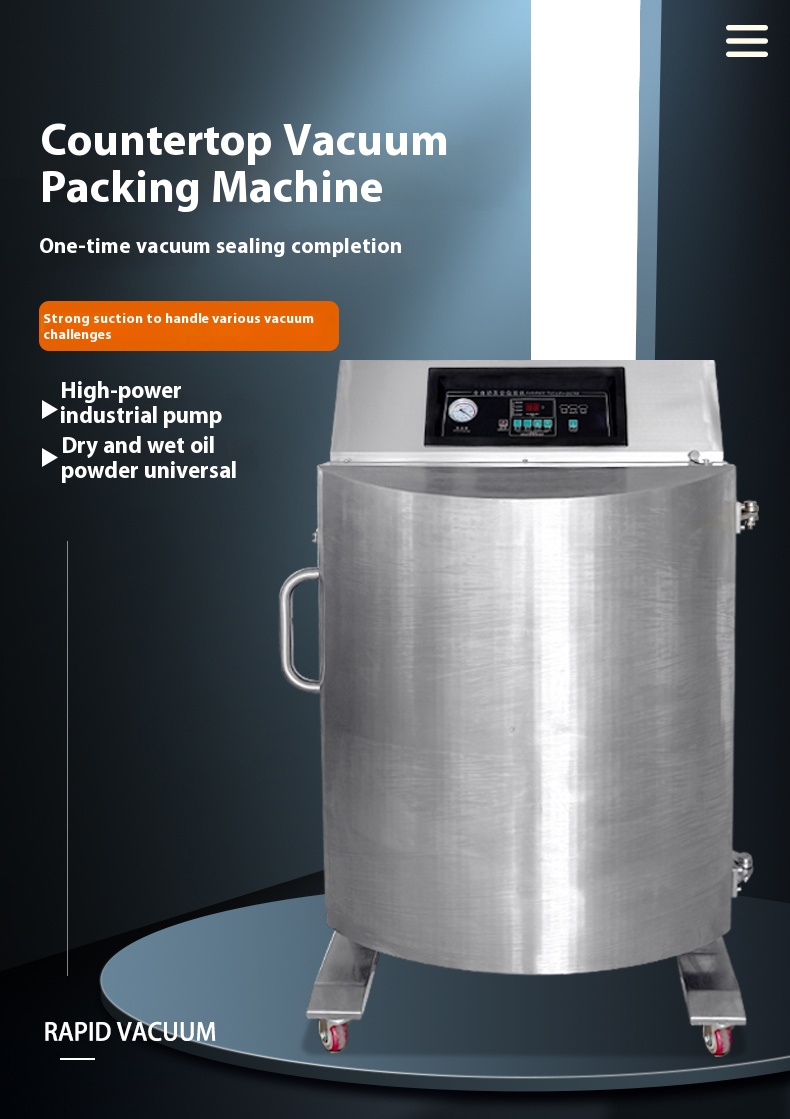

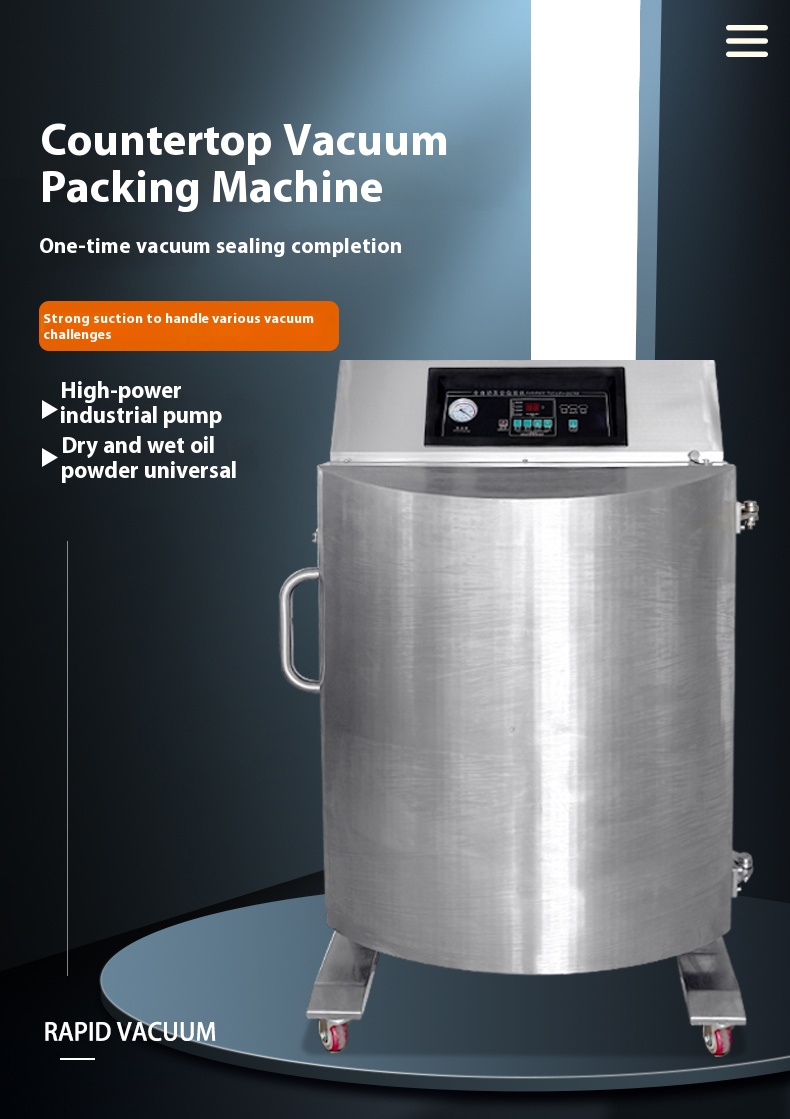

With its structural design and functional features, vertical cabinet vacuum packaging demonstrates significant advantages in commercial packaging scenarios, especially suitable for packaging large-sized and multi-type items. Its core advantages can be elaborated from the following five dimensions:

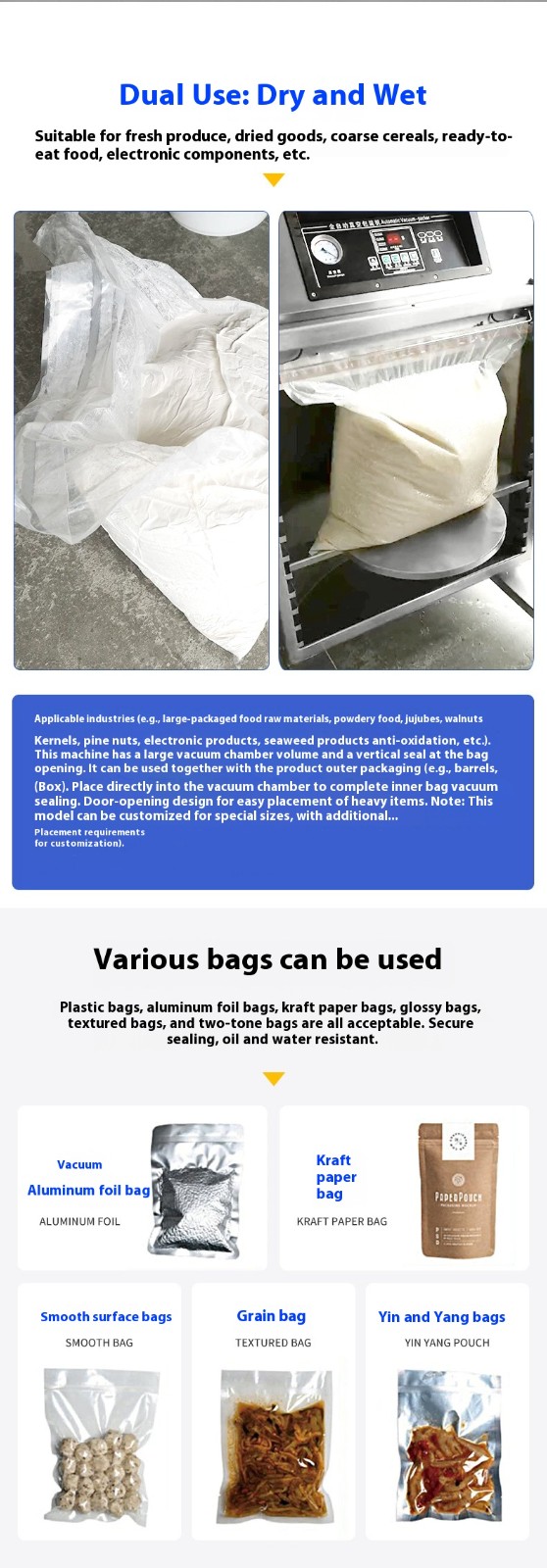

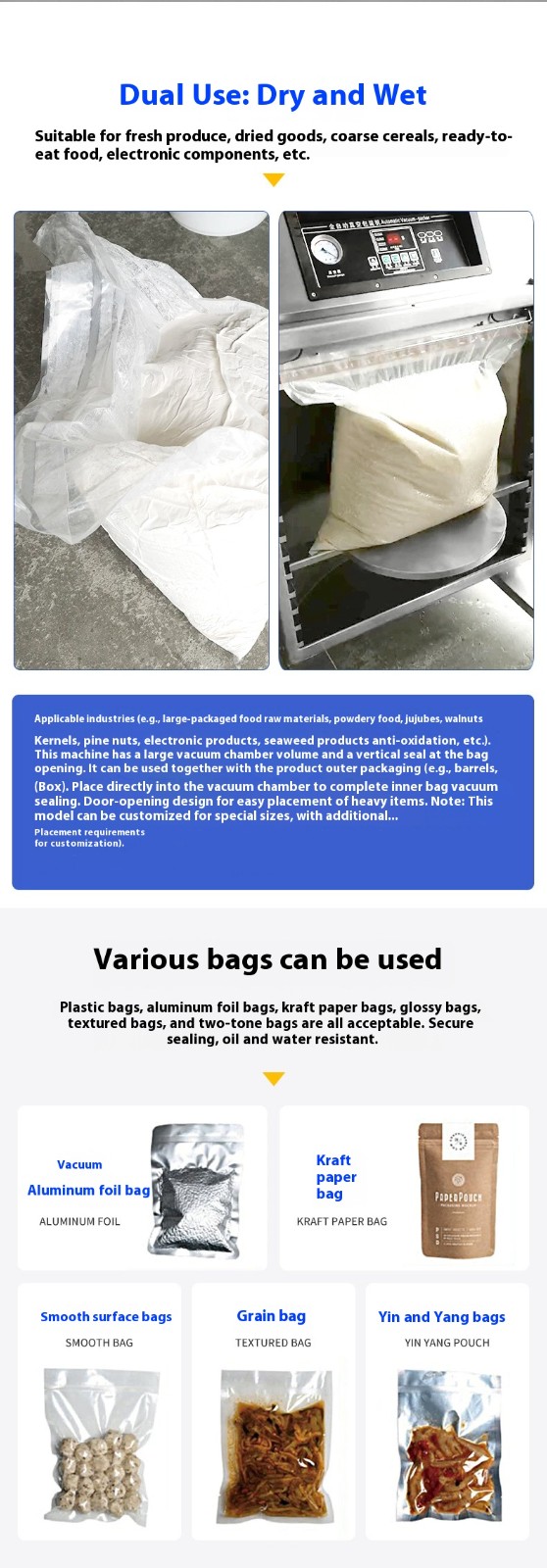

A core advantage of vertical cabinet vacuum packaging lies in its super large vacuum chamber space, whose volume is much larger than that of desktop or tabletop vacuum packaging equipment:

- It can accommodate large-sized single items, such as 20-50kg bags of grains, flour, or entire cartons of nuts and medicinal materials;

- It supports "multi-item co-packaging": multiple small-sized packages (e.g., independent small nut bags) can be placed into the vacuum chamber together with outer cartons or plastic buckets to achieve "secondary vacuum sealing", which reduces the volume of outer packaging while enhancing protection;

- It is compatible with irregularly shaped items, such as meat with hard trays and block-shaped dried goods. No additional adjustment to the packaging shape is required, and its adaptability is far superior to that of small-sized equipment.

Tailored to the "batch production" demand in commercial scenarios, vertical cabinet equipment excels in efficiency and stability:

- High degree of automation: Most are equipped with a PLC touch screen control system, allowing presetting of parameters such as vacuum degree, sealing time, and cooling time. After one-click startup, the equipment automatically completes the entire process of vacuum extraction → sealing → cooling, without the need for full-time manual monitoring, thus reducing operational errors;

- Strong continuous operation capability: It adopts a high-power vacuum pump (some are oil-free pumps) with fast vacuum extraction speed (usually 30-60 seconds per cycle, adjusted according to vacuum degree requirements). It also has good heat dissipation performance and can operate continuously for a long time, meeting the batch packaging needs of food processing plants, pharmaceutical warehouses, and other scenarios;

- Reliable sealing quality: The pressure of the sealing strip is controlled by an air cylinder, and combined with a stainless steel bag-supporting device, it can flatten the bag mouth and apply pressure evenly. The sealing width can reach 10-20mm, ensuring tight and flat sealing, and effectively avoiding air leakage and deterioration caused by poor sealing.

The operation and maintenance of vertical cabinet vacuum packaging equipment are generally not complicated. Its design is originally intended to adapt to efficient use and convenient management in commercial scenarios. Even ordinary operators can master the core processes after simple training. The specific analysis can be broken down into two aspects: "operational difficulty" and "maintenance complexity":

Vertical cabinet vacuum packaging equipment takes "simplified operation" as its core design concept, especially for batch operation needs in commercial scenarios. The operation process can be summarized into four steps: "Preparation - Setting - Startup - Inspection", with almost no complex manual intervention:

Most equipment adopts a PLC touch screen control system with clearly marked interfaces (parameters such as "vacuum degree", "sealing time", and "cooling time" are displayed in Chinese/icons). Operators only need to select a preset parameter template (or fine-tune values) according to the packaged items (e.g., grains, nuts, liquids), close the vacuum cover, and press the "start button". The equipment will automatically complete the entire process of "vacuum extraction → sealing → cooling → cover opening" without manual control of each step.

For novices, some equipment is also equipped with "operation guide pop-ups" and "fault prompt codes" (e.g., "E1 = Insufficient vacuum degree", "E2 = Overheated sealing strip") to reduce the probability of misoperation. The vacuum cover is mostly designed with "pneumatic/hydraulic assistance", requiring no strenuous pressing, so female operators can also open and close it easily.

If "gas-filled packaging" (e.g., nitrogen filling for crispy chips) or "large-sized item positioning" (e.g., whole-box packaging) is involved, only 1-2 additional steps are needed: for example, the gas-filled function only requires checking "gas-filled mode" on the touch screen and setting the gas ratio; for large-sized items, they only need to be placed according to the mark of "aligning the bag mouth with the sealing strip". These details are provided with graphic guidance in the equipment manual, and proficiency can usually be achieved after 1-2 hours of training.

Equipment is generally equipped with "safety interlock devices" (e.g., it cannot start if the vacuum cover is not tightly closed; it will automatically pause if hands accidentally touch the sealing area during operation) and an "emergency stop button". Even if an operational error occurs, the process can be interrupted in a timely manner, further lowering the operational threshold (no need to worry about equipment damage or personal risks caused by misoperation).