The shrinkage temperature and time of the shrink wrapping machine have a significant impact on the packaging effect, which is specifically as follows:

Shrinkage Temperature

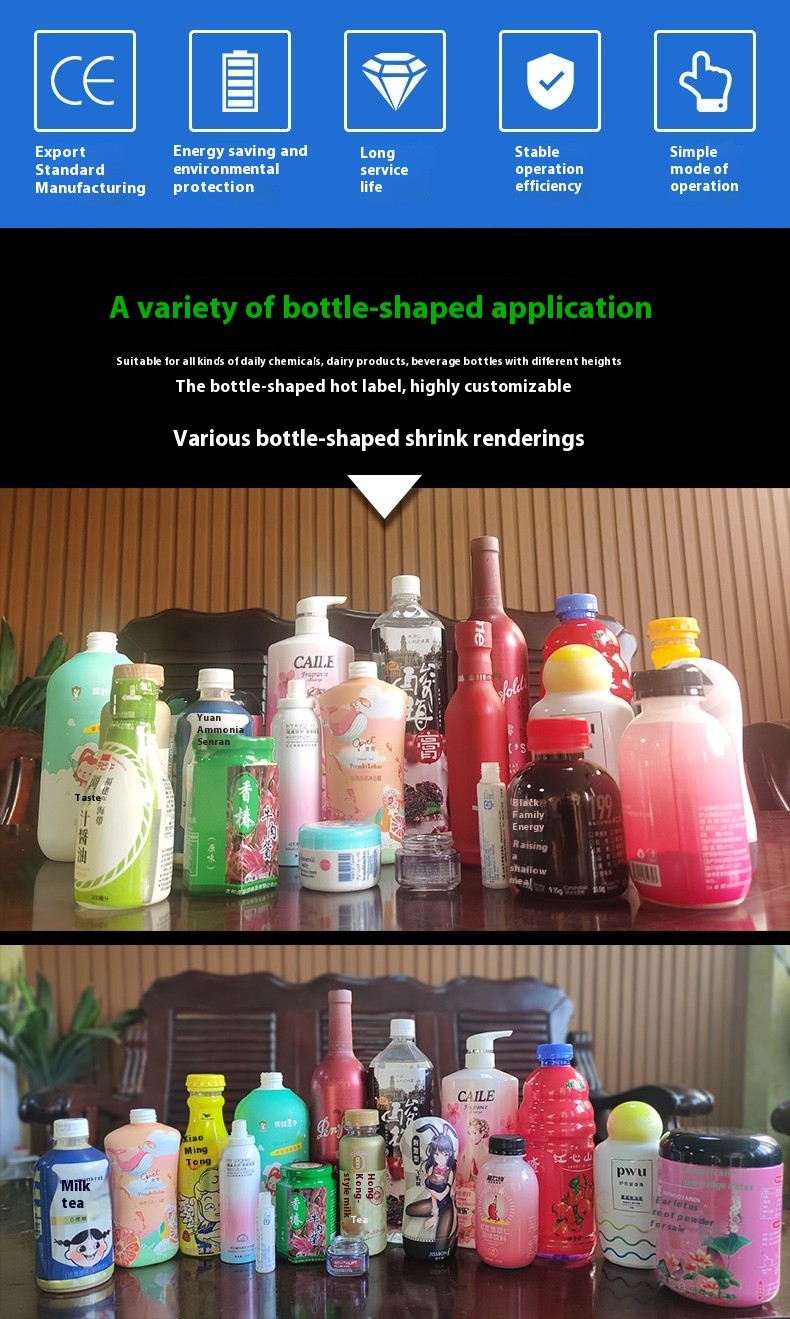

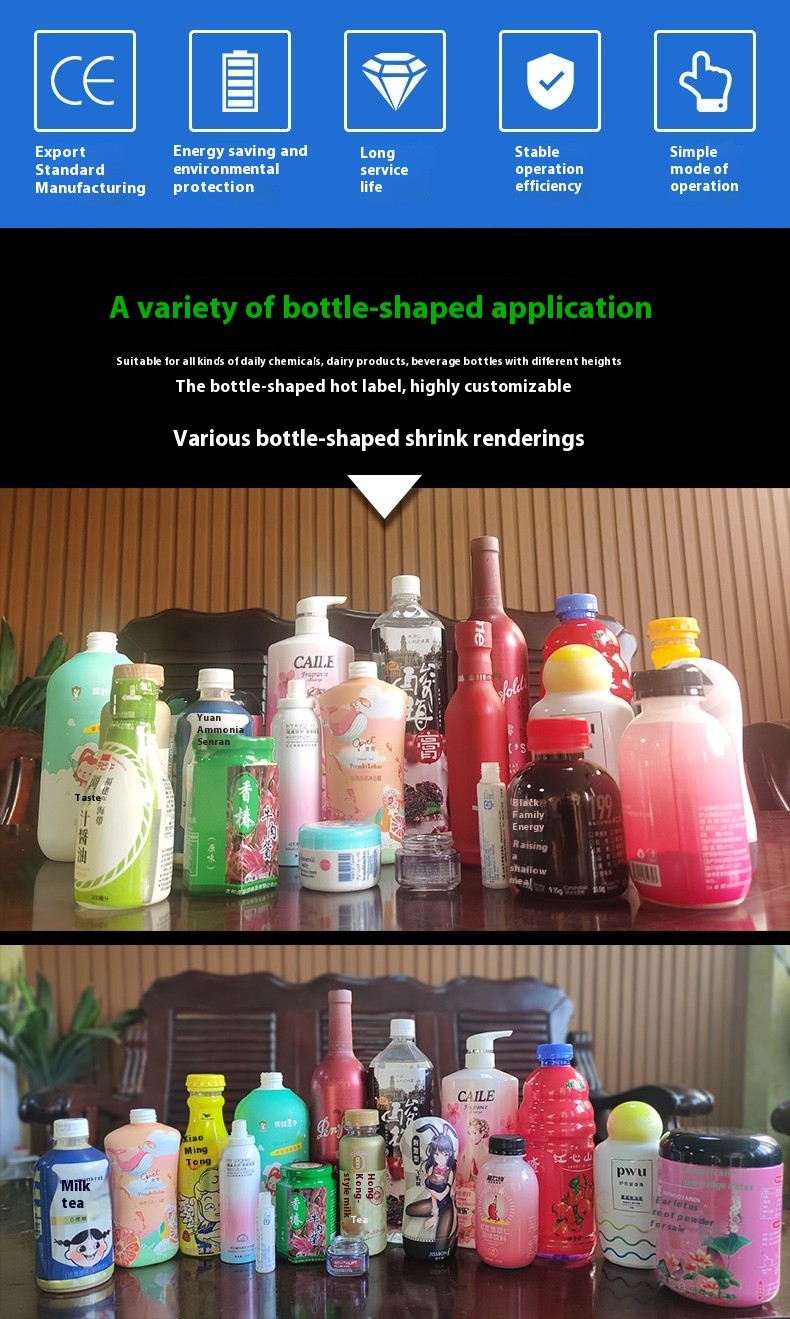

- Too Low Temperature: The heat shrinkable film cannot be fully softened by heating, and it cannot shrink and adhere closely to the surface of the items. This will lead to gaps between the film and the items, resulting in loose packaging and an uneven appearance. It will affect the aesthetic appeal and protective performance of the product packaging. For example, in the food and beverage industry, if the shrinkage temperature of the labels on bottled beverages is too low, the labels will wrinkle and fail to fit the bottle body properly, affecting the overall image of the product.

- Too High Temperature: It may cause the heat shrinkable film to shrink excessively, resulting in a thinner film thickness and a decrease in strength. As a result, problems such as cracking and perforation are likely to occur. Moreover, for some items that are sensitive to temperature, too high a temperature may damage the items themselves. For instance, in the cosmetics industry, too high a shrinkage temperature may cause the packaging bottles of cosmetics such as lotions and creams to deform, and may even lead to the deterioration of the products.

Shrinkage Time

- Too Short Time: The film does not have enough time to complete the shrinkage process, resulting in incomplete shrinkage. Similarly, there will be situations where the packaging is not tight and the film does not adhere firmly to the surface of the items. Taking the hardware and electronics industry as an example, if the shrinkage time of the packaging boxes for electronic products is too short, the shrink film may not be able to completely wrap all the corners of the boxes, making the packaging prone to damage during transportation.

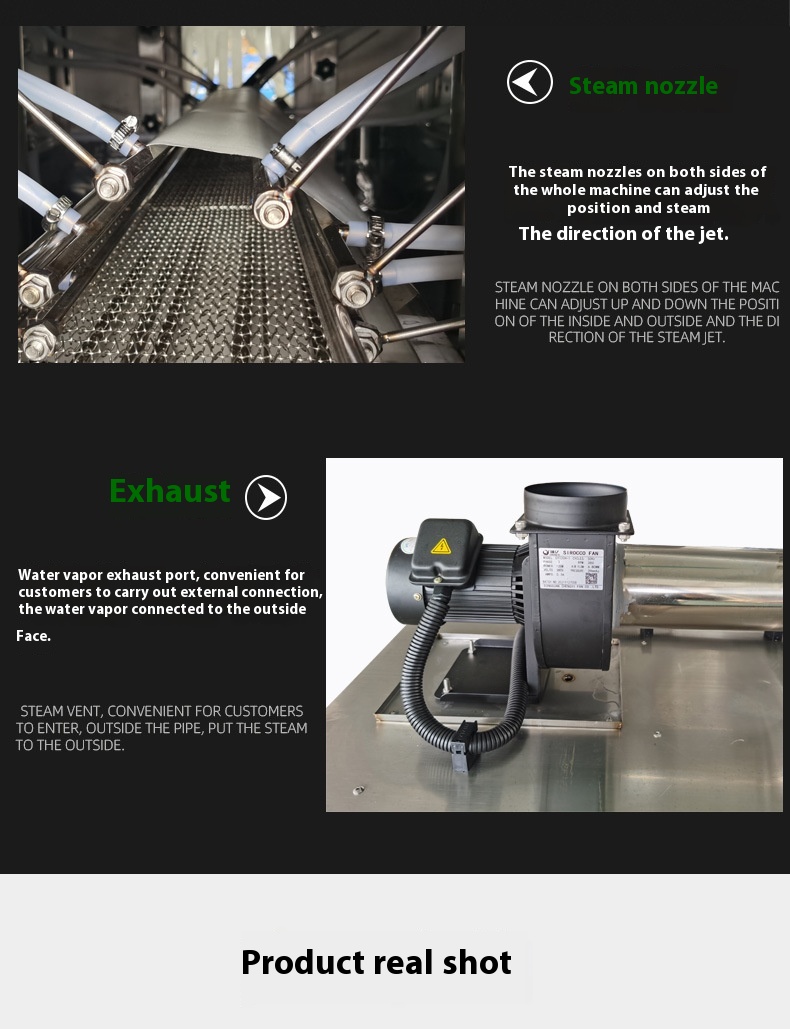

- Too Long Time: The film will be in a high-temperature state for a long time, which will not only increase energy consumption but also cause the film to turn yellow and become brittle, affecting the appearance and quality of the packaging. At the same time, it also has a negative impact on production efficiency, reducing the packaging output per unit of time.

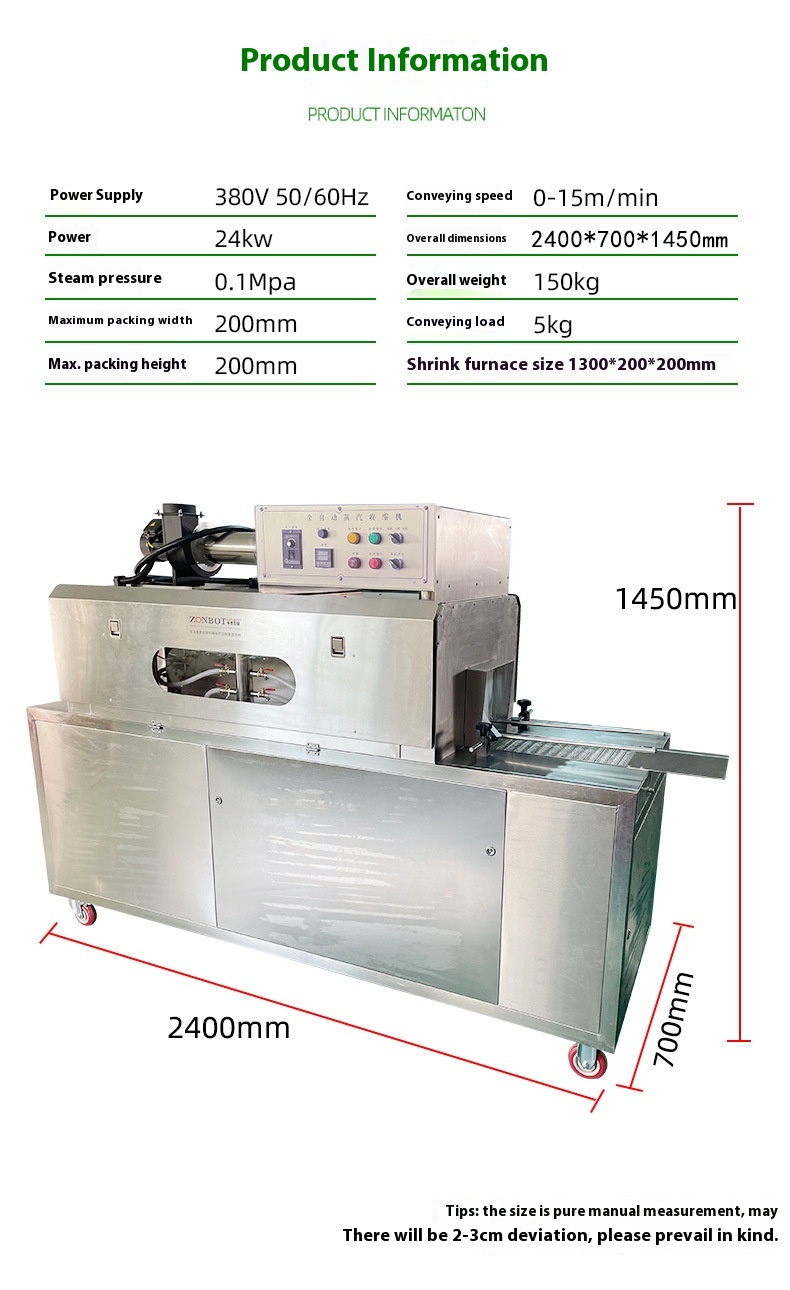

To achieve an ideal packaging effect, it is necessary to reasonably adjust the shrinkage temperature and time of the shrink wrapping machine according to factors such as the material and thickness of the heat shrinkable film, as well as the shape, size, and material of the packaged items. This is to ensure that the film shrinks evenly and adheres closely to the surface of the items, while also guaranteeing the packaging quality and production efficiency.