The maintenance cycle of the cuff-style packaging machine usually falls into two aspects: daily maintenance and regular maintenance. The following is the general maintenance cycle:

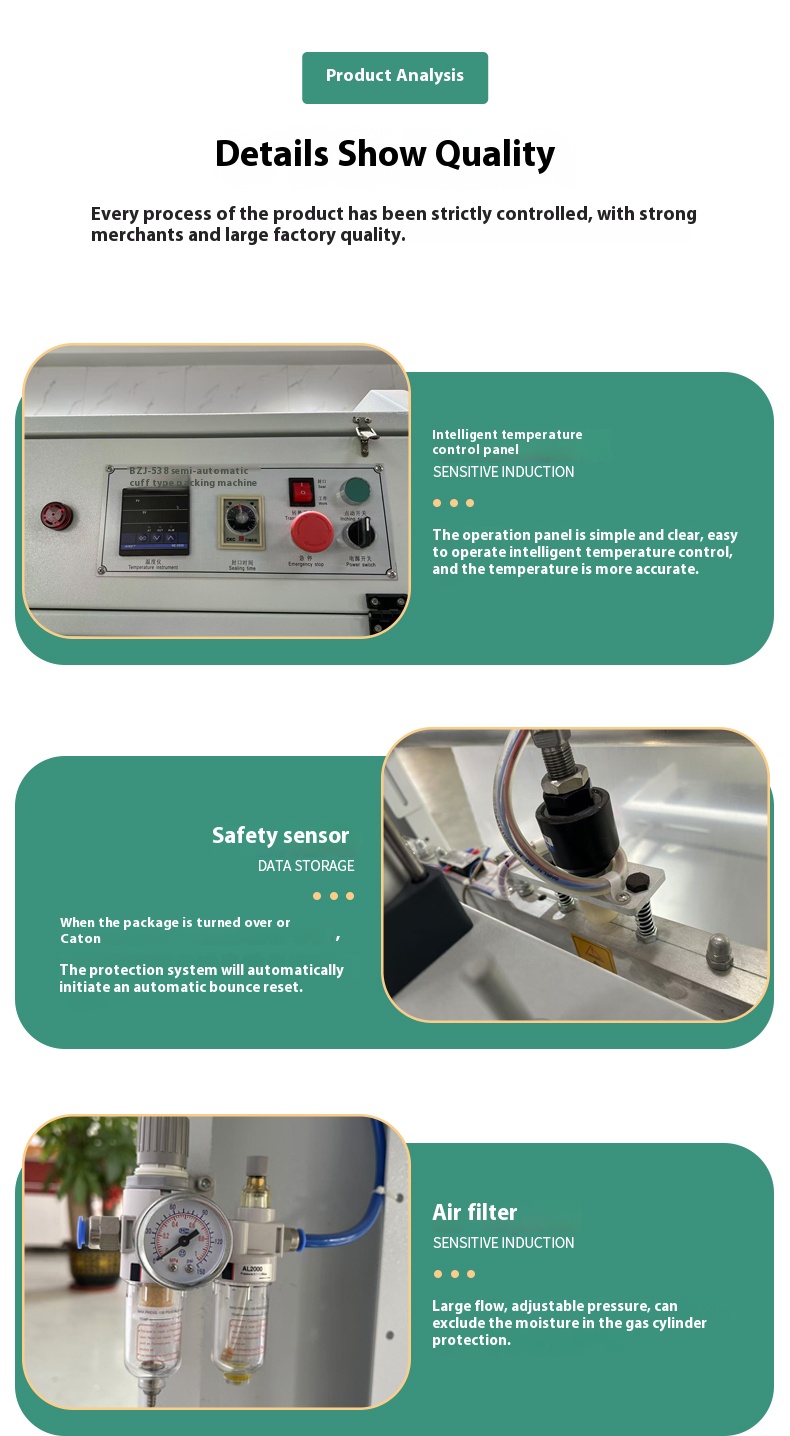

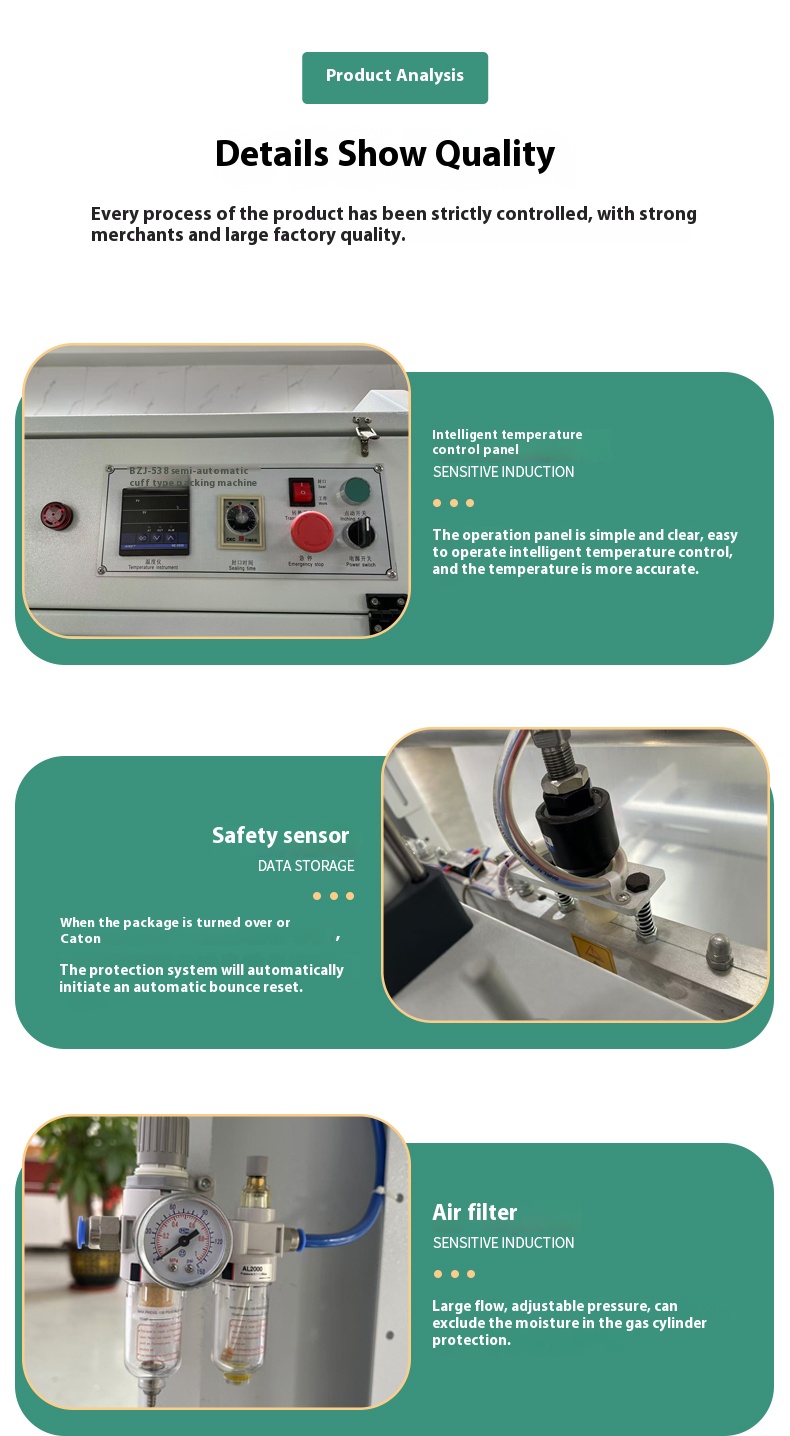

Daily Maintenance: Conducted at the end of each working day. It mainly includes cutting off the power supply, wiping the surface of the machine body with a clean soft cloth to remove dust, debris, and residues of packaging materials; checking whether there are signs of looseness, wear, or damage on each component, with a focus on inspecting components such as the sealing and cutting knife, conveyor chain, and rollers.

Regular Maintenance

- Lubricating Components: Every 1 to 2 weeks, add an appropriate amount of lubricating oil to moving components such as chains, gears, and bearings to reduce wear.

- Inspecting the Heating System: For cuff-style packaging machines using heat sealing, clean the dirt and oxides on the surface of the heating elements every 1 to 2 weeks and check the accuracy of the temperature control system.

- Replacing Vulnerable Parts: Regularly replace vulnerable parts according to their actual wear conditions, such as the sealing and cutting knife, heating wire, rollers, conveyor belts, etc. Generally, when the blade of the sealing and cutting knife becomes dull after a certain number of uses and affects the sealing and cutting quality, it needs to be replaced. There is no fixed replacement cycle, which depends on the specific usage situation.

- Electrical System Inspection: Every 3 to 6 months, have a professional electrician conduct a comprehensive inspection of the electrical system, checking whether the wires are aged or damaged, whether the connections of electrical components are secure, and whether the grounding is in good condition.

- Calibrating Sensors: Generally, calibrate the sensors of the packaging machine every six months or a year to ensure packaging accuracy. The specific calibration time can be determined according to the actual usage situation and product packaging requirements.

The actual maintenance cycle should also be appropriately adjusted according to factors such as the usage frequency of the packaging machine, the working environment, and the suggestions of the manufacturer. Packaging machines that are used frequently and operate in harsh working environments may require a shorter maintenance cycle to ensure their stable performance and service life