There can be multiple reasons for the strapping machine not feeding the strap. The following are common factors:

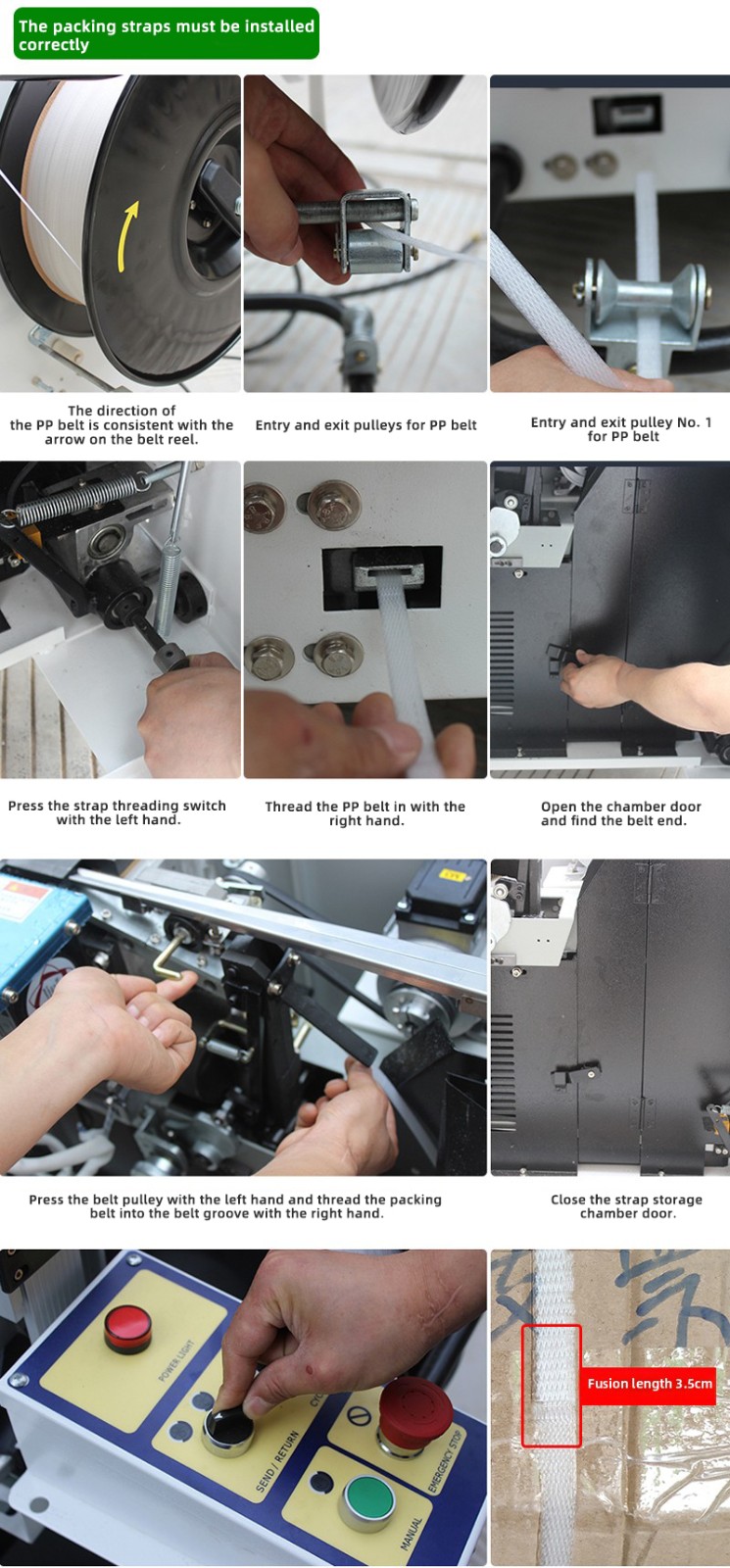

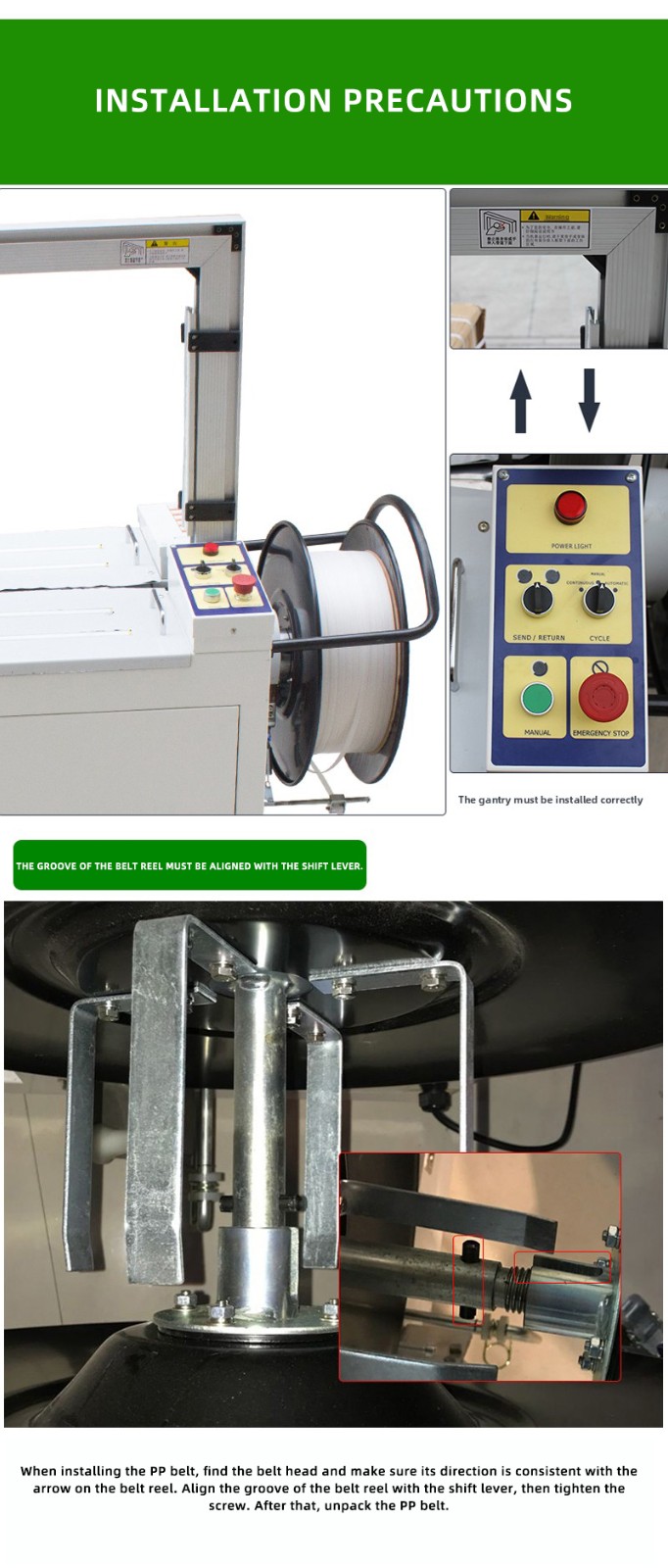

Packing Strap Issues

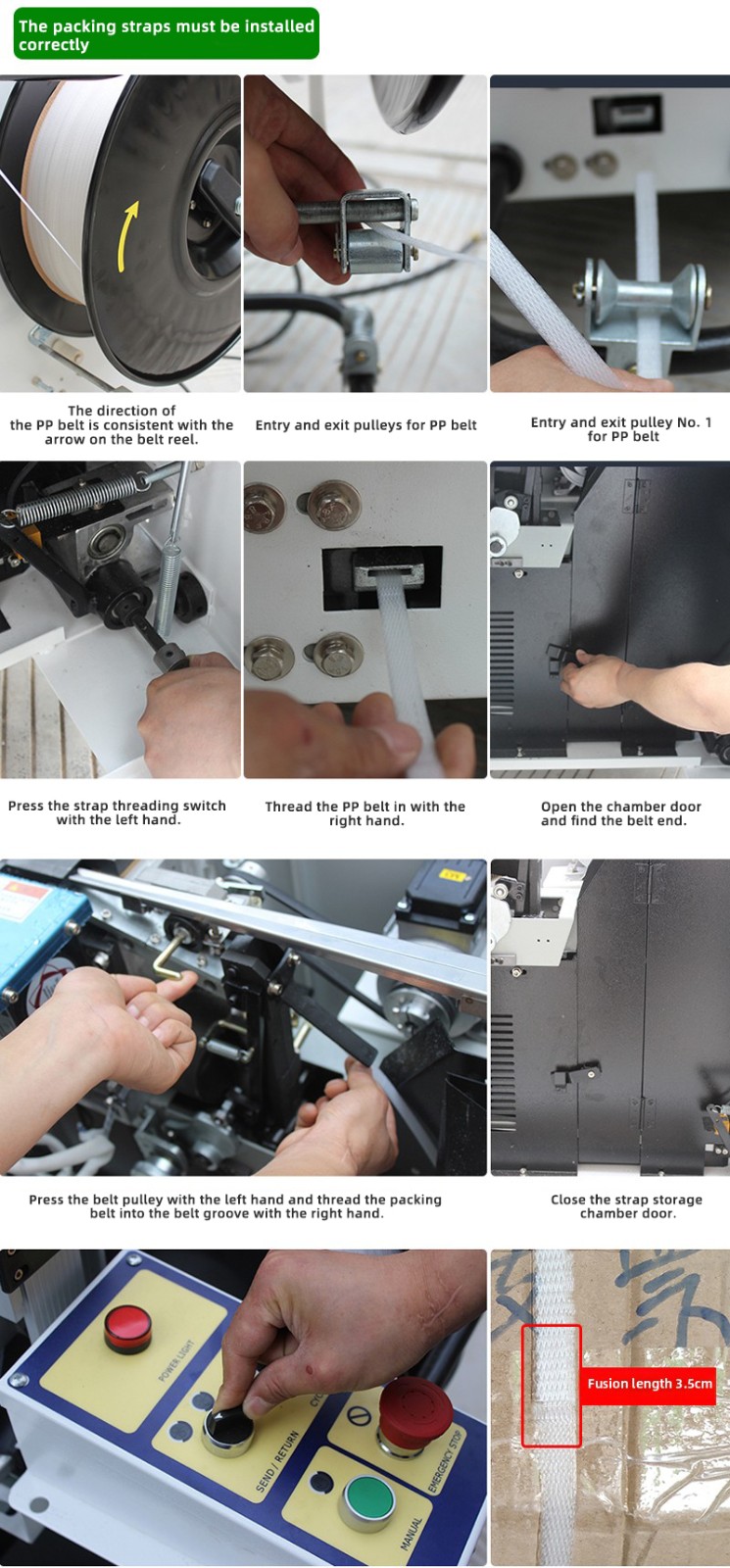

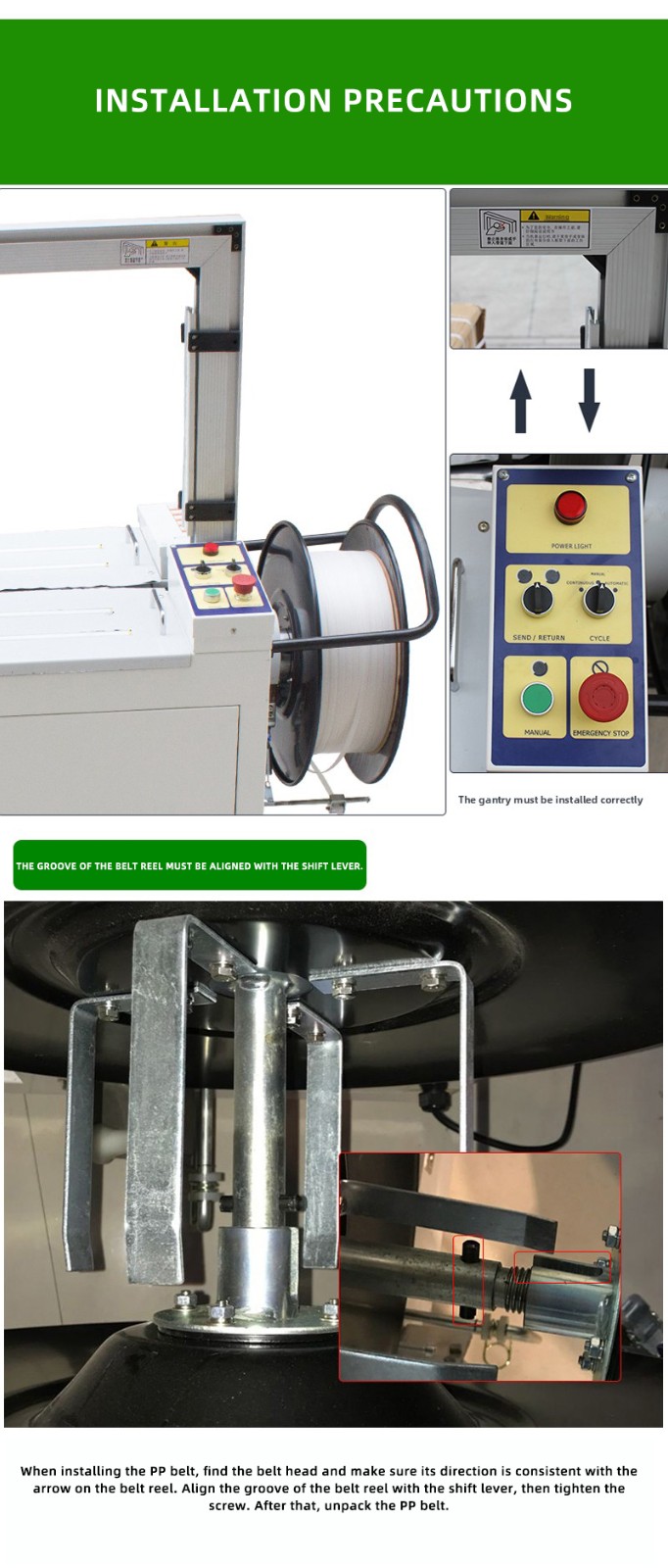

- Incorrect Packing Strap Installation: If the packing strap is not correctly threaded through various components during installation, such as the guide wheels and feed wheels, or if it is installed too tightly or too loosely, it may lead to poor strap feeding.

- Poor Quality of the Packing Strap: Using a packing strap of poor quality, such as one with uneven thickness, impurities, or excessive curvature, can cause the strap to get stuck easily during the feeding process or fail to pass smoothly through the strap feeding mechanism.

Strap Feeding Mechanism Issues

- Wear of the Strap Feed Wheels: After long-term use, the rubber or plastic material on the surface of the strap feed wheels may wear out, reducing the friction force and making it unable to effectively drive the packing strap forward.

- Insufficient Pressure of the Strap Feed Wheels: If the pressure adjustment of the strap feed wheels is improper, with too little pressure, it cannot provide enough friction to push the packing strap; if the pressure is too high, it may cause the packing strap to deform or be damaged, also affecting the strap feeding effect.

- Malfunction of Transmission Components: If components such as the transmission gears, chains, and belts in the strap feeding mechanism experience wear, looseness, breakage, etc., the power transmission will be hindered, resulting in abnormal strap feeding.

Strap Cutting Mechanism Issues

- Incorrect Position of the Cutting Blade: After the cutting blade completes a strap cutting action, if it does not return to the correct initial position, it may block the feeding path of the packing strap, causing the strap not to be fed.

- Malfunction of the Cutting Blade: If the cutting blade becomes dull, damaged, or is stuck by foreign objects and cannot complete the strap cutting action normally, it will also affect the feeding of the packing strap. Because during the strap feeding process, the cutting blade needs to be in a normal standby state; otherwise, it will interfere with the strap feeding process.

Electrical Control System Issues

- Sensor Malfunction: The sensors in the strapping machine are used to detect information such as the position and length of the packing strap. If the sensors malfunction and cannot accurately feedback signals, the control system may not be able to start the strap feeding program normally.

- Fault in the Control Circuit: Problems such as short circuits, open circuits, or component damage in the control circuit for strap feeding will prevent the strap feeding motor from receiving the correct drive signals, resulting in the strap not being fed.

- Program Error: The program of the control system may have errors or malfunctions, affecting the normal execution of the strap feeding function. This situation may be caused by reasons such as the equipment being subjected to electromagnetic interference or a sudden power outage.

Other Issues

- Foreign Object Blockage: If foreign objects such as debris, dust, or packing strap fragments enter the strap feeding channel inside the strapping machine, it will obstruct the normal feeding of the packing strap.

- Machine Overheating: Continuous use of the strapping machine for a long time may cause the machine to overheat, causing a decline in the performance of certain components or malfunctions, affecting the strap feeding function. Especially for the strap feeding motor, if it overheats, it may trigger overload protection and stop working