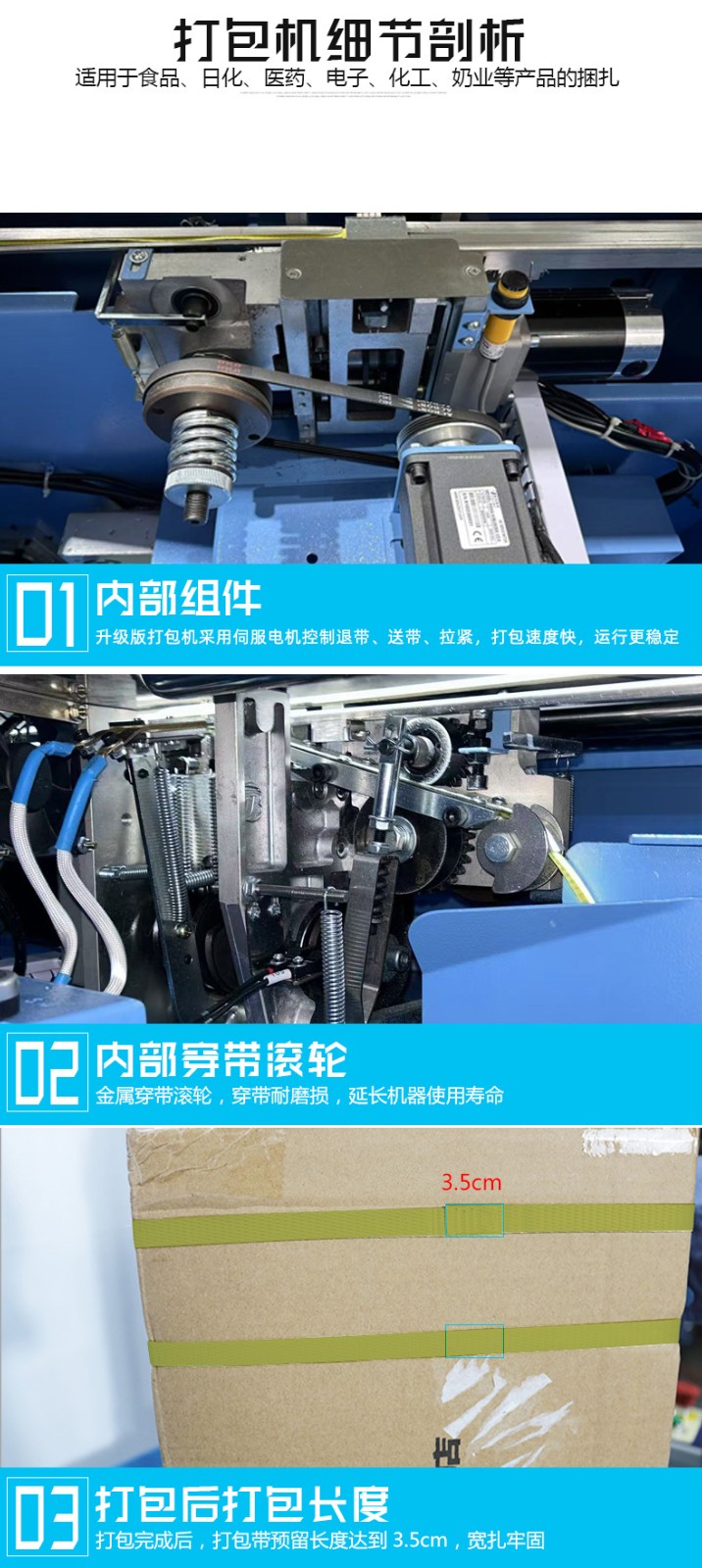

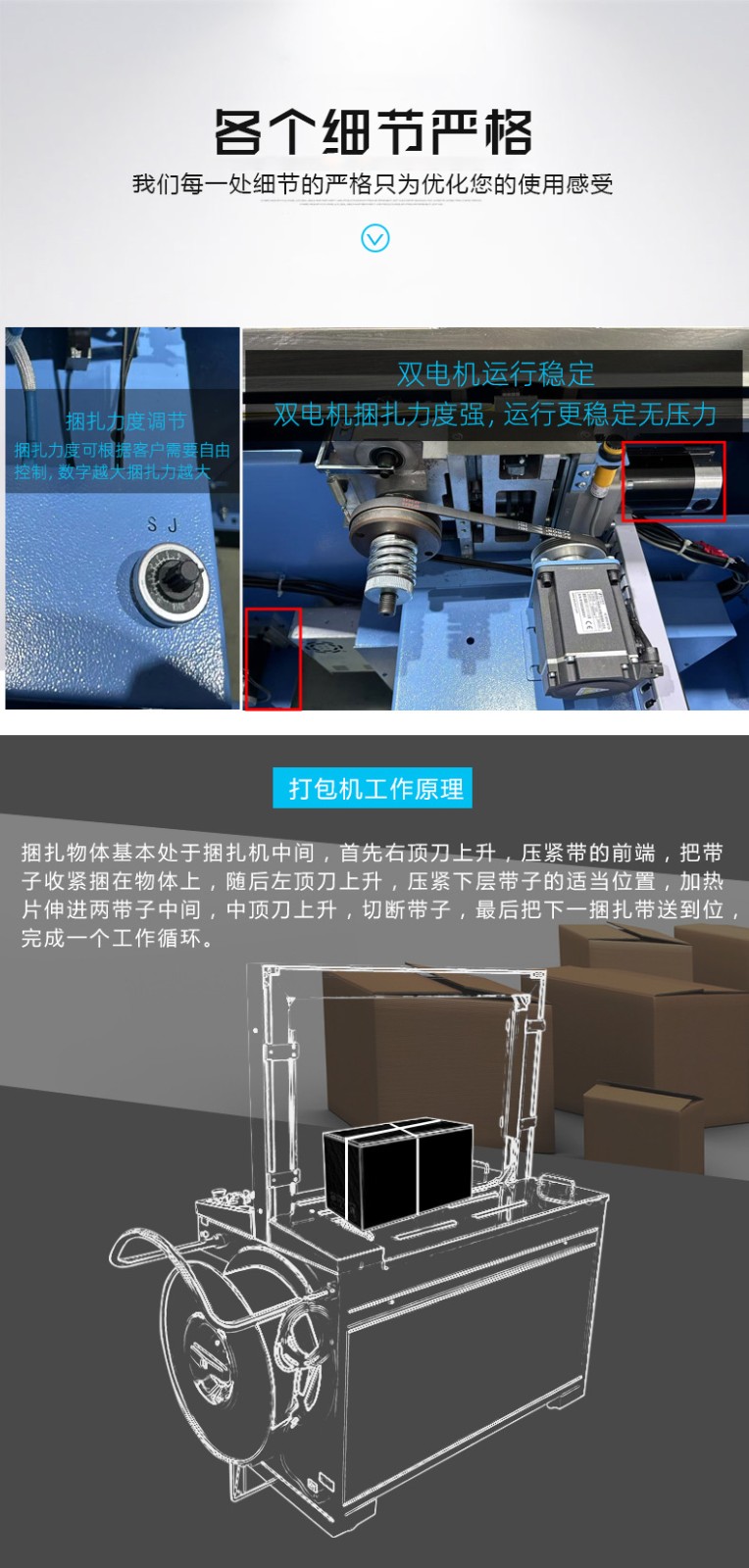

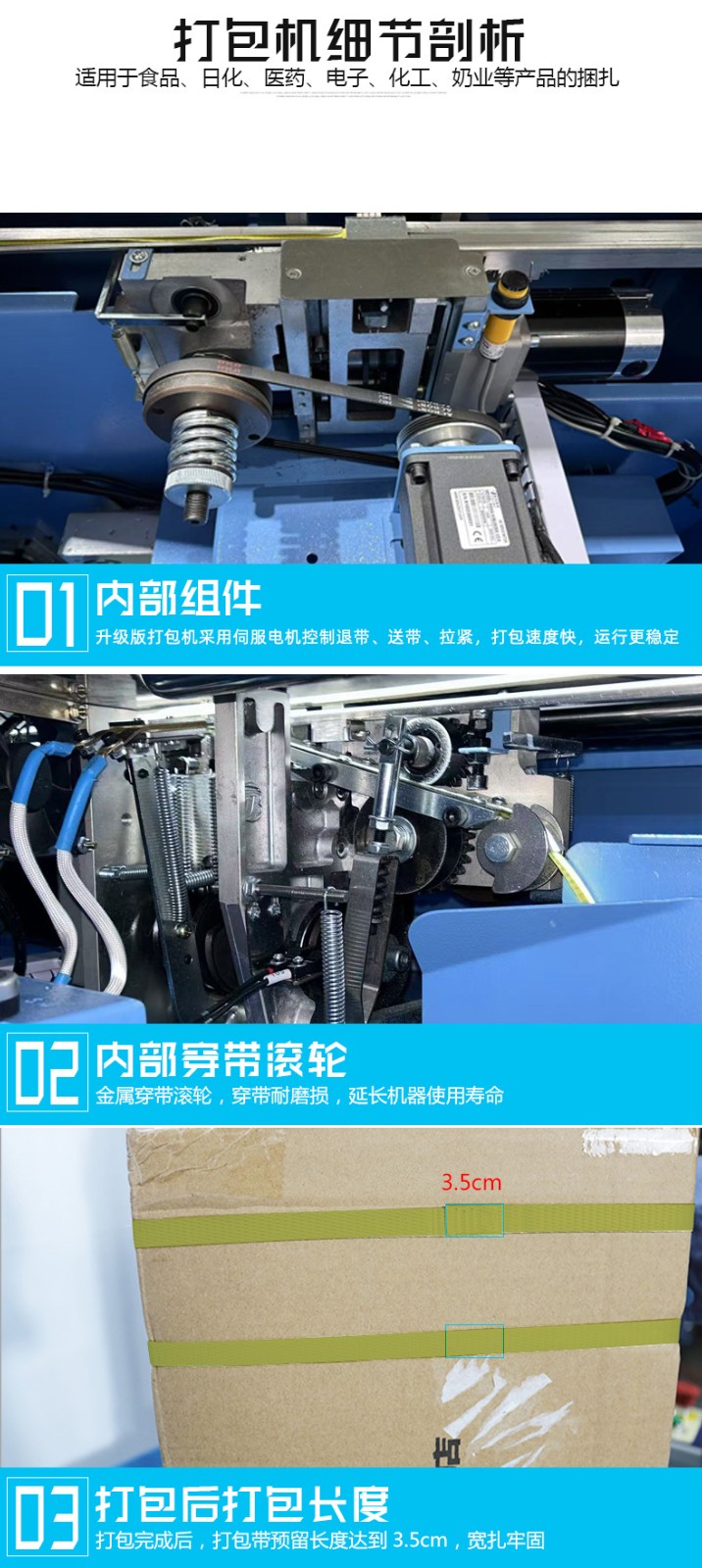

- Accurate Tension & Cutting Control: For strapping materials (PP belt, PET belt, etc.), the servo system can precisely control the tension (adjustable in the range of 0.5-50N) to avoid material damage caused by excessive tension (e.g., deformation of thin-cardboard electronic product boxes) or loose strapping caused by insufficient tension. At the same time, the cutting mechanism driven by the servo motor has a cutting length error of only ±0.3mm, reducing material waste.

- Stable Sealing Quality: The servo motor precisely controls the pressure, temperature retention time and pressing depth (±0.1mm) of the sealing knife, ensuring that each seal is flat, firm and airtight—critical for food packaging (to extend shelf life) and electronic product packaging (to prevent dust and moisture).

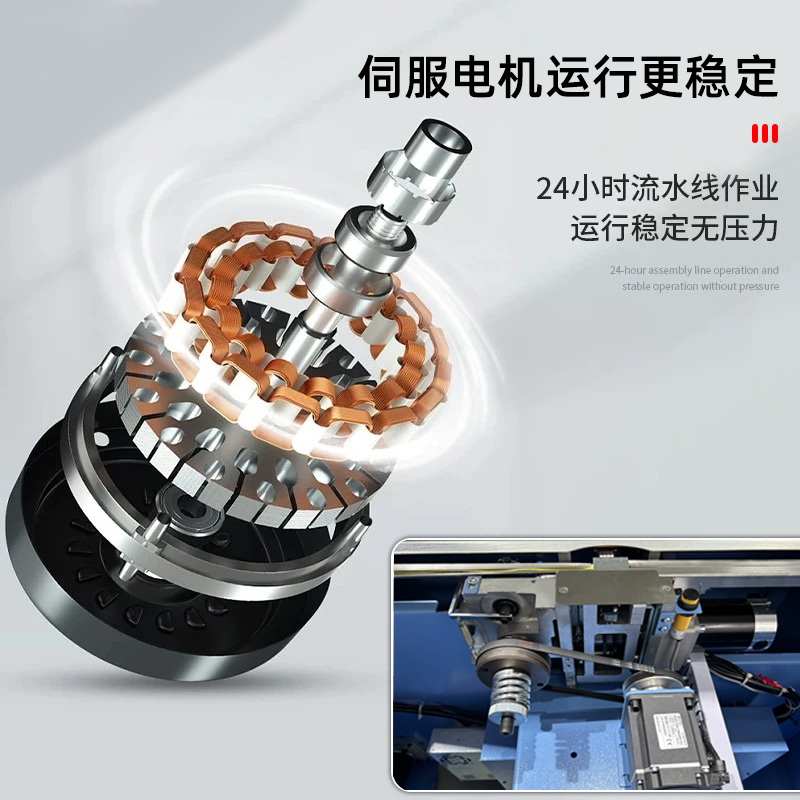

"Smooth strapping" means the machine runs without jamming, material jamming or sudden shutdown during continuous operation, which is supported by the stable performance of the servo system and optimized mechanical structure.

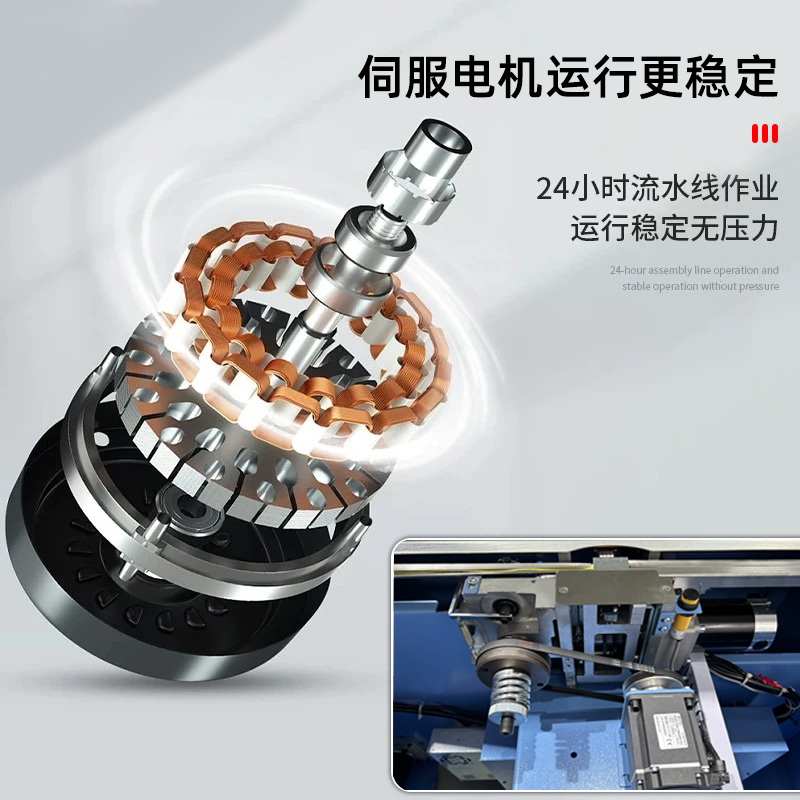

- Stable Power Output: Unlike traditional asynchronous motors that have unstable speed during load changes, servo motors can maintain constant torque and stable speed even when strapping materials of different weights (from 0.5kg small parts to 500kg heavy bundles of building materials), avoiding problems such as belt slipping or breaking caused by unstable power.

- Anti-jamming & Anti-wear Design: The key components (conveyor belt, strapping wheel, cutting knife) are made of wear-resistant materials (such as high-hardness alloy, food-grade rubber), and the servo system’s soft start/stop function reduces mechanical impact. This minimizes jamming caused by material residue or component wear, ensuring smooth operation even in long-term continuous work (e.g., 8-hour uninterrupted strapping in e-commerce logistics workshops).

- Intelligent Fault Self-adjustment: The control system can real-time monitor the running state of the servo motor (current, temperature, speed). If there is a slight abnormality (such as slight resistance in the strapping wheel), it will automatically adjust the motor parameters to eliminate jamming risks, instead of shutting down directly—greatly improving production continuity.

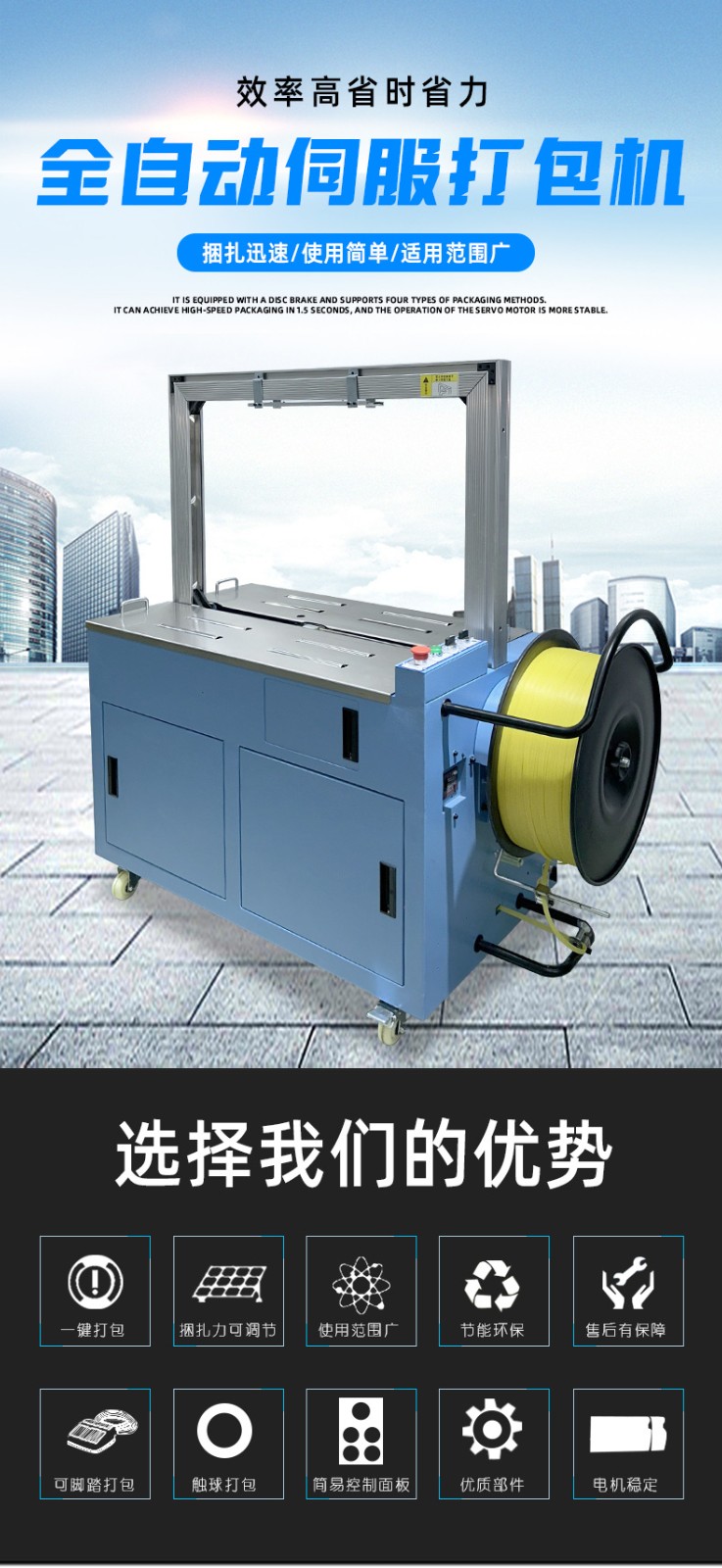

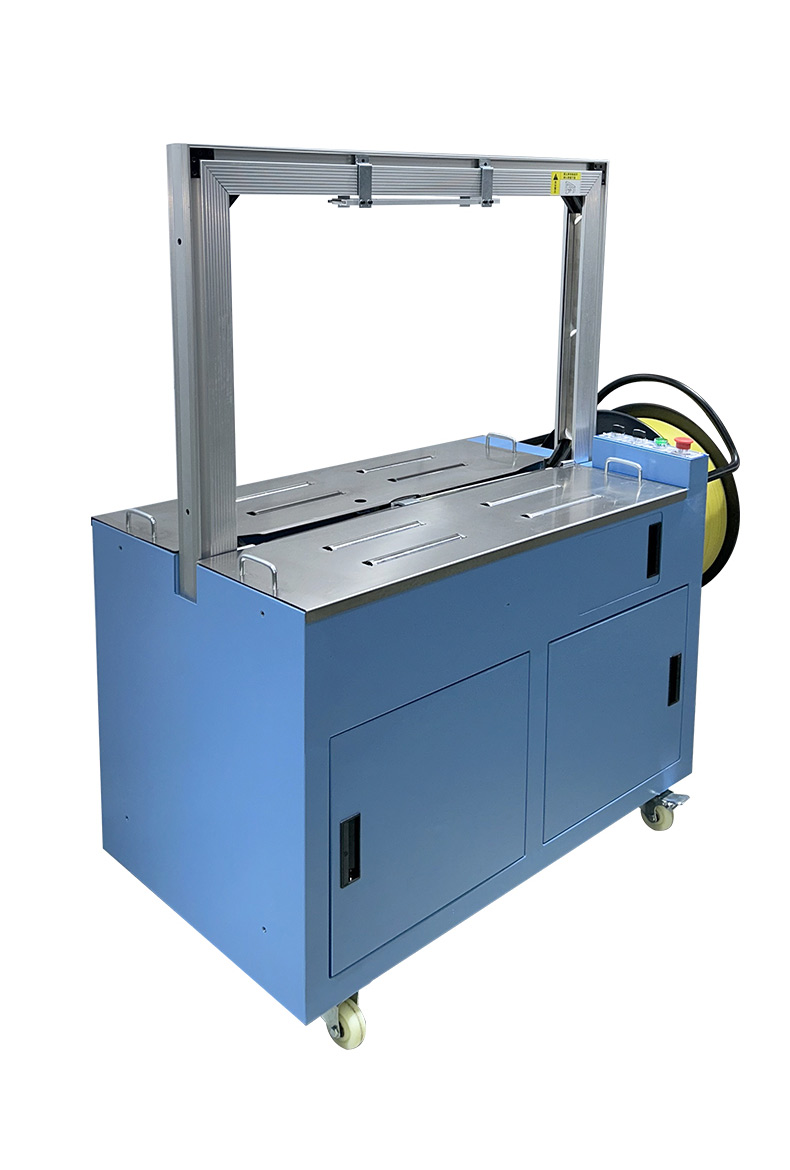

The "one strap in 2 seconds" (i.e., a strapping cycle takes only 2 seconds) represents the machine’s excellent production efficiency, which is achieved through the coordinated optimization of servo motor speed, process flow and intelligent control.

- High-speed Servo Response: The servo motor’s maximum rotation speed can reach 3000rpm, and its response time to control signals is less than 10ms—much faster than traditional motors. This enables rapid completion of actions such as material positioning, belt feeding, tensioning, cutting and sealing in a single strapping cycle.

- Streamlined Process Design: The machine integrates material detection, positioning, strapping and discharging into a seamless flow. There is no waiting time between processes: when one item is discharged after strapping, the next item is immediately positioned, realizing "continuous strapping" without interruption.

- Adaptable to High-volume Scenarios: With a strapping efficiency of 1800 straps per hour (based on 2 seconds per strap), the machine is fully capable of matching high-speed production lines in industries such as e-commerce (peak season order surges), food processing (continuous packaging of snacks/biscuits) and logistics (batch strapping of express parcels). For scenarios requiring higher efficiency, models with adjustable speed (up to 1.5 seconds per strap) are also available.

The combination of "high control precision", "smooth strapping" and "one strap in 2 seconds" brings tangible benefits to enterprises:

- Cost Reduction: High precision reduces packaging material waste (saving 15-20% of strapping material costs annually); smooth operation lowers maintenance frequency (reducing maintenance costs by 30% compared with traditional machines); high efficiency reduces the need for multiple devices (one machine replaces 2-3 semi-automatic strapping machines).

- Quality Improvement: Consistent strapping precision and sealing quality enhance the appearance of packaged products and reduce damage rates during transportation—for example, in the electronics industry, this can reduce the defect rate of product packaging from 5% to less than 0.5%.

- Flexibility Enhancement: While maintaining high efficiency and precision, the machine can still quickly switch parameters (via HMI touch screen) to adapt to different product sizes (from 5cm×5cm small boxes to 1.2m×0.8m large bundles) and strapping requirements, meeting the needs of "multi-SKU, small-batch" production in modern enterprises.