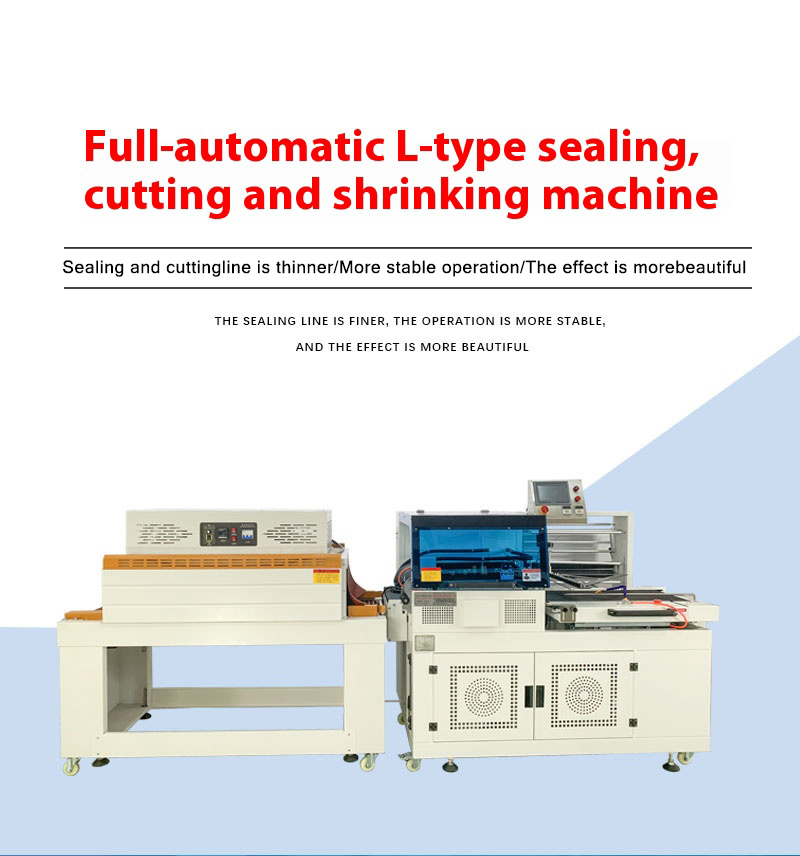

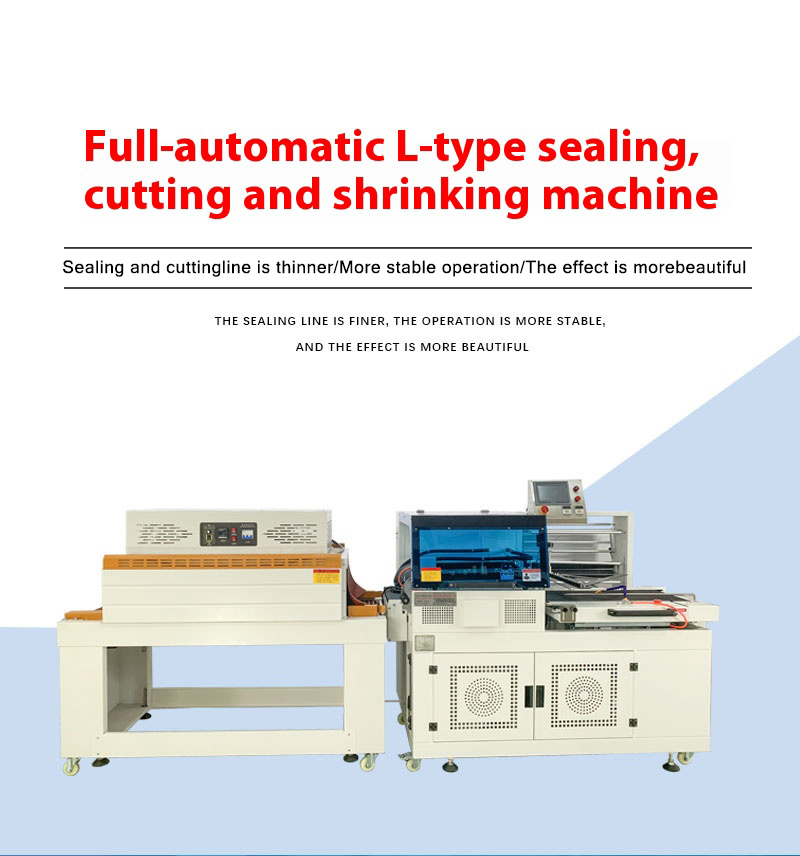

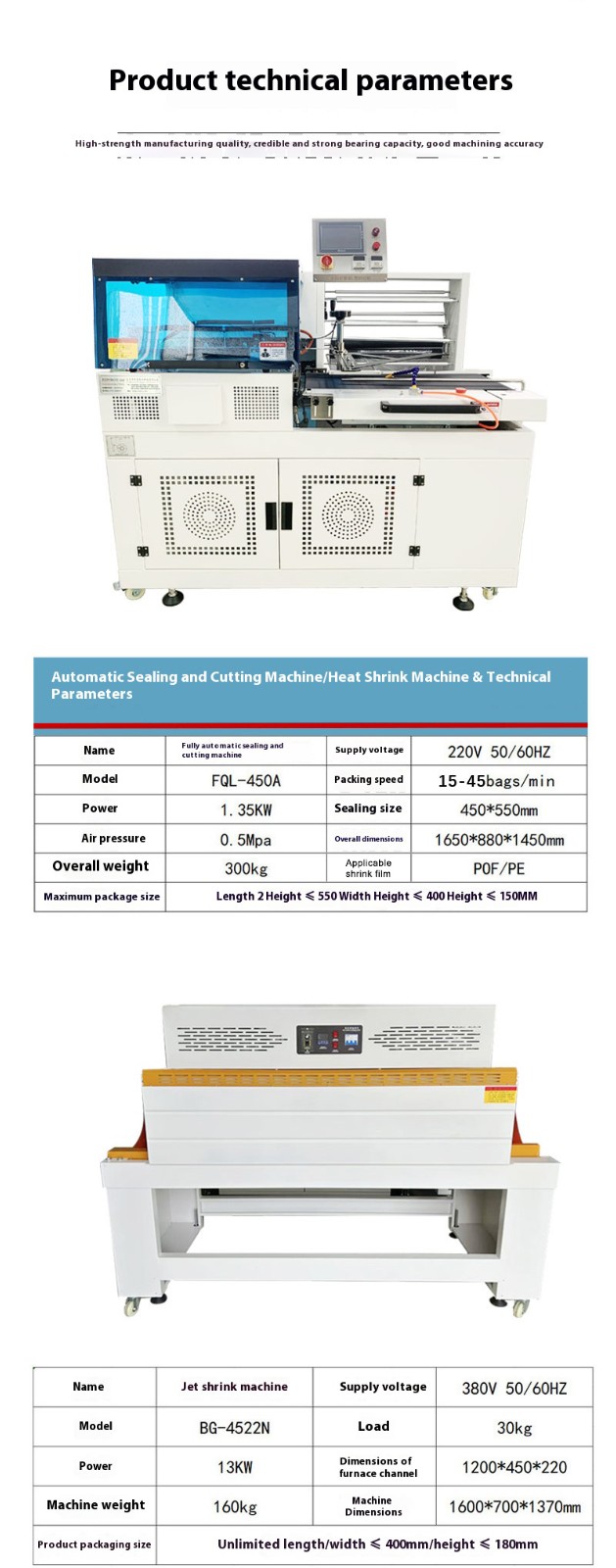

The equipment integrates feeding, film feeding, sealing and cutting, shrinking and discharging in one unit, requiring no manual intervention throughout the entire process. Only 1-2 operators are needed for material replenishment and equipment inspection. Compared with the traditional manual sealing and cutting plus manual shrinking mode, it can reduce labor input by more than 70%, making it particularly suitable for large-batch continuous production scenarios.

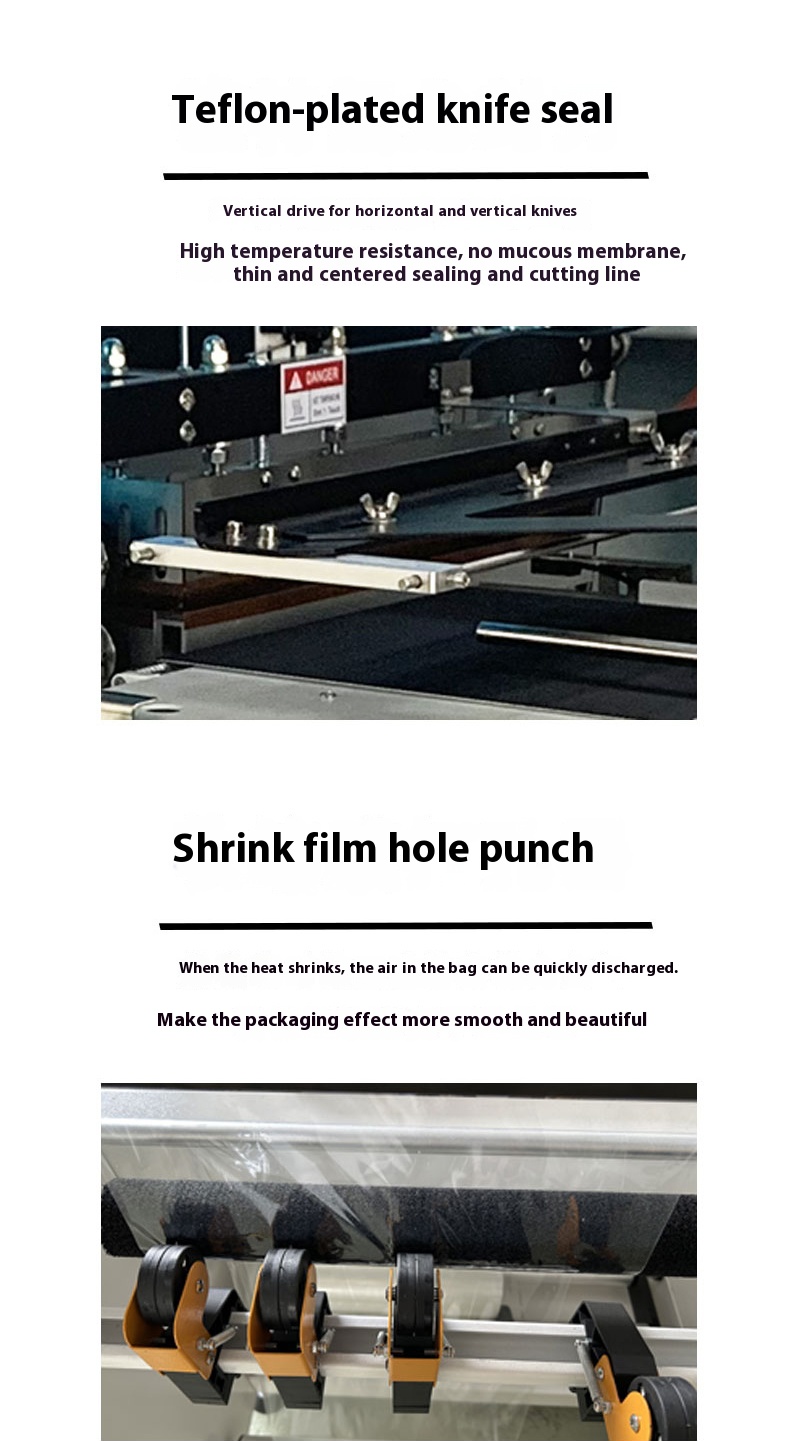

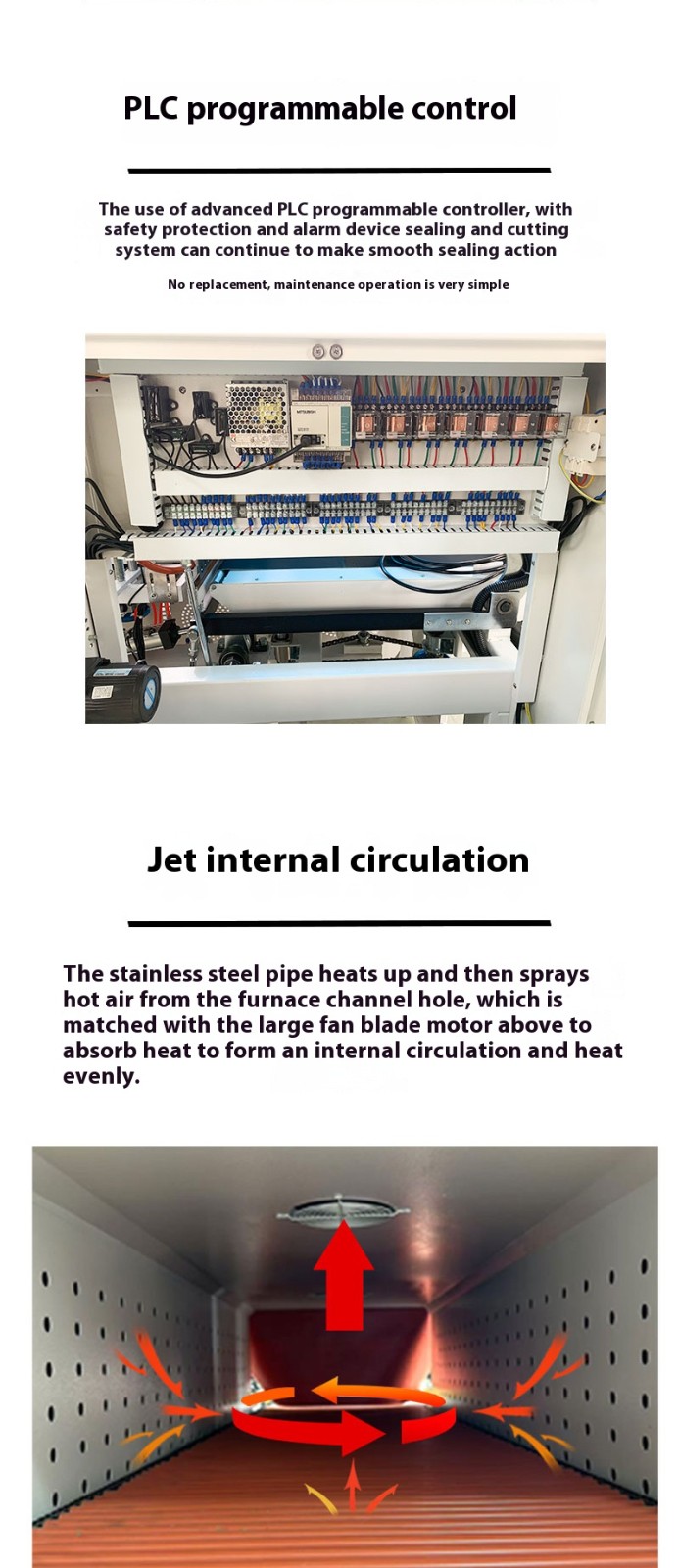

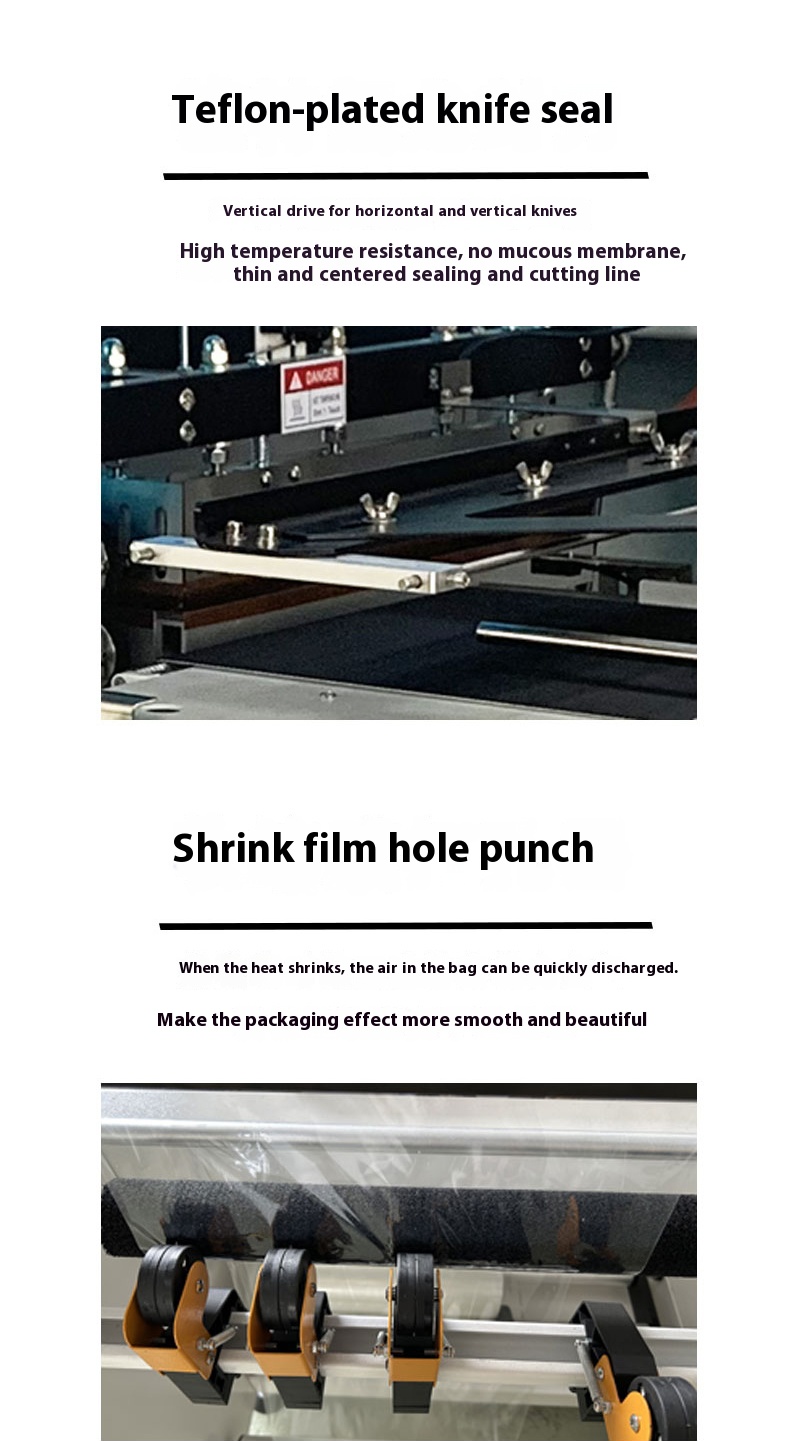

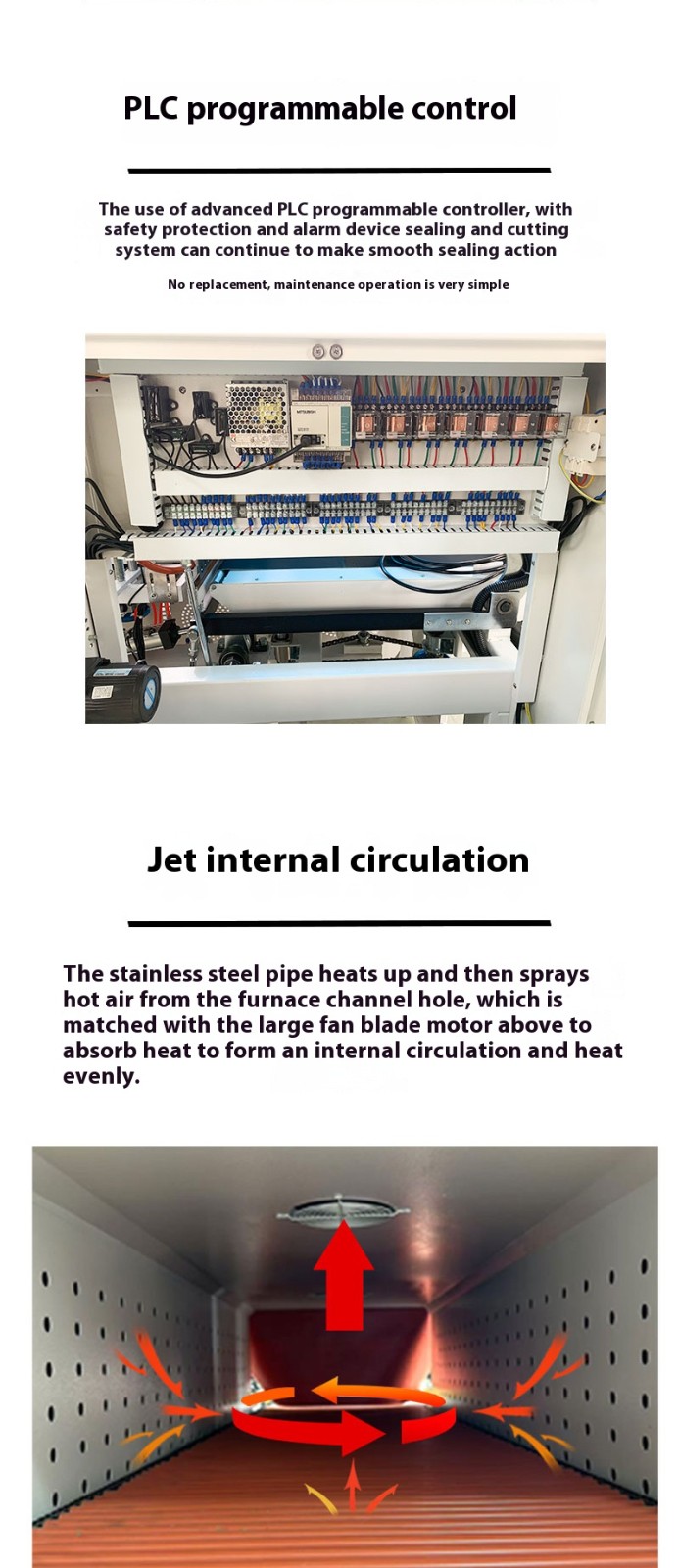

Adopting a PLC programmable control system and servo motor drive, combined with photoelectric induction positioning technology, it can accurately identify product dimensions to realize fixed-length conveying and sealing-cutting of film materials. The sealing line is flat and firm, and the cut is smooth without burrs, effectively avoiding film material waste caused by sealing and cutting deviations, with the yield rate reaching over 99.5%. Meanwhile, the specially made high-temperature resistant aluminum alloy sealing knife has an anti-sticking function, compatible with various heat shrink films such as POF, PVC and PE, eliminating packaging defects caused by film adhesion to the sealing knife.

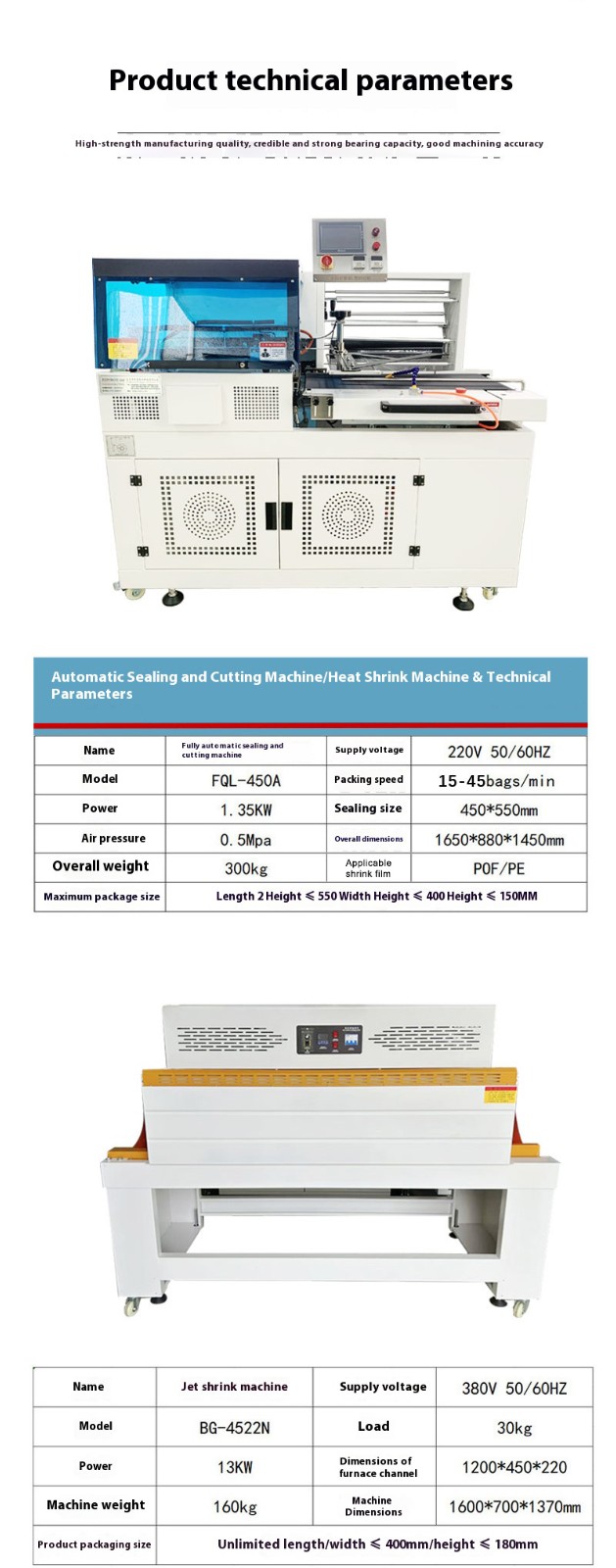

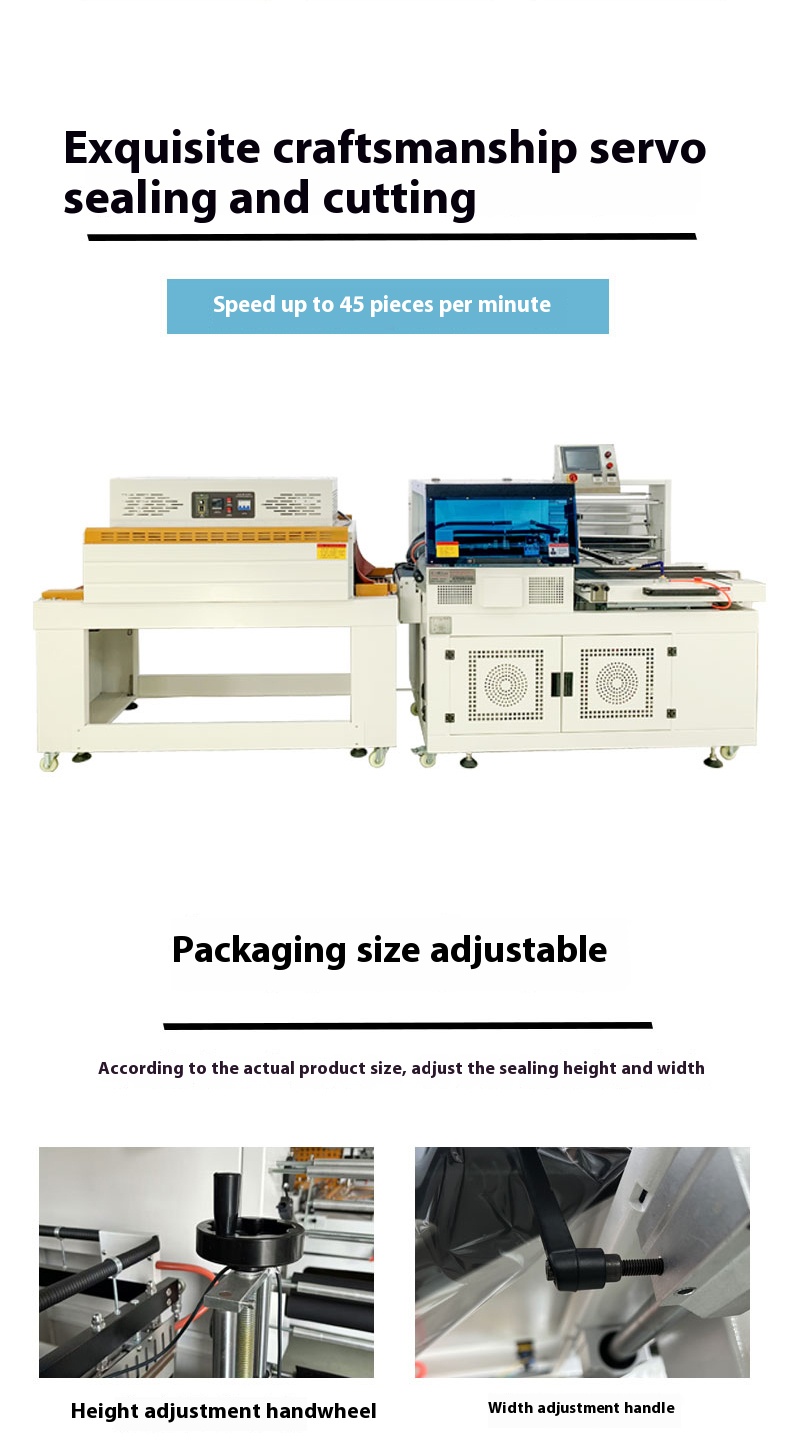

The equipment supports the packaging of products of different specifications and shapes. By adjusting parameters such as conveyor belt speed, sealing and cutting temperature, and shrinking furnace temperature, packaging schemes can be switched quickly. Whether it is boxed, bottled, barreled products or irregular special-shaped parts, it can achieve a tightly fitting packaging effect, suitable for multiple industries including food, pharmaceuticals, electronics, daily chemicals and hardware.

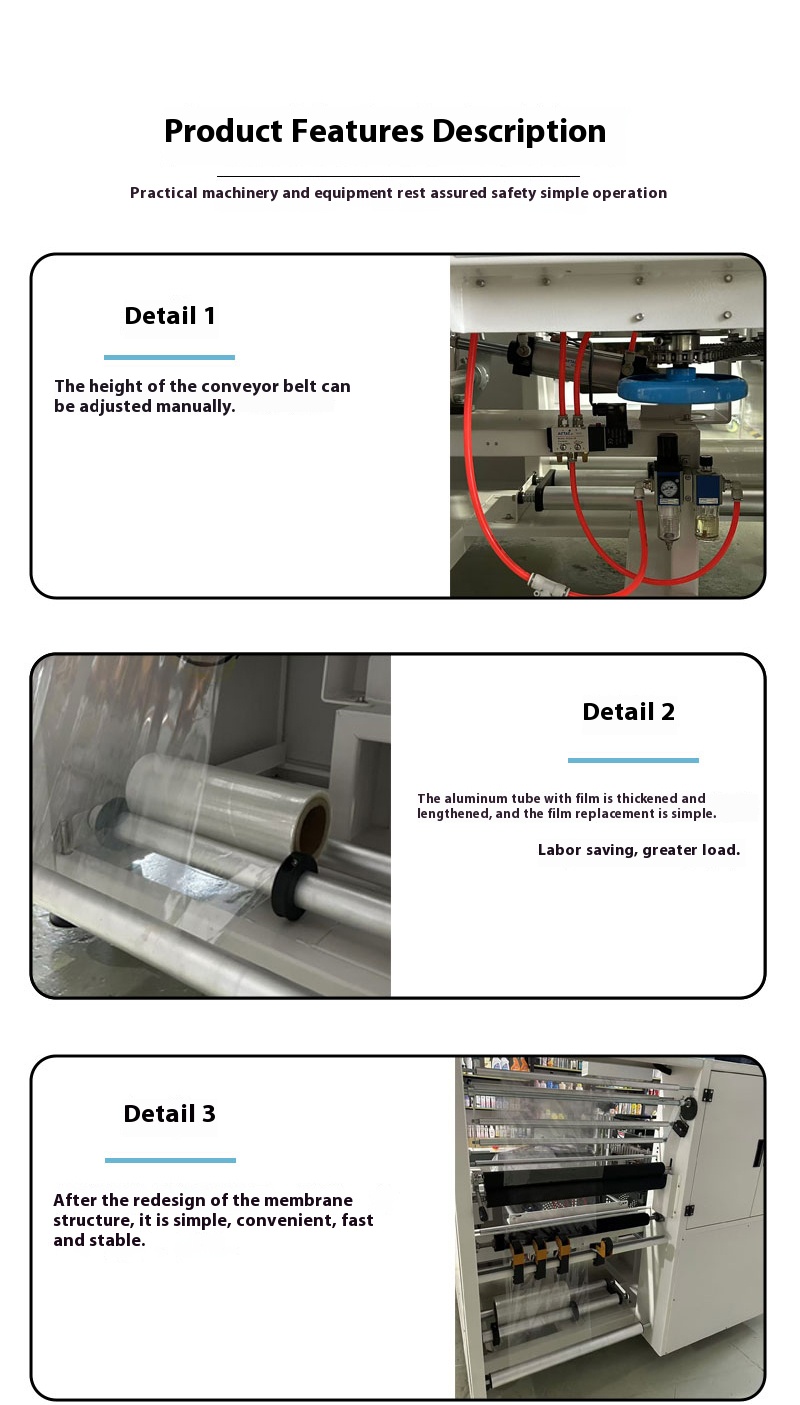

The shrinking furnace adopts a double-layer thermal insulation structure, combined with an intelligent temperature control system, which can accurately adjust the temperature according to product packaging requirements to avoid ineffective energy loss. Meanwhile, the film tension control system ensures uniform stretching of the film, reducing film stretching breakage and excessive consumption, saving 10%-15% of film usage compared with similar equipment.

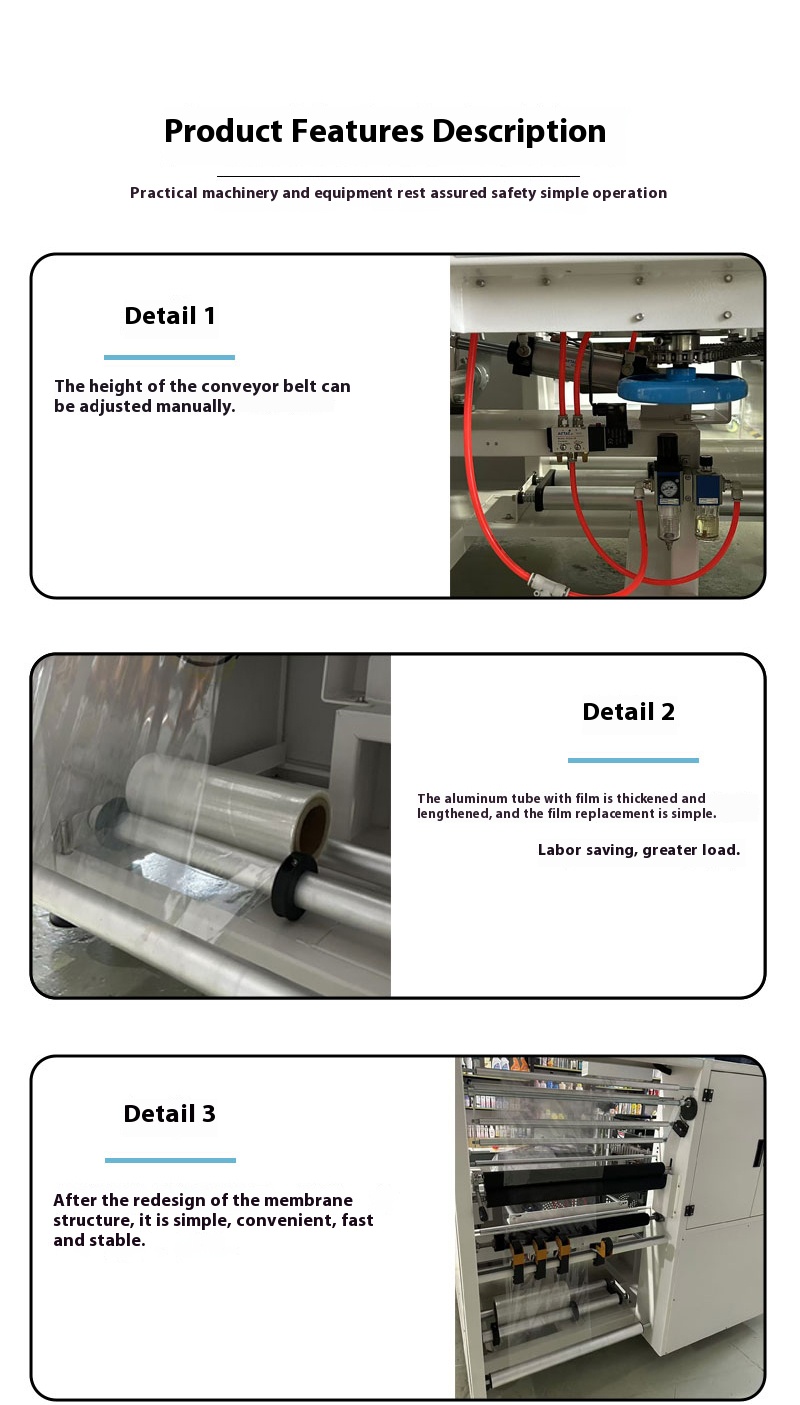

Equipped with multiple safety devices such as emergency stop buttons, sealing knife anti-scald protective covers and over-temperature alarms to ensure the personal safety of operators. The key components of the equipment adopt standardized design with a simple structure for easy disassembly. Daily cleaning, film replacement and maintenance do not require professional technicians, greatly reducing equipment operation and maintenance costs and downtime.

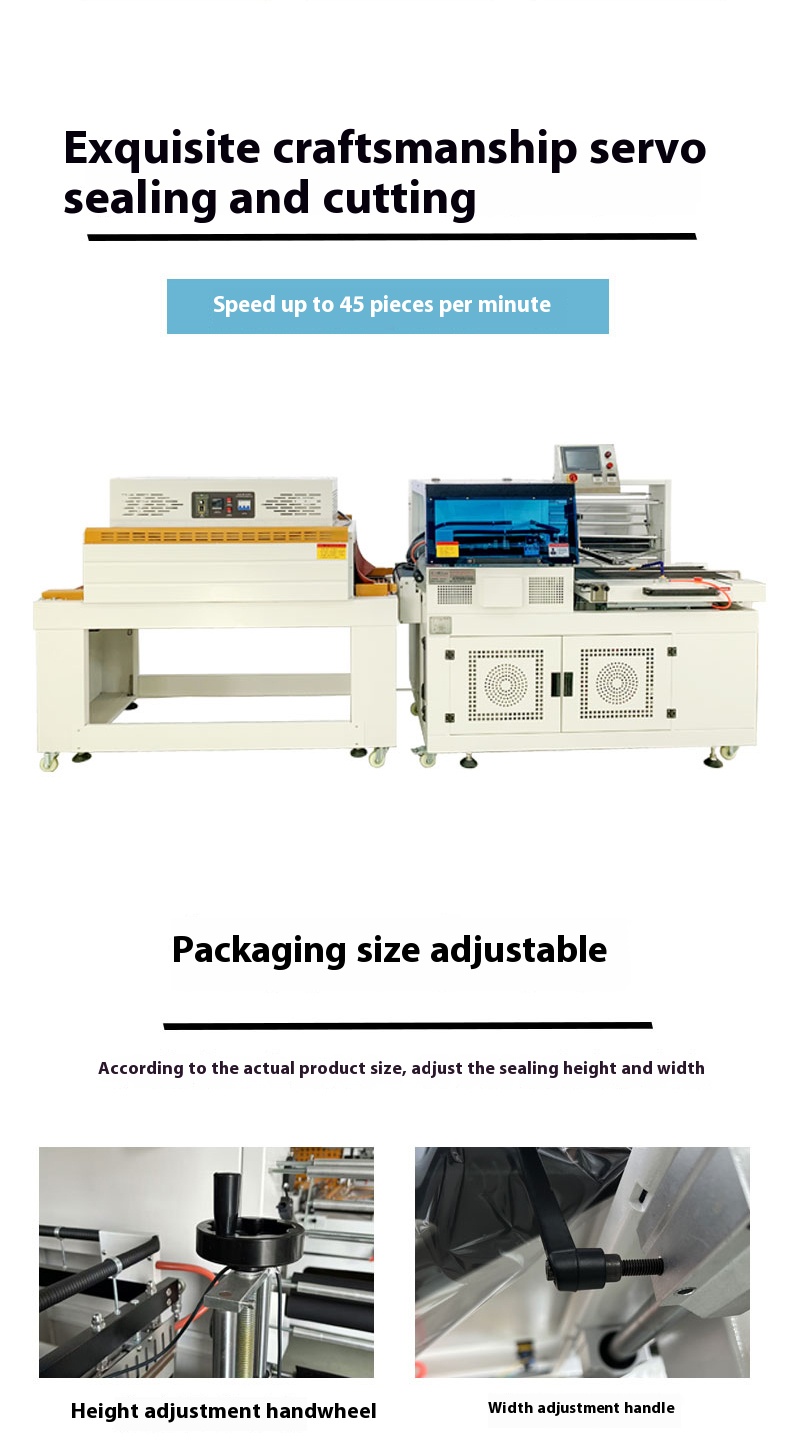

The packaging speed of a single equipment can reach 20-60 pieces per minute, which can be adjusted according to product size and packaging requirements. Taking boxed skin care products in the daily chemical industry as an example, this equipment can achieve stable packaging of 40 pieces per minute, with a daily output (based on an 8-hour working system) of up to 19,200 pieces, increasing the capacity by more than 3 times compared with semi-automatic equipment, meeting the delivery needs of enterprises' large-scale production.

It can be flexibly connected with upstream equipment such as automatic material arranging machines, case erectors and case packers, integrating into the whole-plant automated packaging line to realize unmanned operation throughout the process from product offline, packaging to palletizing. It eliminates the efficiency bottleneck of manual transfer links, greatly shortens the product packaging cycle and improves the operation efficiency of the overall production line.

For the production needs of multiple batches and small batches, the equipment is equipped with a touch-screen operation interface with preset packaging parameters for various commonly used products. When changing product specifications, it only needs to call up the corresponding parameter template or simply adjust the parameters, and the commissioning time can be controlled within 5-10 minutes. Compared with the commissioning time of more than 30 minutes for traditional equipment, it greatly reduces the efficiency loss caused by changeover downtime.