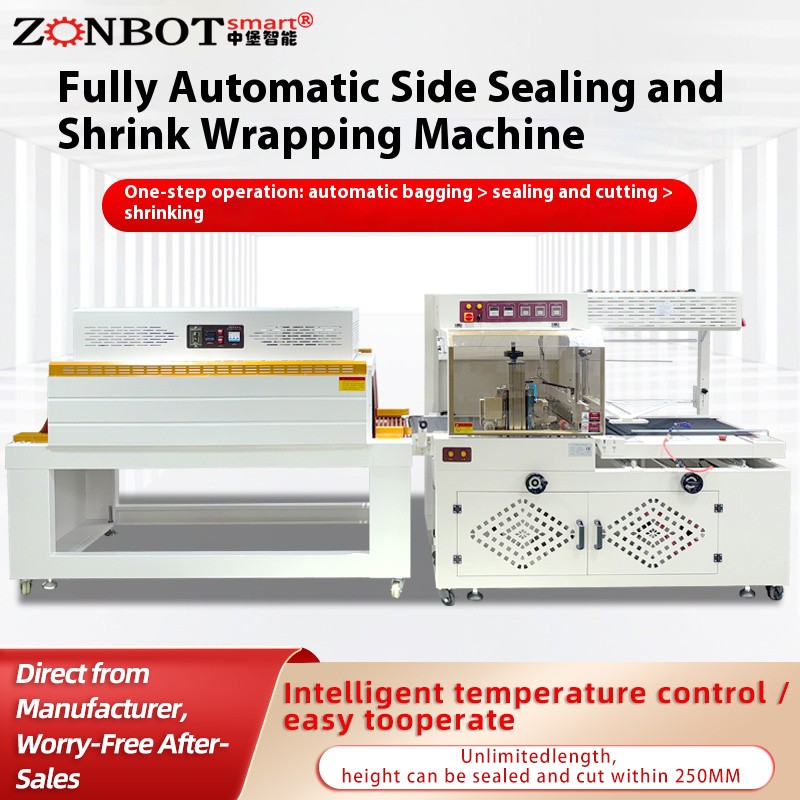

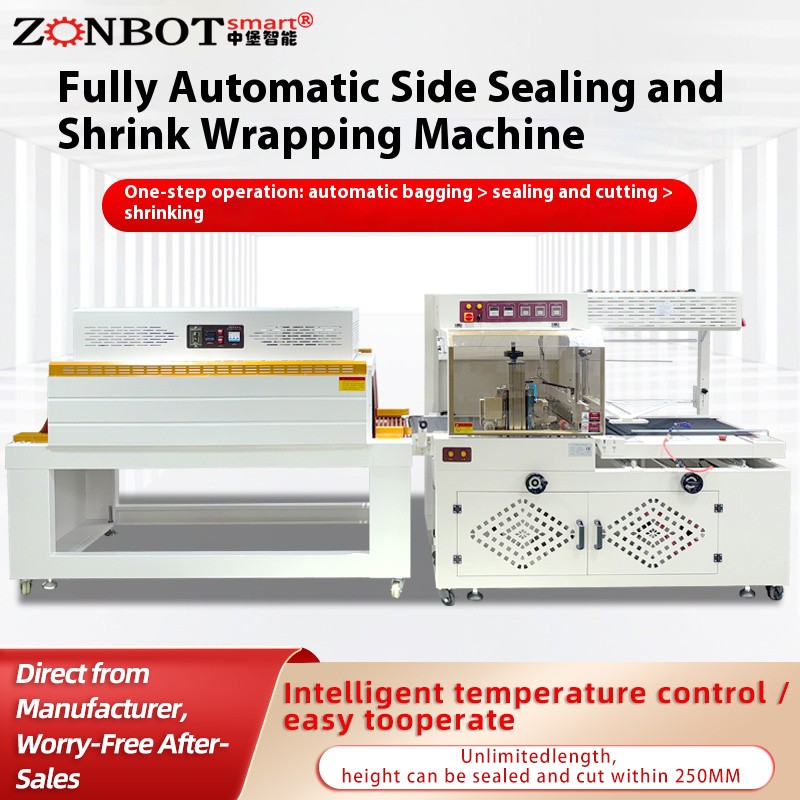

Automatic sealing and cutting heat shrink packaging machine, tableware and cosmetics plastic sealing machine, 550 side sealing machine, heat shrink film shrinking machine

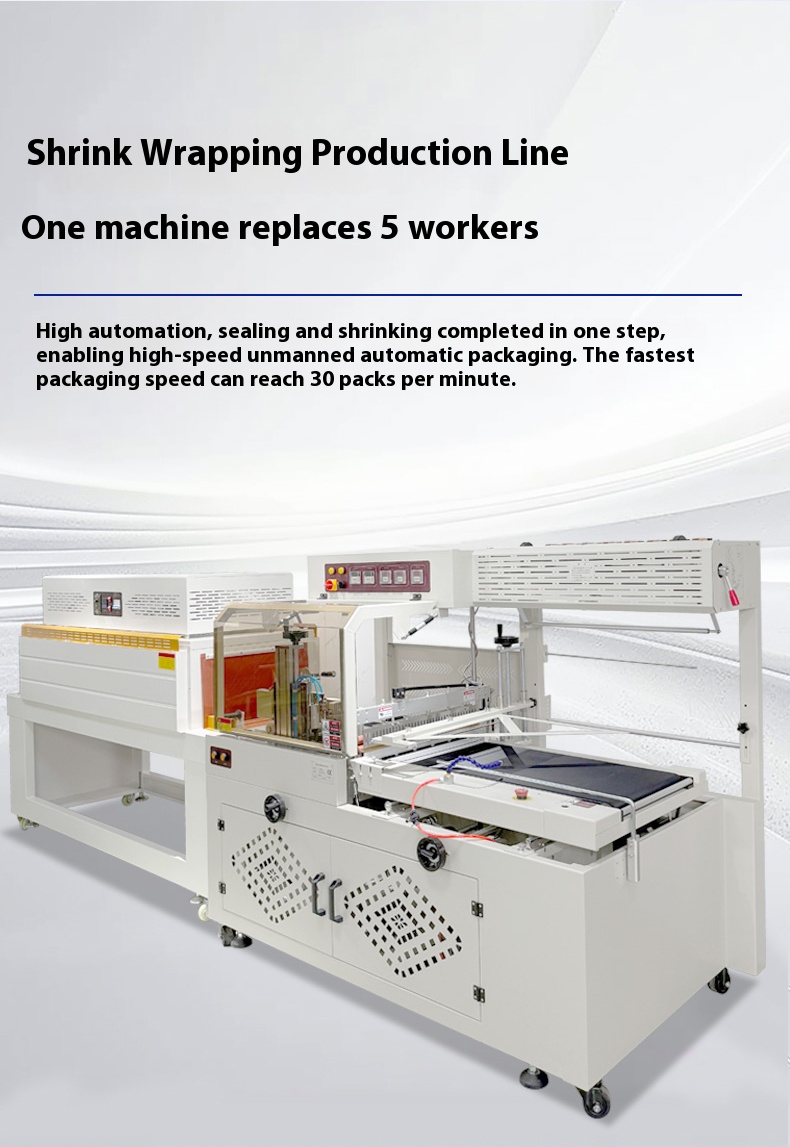

The automatic side sealing heat shrink packaging machine is a high-efficiency packaging equipment that integrates the functions of "automatic sealing and cutting" and "heat shrink shaping". Relying on full-process automation and multi-scenario adaptability, it has become a core device for industries to achieve standardized product packaging. Its core value lies in replacing manual operations with mechanical automation while balancing protection and aesthetics. The following is an explanation from three dimensions: core advantages, key technical features, and practical application value.

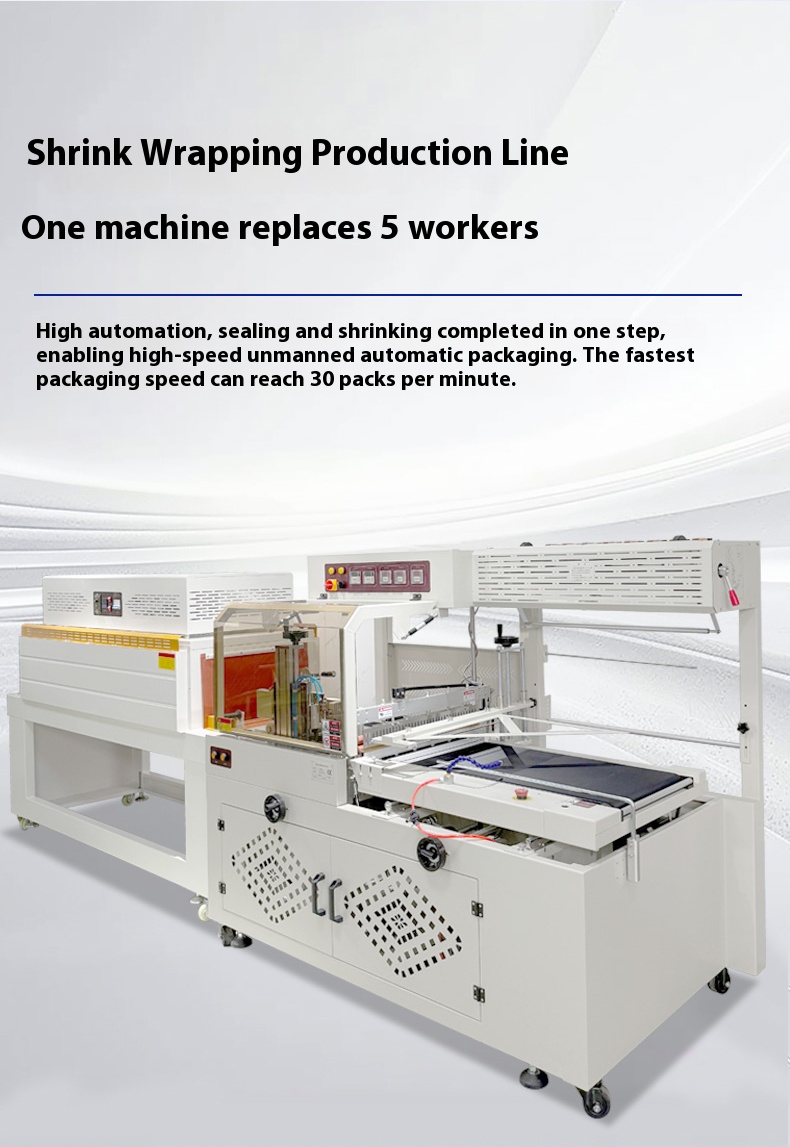

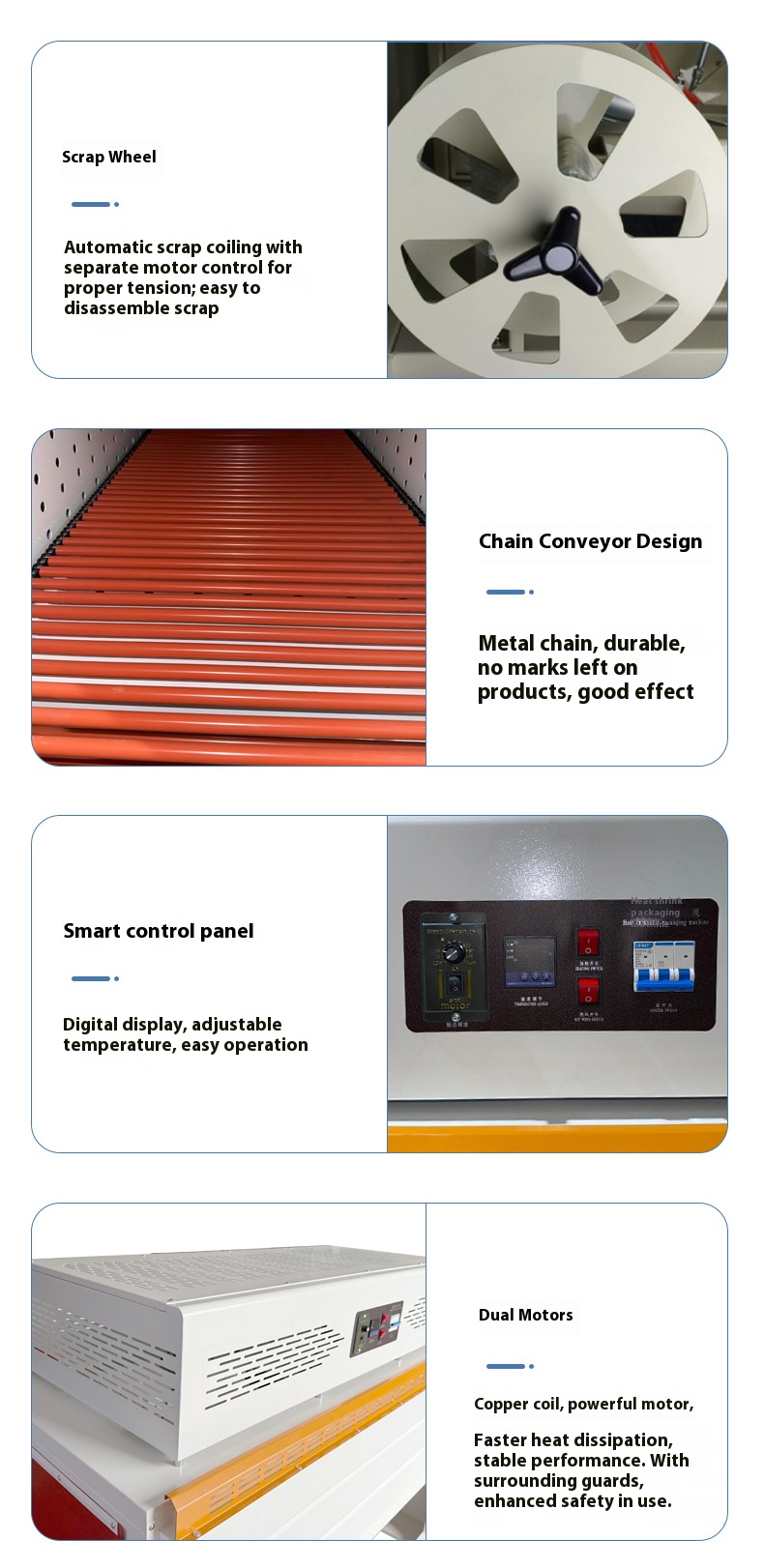

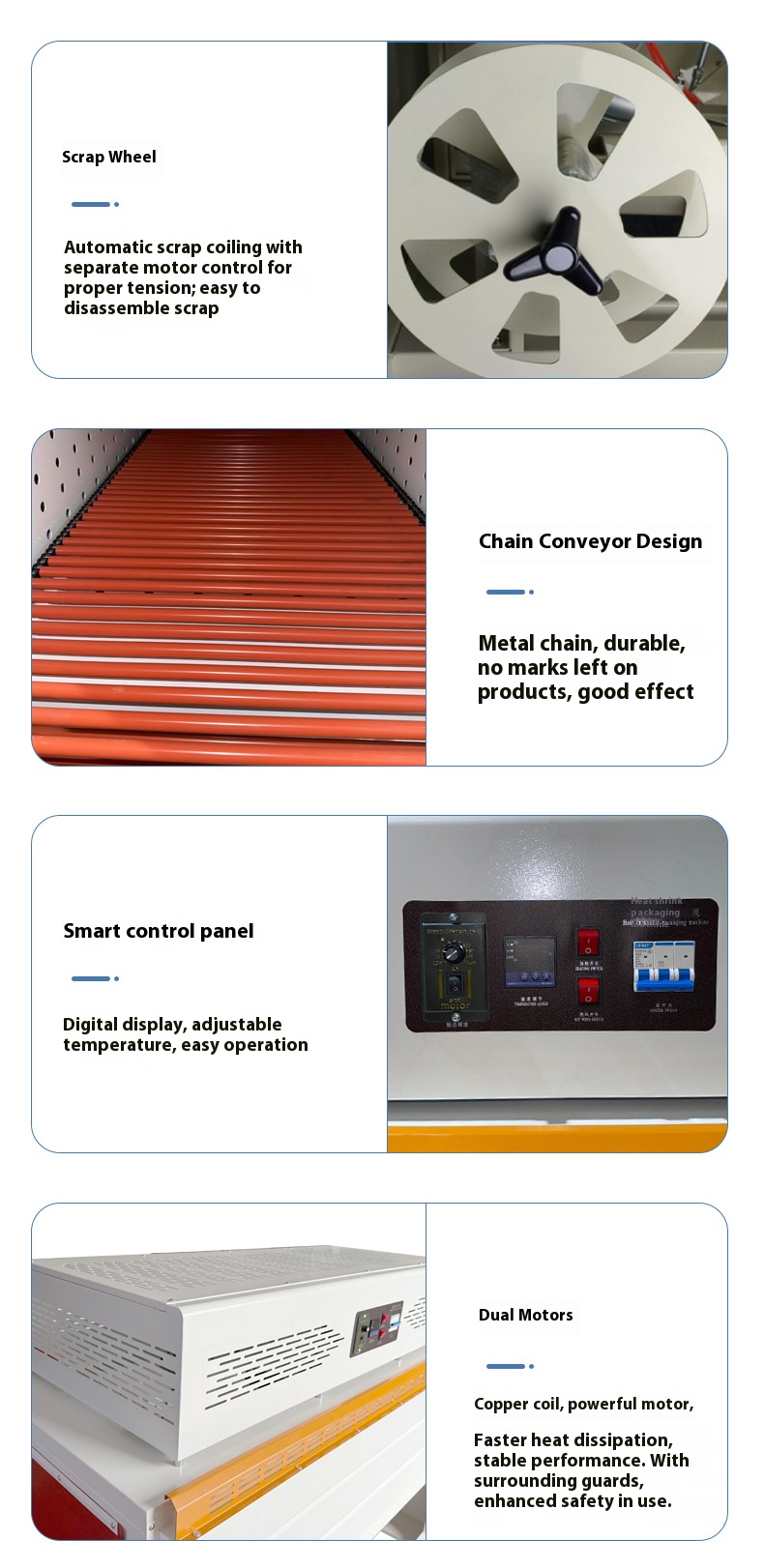

The equipment can independently complete the entire process of "film feeding → product positioning → vertical/horizontal sealing and cutting (including automatic waste recycling) → heat shrink tunnel heating → finished product conveying" without manual intervention at any stage. For example, when packaging multi-pack beverages, it is only necessary to place the products in batches on the feeding conveyor line. The machine will automatically align the products, match the film width, and precisely control the sealing and cutting temperature as well as the shrink time. A single piece of equipment can replace 2-3 manual workers, with a packaging efficiency of 10-80 pieces per minute (depending on the model). At the same time, it avoids problems such as misalignment in sealing and cutting and film waste caused by manual operations.

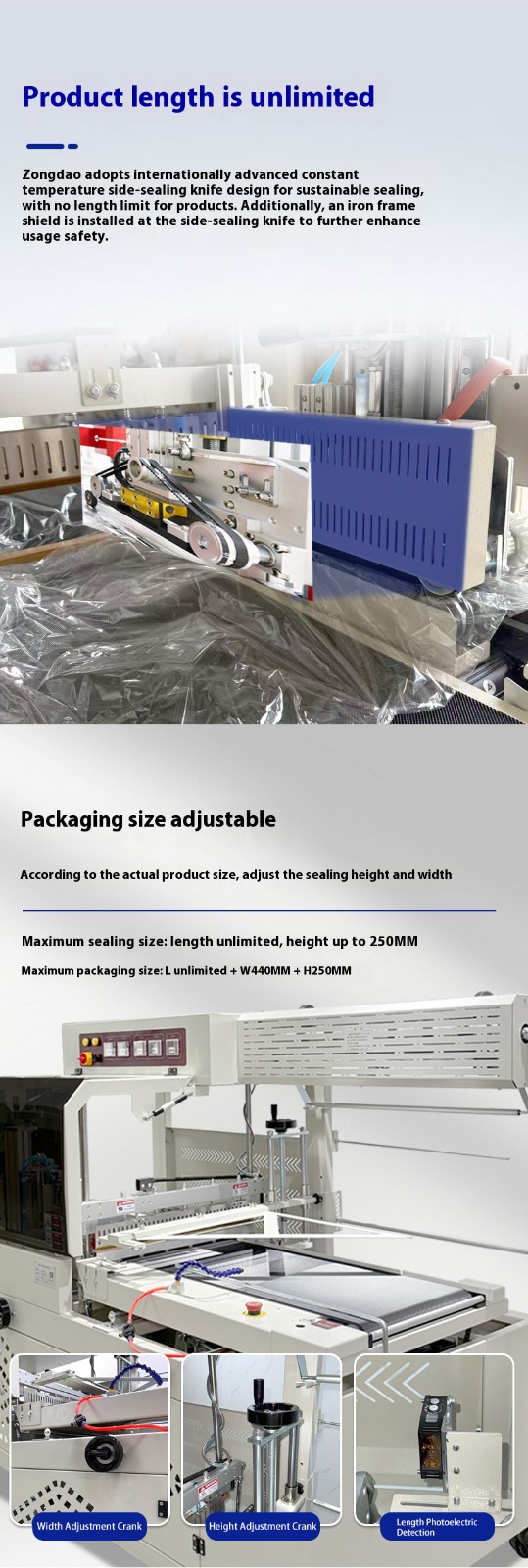

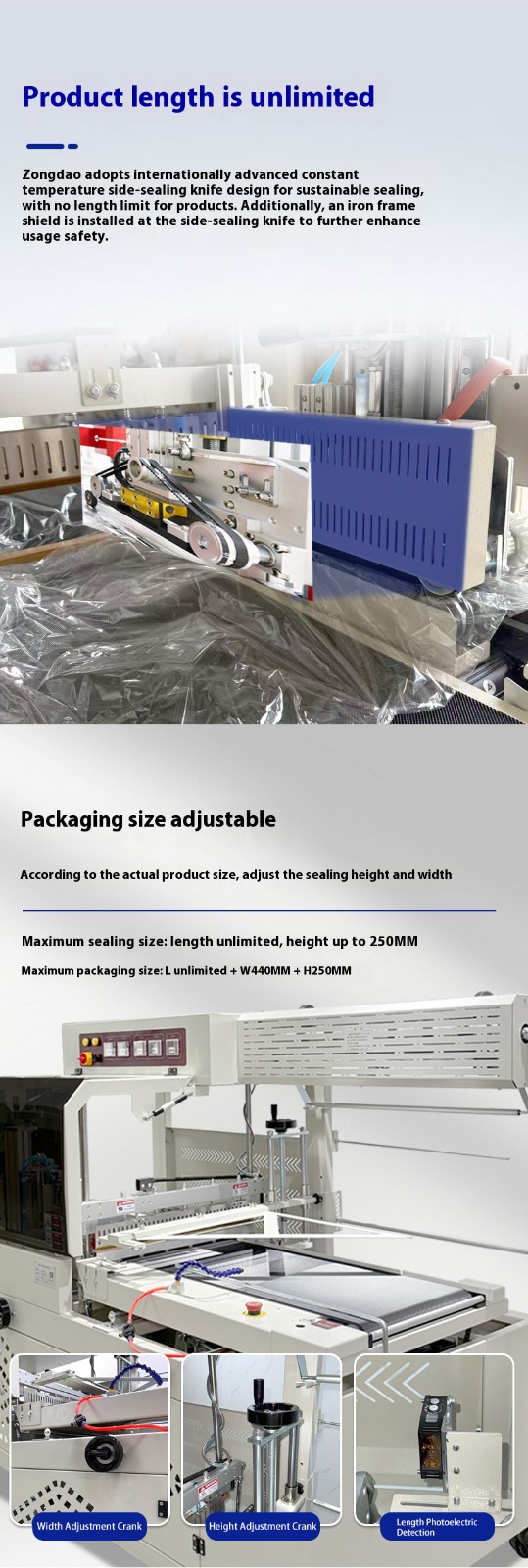

It can be adapted to regular products (such as boxed medicines, square cosmetics), irregular products (such as toy accessories, hardware tools), single products (single lipstick), and combined products (6-pack mineral water) by adjusting parameters. Meanwhile, it is compatible with mainstream shrink films such as POF (environmentally friendly and transparent), PE (puncture-resistant), and PVC (low-cost), meeting the protection and compliance requirements of different industries such as food, pharmaceuticals, electronics, and daily chemicals, without the need for frequent replacement of core components.

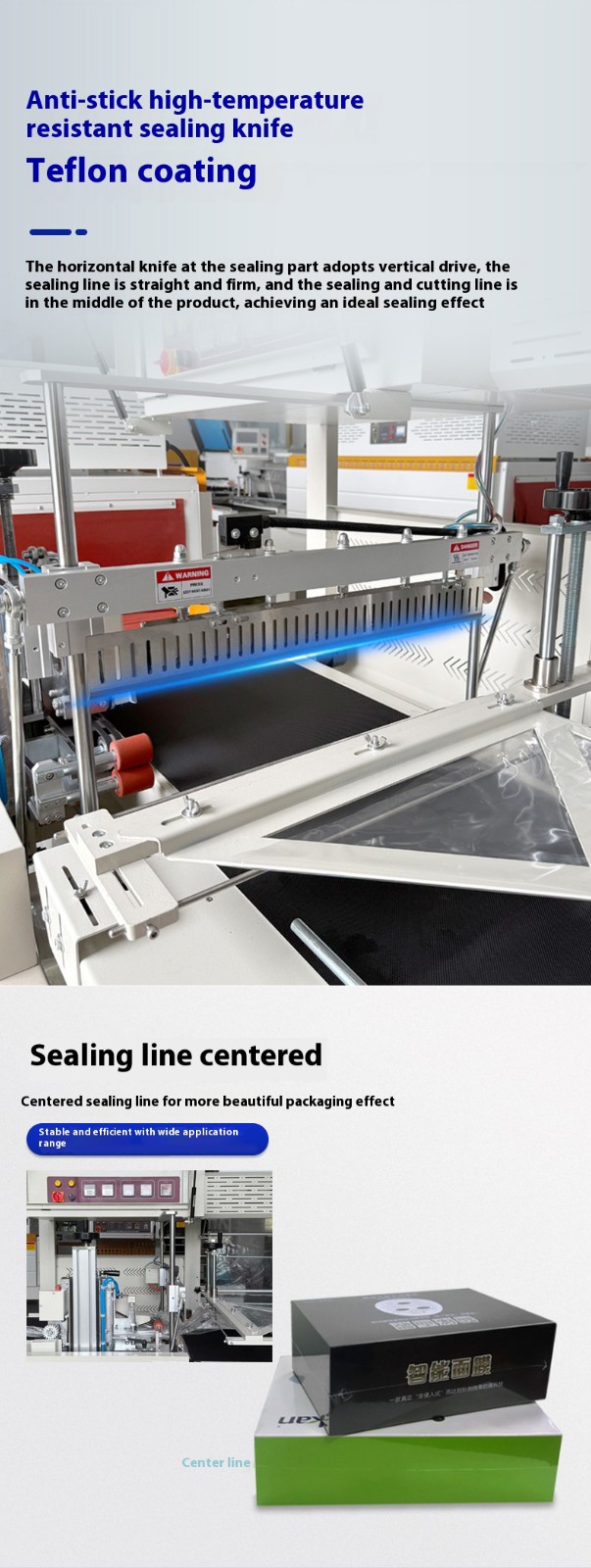

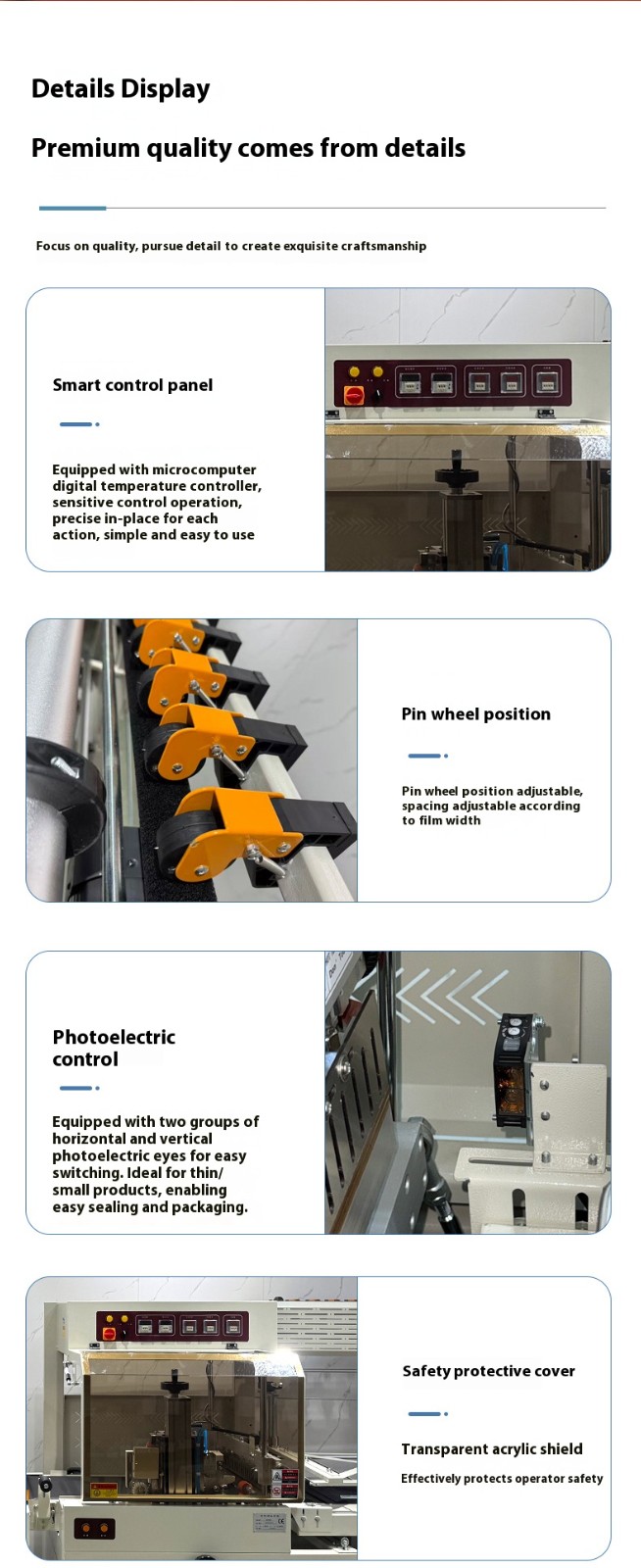

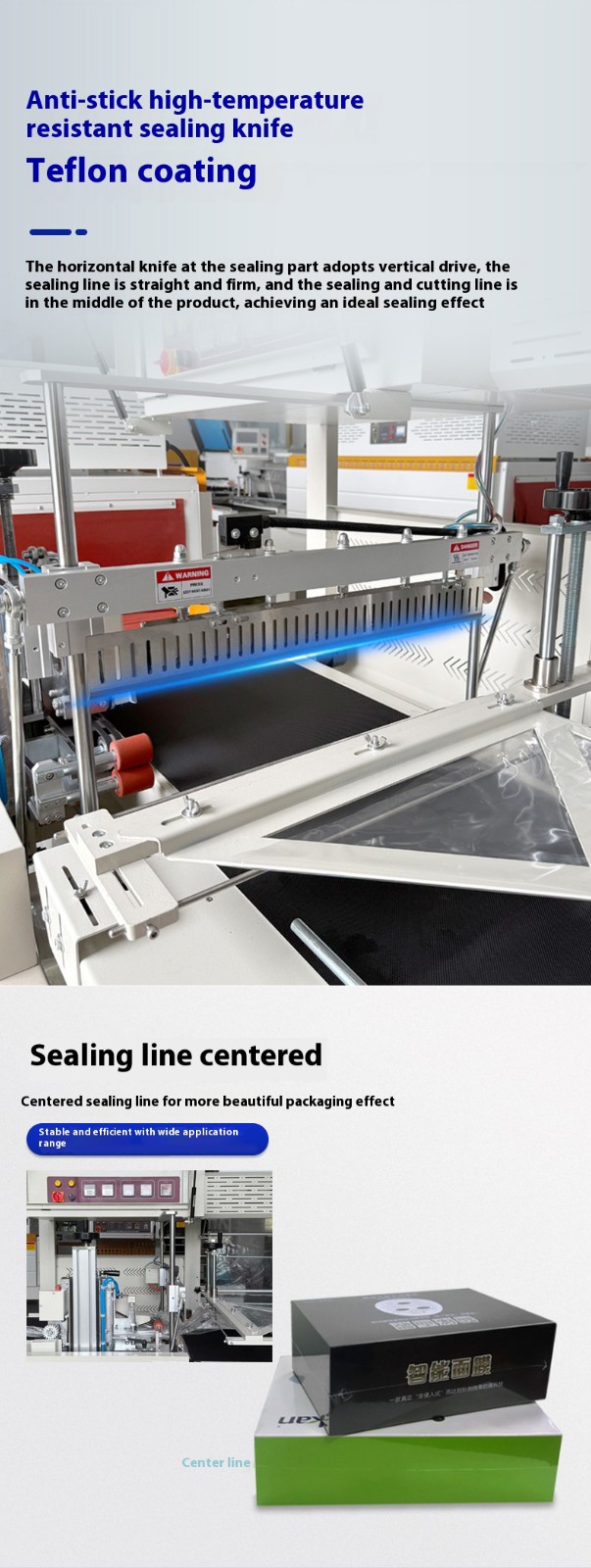

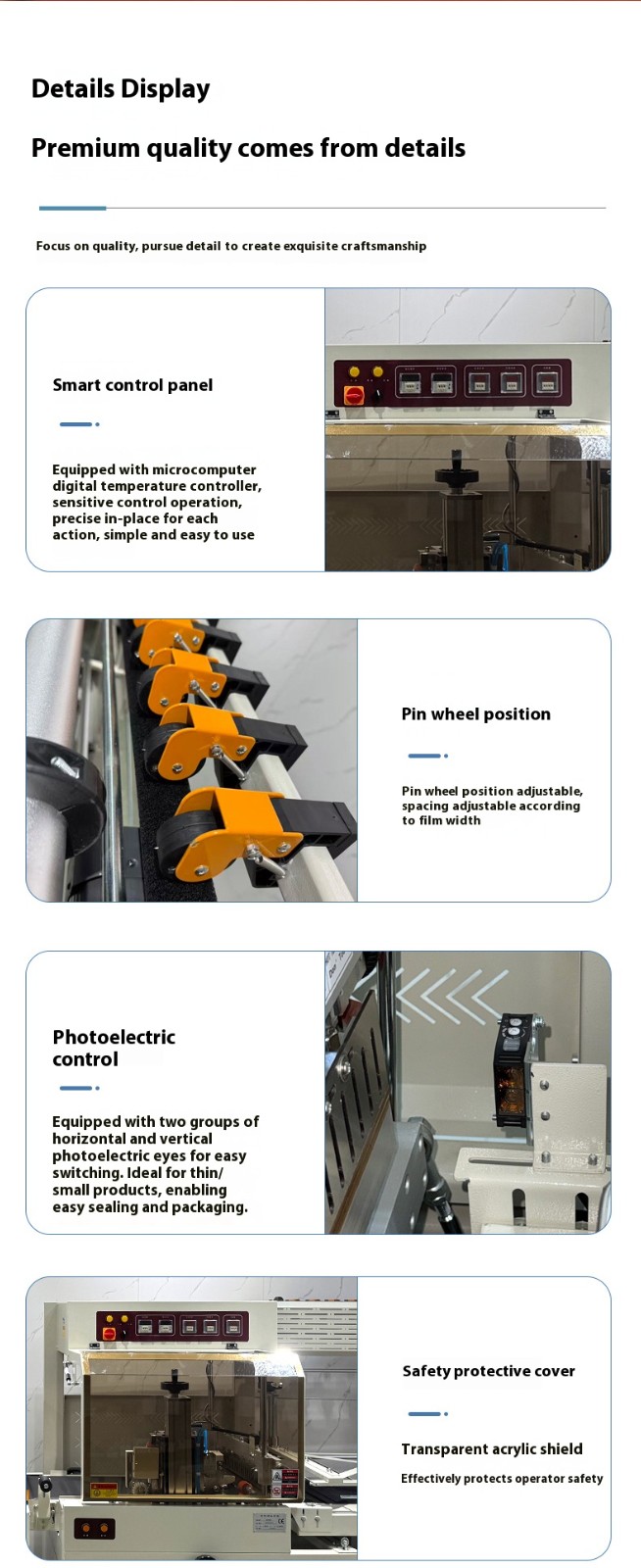

It adopts a design of constant-temperature vertical sealing knife + vertical horizontal sealing knife. The sealing and cutting temperature can be precisely adjusted according to the film material (80-200℃), ensuring straight sealing lines without leakage or scorching. Some models are equipped with an "automatic deviation correction device" that can adjust the film position in real time to avoid packaging skewing caused by film deviation, making it particularly suitable for the food and pharmaceutical industries with high sealing requirements.

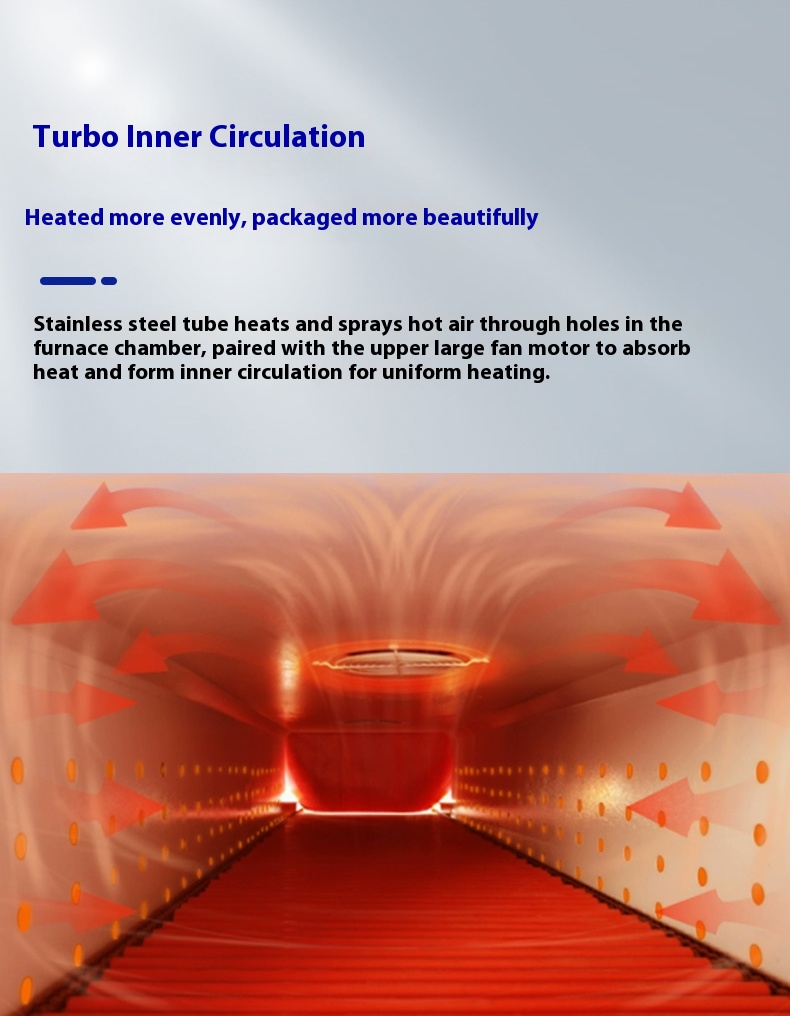

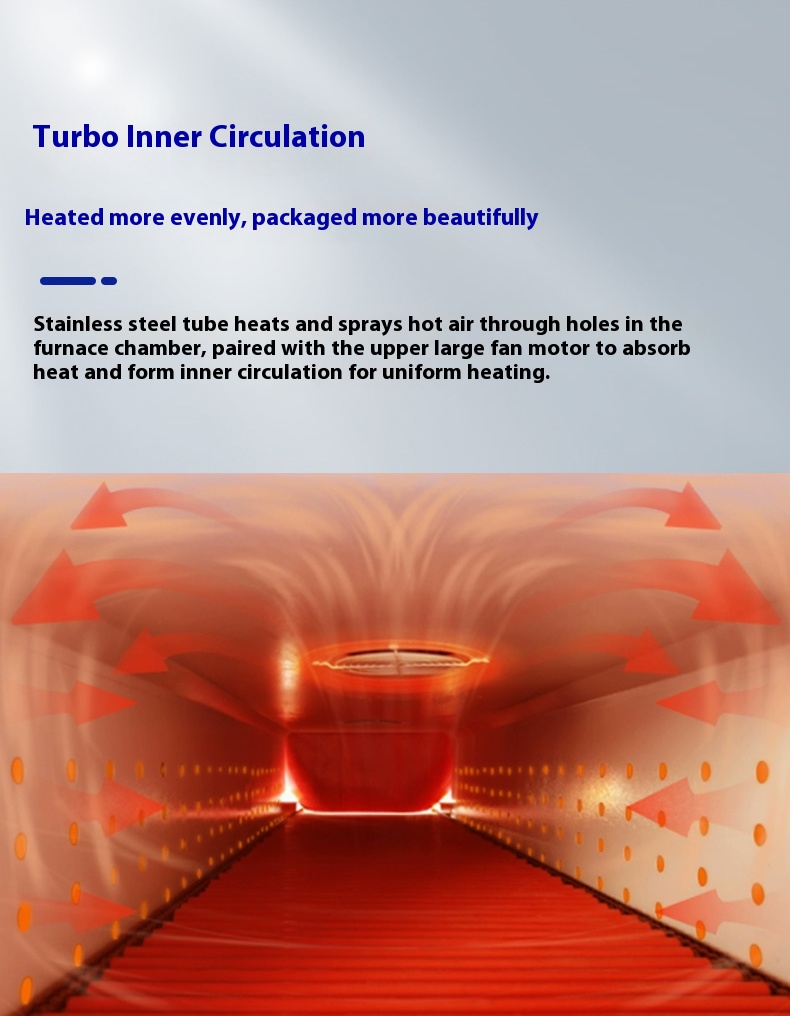

The heat shrink tunnel is equipped with built-in hot air circulation fans and multiple groups of heating tubes, forming a uniform high-temperature air flow field. This prevents film wrinkling or product deformation caused by local overheating. Most tunnels are equipped with a viewing window on the top for real-time observation of the shrink effect. At the same time, the conveyor speed can be adjusted (linked with the heating temperature) to adapt to the shrinkage needs of products with different thicknesses (e.g., thin-walled toys vs. thick-walled home appliance accessories).

Equipped with a PLC (Programmable Logic Controller) and a touchscreen, it allows one-click setting of parameters such as packaging speed, sealing and cutting temperature, and film feeding length. It also supports storage of 10-20 groups of parameters (e.g., direct recall when switching between "biscuit packaging" and "shampoo packaging"). Additionally, it has a built-in fault alarm function (e.g., film exhaustion, abnormal temperature), reducing downtime for troubleshooting and lowering the technical requirements for operators.

Through tight wrapping with heat shrink film, it can achieve moisture resistance (e.g., electronic components), dust resistance (e.g., cosmetics), anti-collision (e.g., hardware tools), and anti-scattering (e.g., combined stationery sets). It is especially suitable for long-distance transportation or warehouse stacking scenarios, reducing the product damage rate.

Transparent shrink film can fully display the product appearance (e.g., gift-boxed food, toys), and the seal is flat without wrinkles, appearing more neat compared to traditional manual packaging. Some models support the integration of coding/printing modules, which can print information such as production date and batch number on the film, balancing compliance and brand display.