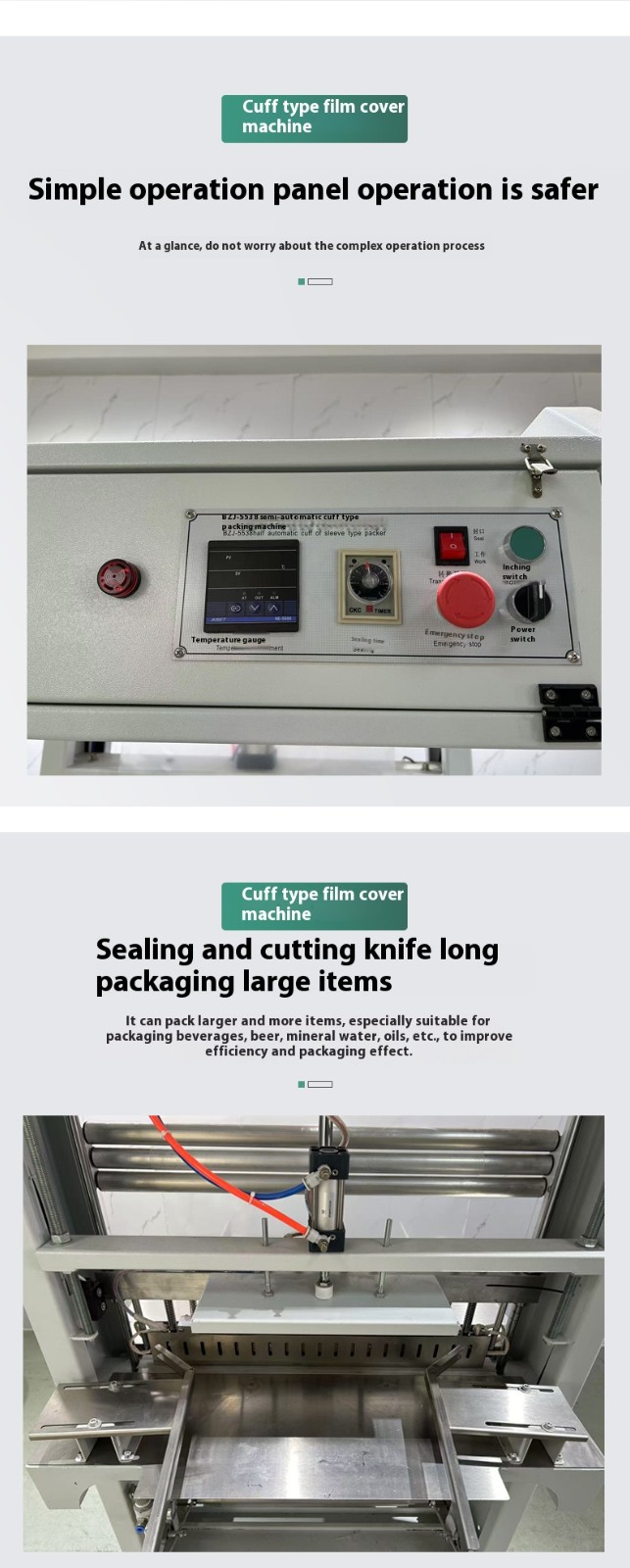

After the products enter the machine via the conveyor belt, the film is automatically wrapped around the exterior of the products. It then undergoes high-temperature sealing and cutting by electric heating wires to form a sleeve-shaped package. Subsequently, the package enters the heat-shrinking tunnel, where high temperature is used to make the film shrink evenly and adhere tightly to the product surface, completing the three-step packaging process of "film sleeving - sealing & cutting - heat shrinking".

- By automation level: It can be divided into semi-automatic sleeve-type heat-shrink packaging machines and fully automatic sleeve-type heat-shrink packaging machines. The semi-automatic type requires manual assistance for product placement or sealing operations, and is suitable for small and medium-scale production; the fully automatic type completes the entire process of conveying, sealing & cutting, and shrinking automatically, making it suitable for large-scale production.

- By sealing technology: It includes heat-sealing sleeve-type packaging machines and cold-sealing sleeve-type packaging machines. Heat-sealing sleeve-type packaging machines achieve sealing by heating the sealing strip, and are applicable to heat-shrinkable films such as PE and POF; cold-sealing sleeve-type packaging machines use pressure to bond cold-sealing materials without the need for heating, and are suitable for temperature-sensitive products.

- By forming method: There are sleeve-type packaging machines and fully enclosed packaging machines. Sleeve-type packaging machines form a "sleeve" structure by wrapping the film, and are suitable for single-row/multi-row packaging of bottled beverages and other products; fully enclosed packaging machines allow the film material to completely wrap the products before shrinking, providing stronger sealing performance.

- By film material compatibility: The main types are machines compatible with PE films and machines compatible with POF films. PE films have strong puncture resistance and are suitable for heavy-duty packaging; POF films have high transparency and excellent shrinkage performance, and are mostly used in industries with high hygiene standards such as food and pharmaceuticals.

- High efficiency and energy saving: It adopts infrared radiation or quartz tube heating technology, which saves 30%-50% more energy compared with traditional electric heating wires. It also heats up faster and has a service life of 5-10 years.

- Strong compatibility: It can be adapted to various product shapes such as square, circular and irregular shapes, and supports multi-row combined packaging. The mode can be switched with one click through the control panel, and it only takes 2-3 minutes to change specifications.

- Environmental protection and safety: It uses non-toxic PE/PVC film materials that meet FDA and ROHS standards. There is no smoke or odor during the sealing and cutting process, and it is equipped with fire and explosion prevention devices to ensure operational safety.

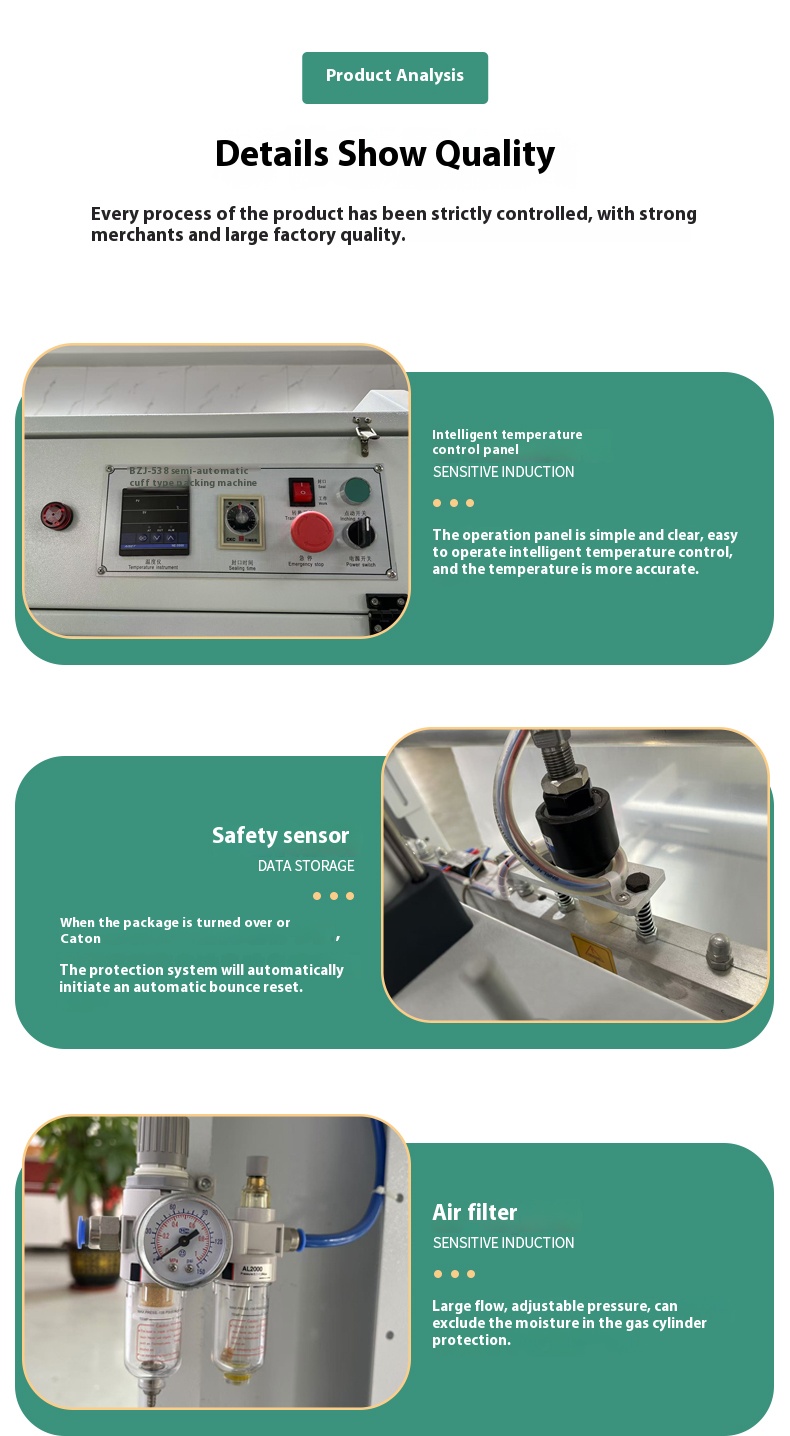

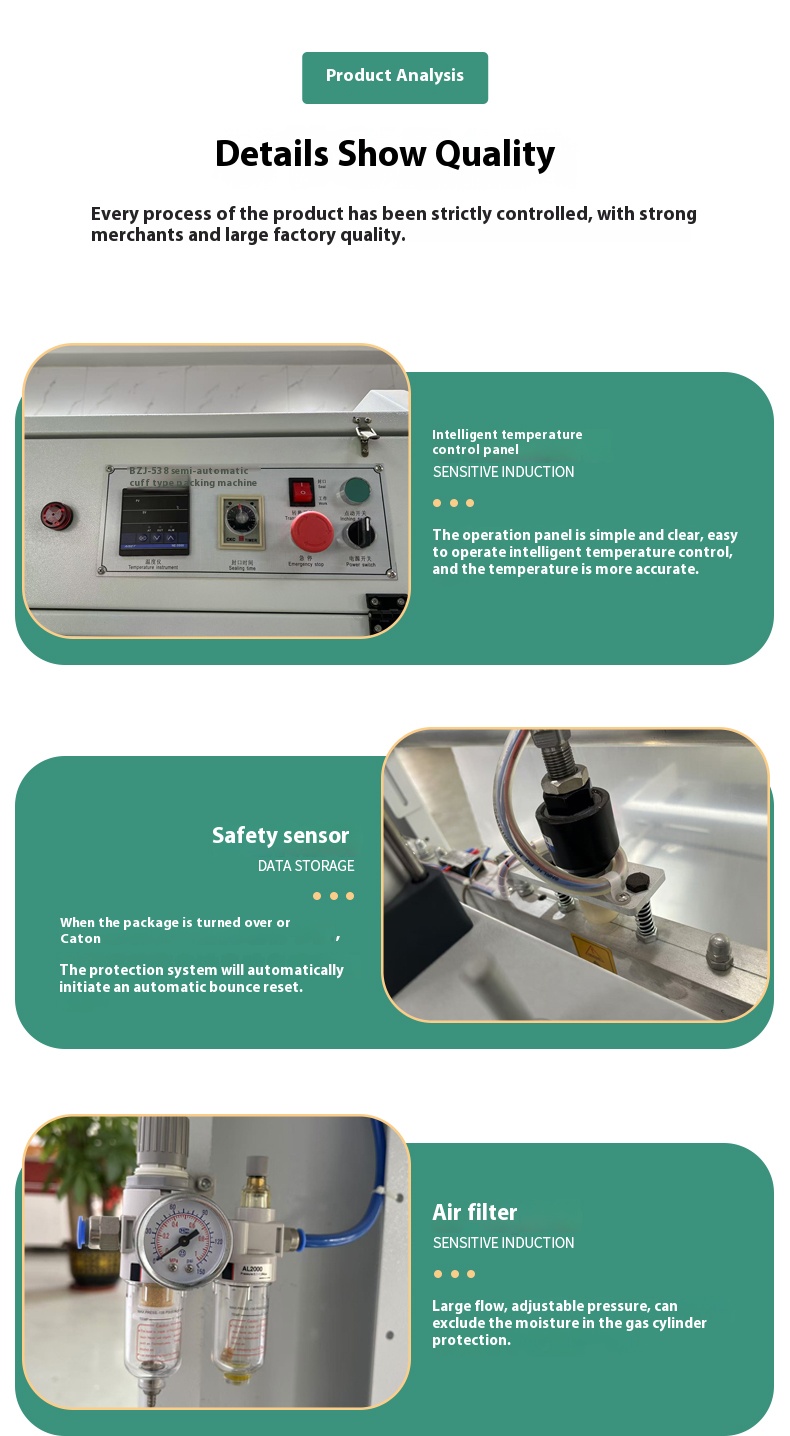

- High intelligence level: The touch screen man-machine interface and PLC program control realize precise parameter adjustment and fault self-detection. The modular structure facilitates the replacement of vulnerable parts, reducing maintenance costs by 40%.

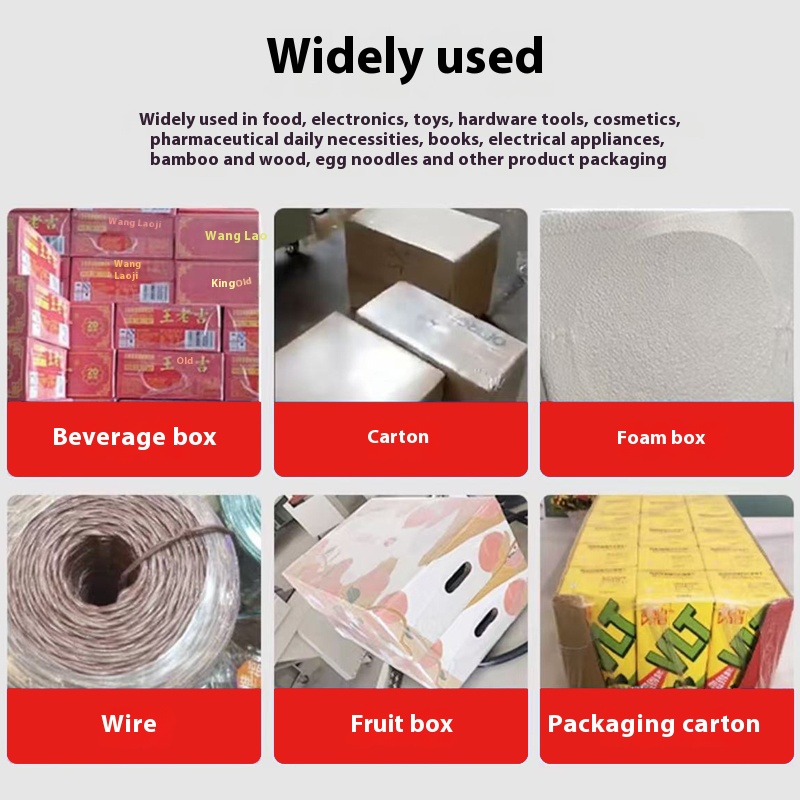

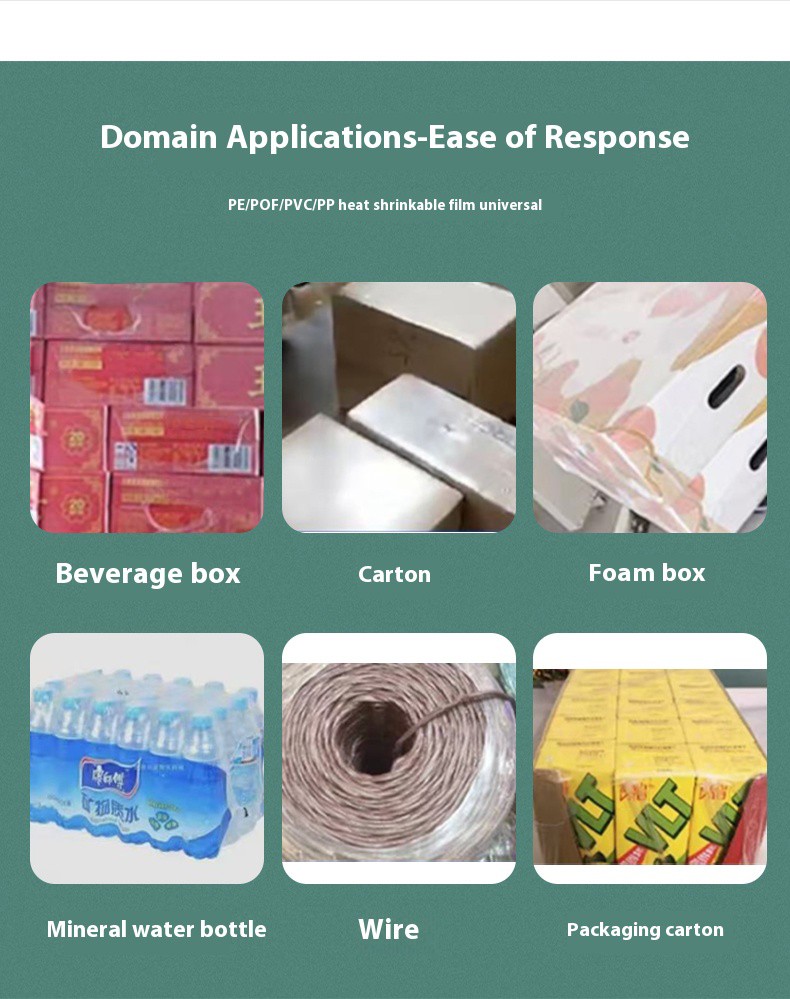

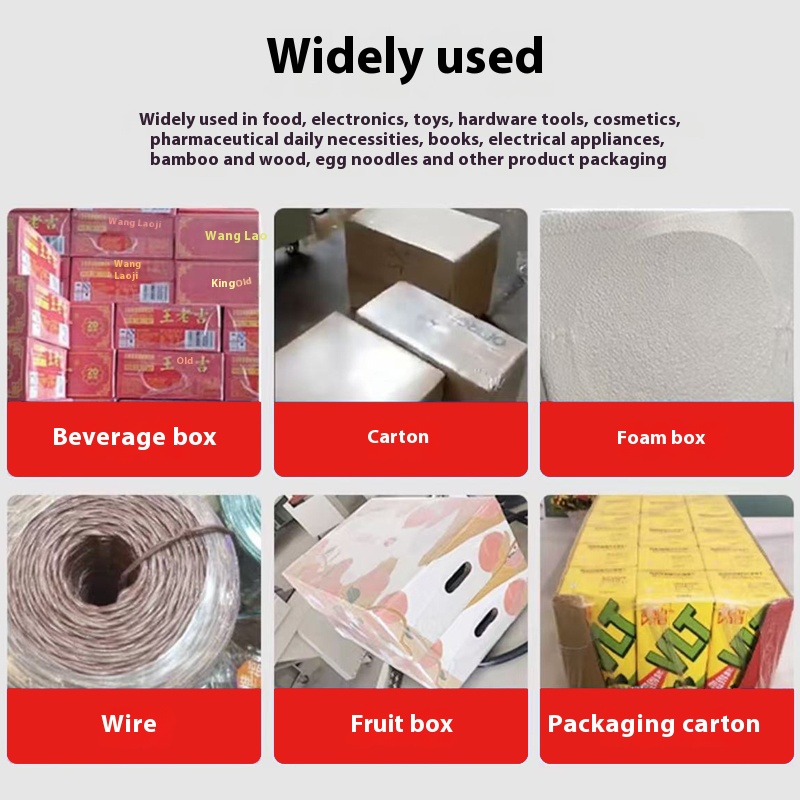

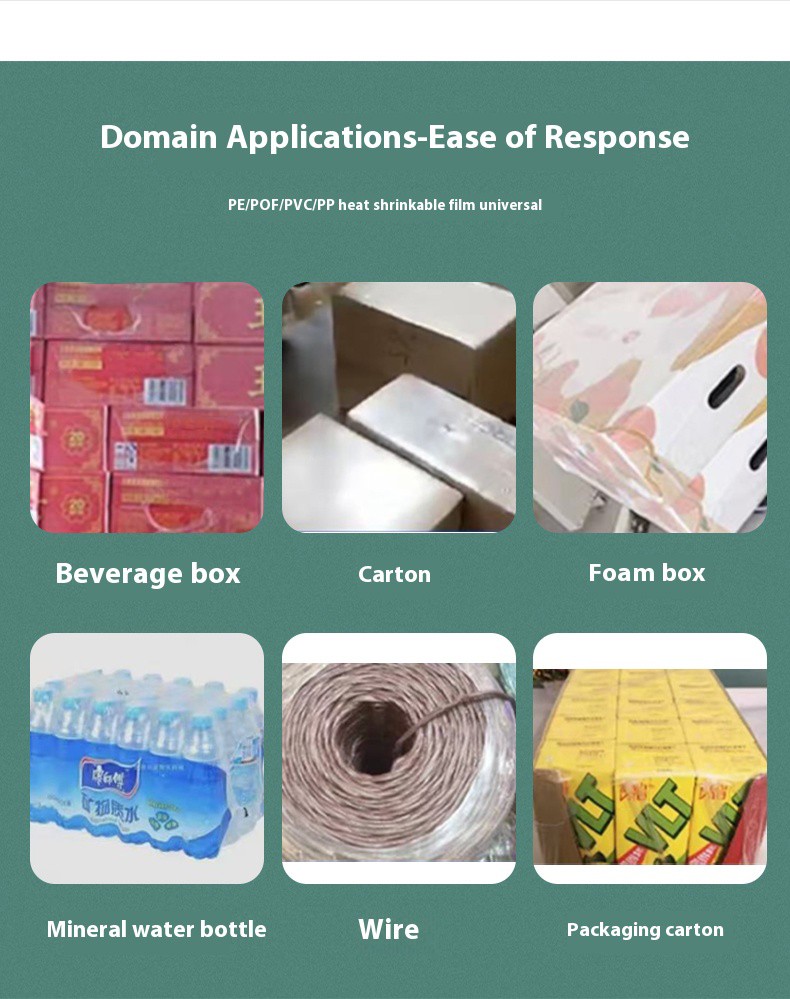

It is widely used in industries such as food and beverage, daily chemicals, pharmaceuticals, and industrial and electronic products. For example, in the food and beverage industry, it is used for bottomless combined packaging of mineral water and beer; in the daily chemical industry, it is used for sealed packaging of cosmetic bottles; in the pharmaceutical industry, it is used for packaging of medicine boxes. It can not only protect products from transportation damage, but also display the appearance of products through the transparent film, enhancing the brand image.