In the mass production processes of industries such as food and beverage, daily chemicals, the efficiency and quality of packaging procedures directly affect enterprise production capacity and product market competitiveness. As a professional equipment specifically designed for single-bottle/multi-bottle combined packaging, the sleeve-type heat shrink packaging machine has become a key solution to industry packaging pain points with its core characteristics of "strong adaptability, stable performance, and excellent results", and its functional details and application value are worthy of in-depth exploration.

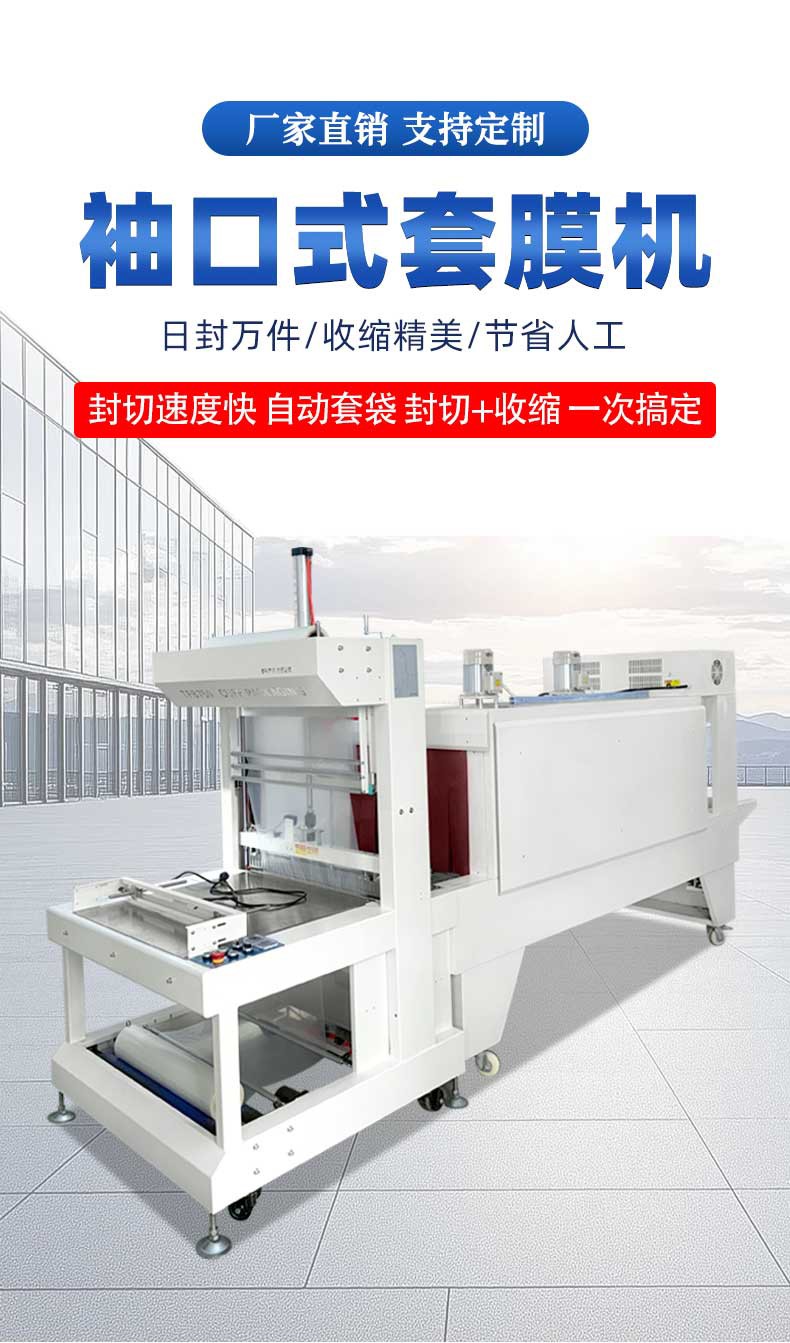

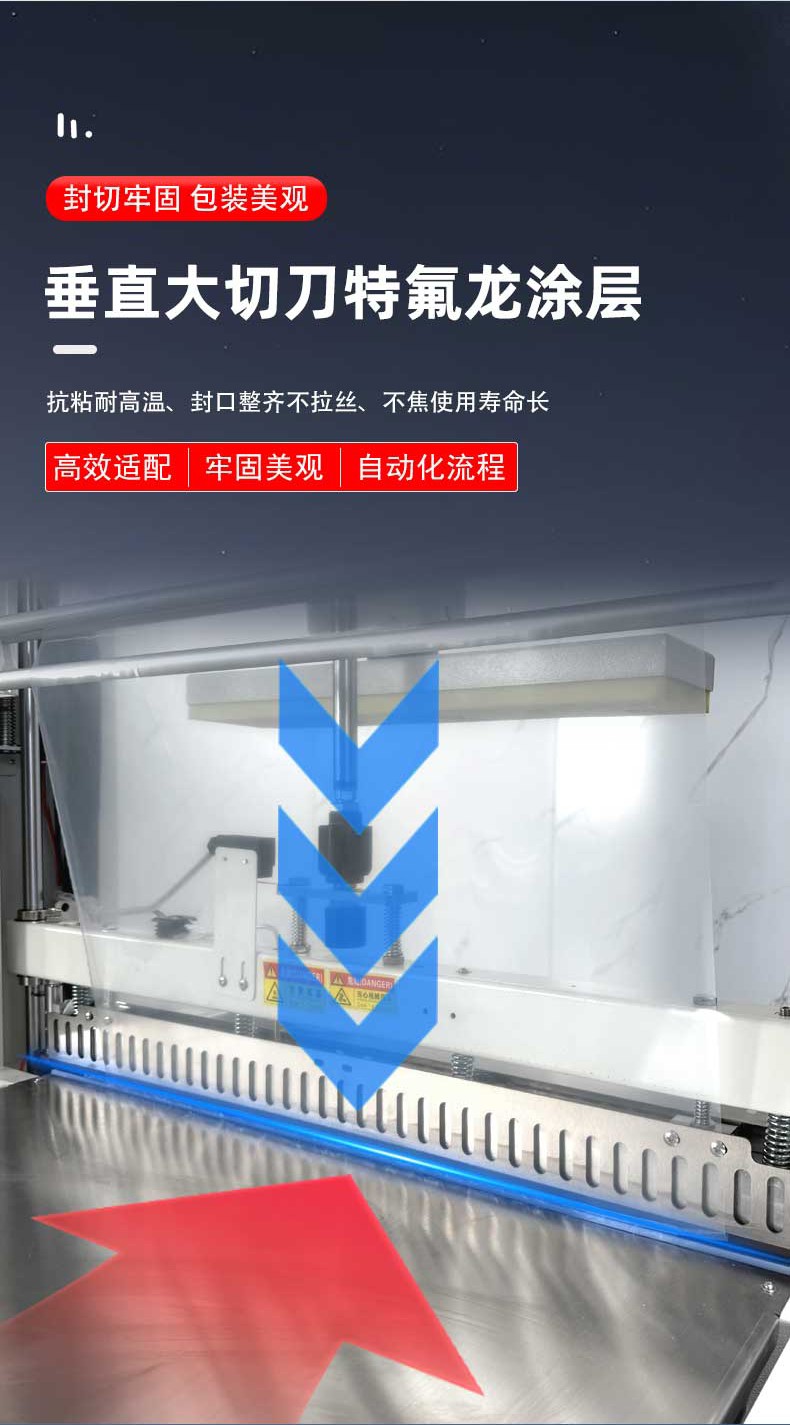

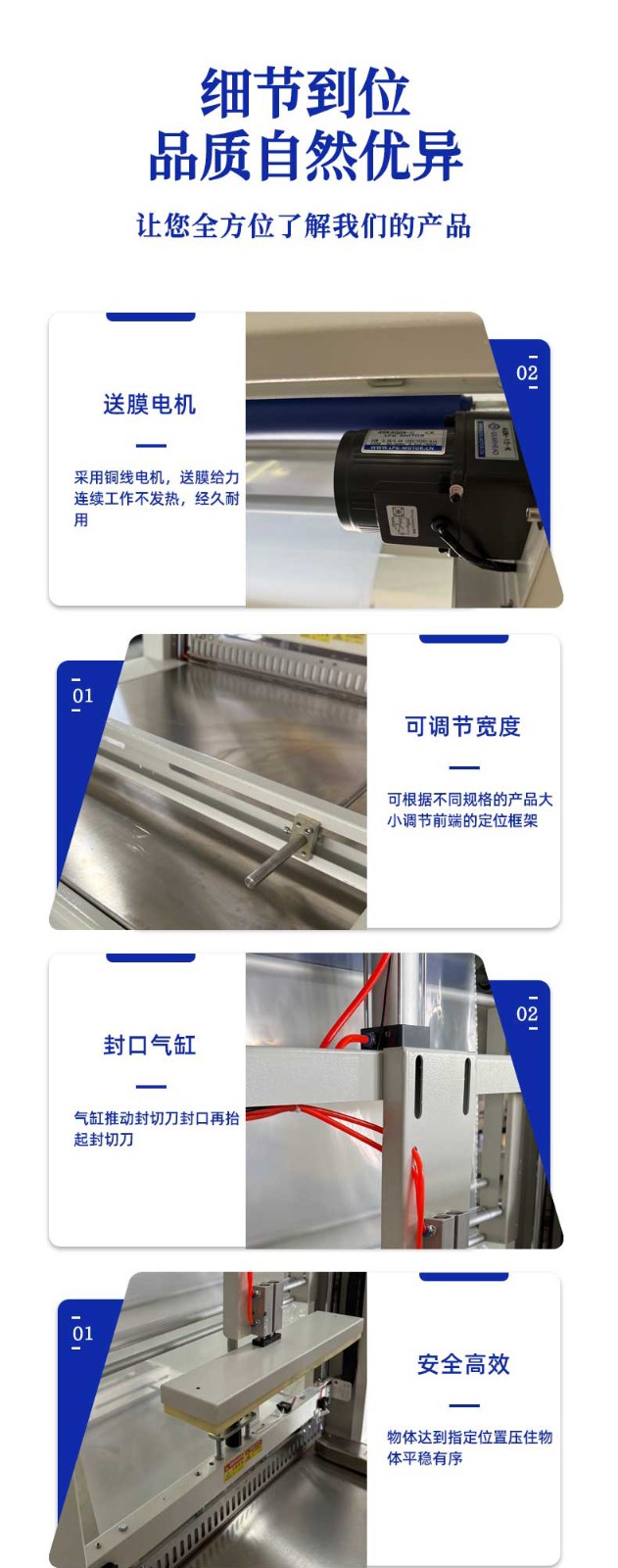

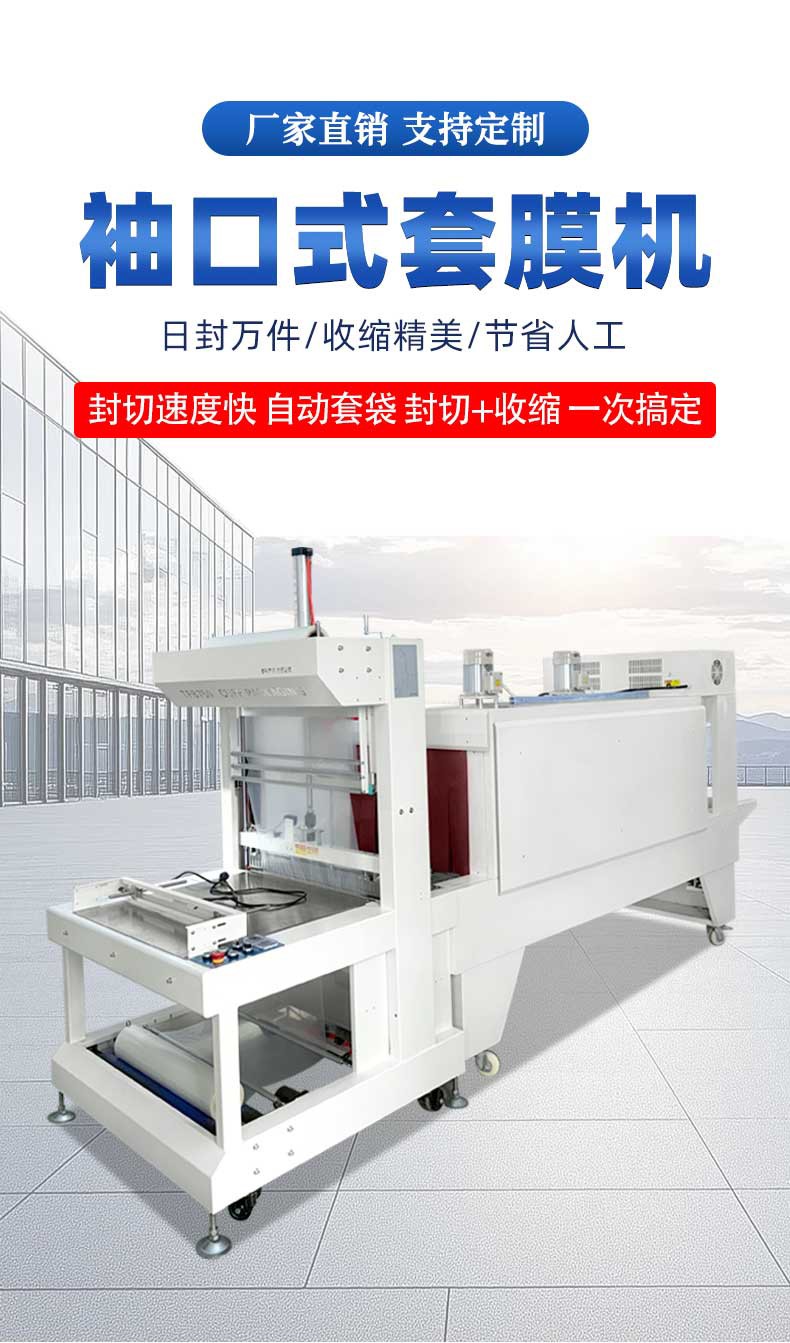

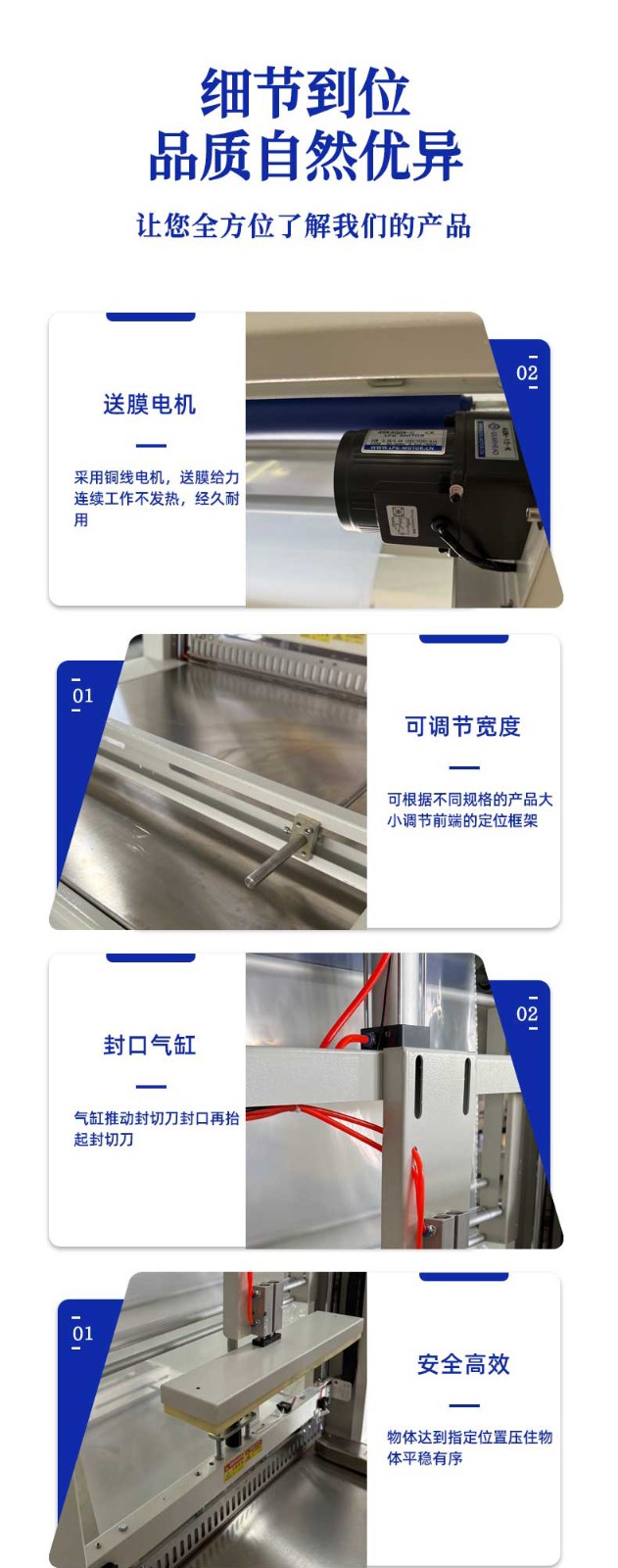

Different from traditional general-purpose packaging equipment, the sleeve-type heat shrink packaging machine targets the "combined packaging of bottle products" scenario from the design source, completely breaking away from the limitation of "one machine for one use". Tailored to the particularity of bottle packaging, it adopts an integrated structure of "conveyor belt + film frame + heat shrink tunnel":

- The conveyor belt can flexibly adjust its width and conveying speed according to the bottle diameter and height. Whether it is a 500ml standard mineral water bottle, a 1.2L juice bottle, a hand sanitizer bottle with a pump design, or a disinfectant bottle with a handle, all can be stably conveyed without deviation.

- The film frame is equipped with an automatic tension control system, which can precisely adjust the film output force according to the thickness of the packaging film (commonly used POF and PE films), avoiding packaging wrinkles or damage caused by uneven film tension.

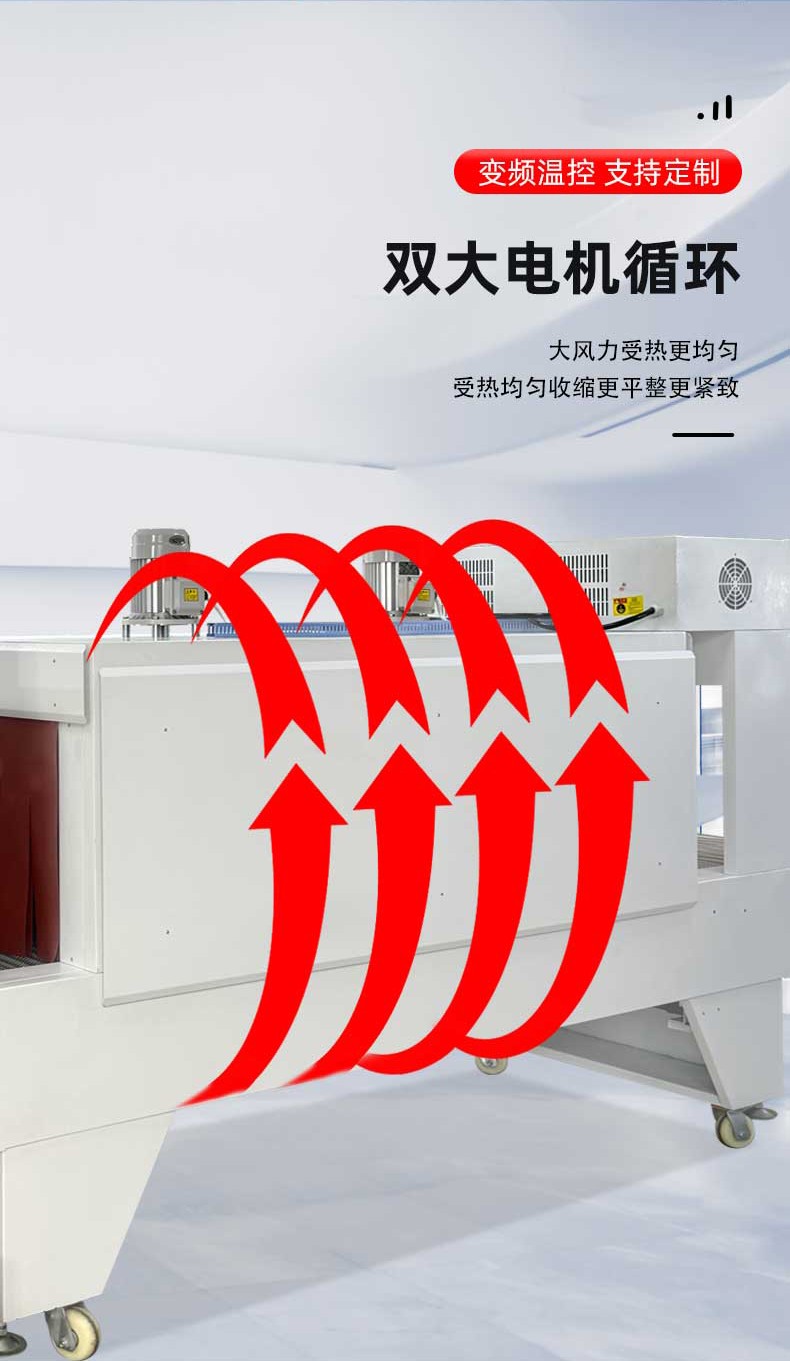

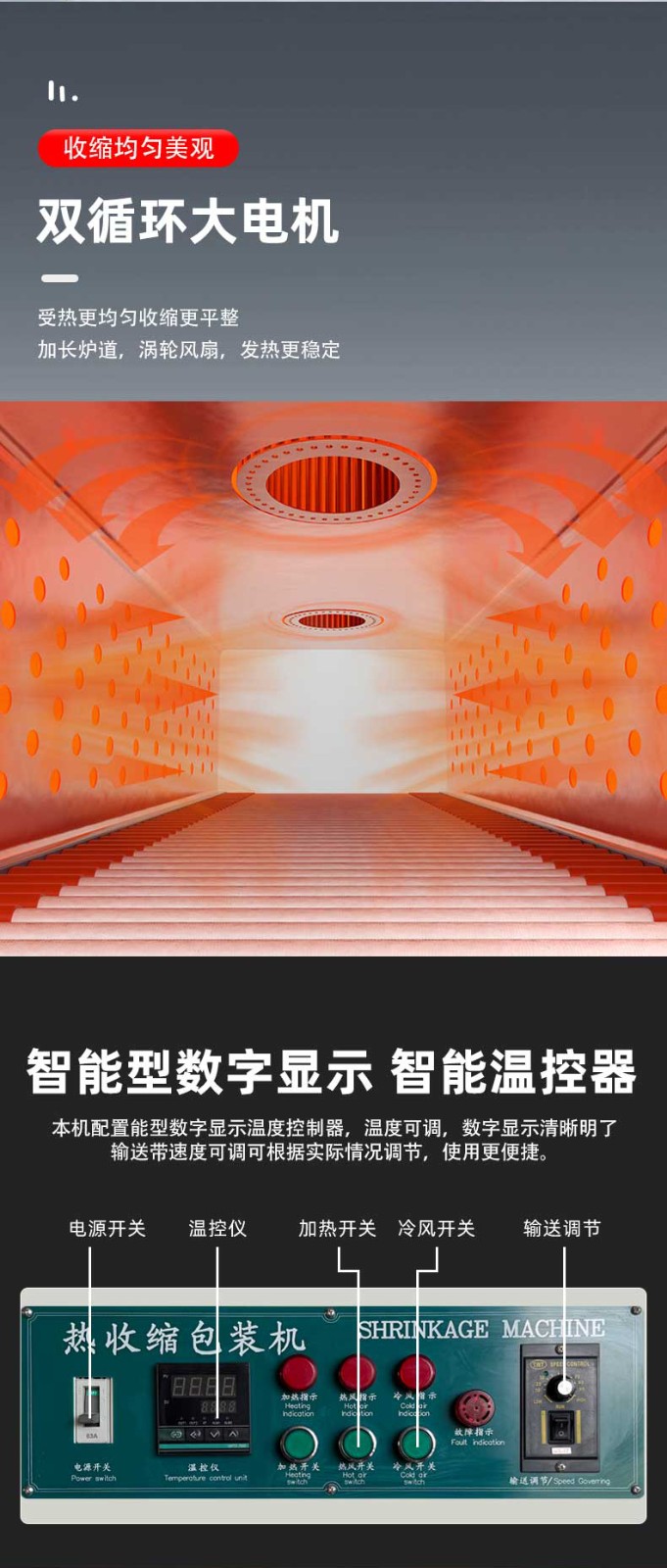

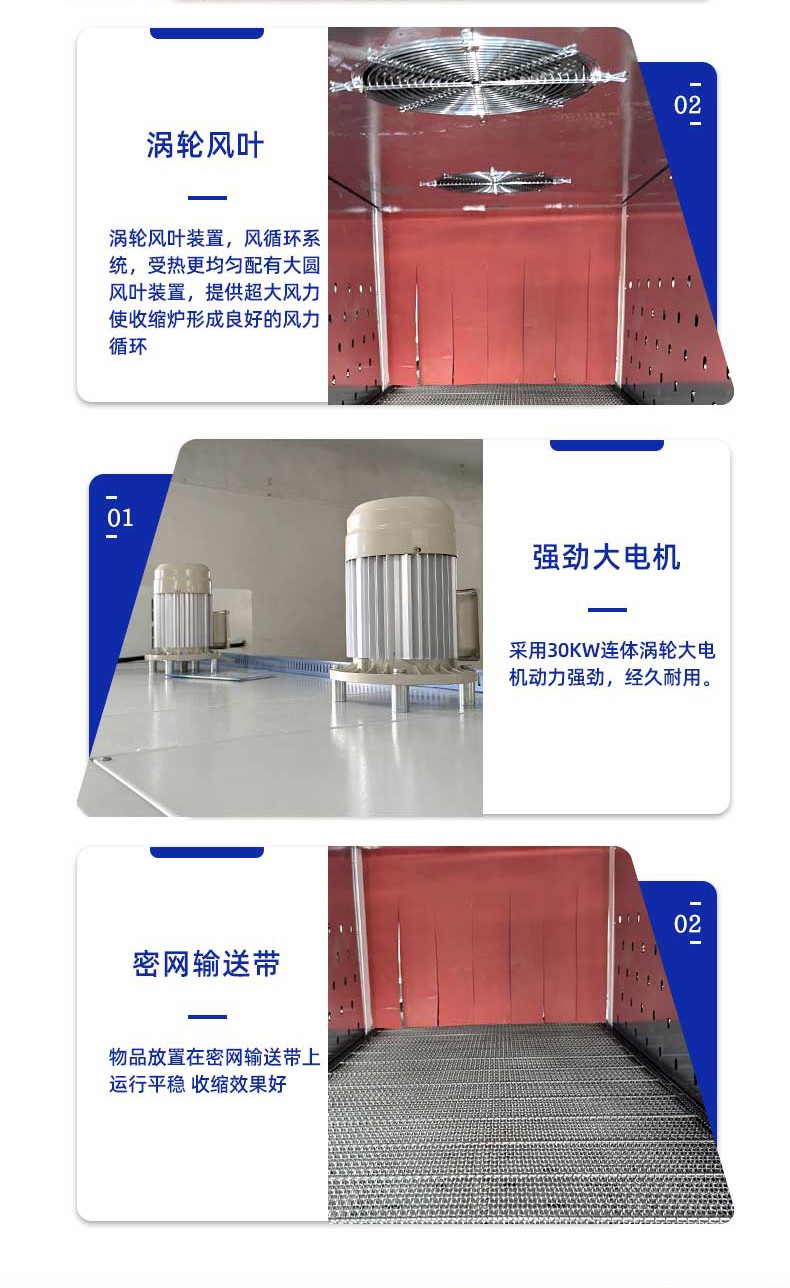

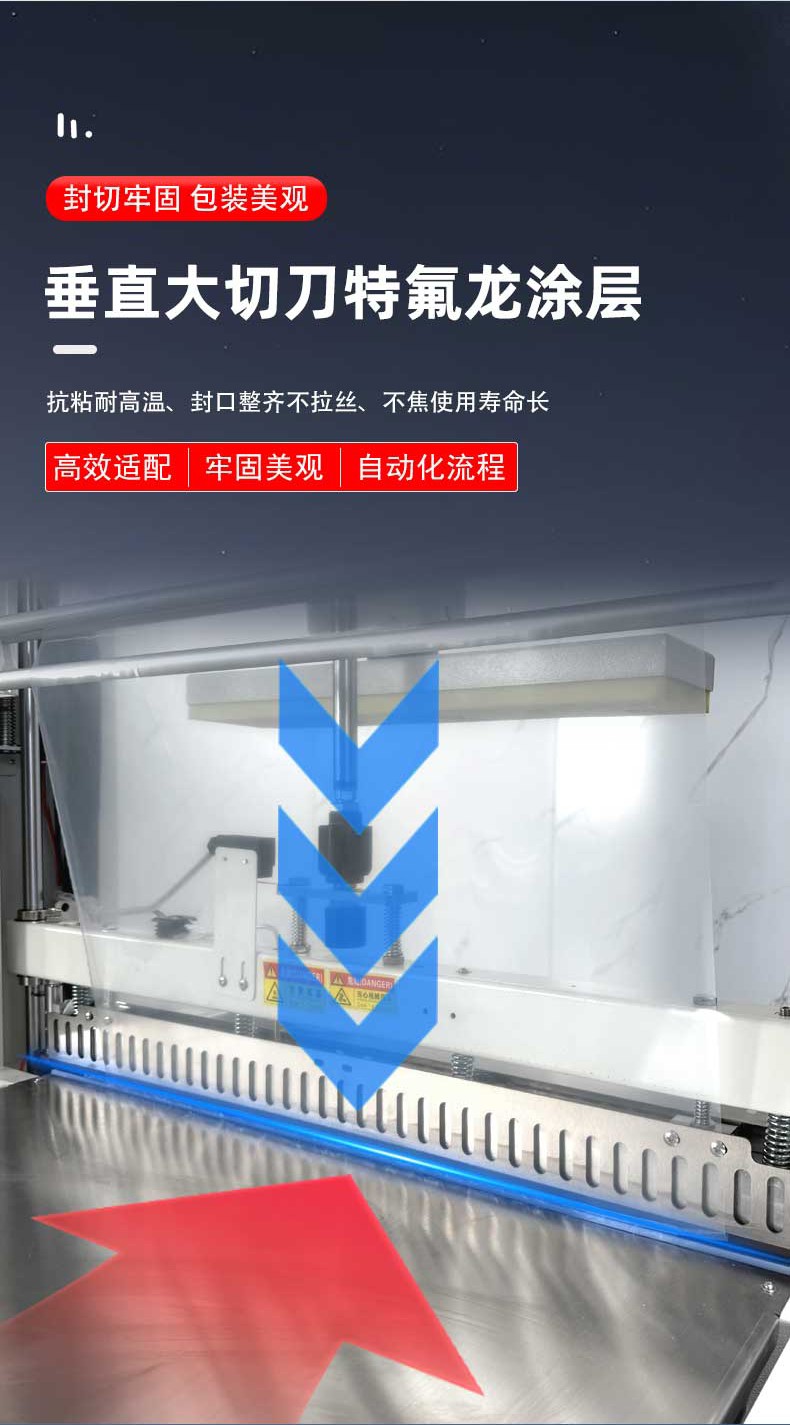

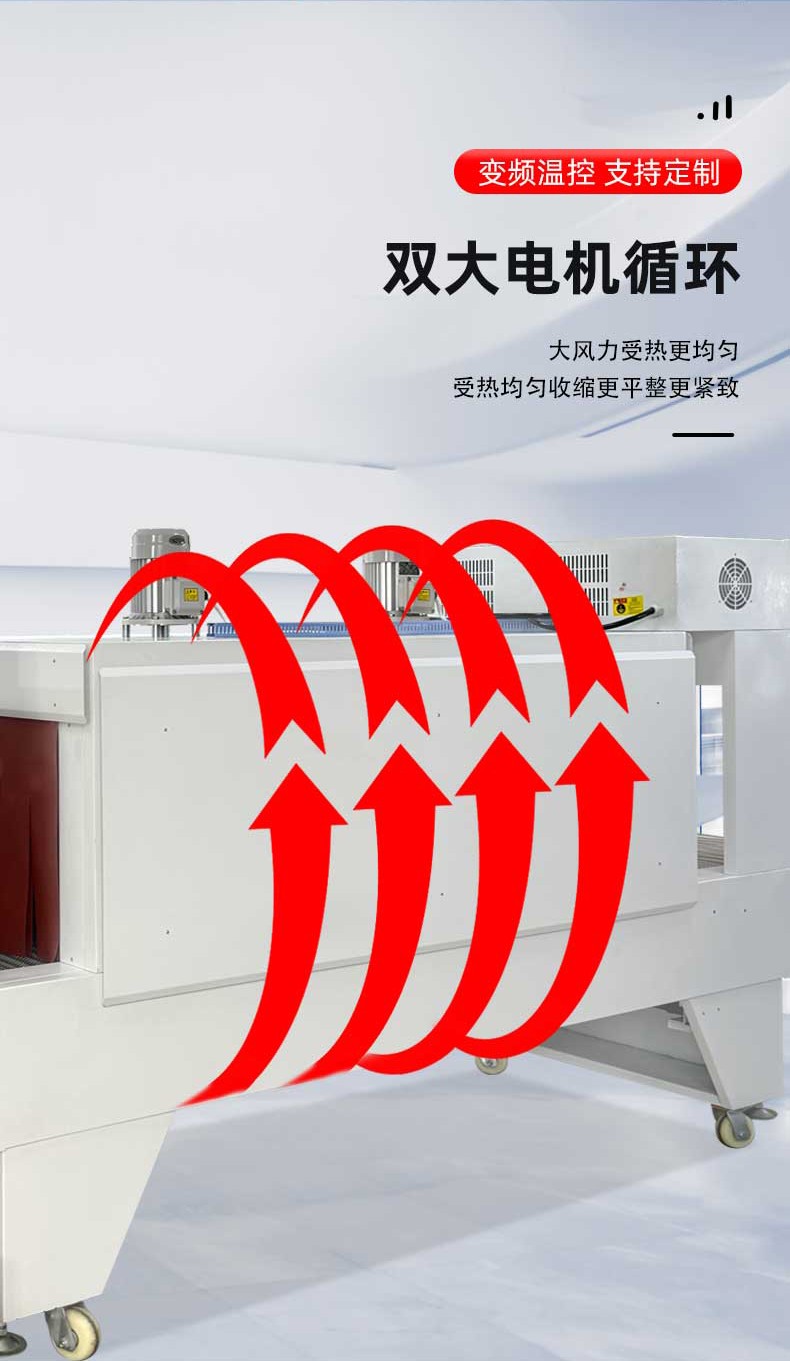

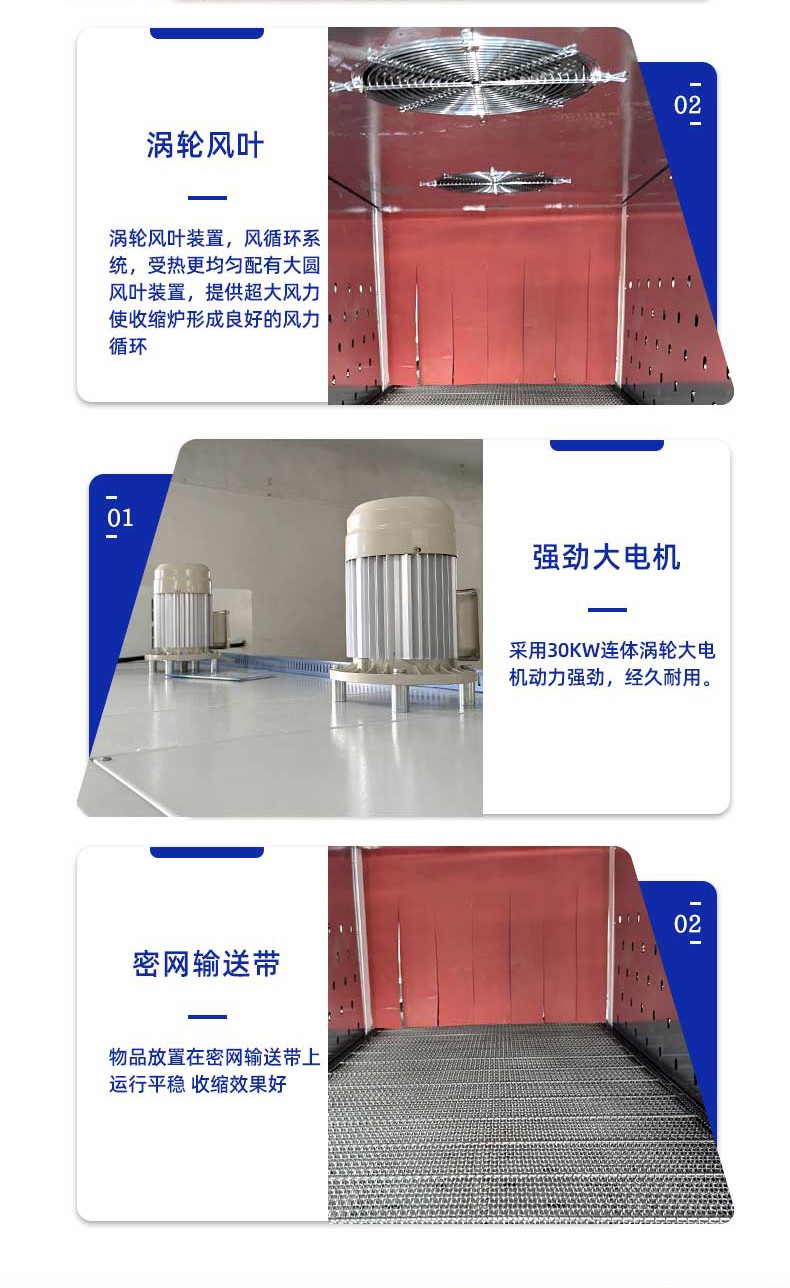

- The heat shrink tunnel adopts a zoned heating design. It achieves uniform heating according to the different heat shrinkage needs of the bottle body and combined gaps, ensuring that the film fits closely to the bottle body during single-bottle independent packaging, and tightly wraps the whole during multi-bottle combination (such as 2 bottles side by side, 4 bottles in a pack, 6 bottles stacked), eliminating the problem of "incomplete local shrinkage".

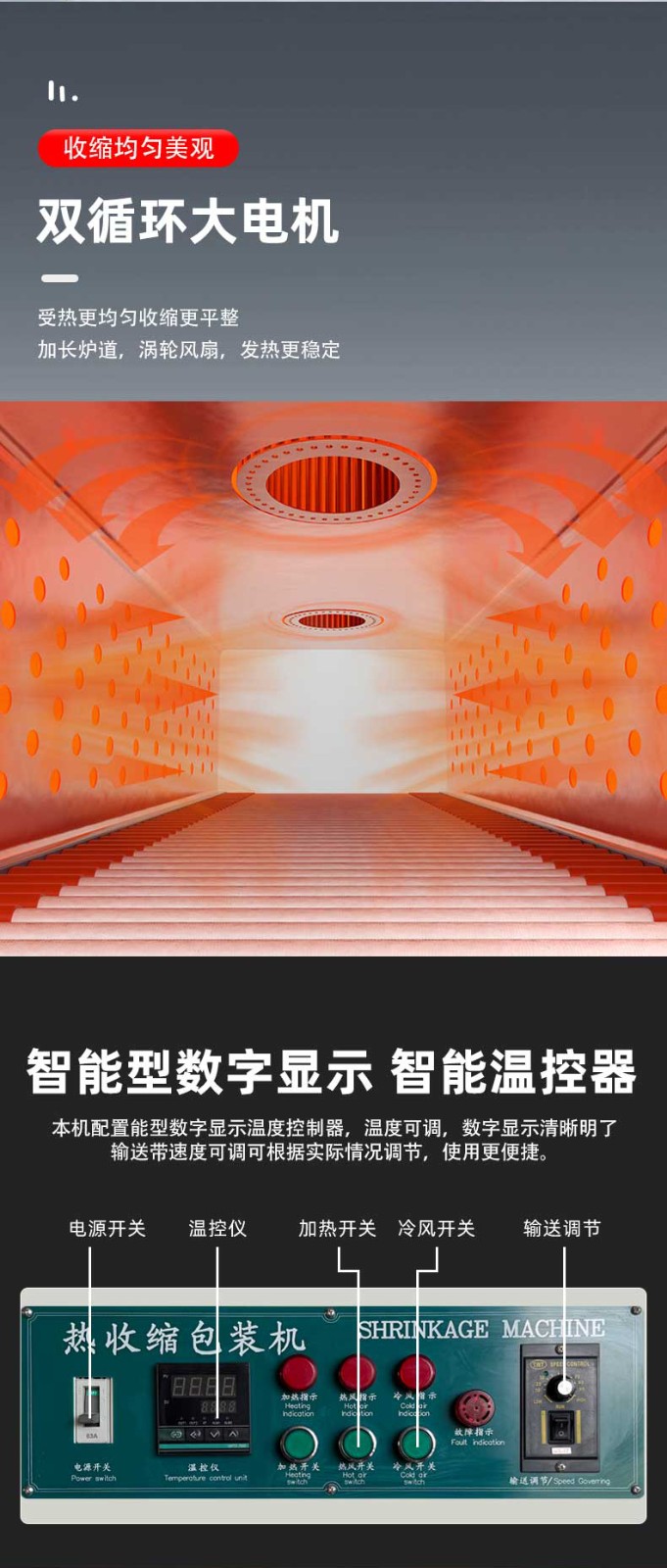

The equipment excels in the flexibility of multi-bottle combined packaging. Equipped with an intelligent touch screen, operators can call up preset packaging parameters with one click. For example, when switching between "6-bottle mineral water whole-pack film wrapping" and "4-bottle hand sanitizer combined packaging", the equipment will automatically adjust the conveyor belt spacing, film frame output length, and heat shrinkage temperature. The entire model change process only takes 2-3 minutes without disassembling or replacing mechanical parts, which greatly improves the production change efficiency of multi-category manufacturing enterprises. It is especially suitable for the flexible production needs of the food and beverage industry, such as "mass production of multiple specifications in peak seasons and small-batch trial production in off-seasons".

- In terms of materials: Whether it is PET beverage bottles (with strong temperature resistance), PE daily chemical bottles (soft texture), or glass high-end beverage bottles (fragile and requiring protection), the sleeve-type heat shrink packaging machine can find the optimal packaging parameters by adjusting the heat shrinkage temperature (usually adjustable in the range of 120-180℃) and conveying speed. For PET bottles, a medium-temperature rapid shrinkage mode is adopted to avoid bottle deformation caused by high temperature. For glass bottles, the conveying speed is reduced and the temperature balance of the upper and lower heating zones is improved to ensure the film fits closely without scratching the bottle label.

- In terms of specifications: The equipment can adapt to bottles with a diameter of 30mm-150mm and a height of 80mm-350mm. From small oral liquid bottles (needing multi-bottle combination into boxes) to large 5L barreled laundry detergent (single-barrel independent packaging), all can achieve stable packaging. Some high-end models can also be equipped with "bottle shape detection sensors". When bottles are skewed or missing on the conveyor belt, the equipment will automatically pause and alarm, preventing unqualified packages from entering the next process.

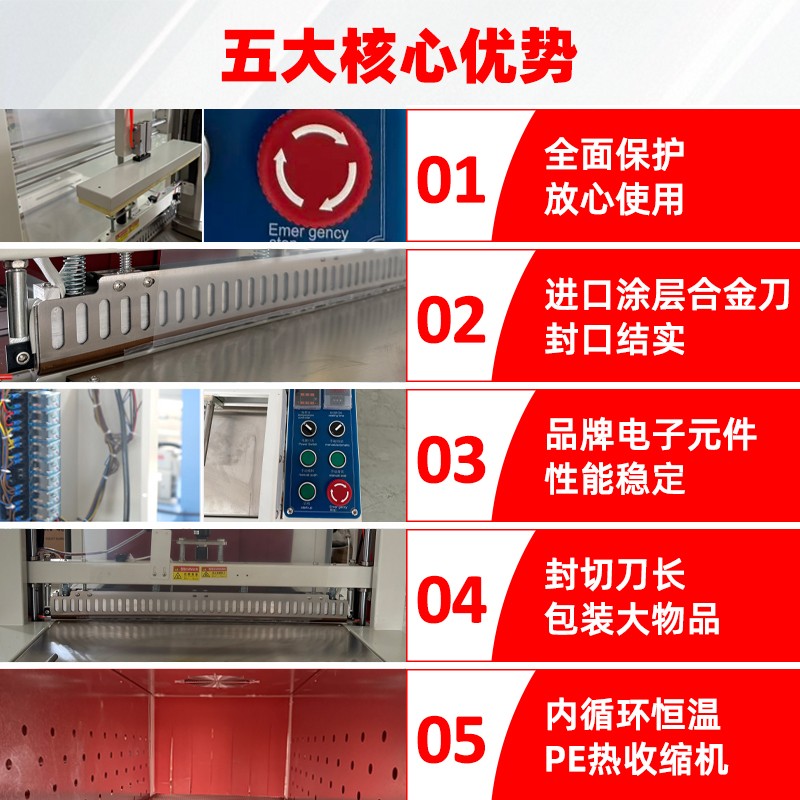

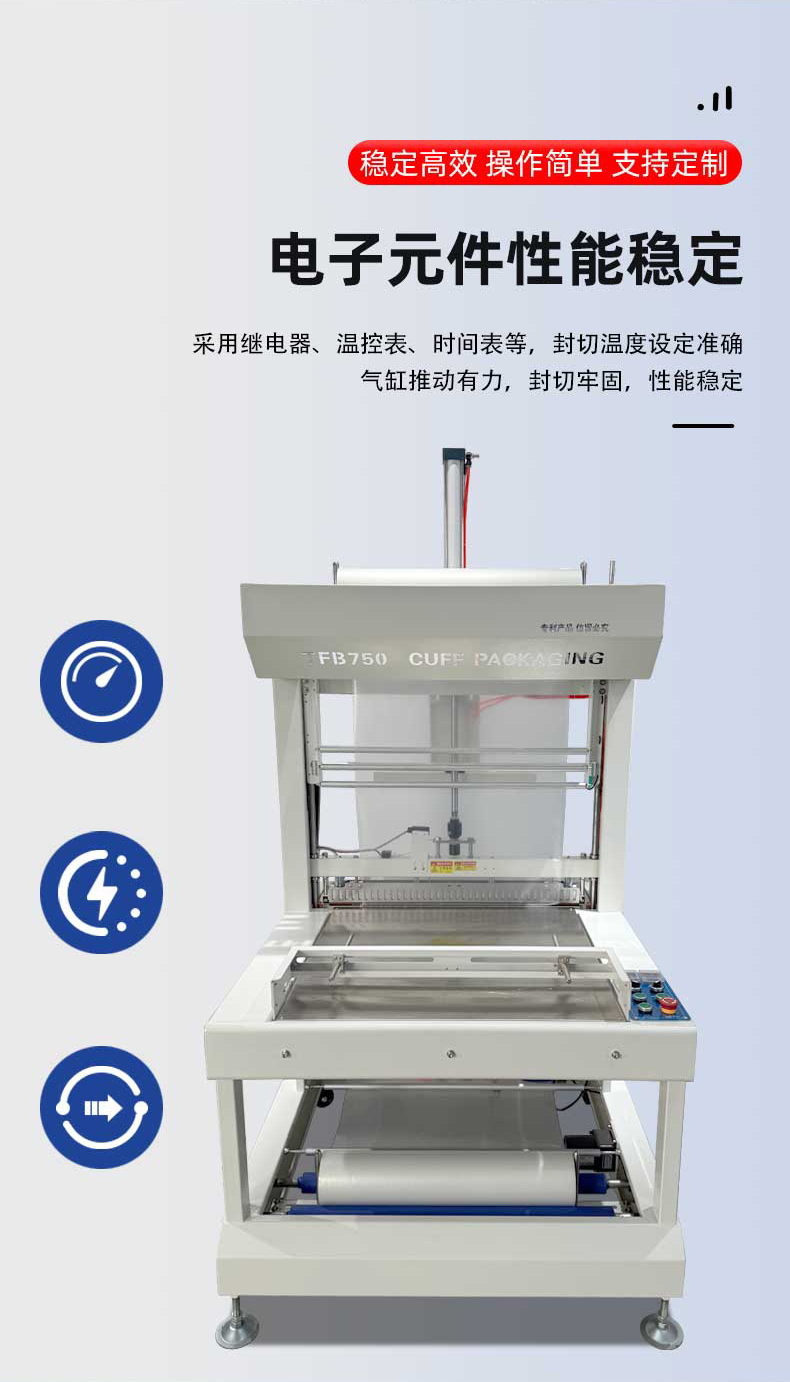

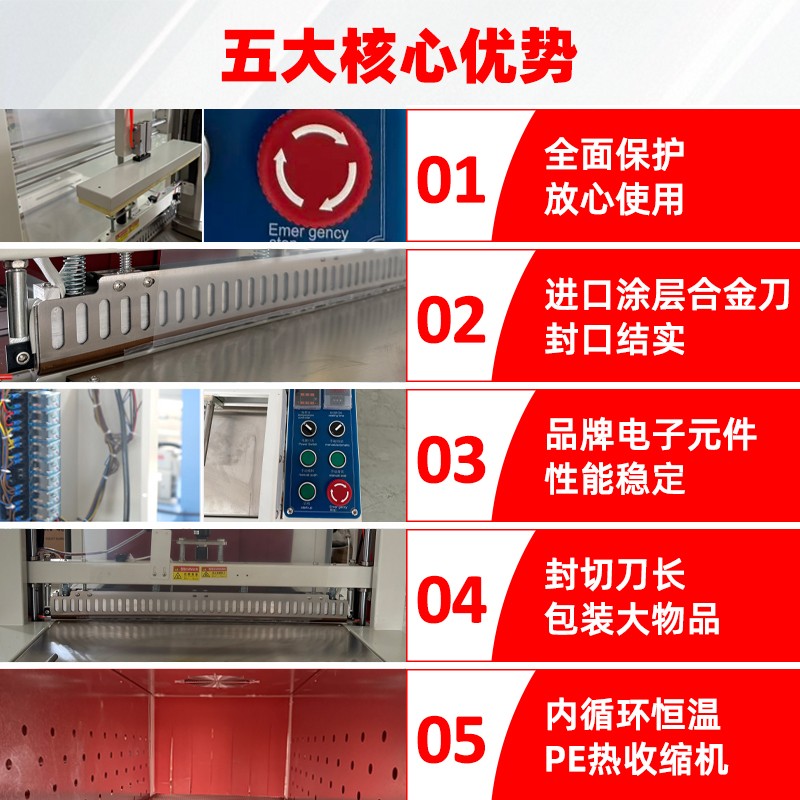

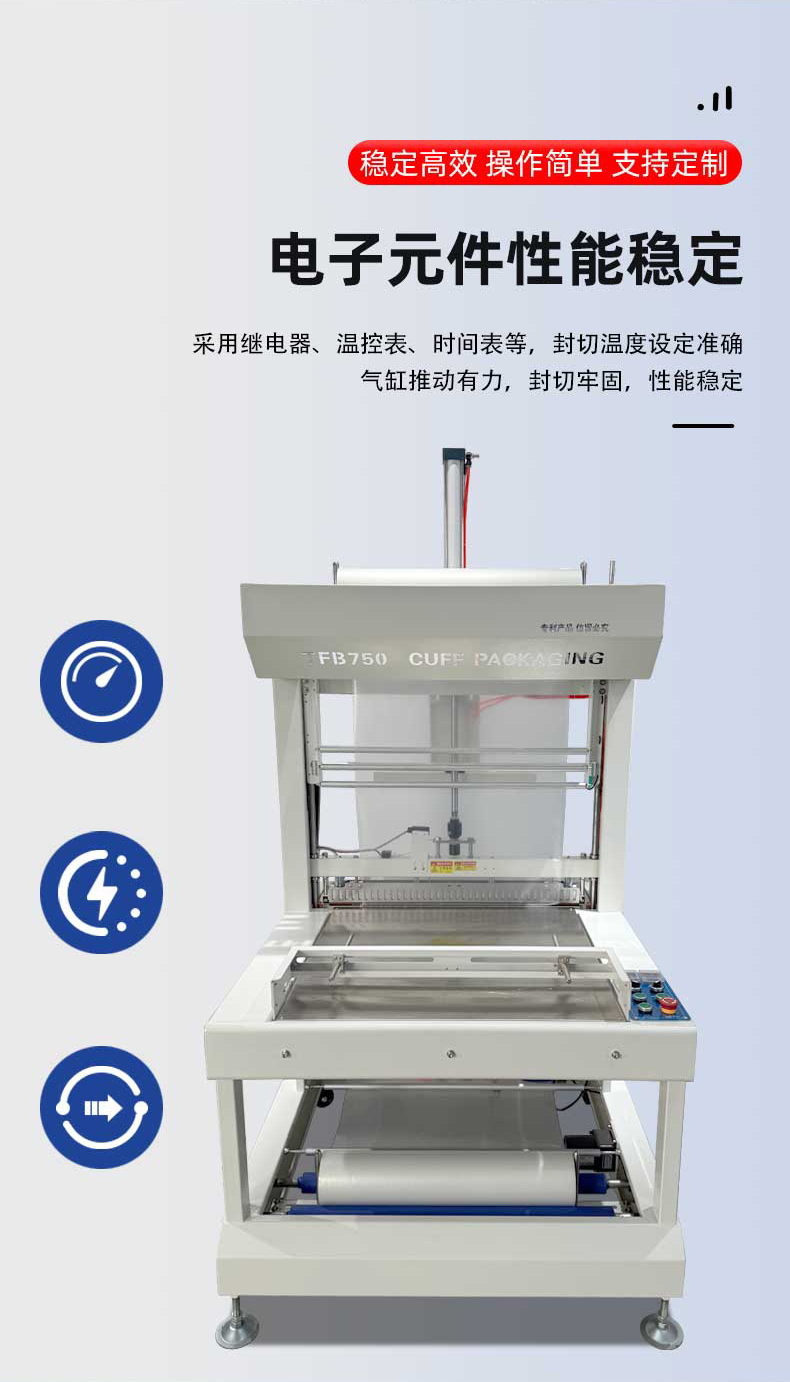

Mass production has high requirements for the continuous operation capability of equipment. The sleeve-type heat shrink packaging machine ensures stability through three major designs:

- First, it adopts a heavy-duty steel structure body, combined with precision bearings and wear-resistant conveyor belts. After long-term operation, the body has no obvious shaking, the wear rate of the conveyor belt is reduced by 60%, and the service life can reach 3-5 years.

- Second, it is equipped with an imported PLC control system and servo motor. The failure rate of core components is less than 0.3%, supporting 24-hour continuous operation. Even in the high-intensity production scenario of "100,000 bottles per day in peak seasons" in the food and beverage industry, it can maintain stable operation.

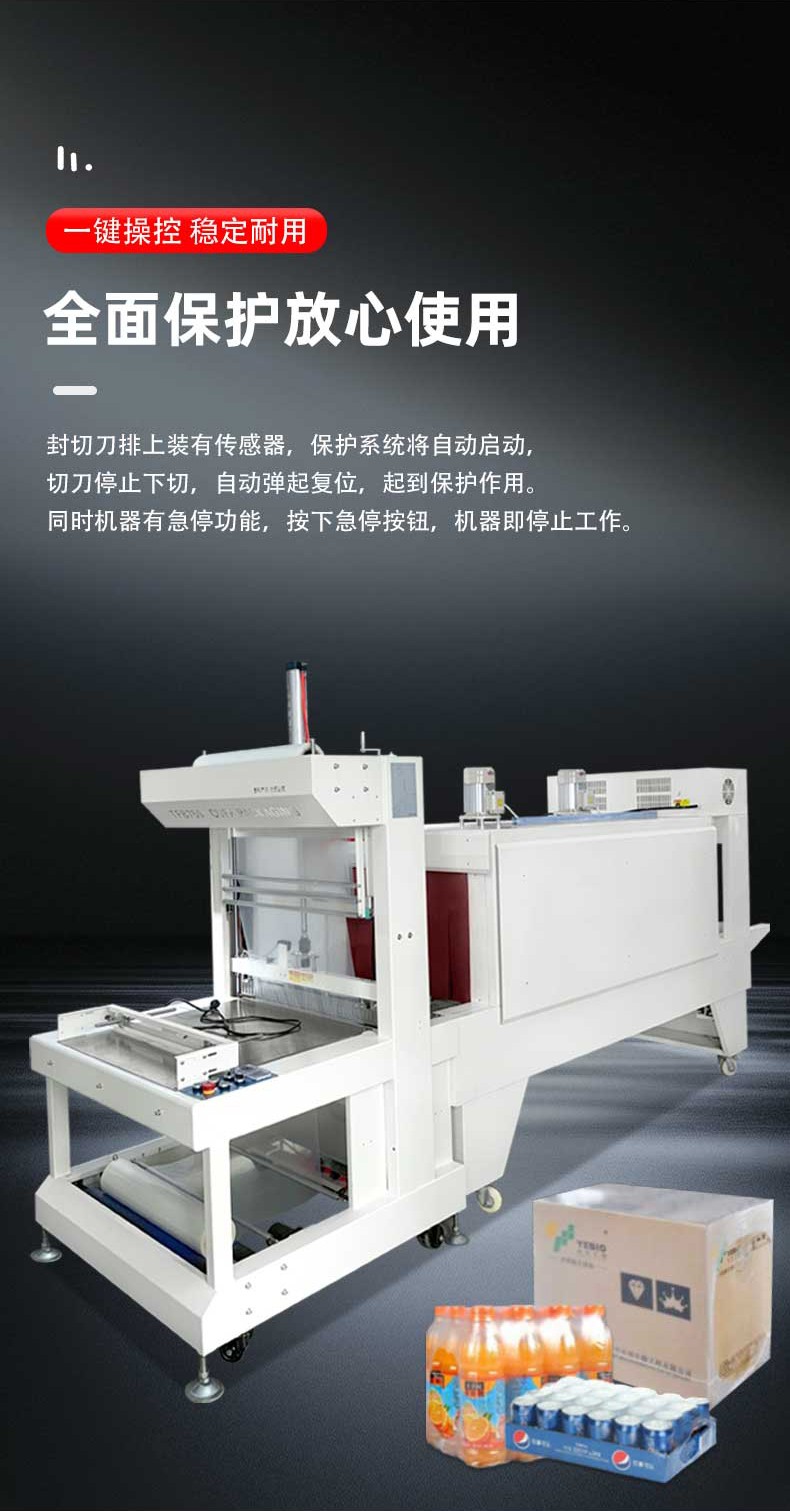

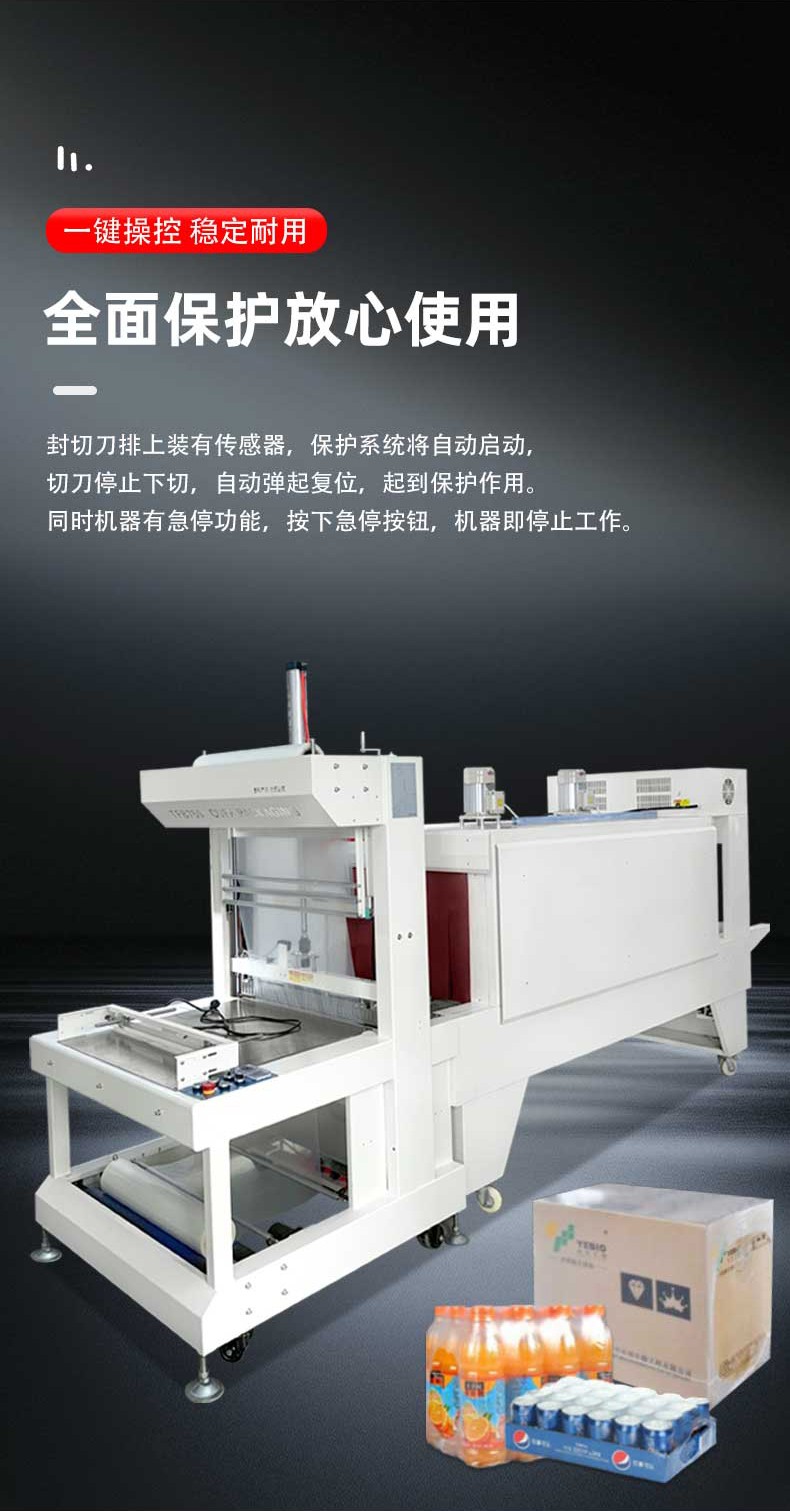

- Third, it is equipped with a complete protection mechanism. When the heating tube temperature is abnormal, the packaging film breaks, or the conveyor belt jams, the equipment will automatically cut off the power or pause operation, and display the cause of the fault on the touch screen. Operators can quickly troubleshoot and repair, with the average downtime maintenance time controlled within 15 minutes, greatly reducing production capacity loss caused by equipment failures.

For food, beverage and daily chemical products, the protection of packaging directly affects product quality and shelf life. The sleeve-type heat shrink packaging machine forms a fully sealed protective layer after heat shrinkage of the packaging film through "sealed heat shrinkage" technology:

- On one hand, it can isolate dust and impurities in the air, avoiding the appearance of products being affected by dust adhesion during storage and transportation.

- On the other hand, it can block moisture intrusion, which is especially suitable for food and beverages such as mineral water and juice that are susceptible to microbial contamination, as well as daily chemical products such as hand sanitizer and laundry detergent that are afraid of moisture. Tests show that mineral water packaged by this equipment can have a shelf life extended by 1-2 months under normal temperature storage conditions; packaged hand sanitizer will not have damp and wrinkled bottle labels even when stored in humid southern regions.

Regular packaging is the key for products to stand out on terminal shelves. Through precise temperature control and conveying positioning, the sleeve-type heat shrink packaging machine achieves the packaging effect of "flat and wrinkle-free film surface and neatly arranged bottles":

- For multi-bottle combined packaging, the gaps between bottles are uniform with no obvious deviation.

- For single-bottle packaging, the film fits closely to the bottle curve without "bulging" or "depression".

This regular packaging not only facilitates subsequent storage and stacking (improving warehouse utilization by 20%), but also forms a unified visual image on terminal shelves, enhancing consumers' trust in the product. A beverage enterprise reported that after introducing this equipment, the terminal display damage rate of its bottled products dropped from 5% to 1%, and consumers' purchase intention increased by 8%.