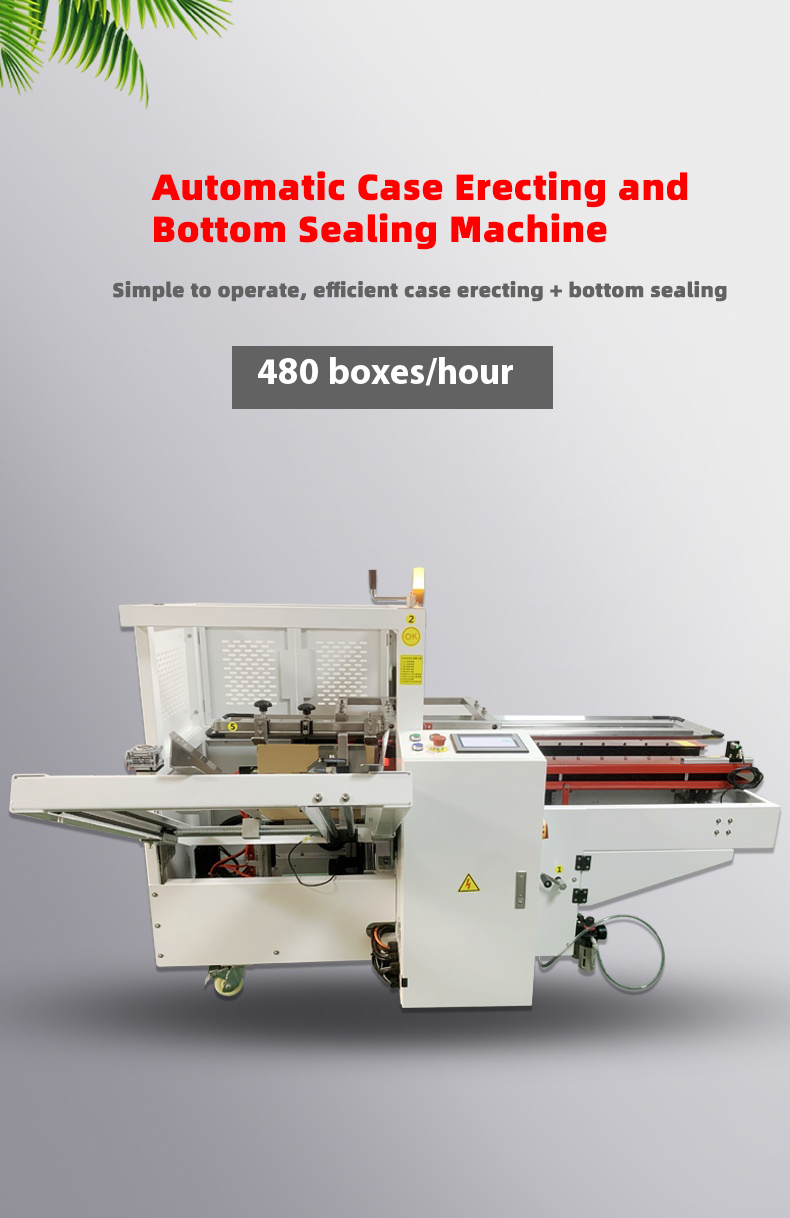

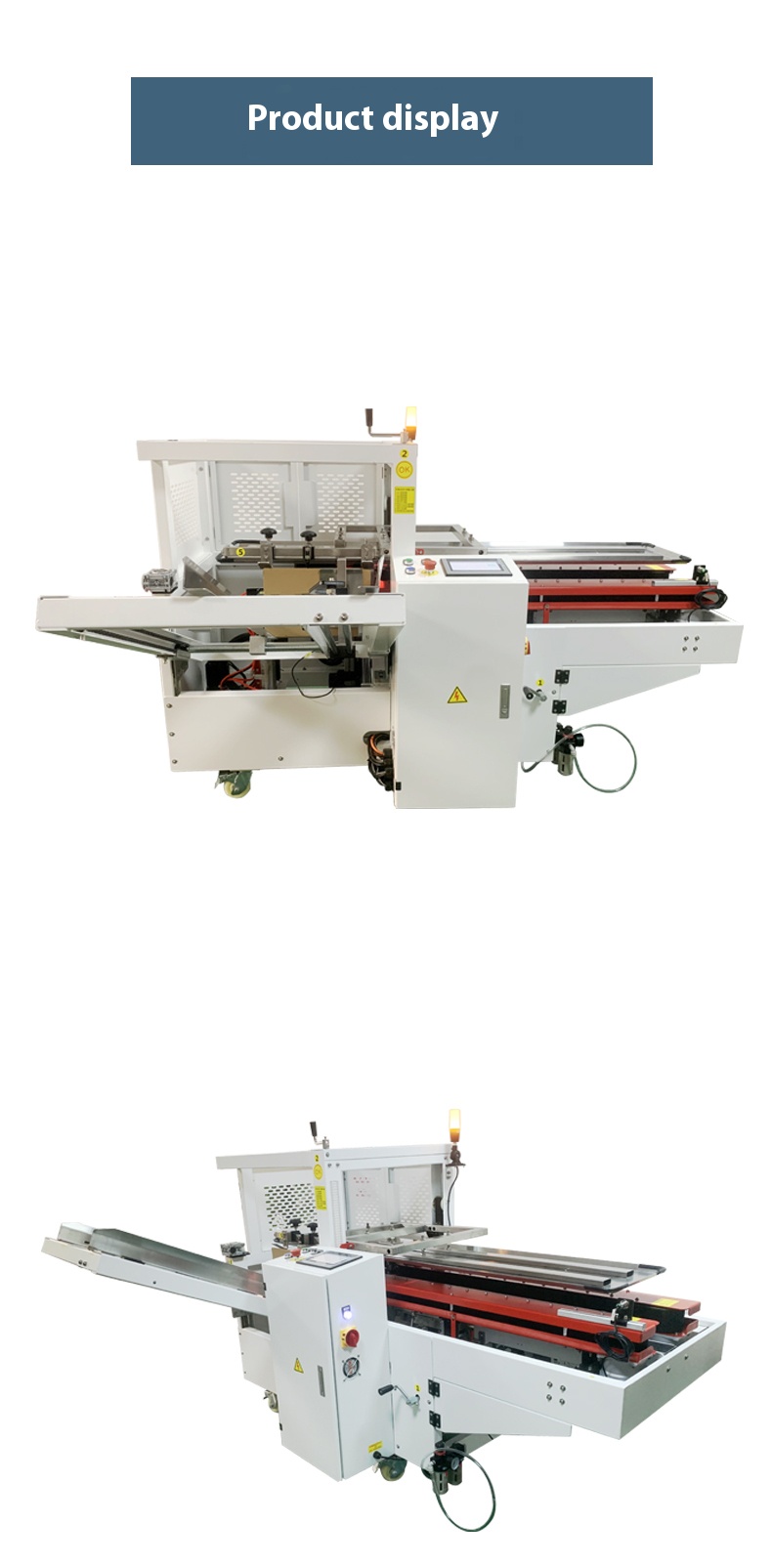

Traditional manual case unpacking and bottom sealing require manually unfolding cartons, folding bottom flaps, and applying adhesive tape. A single worker can only complete 1-3 cartons per minute, and this efficiency is easily affected by fatigue and proficiency. In contrast, the automatic case unpacking and bottom sealing machine, relying on mechanical linkage and automated control, achieves much higher efficiency: medium-speed models (e.g., horizontal ones with a speed of 18-25 cartons per minute) can reach 5-8 times the efficiency of manual operations, while high-speed models (with a speed of over 40 cartons per minute) can meet the needs of large-scale production lines. Meanwhile, the equipment can operate continuously for 24 hours without the need for manual shift changes, completely breaking free from the "labor bottleneck." For example, during the peak season in the food and beverage industry, one piece of such equipment can replace 3-5 packaging workers, avoiding production delays caused by labor shortages.

- Labor Cost Savings: In the long run, the one-time investment in the equipment can replace the ongoing expenditures such as salaries and social security for multiple workers. Typically, the equipment cost can be recovered within 1-2 years.

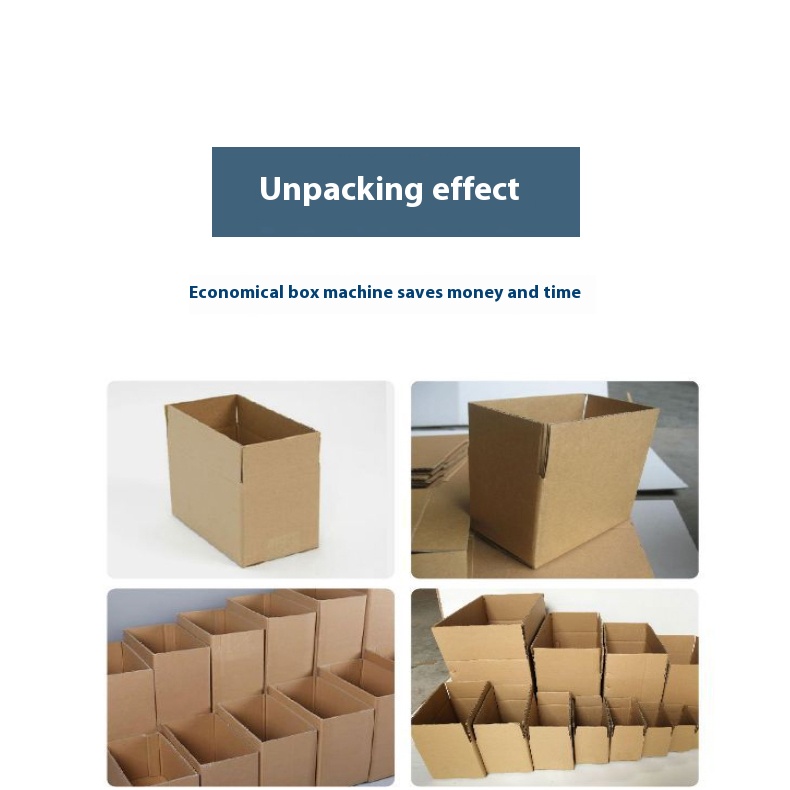

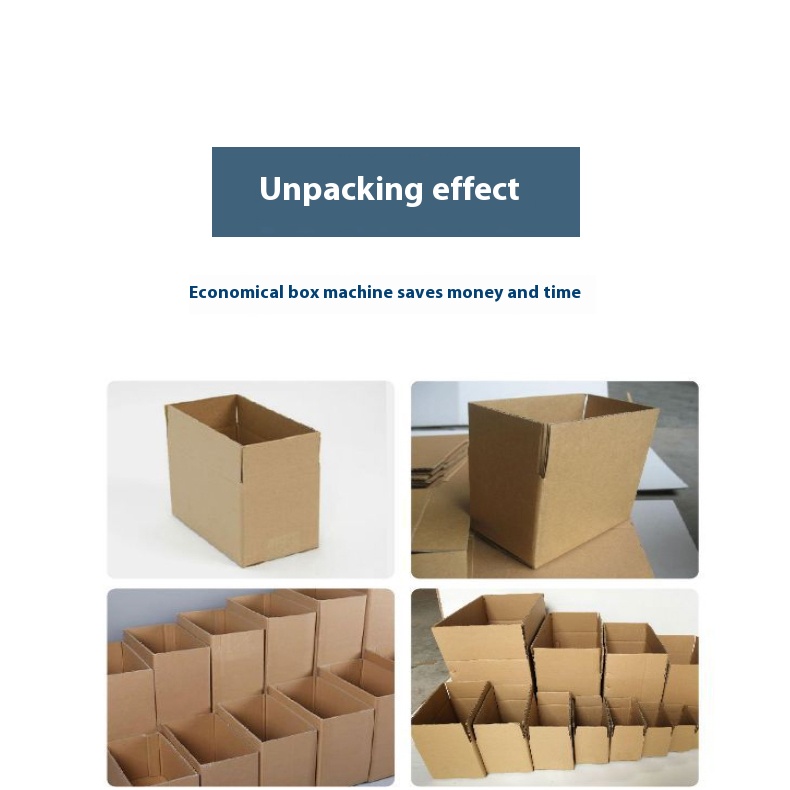

- Reduced Material Waste: Manual operations often lead to carton damage and adhesive tape waste due to folding deviations and uneven tape application. The equipment, however, adopts precise mechanical positioning (e.g., guide rail guidance and flap folding mechanism calibration) and constant-pressure bottom sealing, enabling a carton qualification rate of over 99% and a 5%-10% reduction in adhesive tape usage compared to manual operations.

- Lower Management Costs: There is no need to invest efforts in manual training and attendance management, and production fluctuations caused by staff turnover are reduced.

The equipment precisely controls every step of the operation (e.g., carton suction force, flap folding angle, and adhesive tape application pressure) through a PLC program, ensuring that all cartons have consistent forming dimensions, flat-folded bottom flaps, and firm adhesive tape application without air bubbles or deviations—thus avoiding random errors caused by manual operations. This advantage is particularly crucial in industries with high requirements for packaging standardization. For instance, the pharmaceutical industry needs to comply with GMP (Good Manufacturing Practice) cleanliness standards, and the equipment can reduce the risk of contamination caused by manual contact; packaging of electronic products needs to avoid transportation damage due to unstable cartons, and the stable bottom sealing of the equipment can reduce after-sales losses.

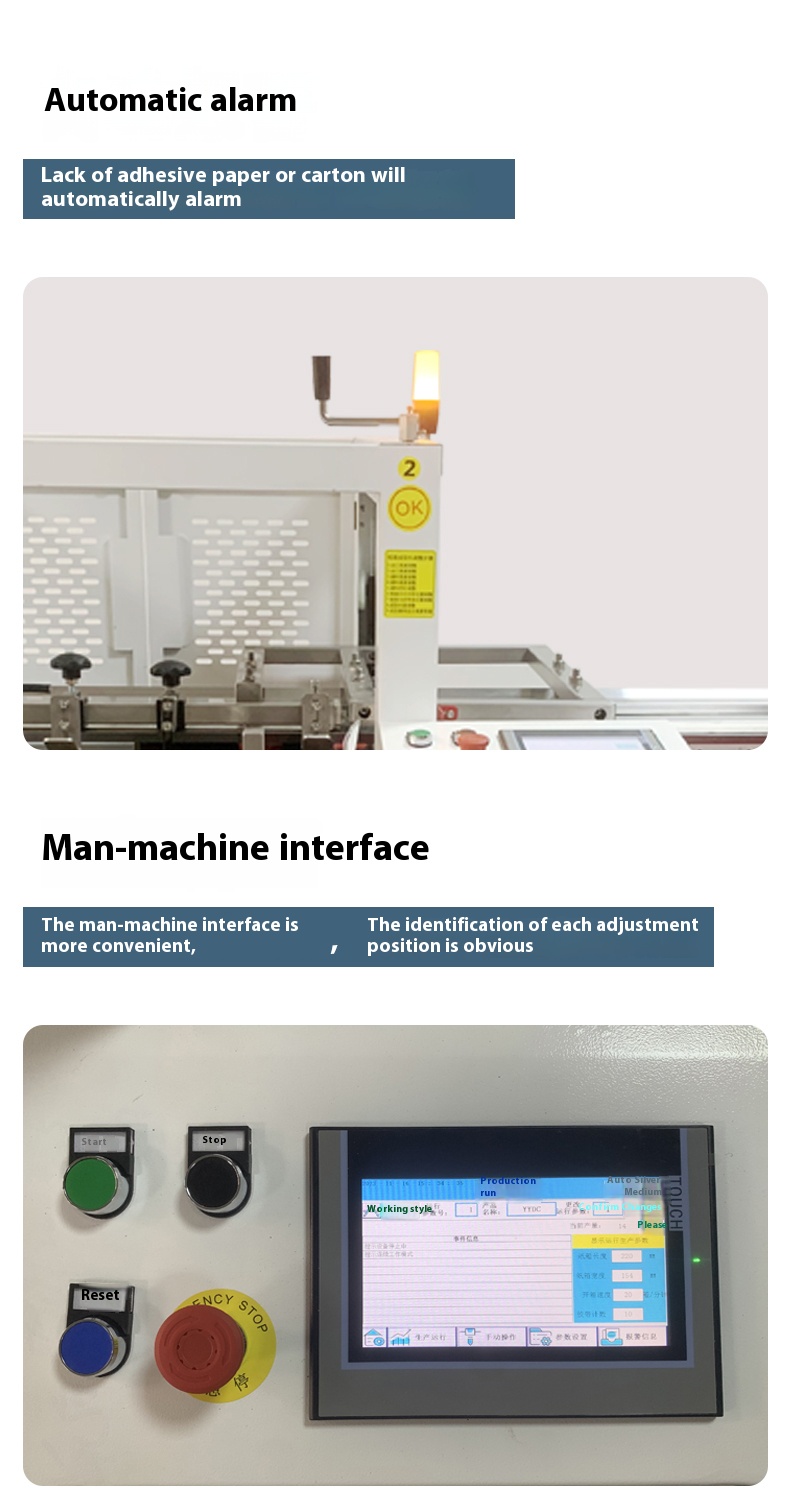

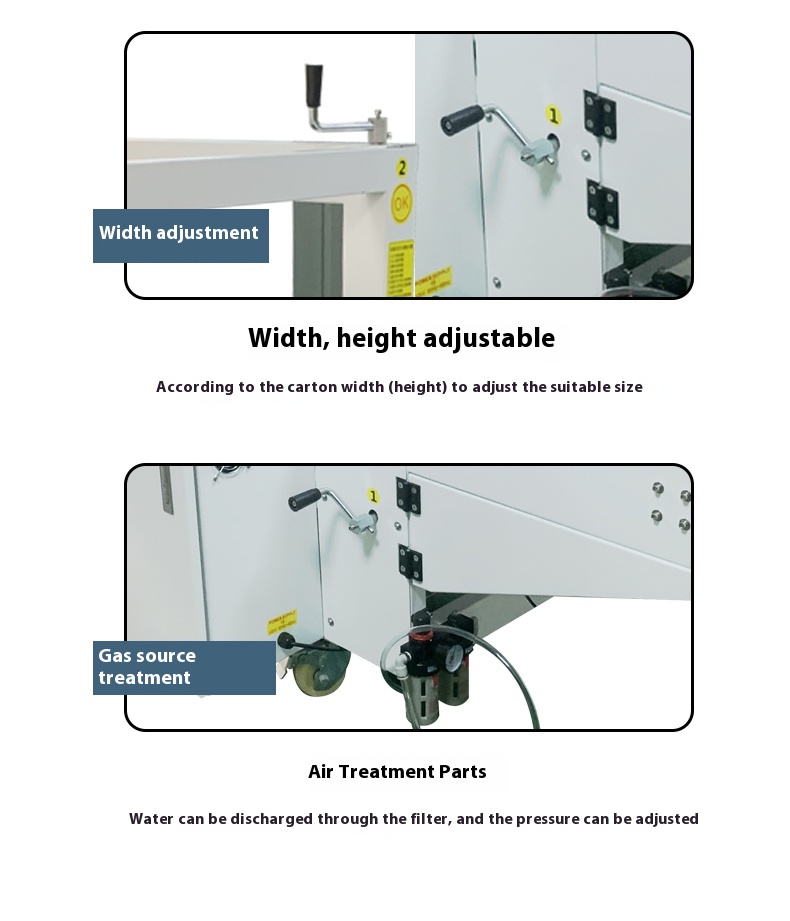

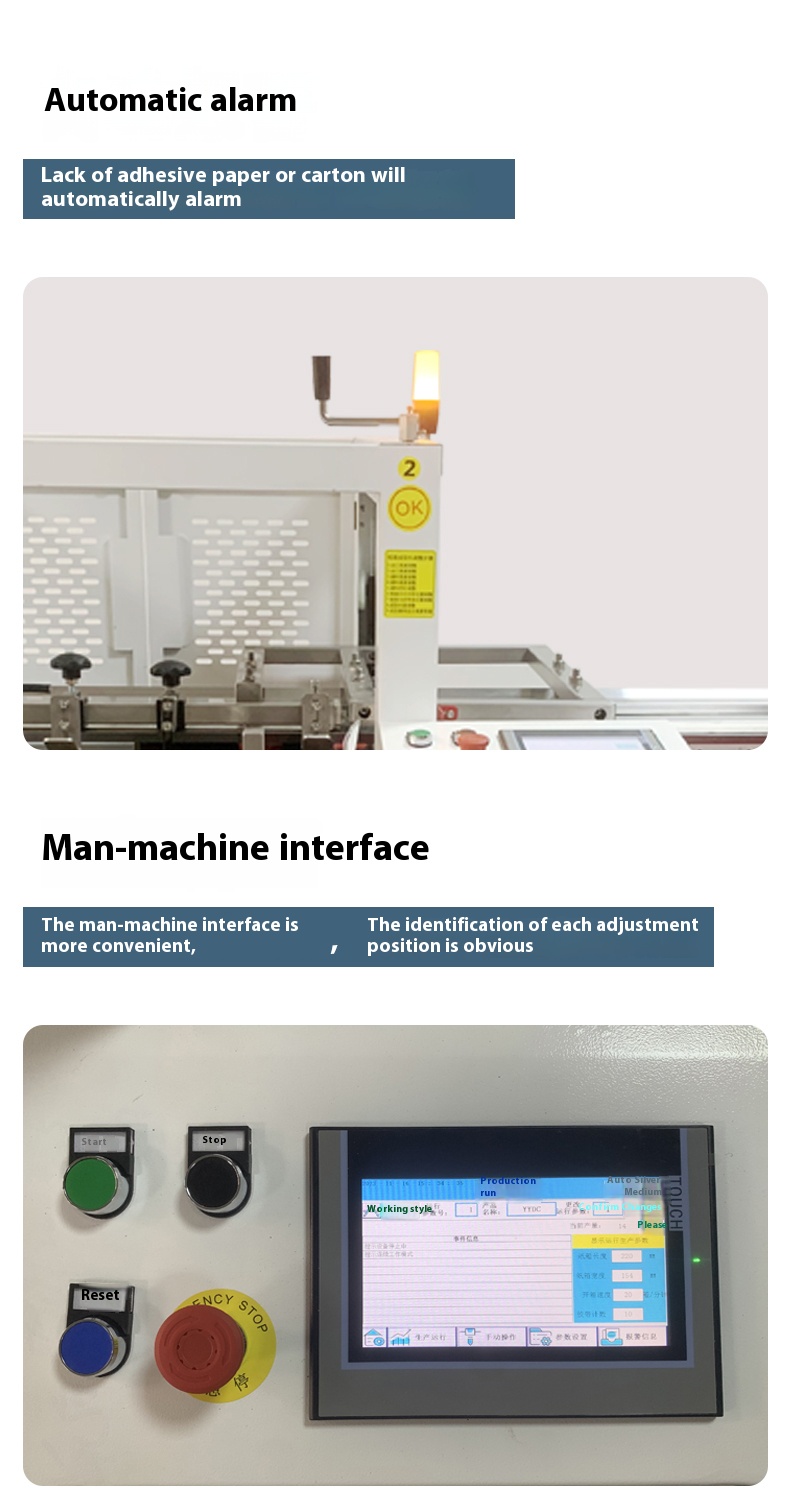

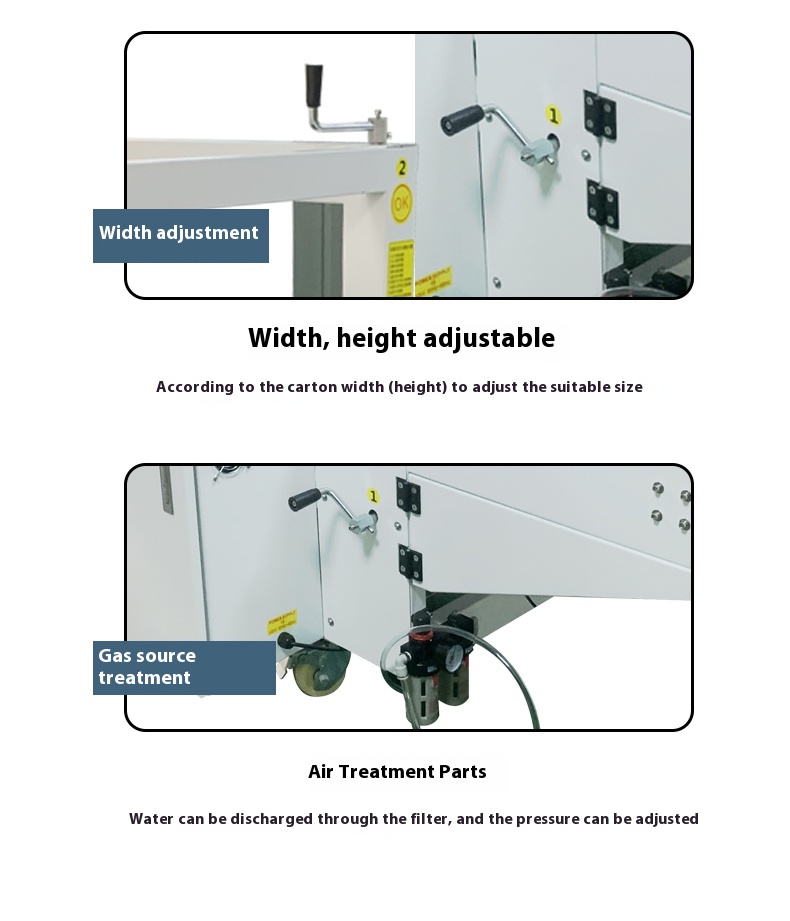

- Easy to Operate: Equipped with "PLC + touch screen" control, the equipment does not require operators to have professional skills. Operators only need to set carton specifications (e.g., length, width, and height) through the interface, and the equipment can automatically adapt and adjust. Switching between different specifications only takes 1-3 minutes (whereas manual specification switching requires re-familiarizing with the carton type, which takes much longer).

- Easy to Maintain: The core components of the equipment (e.g., vacuum suction cups, drive motors, and tape mechanisms) are designed in a modular manner, allowing quick disassembly and replacement in case of faults. Some models are equipped with a "fault self-diagnosis function," which directly displays fault points (e.g., "suction cup air leakage" and "tape exhaustion") on the screen, reducing downtime for maintenance and repair.