The multi-functional integrated external vacuum packaging machine is a device that integrates multiple functions such as gas-filled fresh-keeping, sealing, and coding on the basis of the basic external vacuum function. It can meet the packaging needs of different items in one stop, with core advantages of high function integration and strong scenario adaptability, eliminating the need to purchase additional multiple devices.

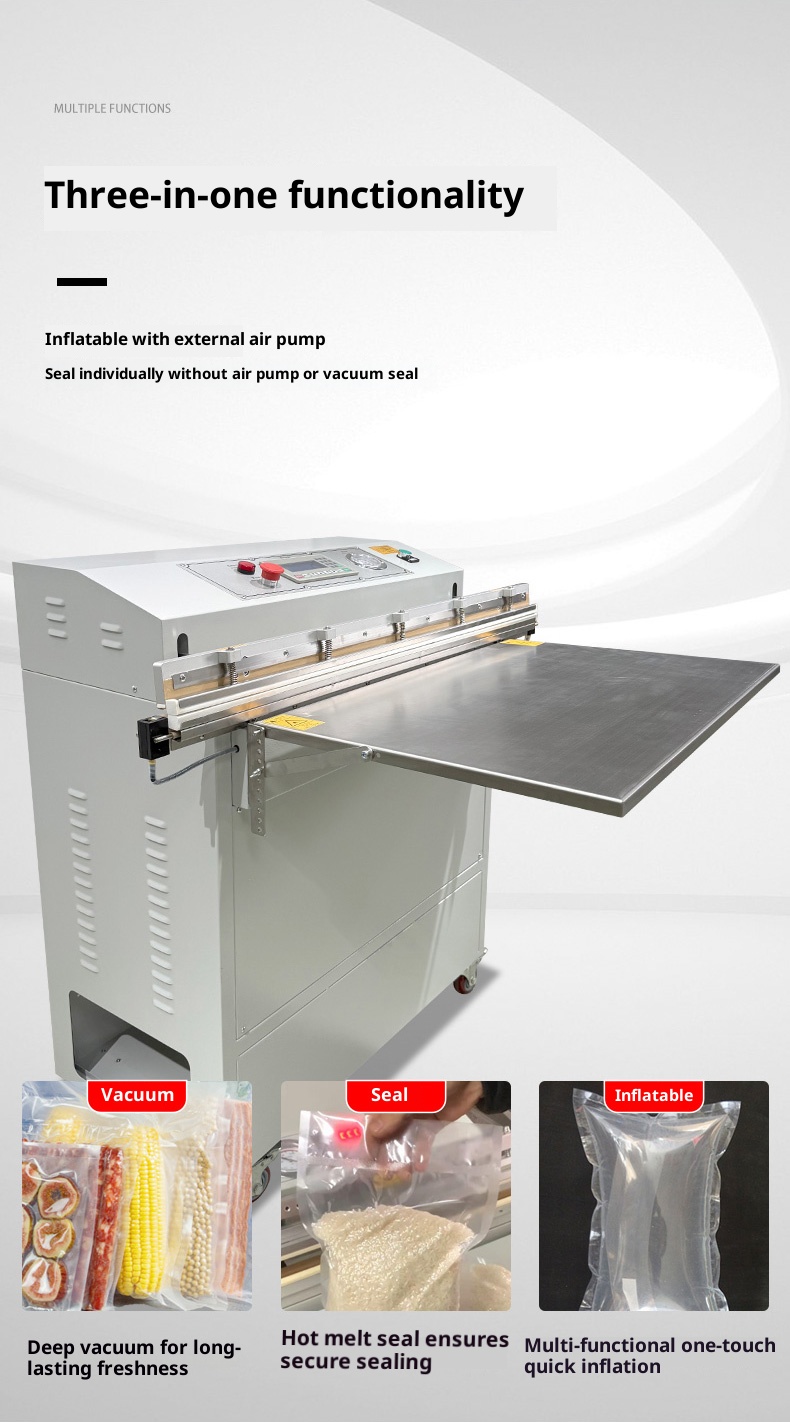

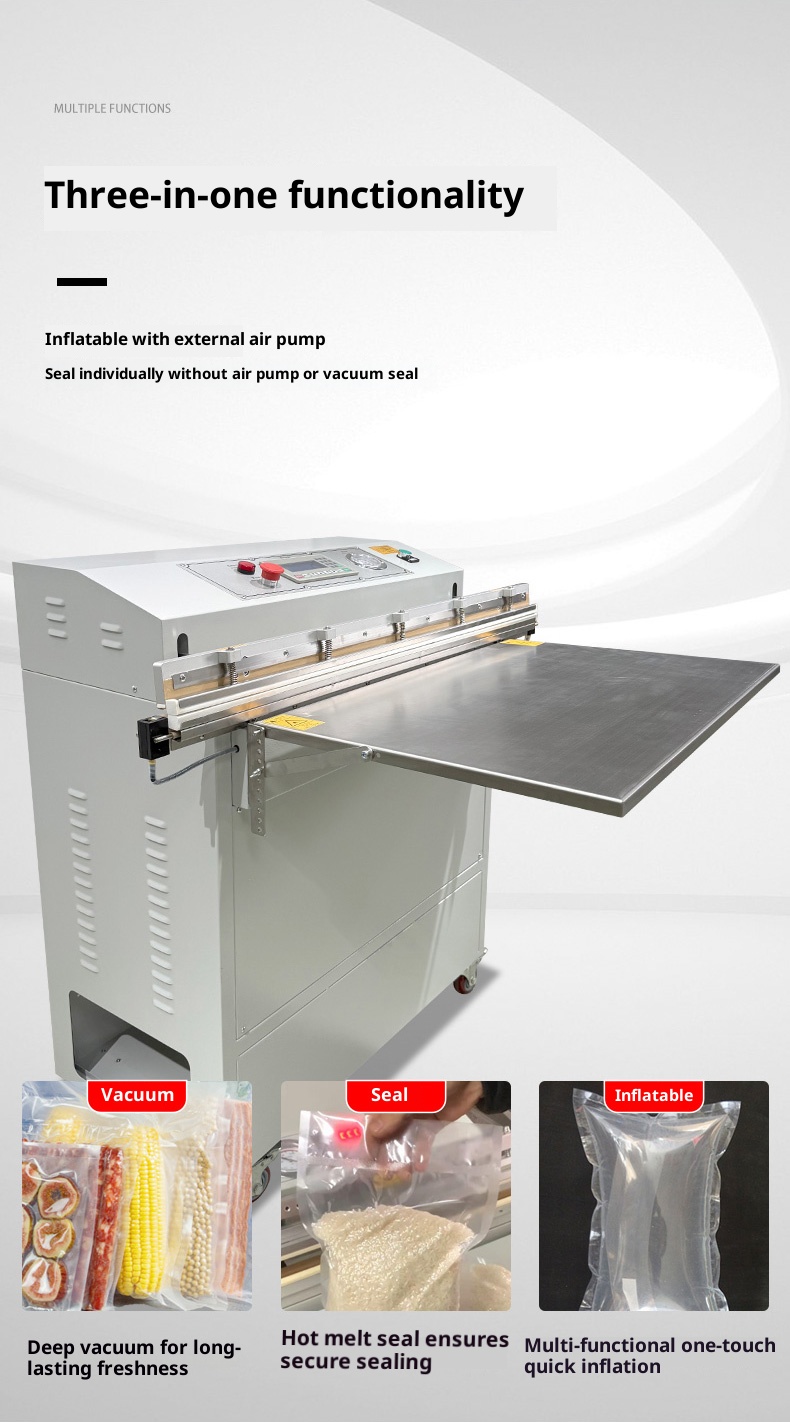

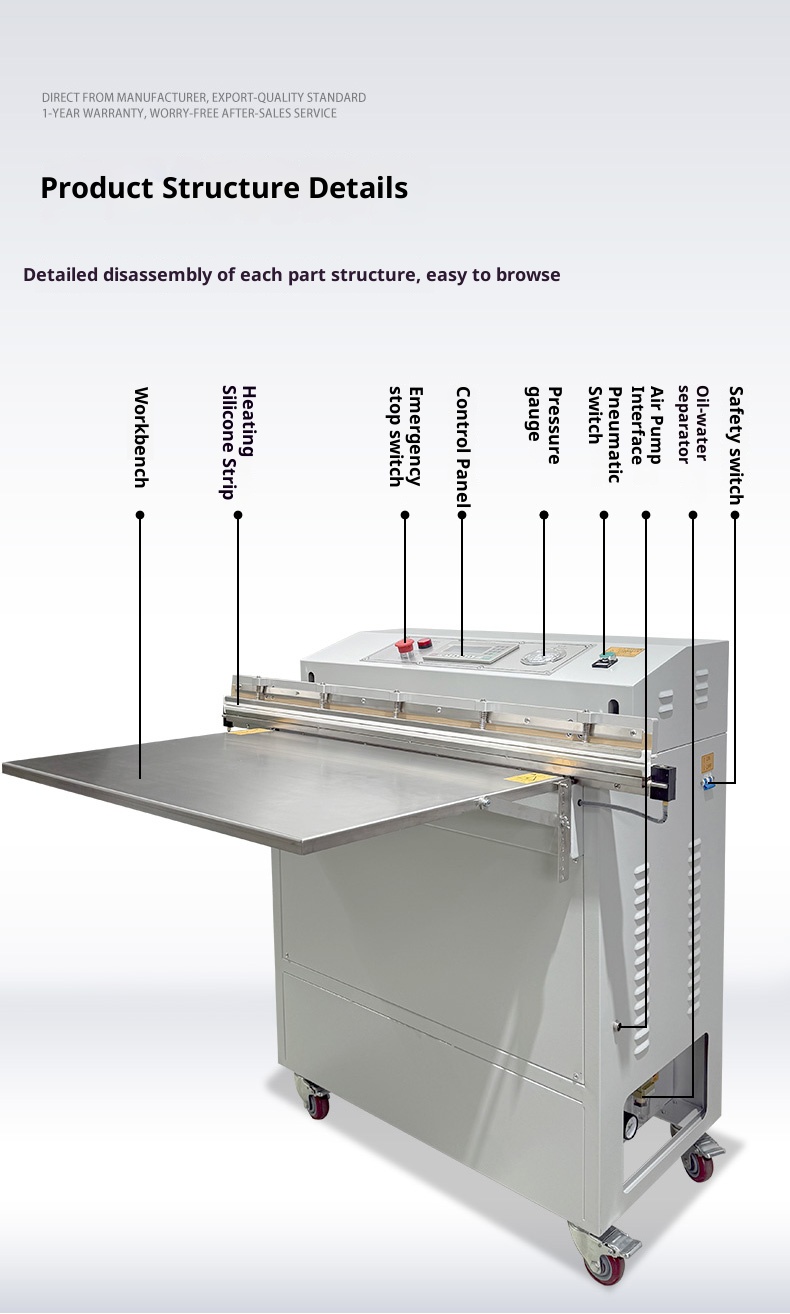

This type of equipment usually includes the following 3-4 core functions, which can be switched according to needs:

- Basic External Vacuum: It extracts air from the bag through an external air suction nozzle, suitable for moisture-proof and compressed packaging of large-sized, pressure-sensitive items (such as furniture accessories, plush toys), and is not limited by the size of the equipment chamber.

- Gas-Filled Fresh-Keeping: After vacuum extraction, inert gases such as nitrogen and carbon dioxide can be filled. It is mostly used for packaging food (such as bread, pastries, fresh meat), which can prevent oxidation and deterioration, maintain taste, and also avoid collision of fragile items during transportation.

- Multi-Functional Sealing: In addition to conventional heat sealing, some models support wide-edge sealing (to enhance sealing performance) and pattern sealing (to improve packaging aesthetics). They can also be adapted to various packaging materials such as PE, aluminum foil, and composite films.

- Date/Mark Coding: It integrates a ribbon coding module, which can print information such as production date, shelf life, and batch number synchronously during sealing. It is especially suitable for scenarios that require traceability, such as food, medicine, and industrial parts.

Compared with single-function external vacuum machines, it has stronger comprehensive adaptability. Typical application scenarios include:

- Food Industry: It can not only vacuum-package large quantities of meat and seafood (for moisture-proof and fresh-keeping), but also gas-fill package cakes, fruits and vegetables (for pressure-proof and oxidation-proof). It can also perform synchronous coding to meet the compliance requirements of food packaging.

- Industrial Field: It can vacuum-package large mechanical parts (for rust prevention) and whole boxes of electronic components (for dust prevention). Some models support adjusting the vacuum strength to avoid damage to precision components.

- Home and Retail: It can perform compressed vacuum packaging on curtains, quilts, etc. (to save storage space), and also gas-fill package gifts and accessories (to improve texture), balancing practicality and aesthetics.

Its core advantages are as follows:

- Cost Saving: One device replaces a vacuum machine, a gas-filling machine, and a coding machine, reducing equipment purchase costs and floor space.

- Efficiency Improvement: There is no need to transfer items between multiple devices, and multiple processes can be completed in a single operation. It is especially suitable for small-batch, multi-category packaging needs.

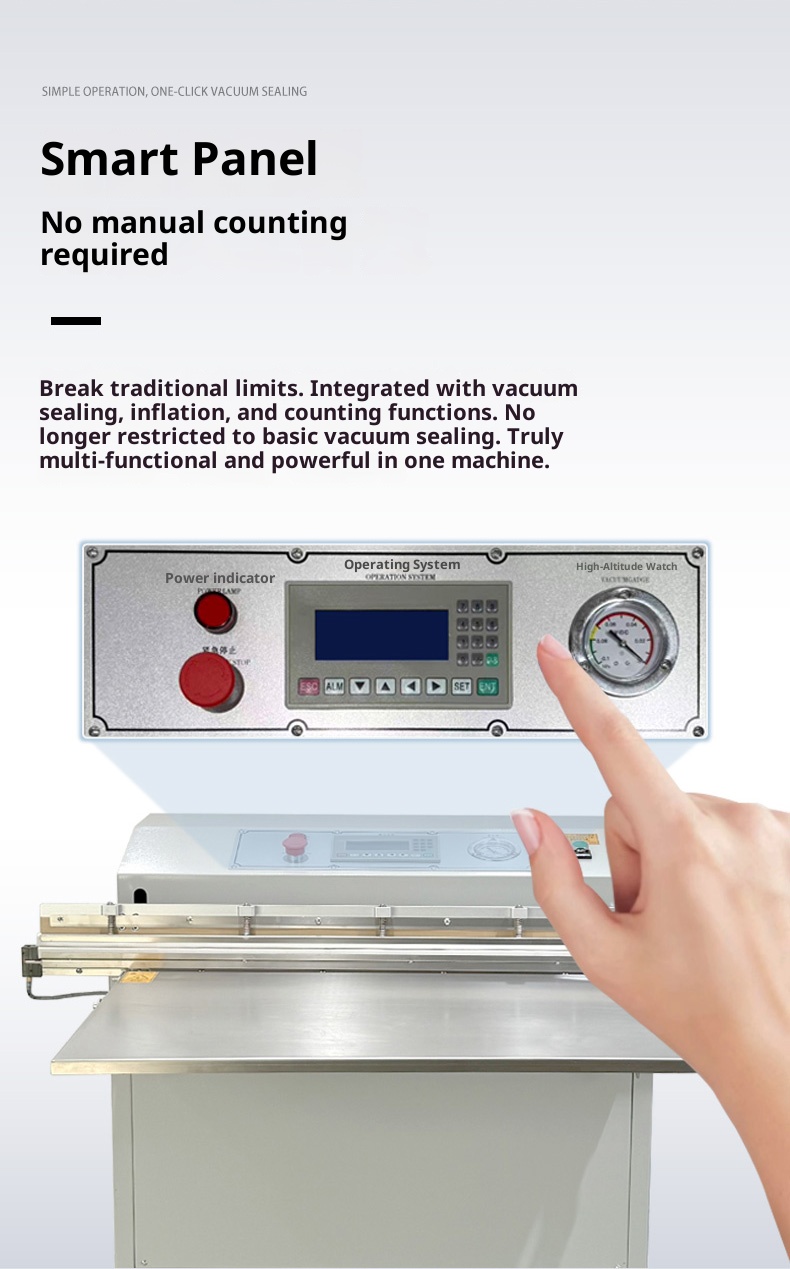

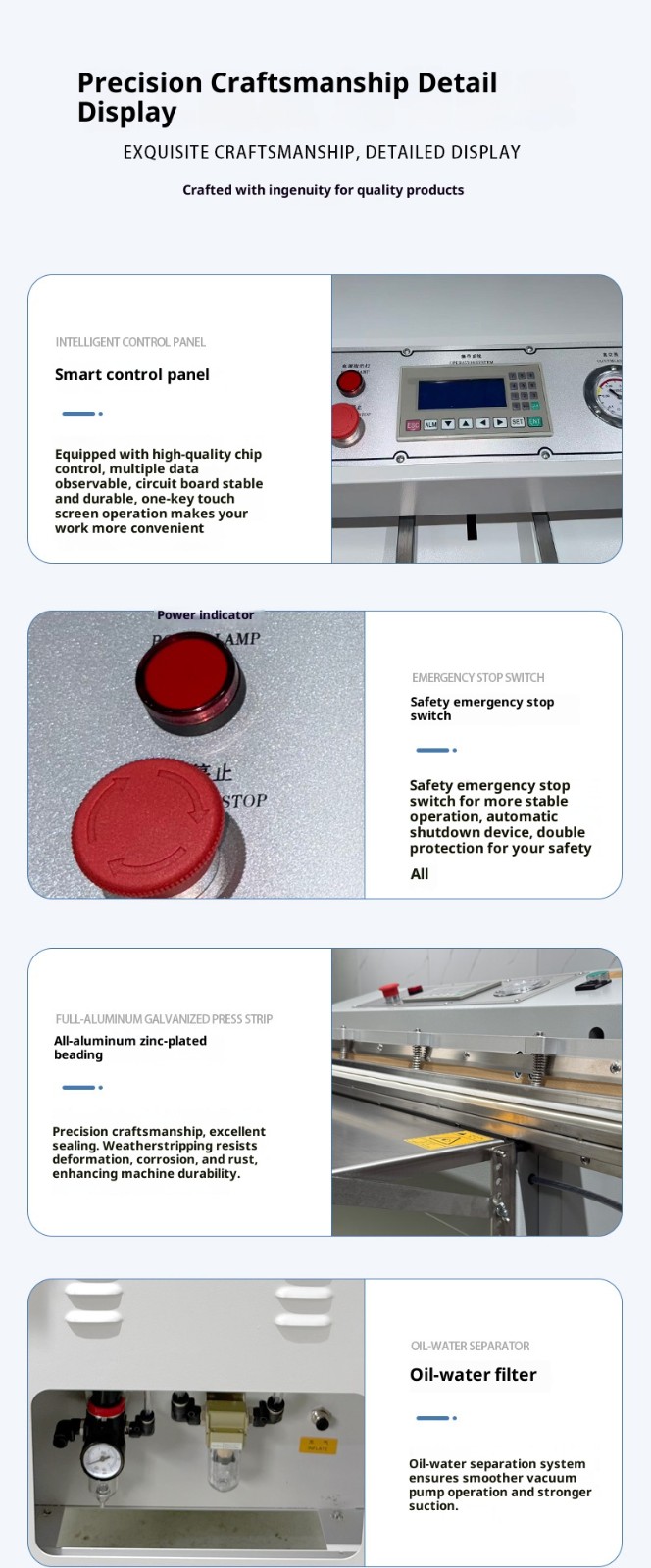

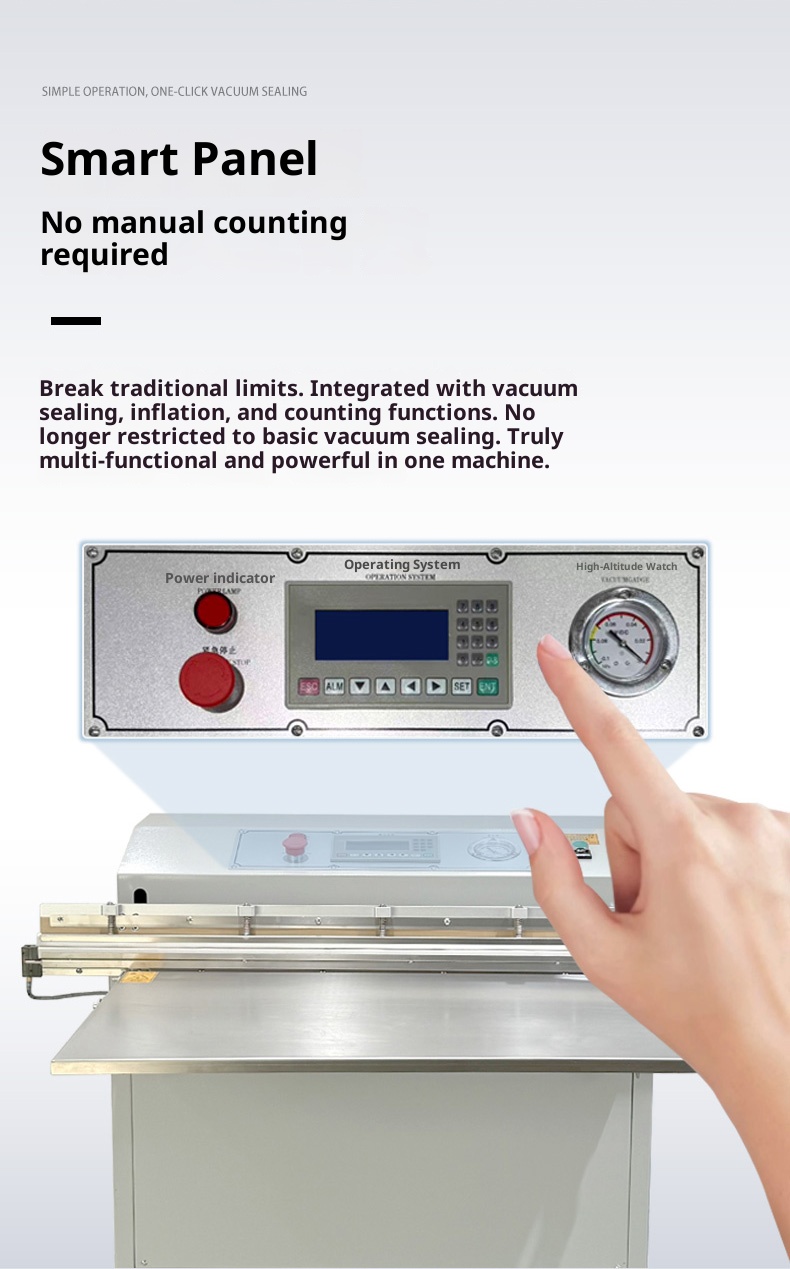

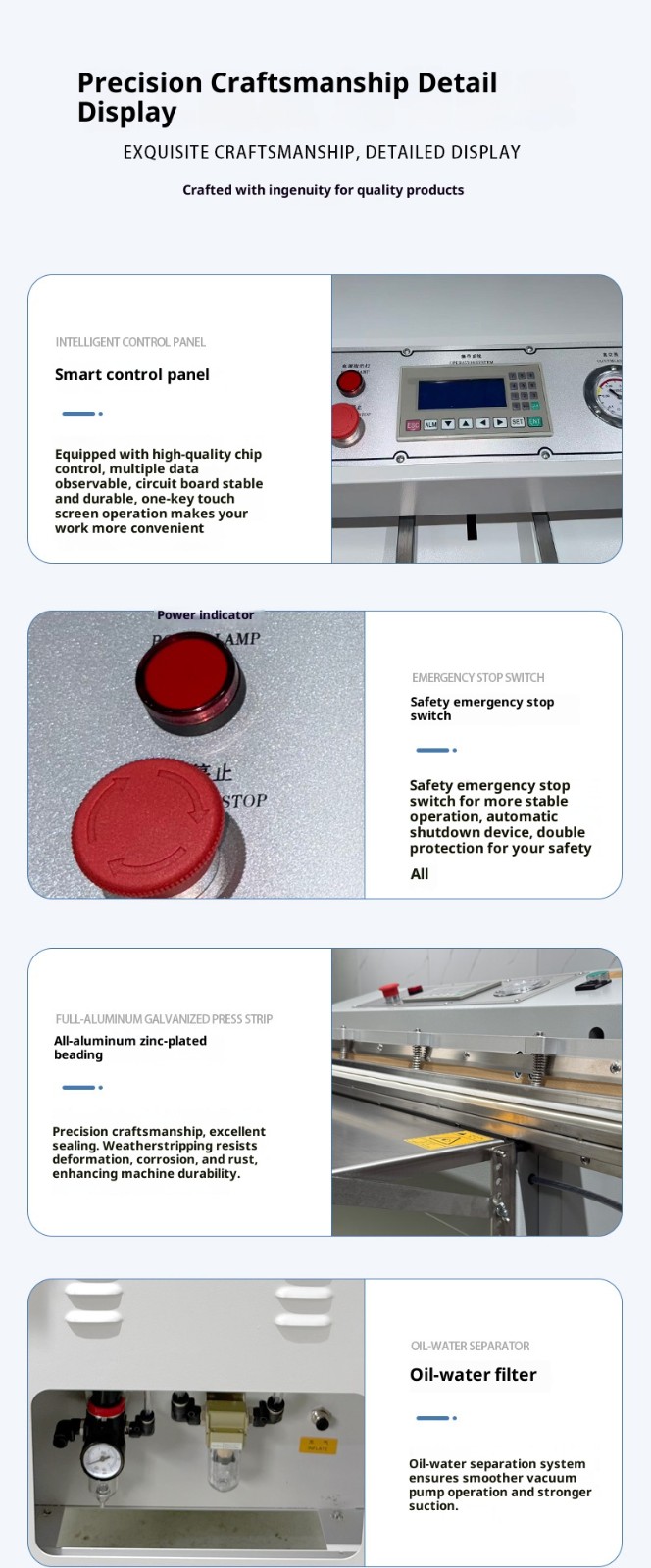

- Flexible Operation: Most models are equipped with a touch screen or knob, allowing one-key switching of function modes without complex debugging.

- Function Matching: Select integrated functions according to core needs. For example, the food industry should prioritize models with "vacuum + gas filling + coding" functions, while the industrial field can focus on models with "vacuum + wide-edge sealing" functions.

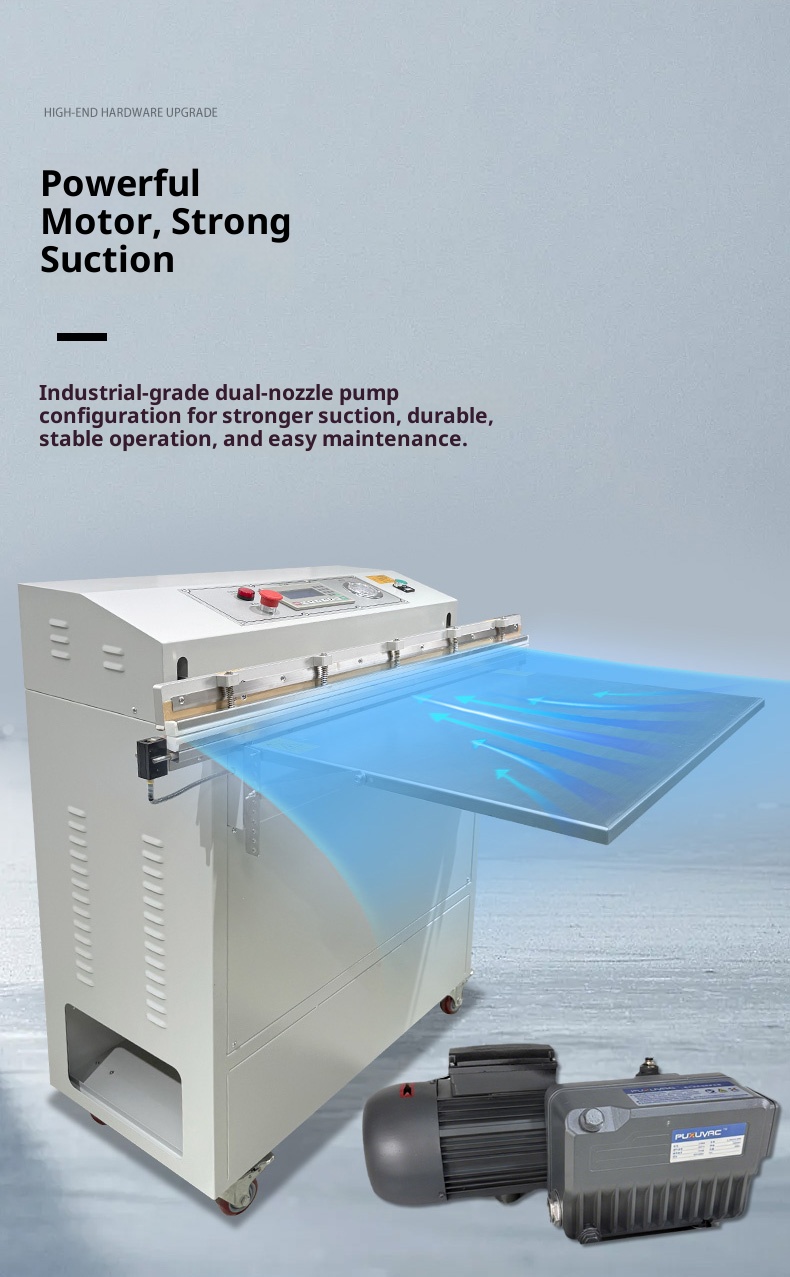

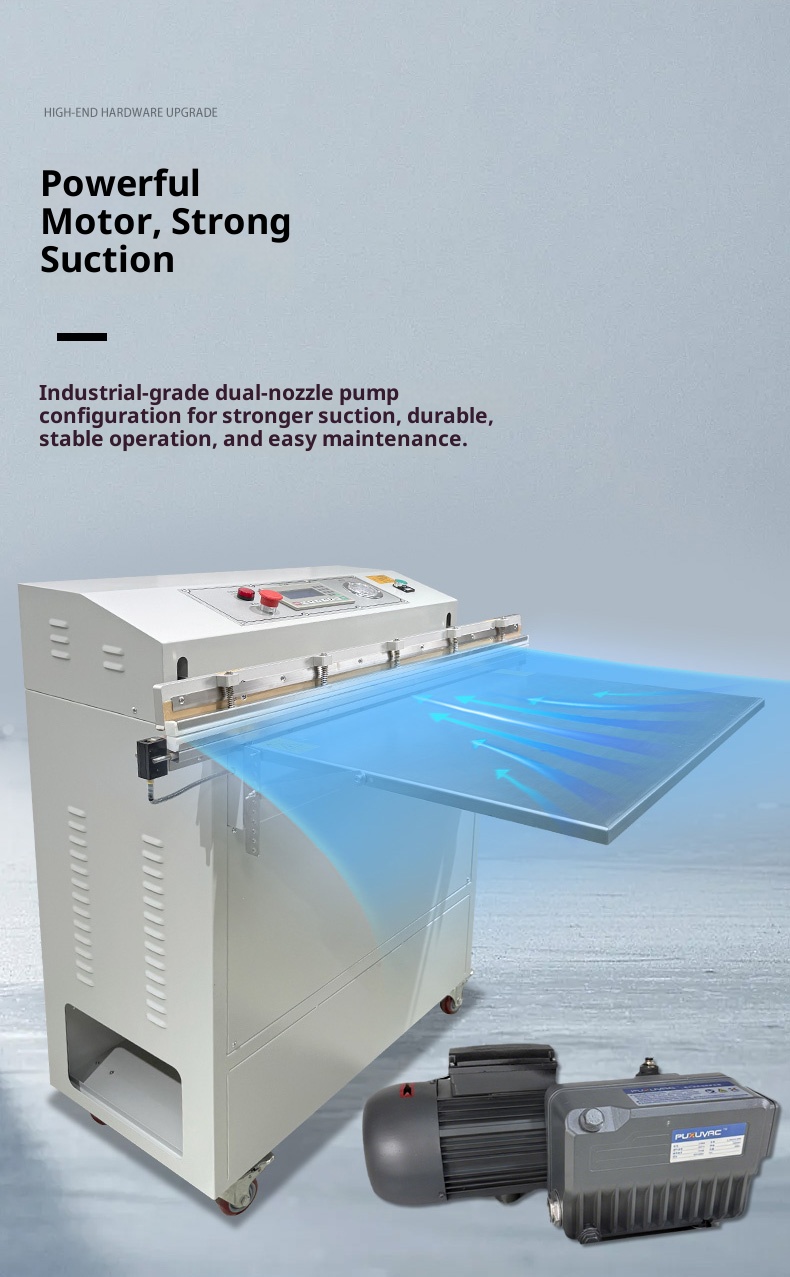

- Vacuum Degree and Speed: Confirm the equipment's ultimate vacuum degree (usually -0.08~-0.095MPa is appropriate) and packaging speed (1-3 pieces per minute, depending on the size of the item) to avoid efficiency impact due to insufficient performance.

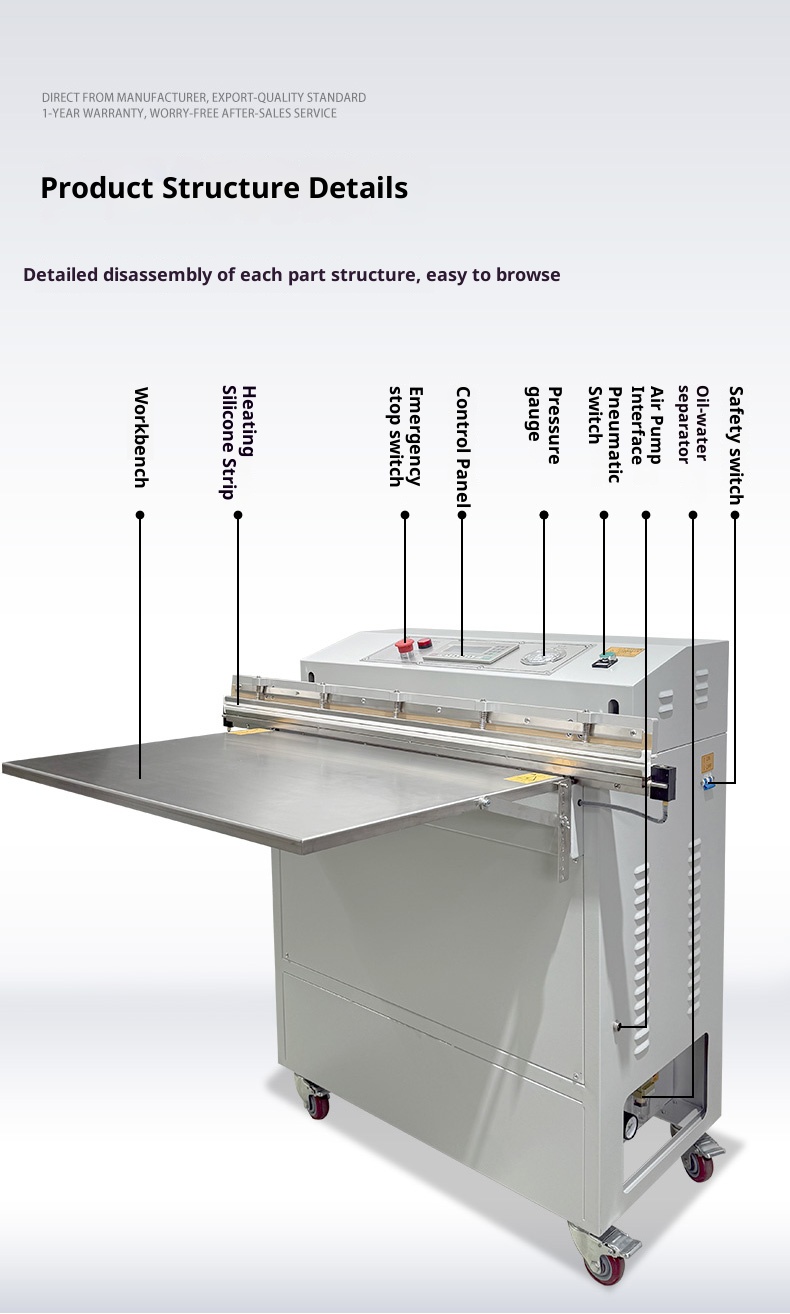

- Daily Maintenance: Regularly clean the air suction nozzle (to prevent clogging by impurities), replace the coding ribbon (to ensure clear marks), and check the sealing strip (to avoid poor sealing) to extend the service life of the equipment.