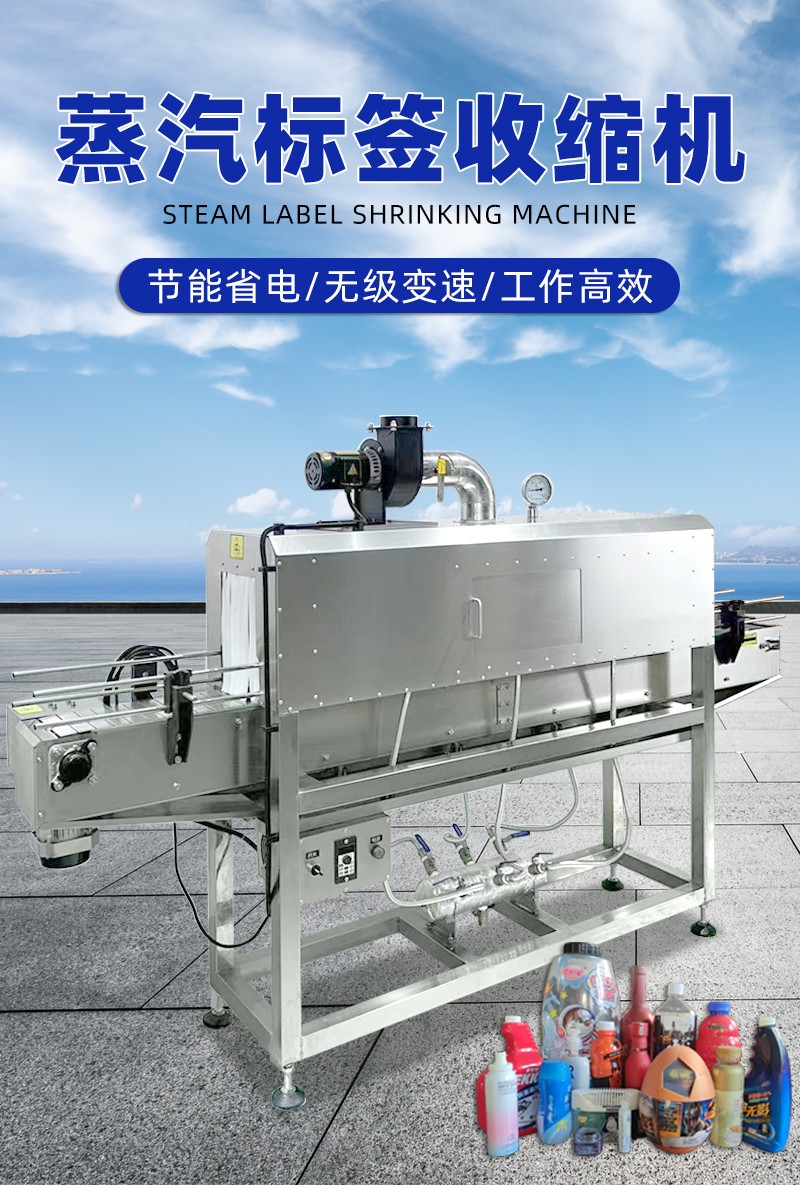

The core working principle of a steam shrink tunnel machine is to utilize the uniform heat of steam to make the heat-shrinkable film tightly wrap around the product after being heated, ultimately completing the automated packaging process of sealing and shaping.

The entire process is mainly divided into four key stages, which are interconnected to achieve continuous packaging.

Product Conveying and Film Covering

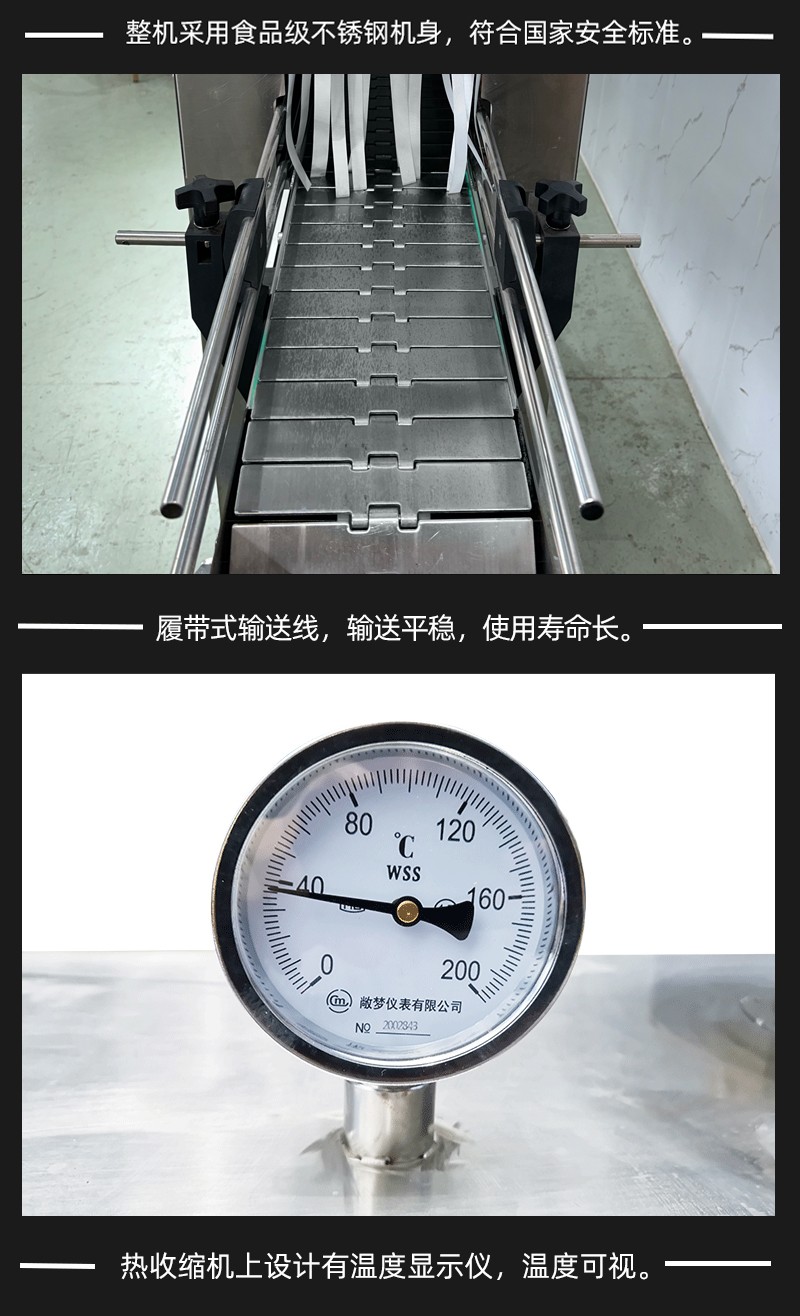

The products to be packaged are conveyed at a constant speed into the packaging area of the equipment via a conveyor belt.

The pre-installed heat-shrinkable film (such as PE or PVC film) is smoothly unwound from the film roll under the action of a tension control system, and automatically covers the surface of the product, forming an initial wrapped state.

Film Sealing and Cutting

The product covered with film moves to the sealing and cutting device. The sealing knife heats and seals the film according to the product size.

After sealing is completed, the cutting knife synchronously cuts off the excess film, so that each product is wrapped in an independent sealed film, forming a closed "film sleeve".

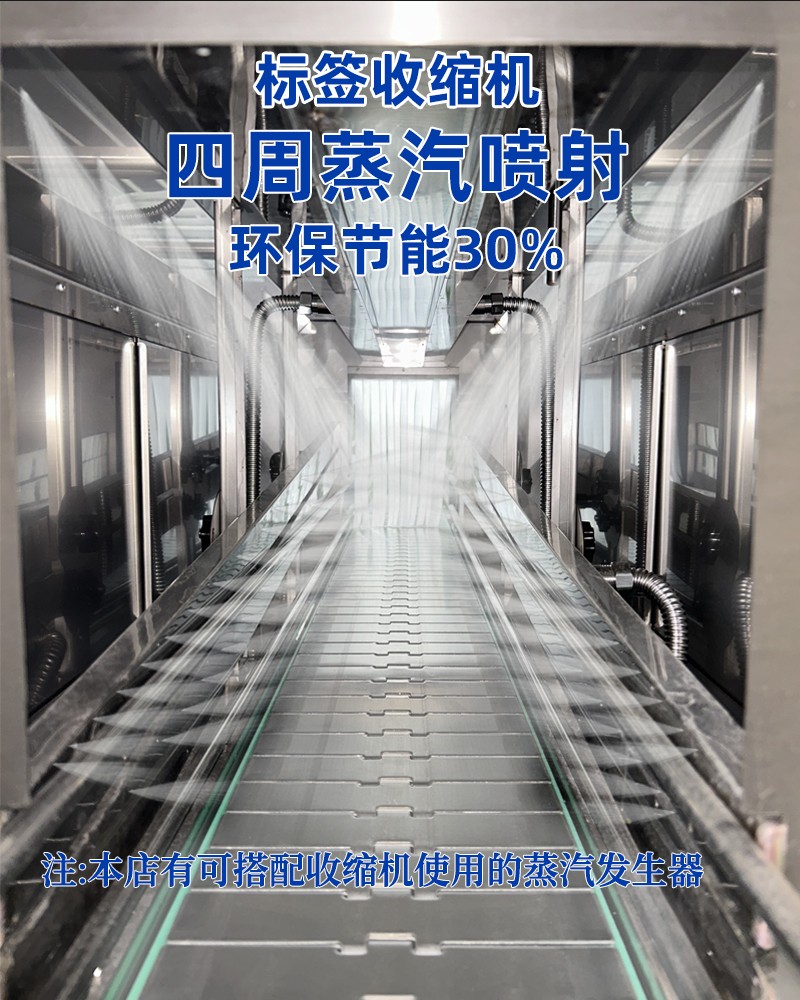

Steam Heating and Shrinking

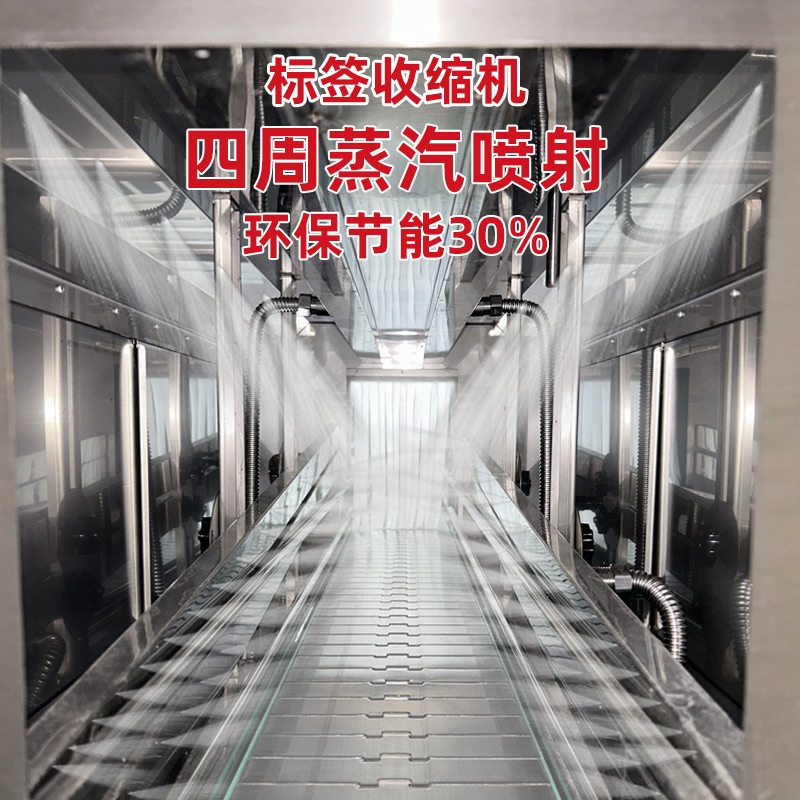

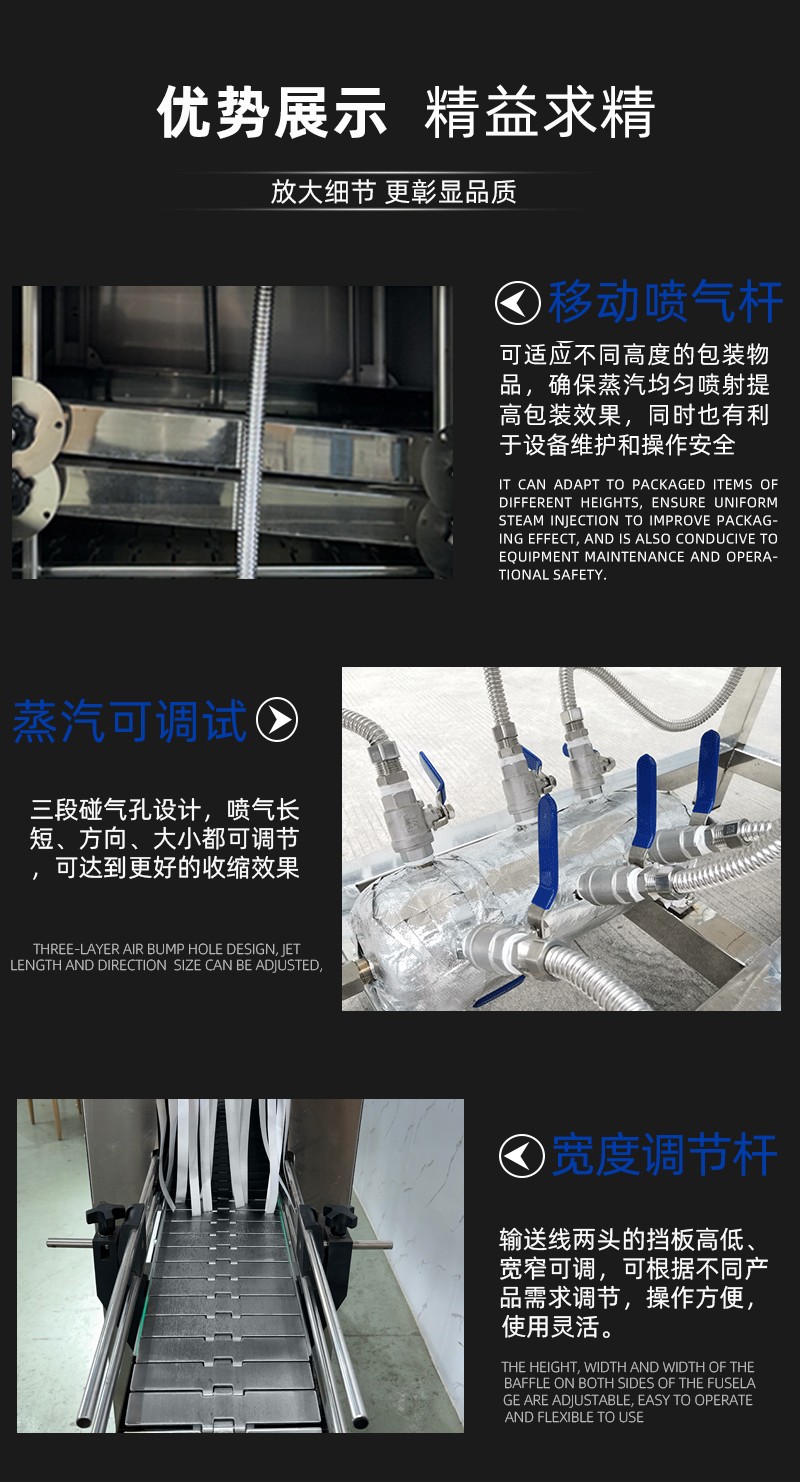

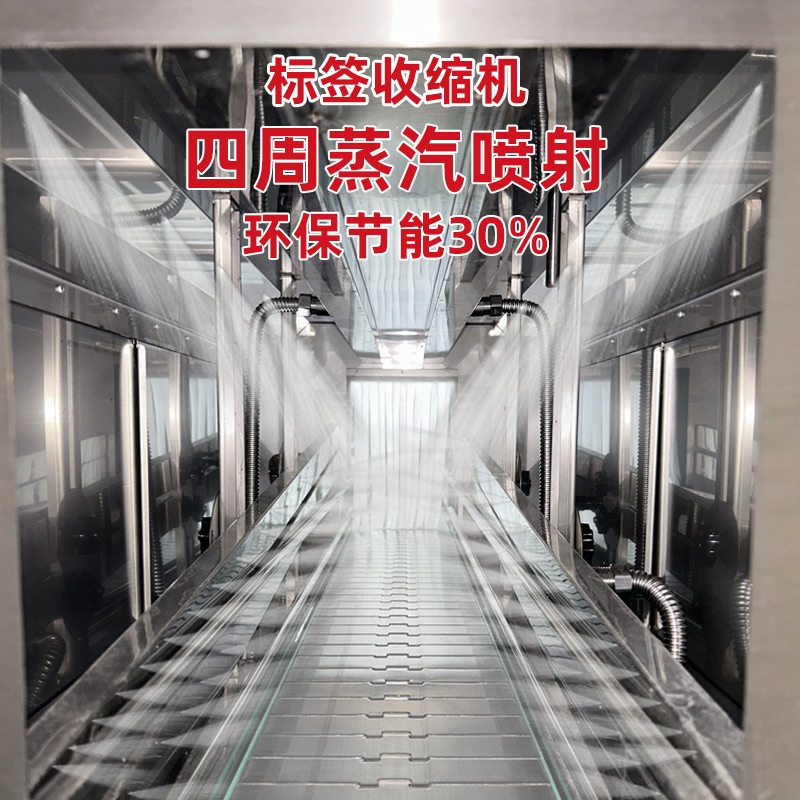

The product with the closed film is conveyed into the steam shrink tunnel by the conveyor belt.

The built-in steam generator of the equipment produces high-temperature steam, which is evenly sprayed onto the film surface through the nozzles inside the tunnel.

The film softens and shrinks rapidly when heated, tightly fitting the shape of the product and eliminating wrinkles and gaps.

Cooling, Shaping and Output

The product that has completed shrinking continues to move in the tunnel. The ventilation device at the end of the tunnel discharges excess steam and cools the product quickly.

The film sets after cooling, maintaining a state of tightly wrapping the product, and is finally sent out through the exit conveyor belt, completing the entire packaging process.

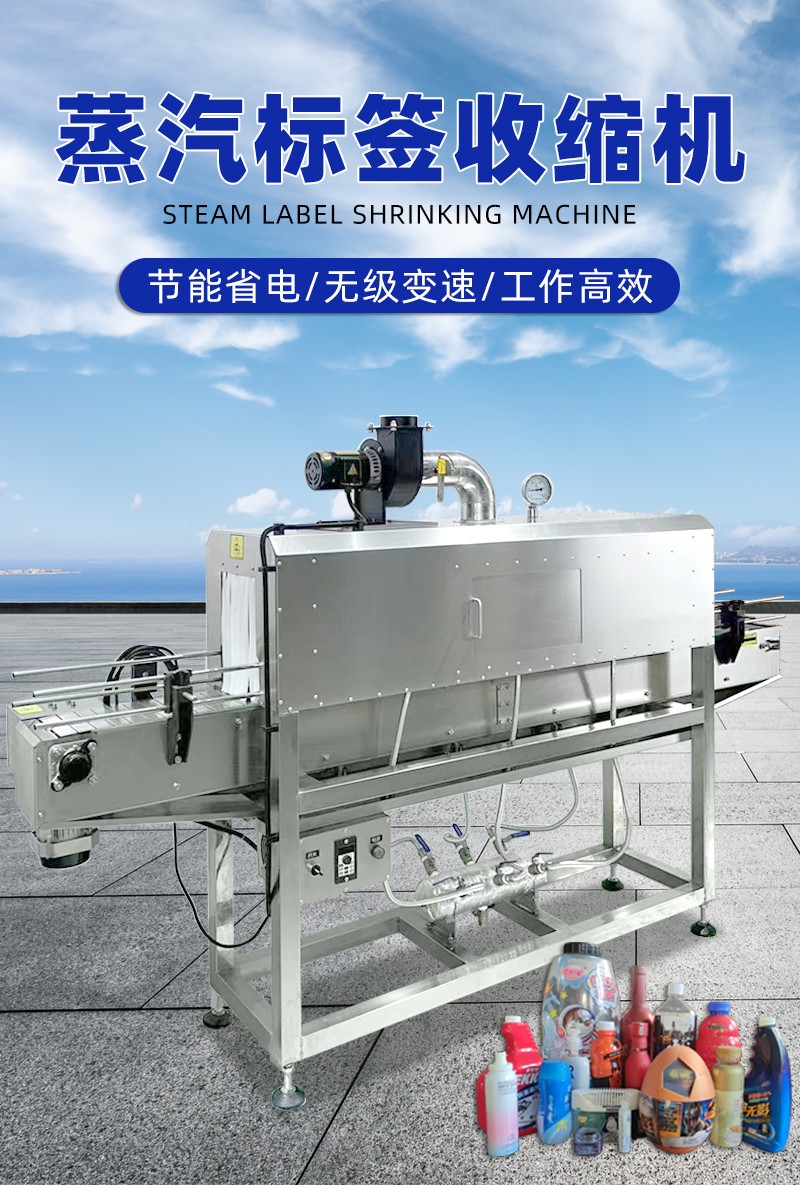

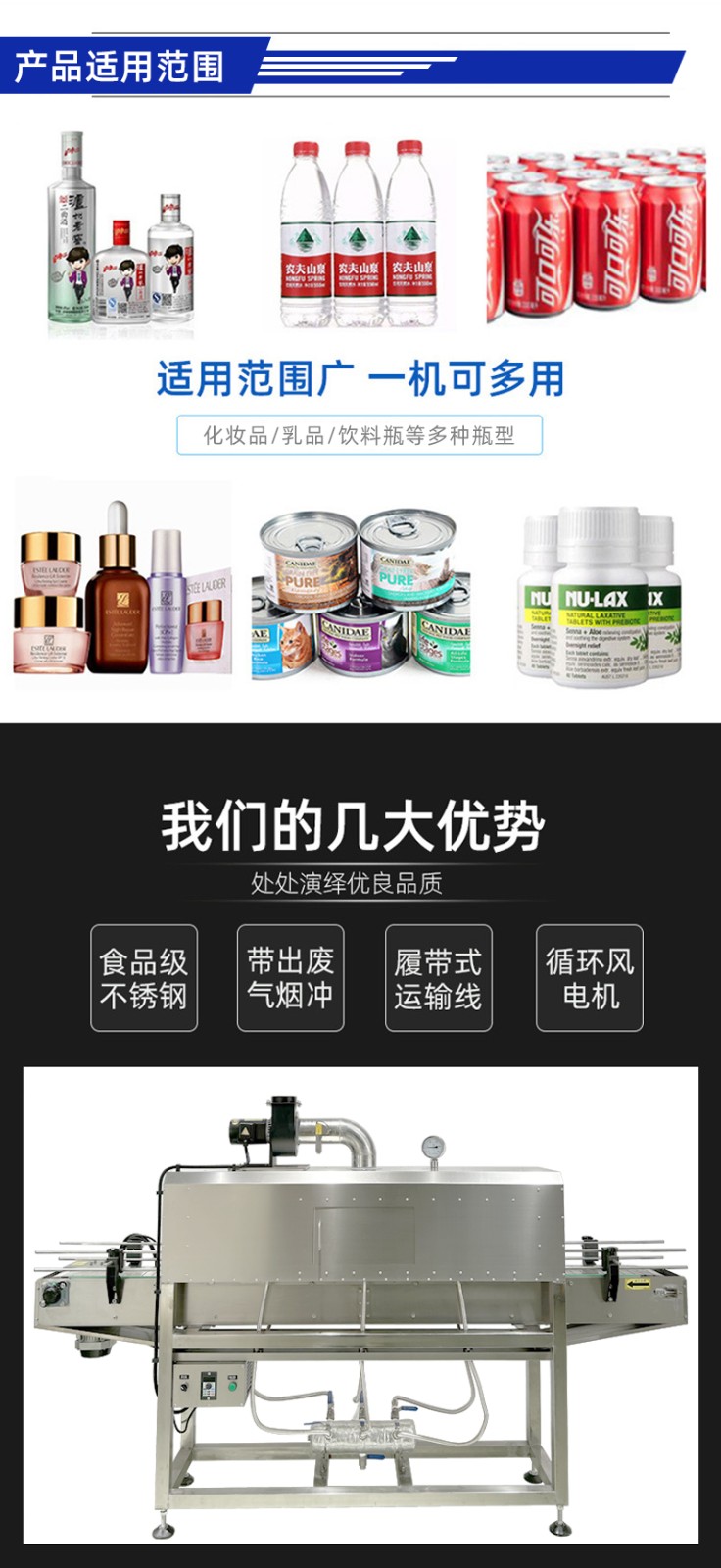

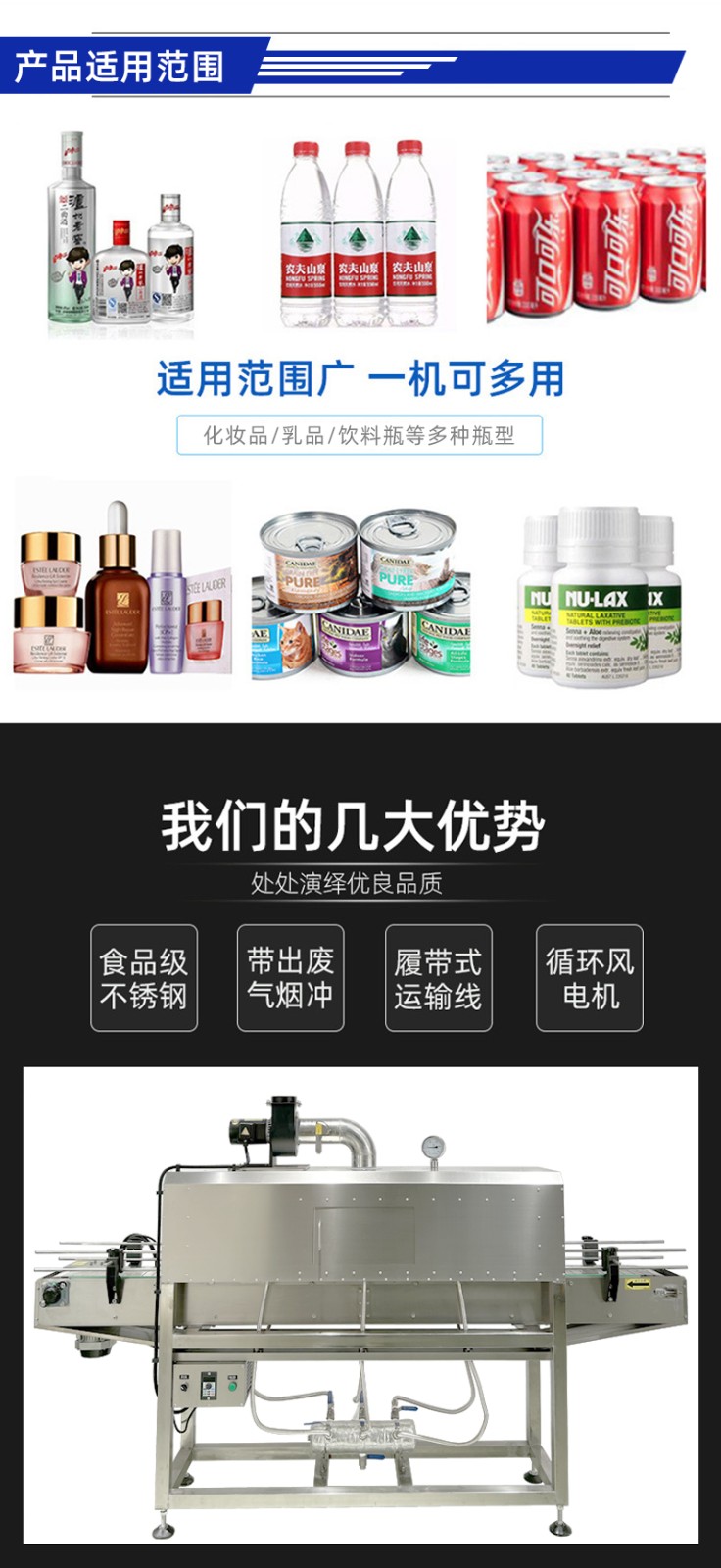

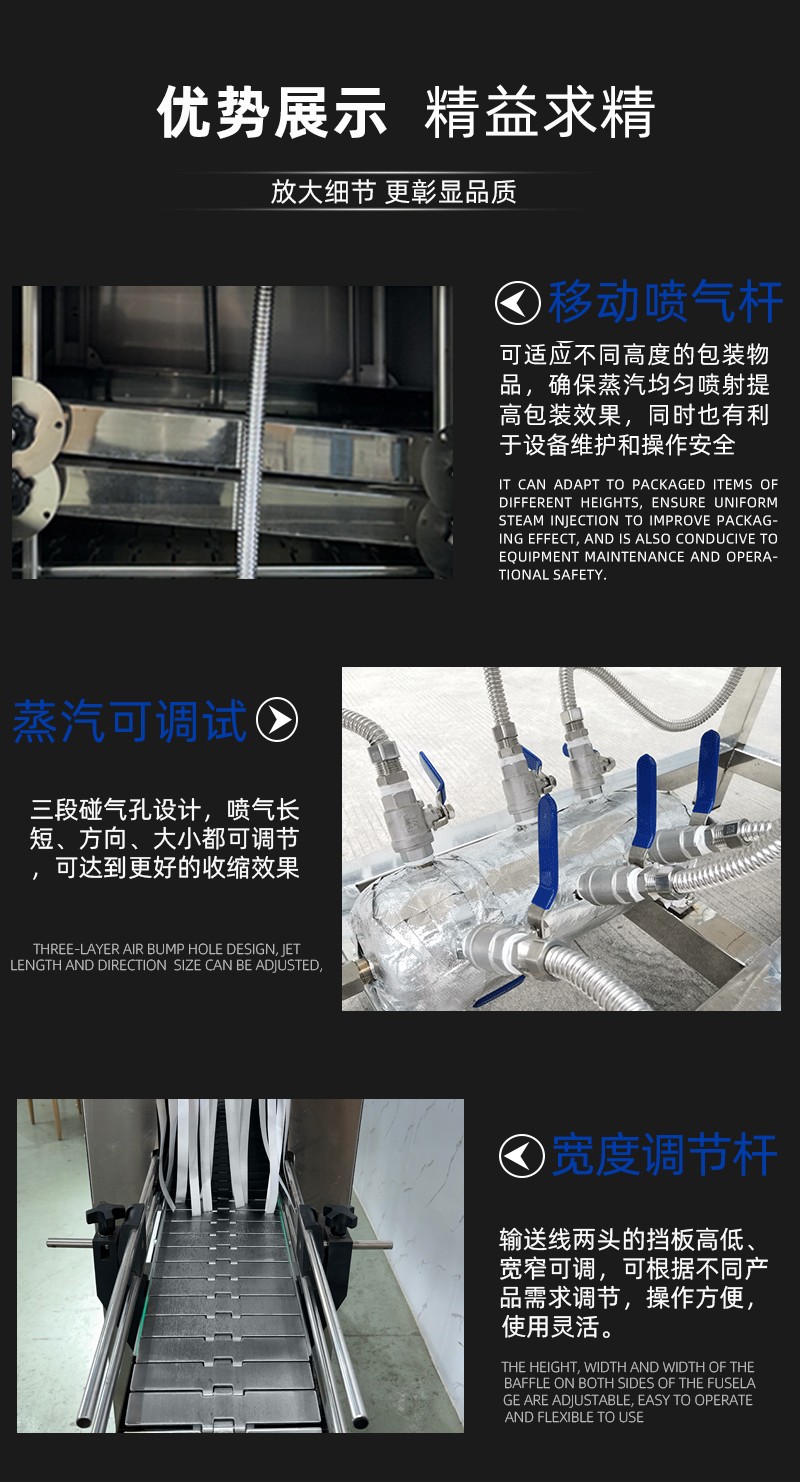

Compact and Ingenious Structural Design: It adopts a compact structure with a simple and attractive appearance, small floor space, and convenient movement and installation. Some models are equipped with a width adjustment system, which can be adapted to conveyor belts and slides of different specifications.

Superior Heating Effect: It works by utilizing the characteristics of steam, such as constant temperature and uniform temperature diffusion, and can achieve an effect that ordinary electric heating infrared shrink machines cannot match. The equipment uses a heater to heat water to generate steam, without the need for an additional steam boiler. The main machine is equipped with two heaters (primary and secondary), and the power can be adjusted according to the production speed. The conveyor belt adopts stepless speed regulation, and the conveying speed can be adjusted arbitrarily.

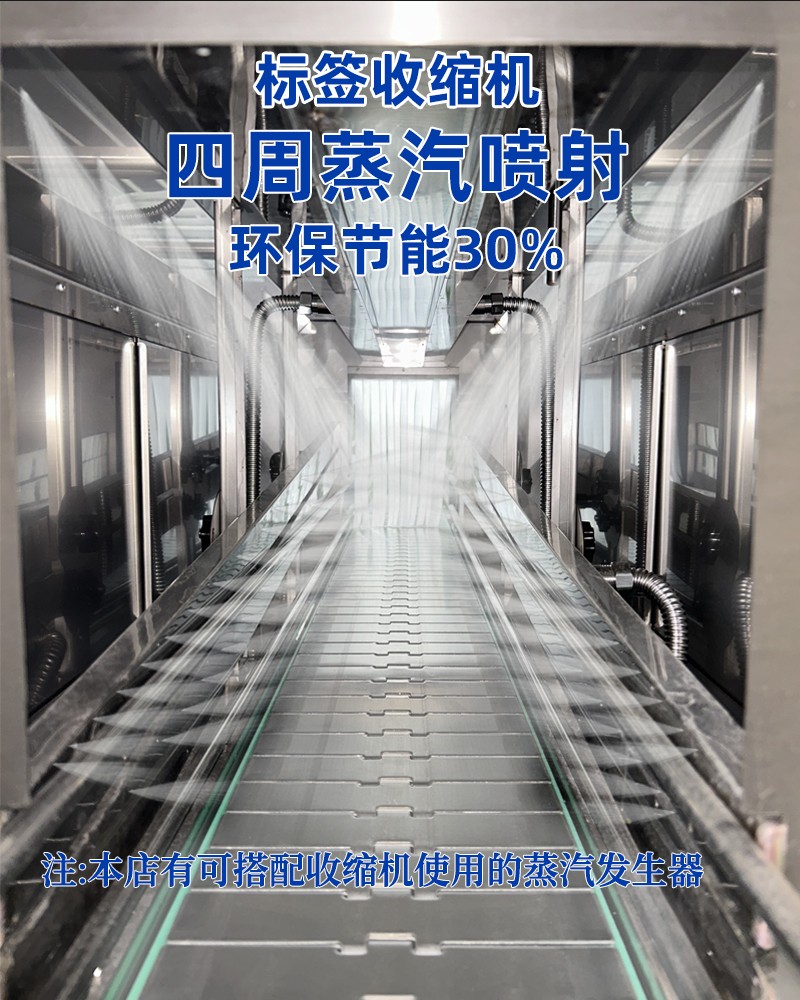

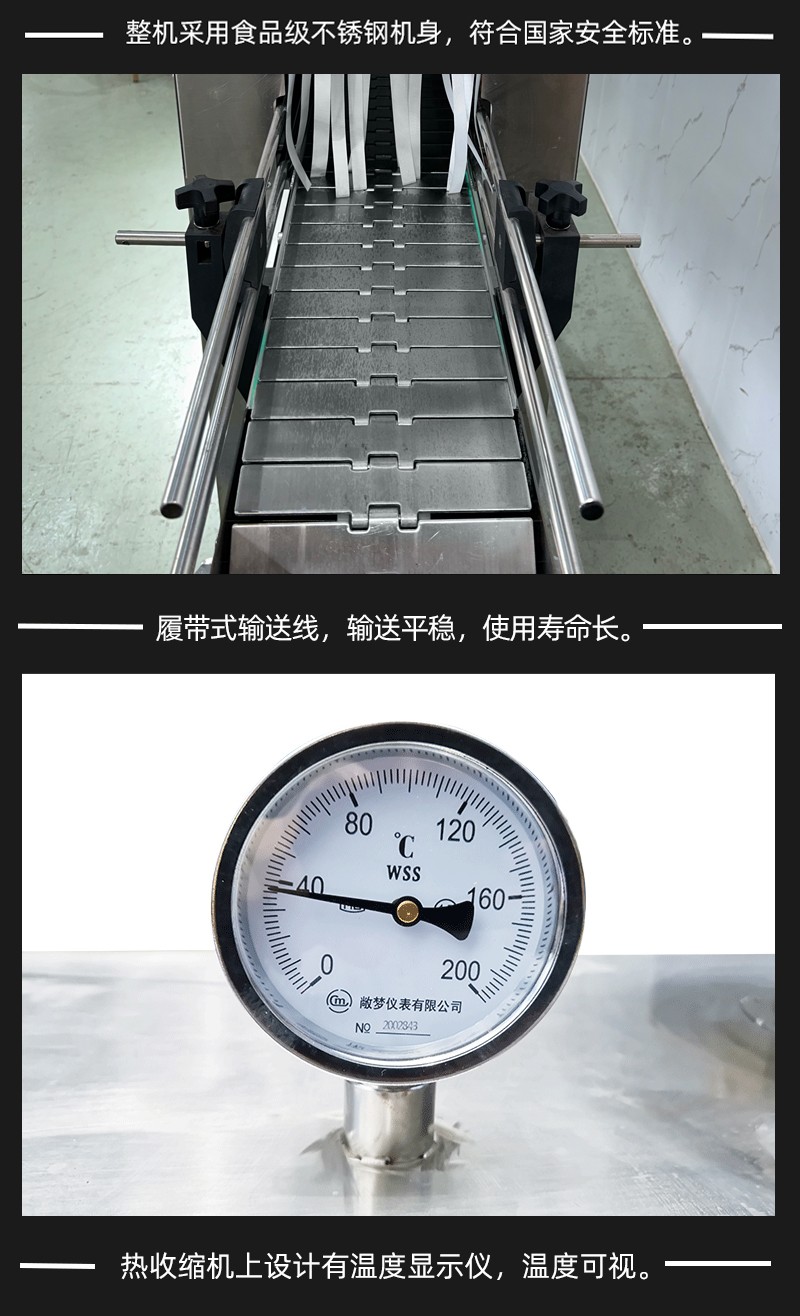

Good Heat Insulation and Waterproof Performance: The whole machine has three layers of heat insulation to reduce heat loss, and adopts a waterproof design. Most parts are made of 304 stainless steel. It is equipped with a thermometer and a pressure gauge, so that the steam pressure and shrinkage temperature are clearly visible. The steam inlet valve is equipped with a dial, which can save the start-up time.

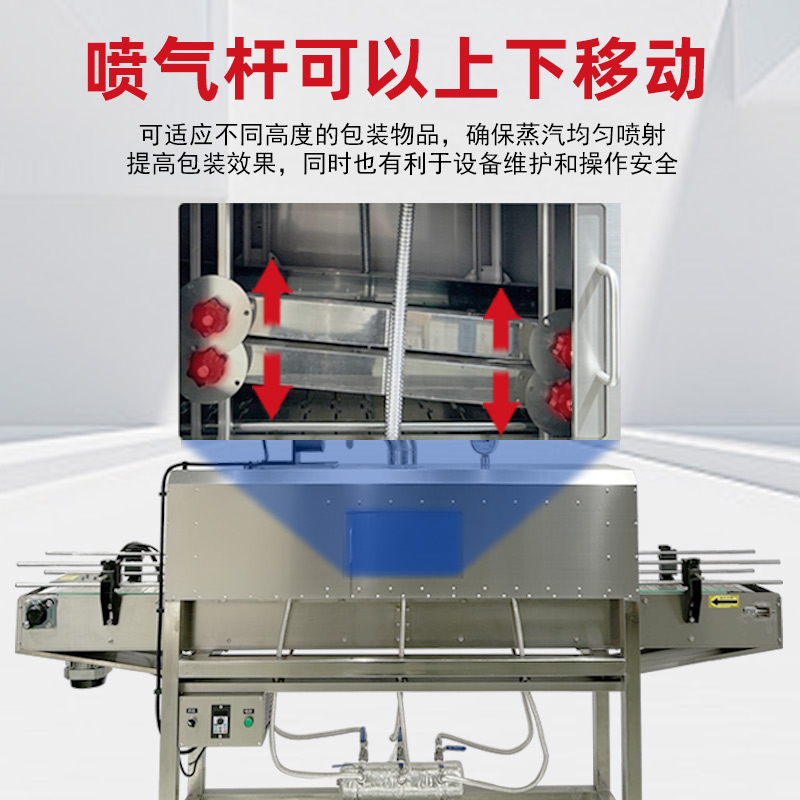

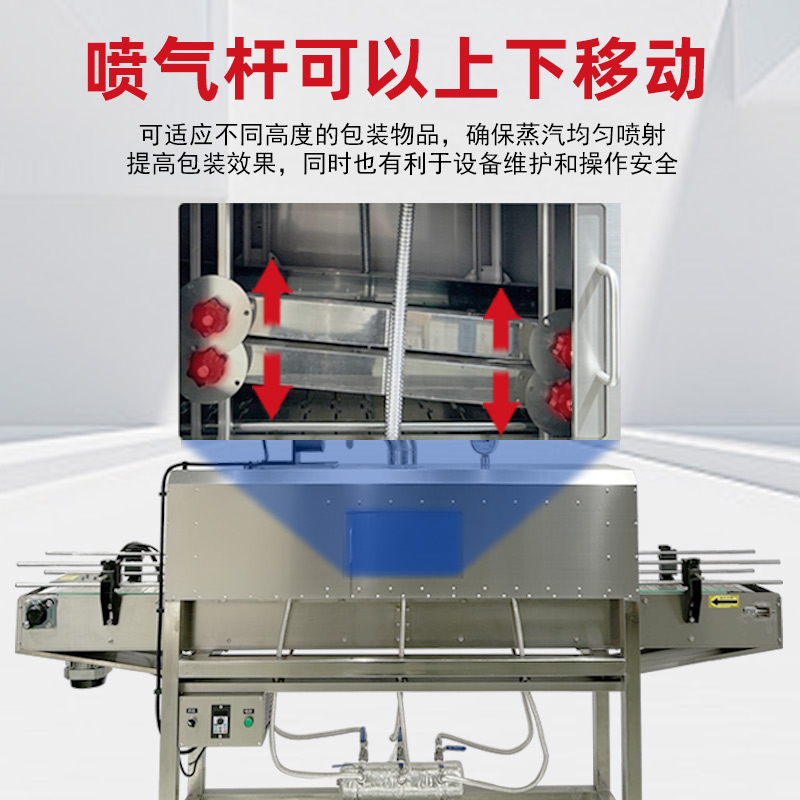

Convenient Operation and Adjustment: Each nozzle on both sides of the whole machine can be adjusted in terms of its up-down, inside-out positions and spray direction. The front and rear ends are equipped with inlet and outlet shield devices to reduce steam leakage. A water receiving tray is installed at the lower part of the machine body to collect and discharge condensed water in a centralized manner, eliminating the problem of site moisture.

In case you need to use this content for equipment manuals or foreign business communication, would I help you sort out a bilingual comparison table of key terms for steam shrink tunnel machines? It will include the Chinese and English correspondences of core components, technical parameters and operating steps, making it easier for you to check and use.