With core advantages of efficient sealing, moisture/dust resistance, contour-fitting shaping, and easy stacking & transportation, the sleeve-type sealing and cutting heat shrink packaging machine is widely used for standardized packaging needs across multiple industries. It is particularly suitable for combined packaging of regular/irregular products in mass production.

- Multi-bottle bundling (e.g., 6/12/24-bottle packs) for mineral water, beer, beverages, herbal tea, etc. The tray-less shrink film wrapping directly replaces traditional cartons and adhesive tapes, reducing packaging material costs by over 30% while allowing brand visibility through the transparent film.

- Single/multi-bottle sealed packaging for cans, sauce bottles, edible oil buckets, etc. Prevents leakage and oxidation during transportation, extending shelf life (especially for oil-containing and moisture-sensitive foods).

- Multi-box combined packaging (e.g., 3/6-box sets) for cookie boxes, chip cans, bread gift boxes, etc. The tightly fitting shrink film prevents box scattering, provides moisture/dust protection, and enhances product premiumness.

- Outer carton shrink packaging for frozen foods (e.g., quick-frozen dumplings, glutinous rice balls). Strengthens carton sealing to avoid moisture absorption and thawing during cold chain transportation.

Complies with food-grade packaging standards (compatible with non-toxic PE/POF films) and features high packaging speed (8-15 packs/minute), adapting to continuous production line operations. The transparent packaging also facilitates end-of-shelf display.

- The automatic model achieves a packaging speed of 8-25 packs/minute (single row) and 15-40 packs/minute (multi-row), supporting 24/7 continuous operation to match the production rhythm of food & beverage, daily chemical, and other industries.

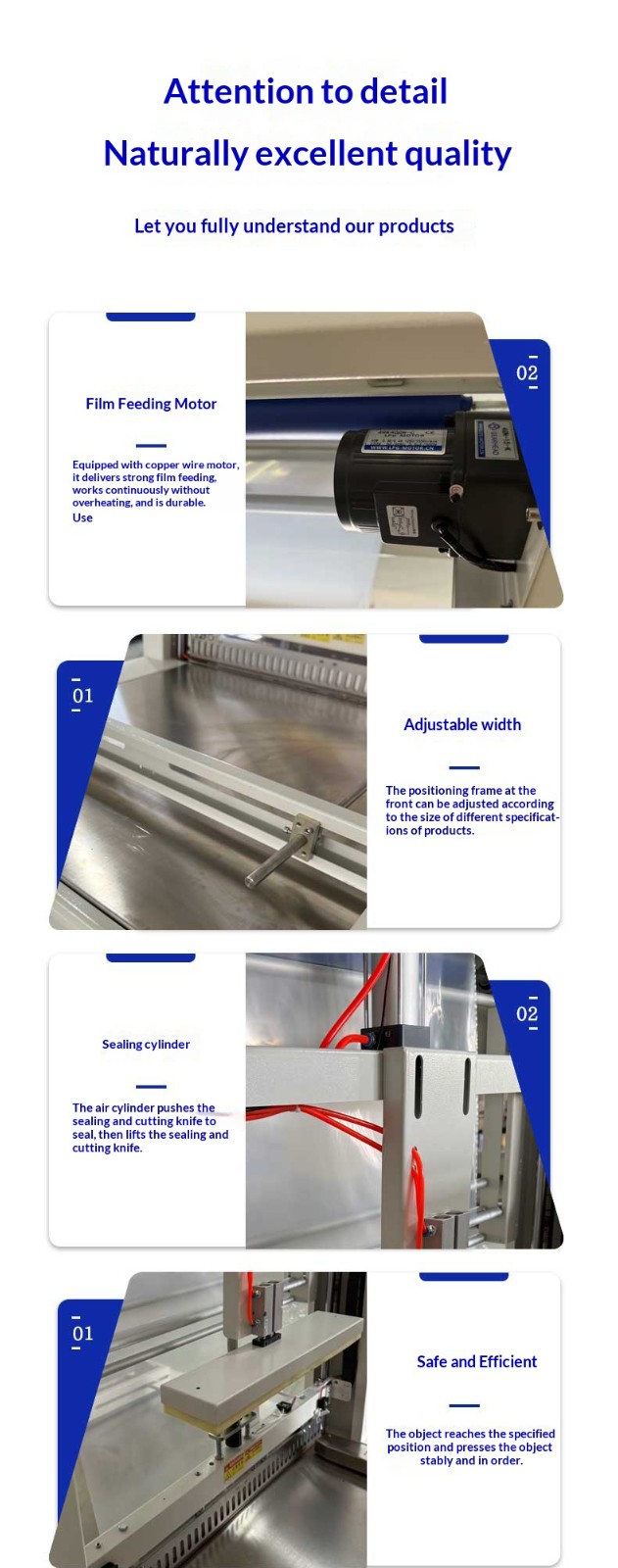

- Flexible product changeover with parameterized storage for over 100 sets of product specifications. Switchover takes only 2-5 minutes without disassembling mechanical components.

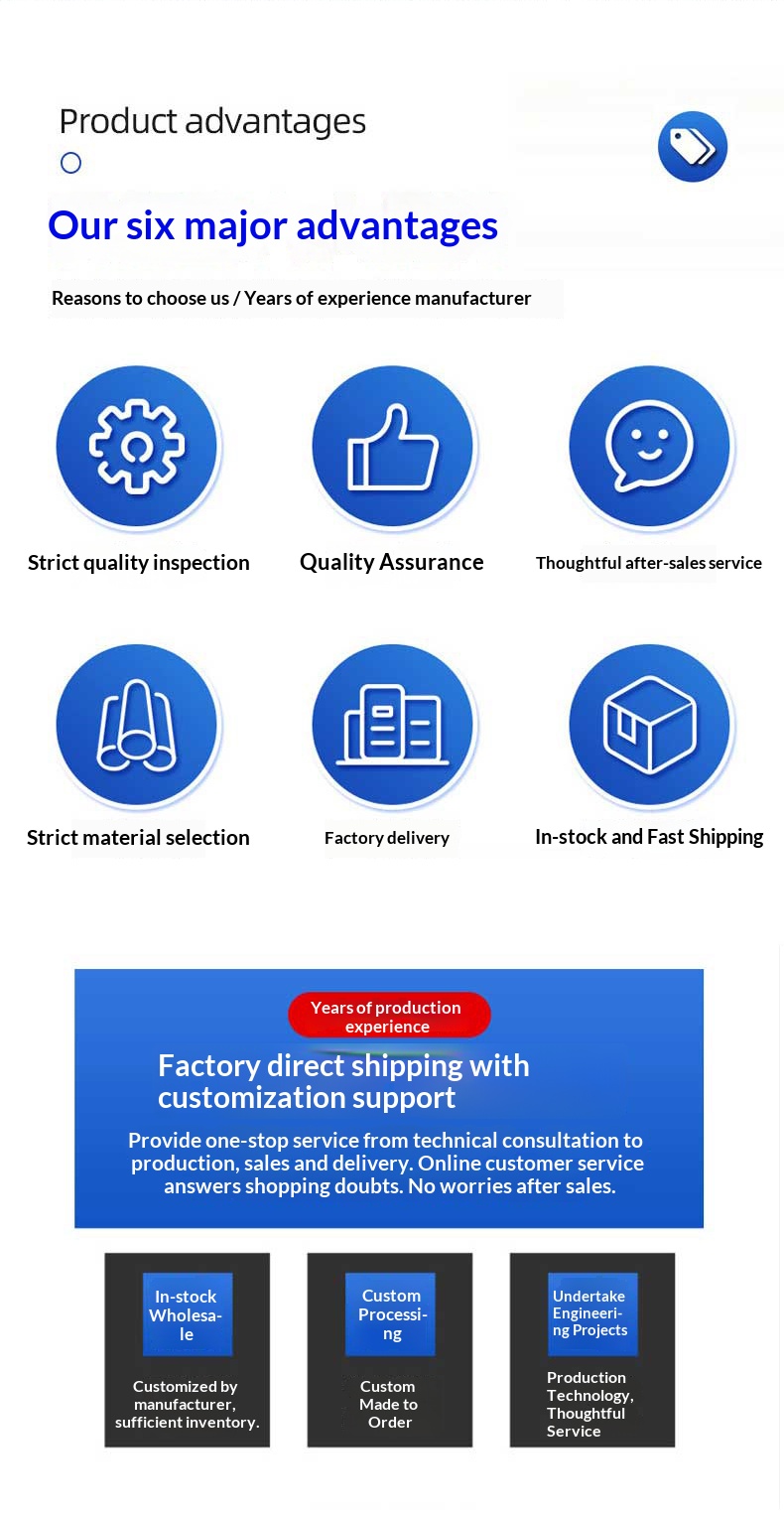

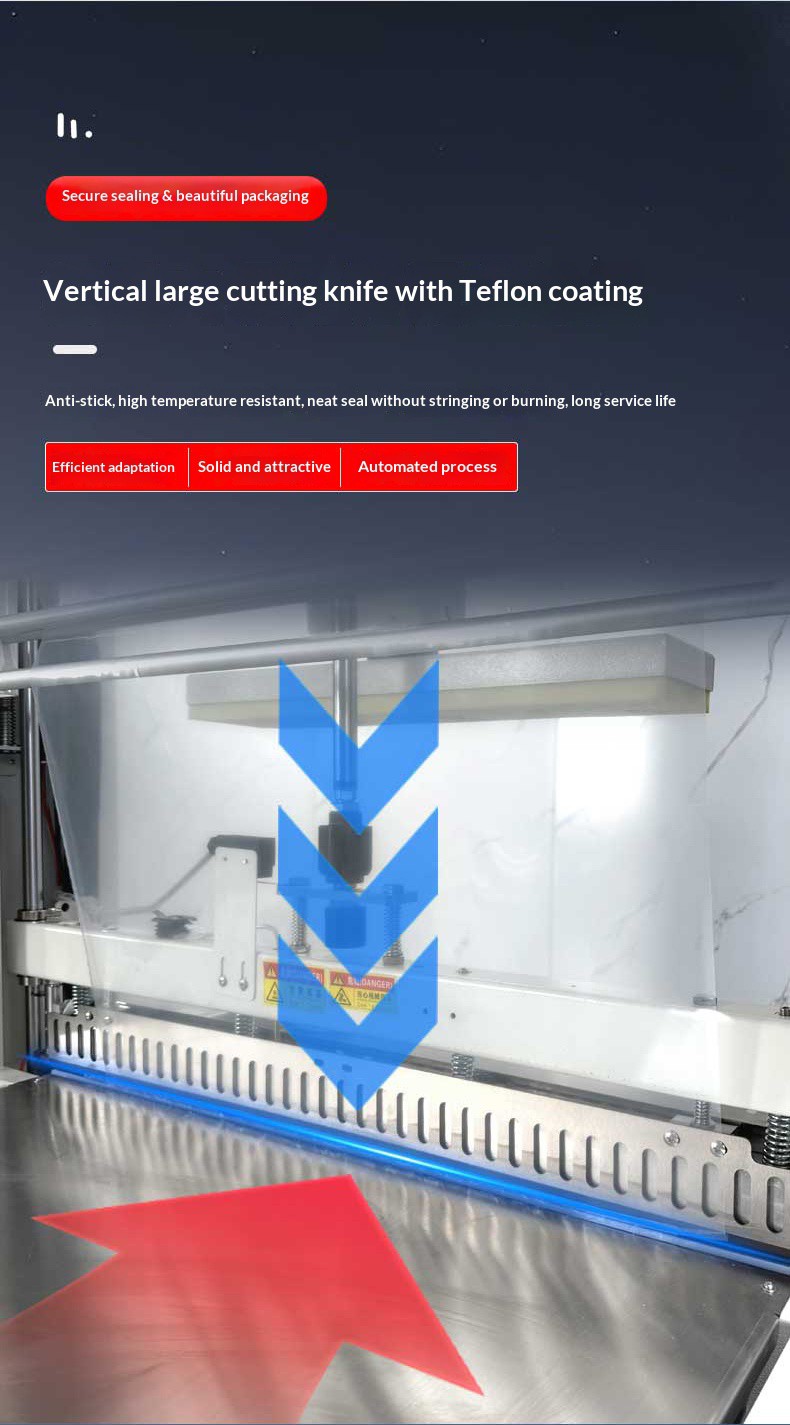

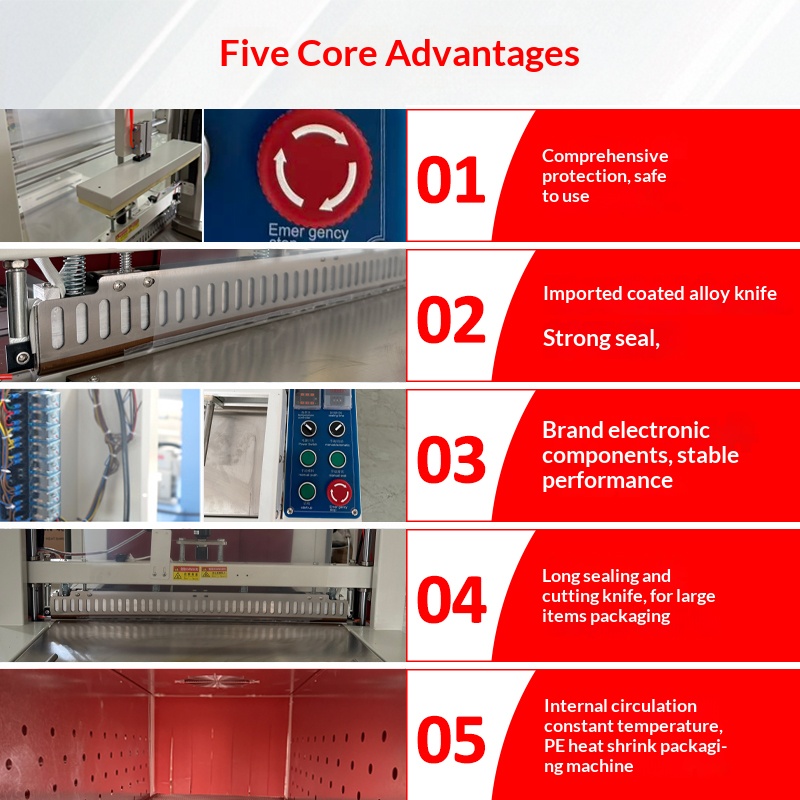

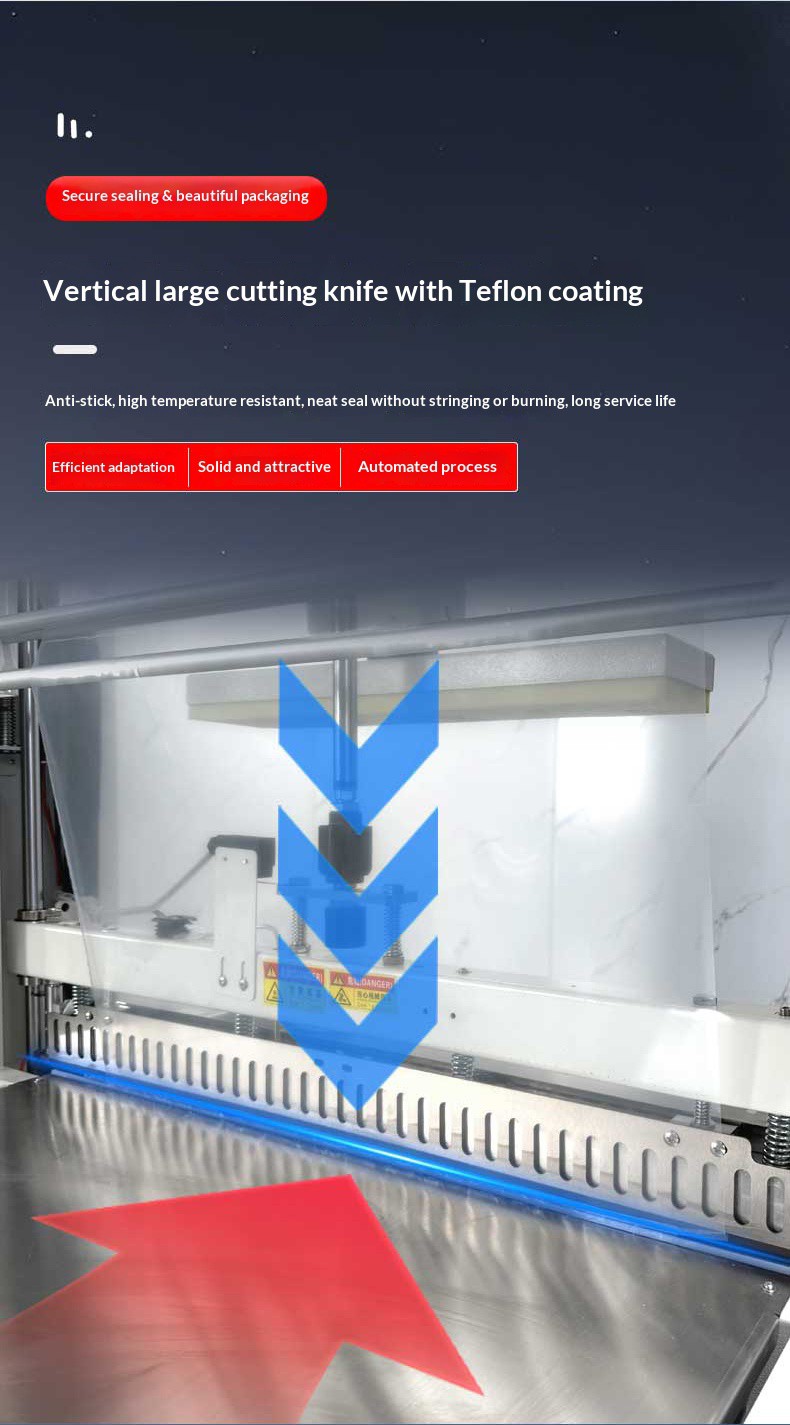

- The heat shrink film closely fits the product contour, forming a sealed, moisture-proof, dust-proof, and scratch-proof three-dimensional package, reducing the transportation damage rate to below 0.5%.

- Supports transparent/printed shrink film packaging: transparent film displays product details, while printed film can be customized with brand logos and promotional information, balancing protection and brand marketing.

- Tray-less packaging design replaces traditional cartons and adhesive tapes, reducing packaging material costs by 30%-50% and saving 40% of storage and transportation space.

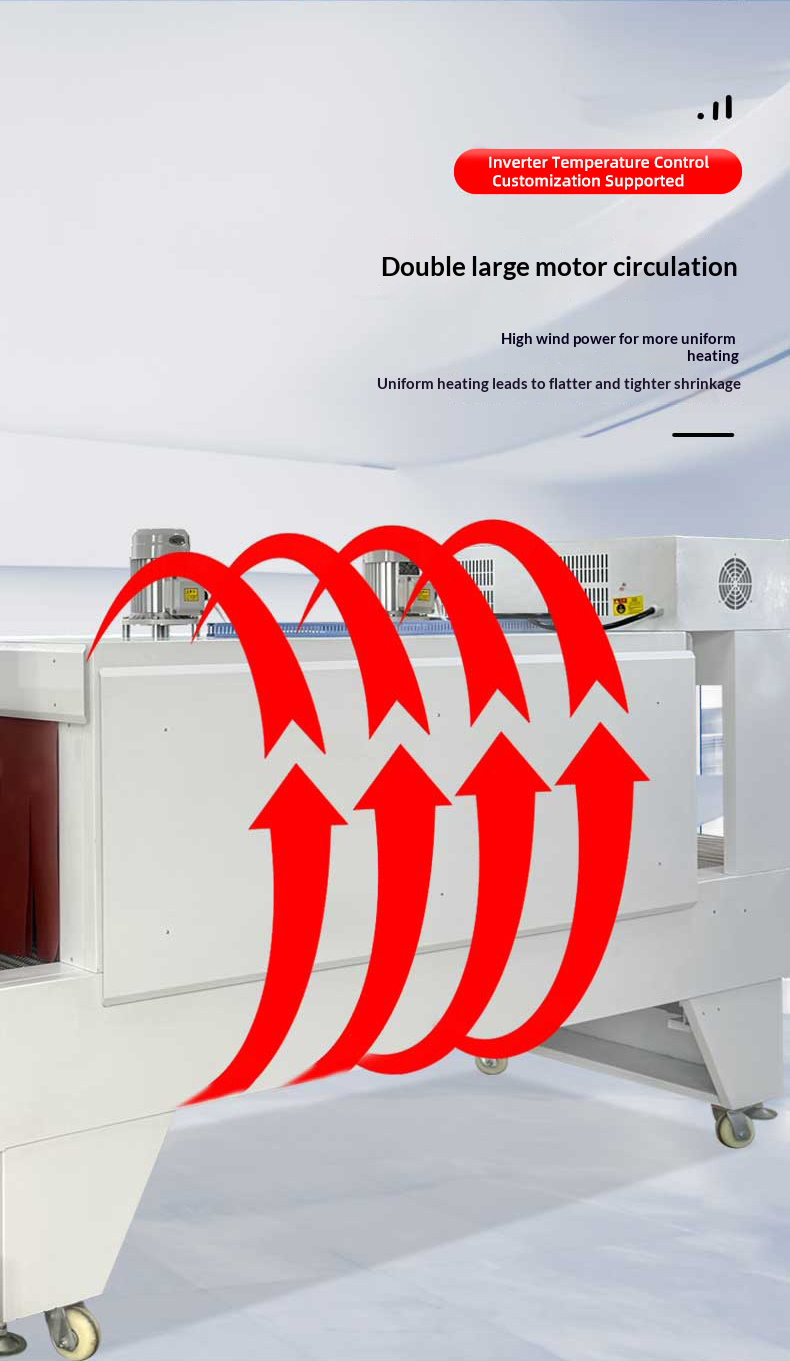

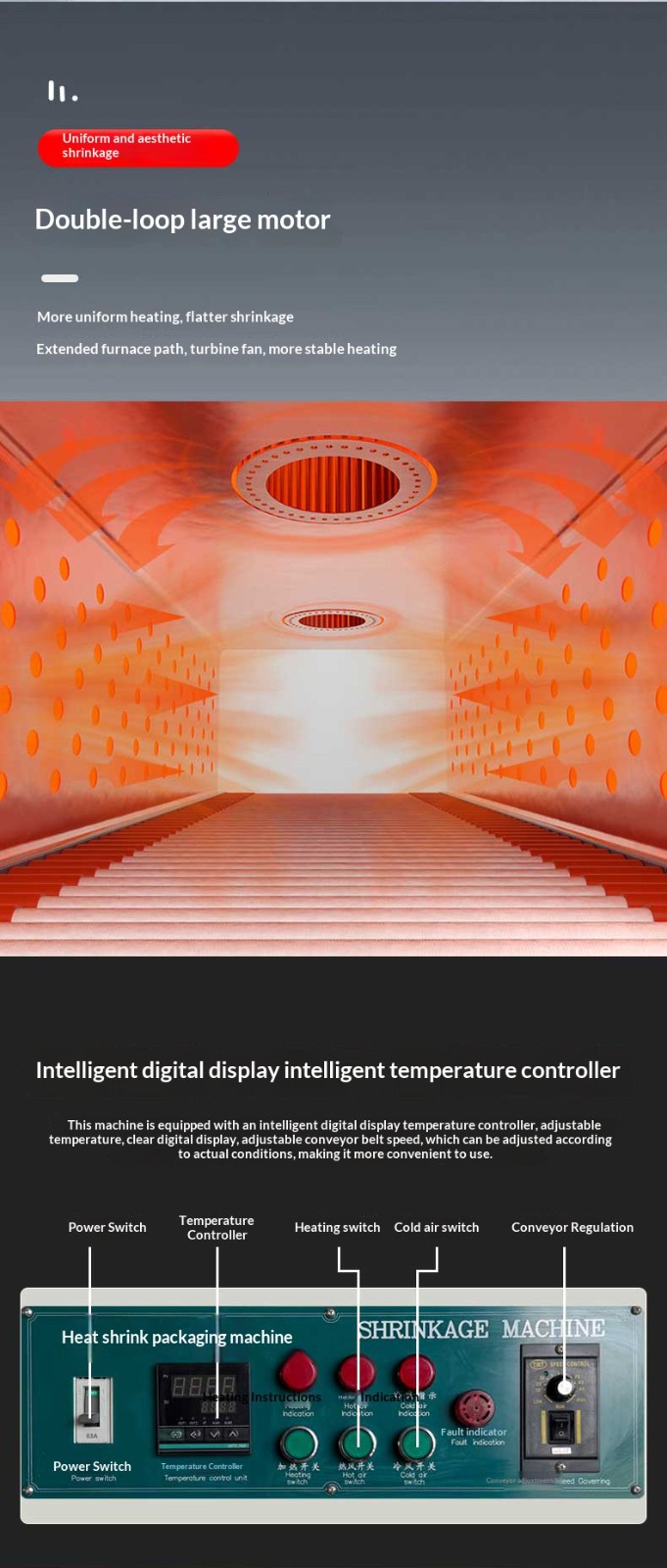

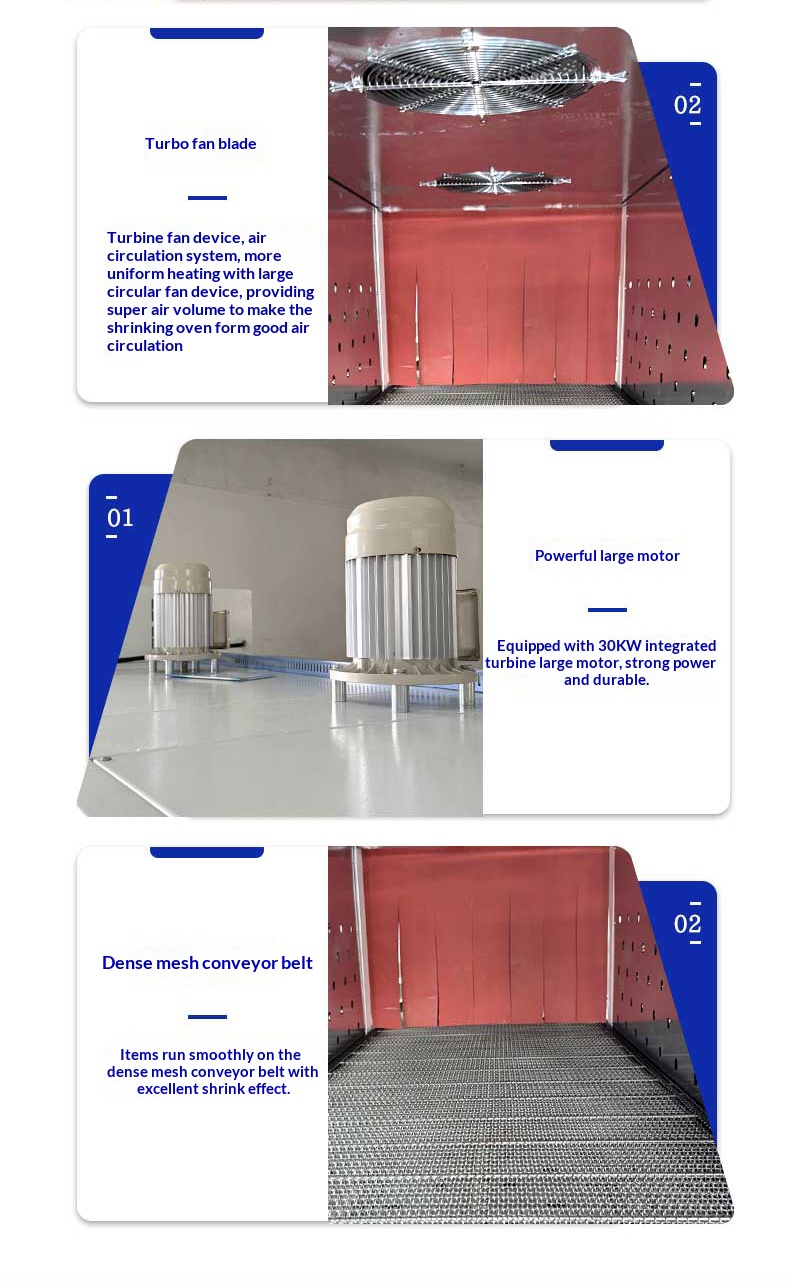

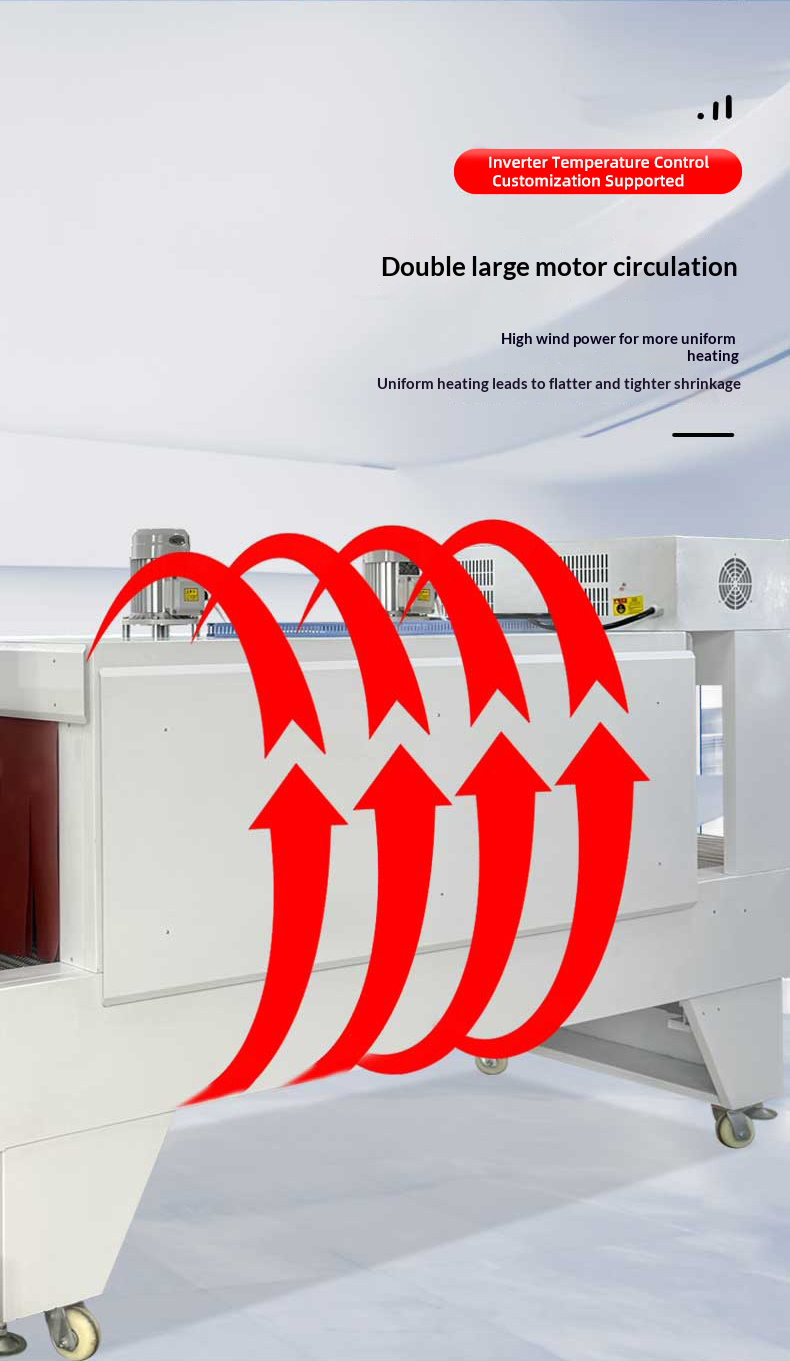

- Adopts infrared heating or quartz tube heating technology, saving 30%-50% energy compared to traditional heating wires. Features automatic power reduction in standby mode for lower long-term operating costs.

- The automatic model only requires 1 person for inspection, reducing labor costs by 80% and avoiding human operation errors.

- Capable of packaging products of various shapes (square, circular, irregular) and supporting single/multi-piece combined packaging. Product size range covers 50mm×30mm×20mm to 800mm×600mm×500mm (larger specifications customizable).

- Compatible with various heat shrink films (PE, POF, PVC), meeting industry standards such as food grade (FDA/ROHS), pharmaceutical grade (GMP), and industrial anti-static requirements.

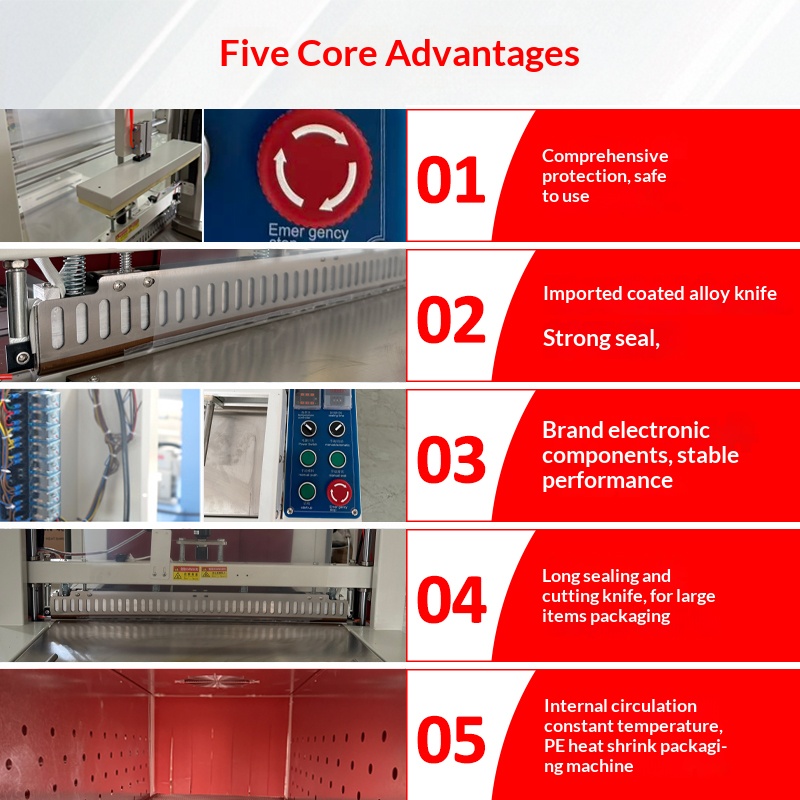

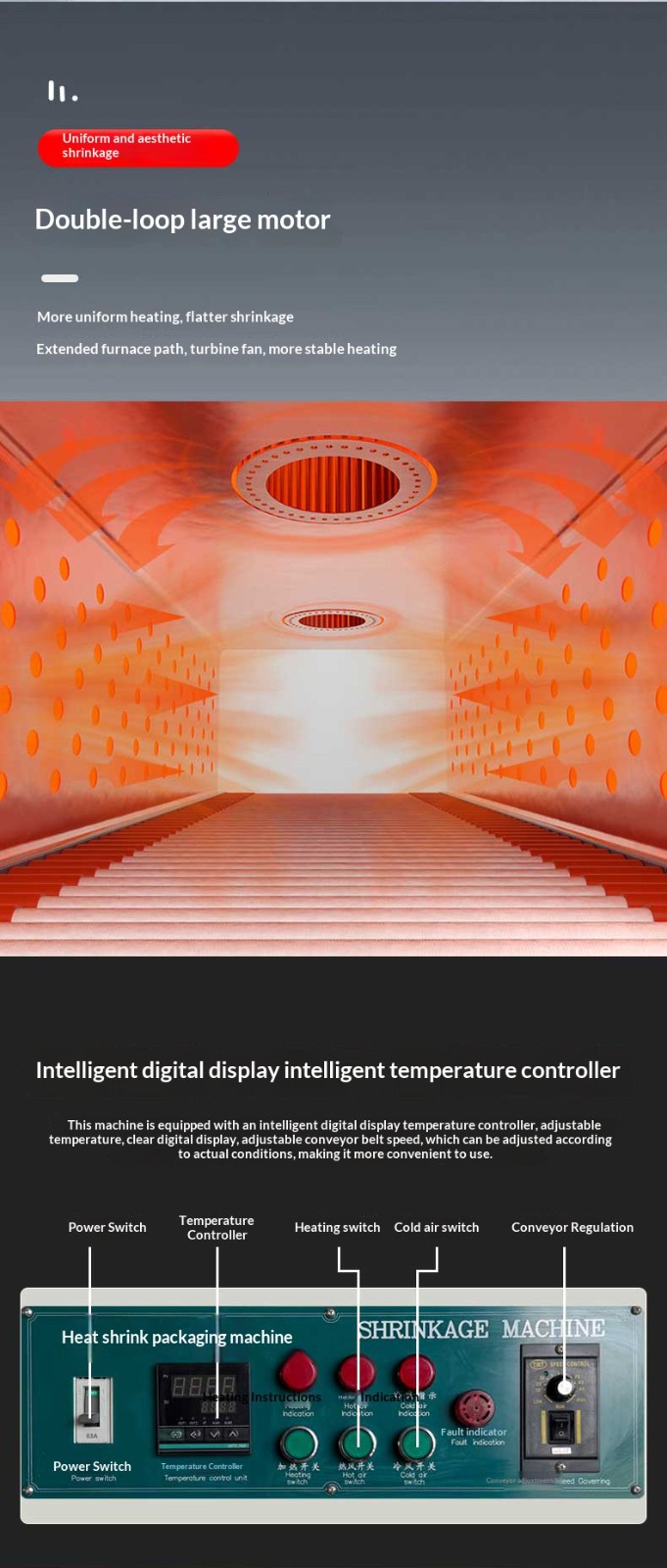

- PLC touch screen with visual operation and intuitive parameter setting. Ordinary workers can operate independently after 1-2 hours of training. Supports automatic fault alarm and repair prompts.

- Modular structure design enables easy replacement of wearing parts (e.g., sealing knives, heating tubes). Daily maintenance only involves cleaning and tightening, reducing maintenance costs by 40%.

- Uses recyclable, non-toxic, and environmentally friendly film materials with no dust or odor emissions, complying with global green packaging policies.

- Reduces the use of non-degradable materials (e.g., cartons, adhesive tapes), minimizing express waste and resource consumption. Suitable for environmental requirements of e-commerce and logistics industries.