Here are the common faults and solutions of the full-automatic side-sealing heat shrinkage machine:

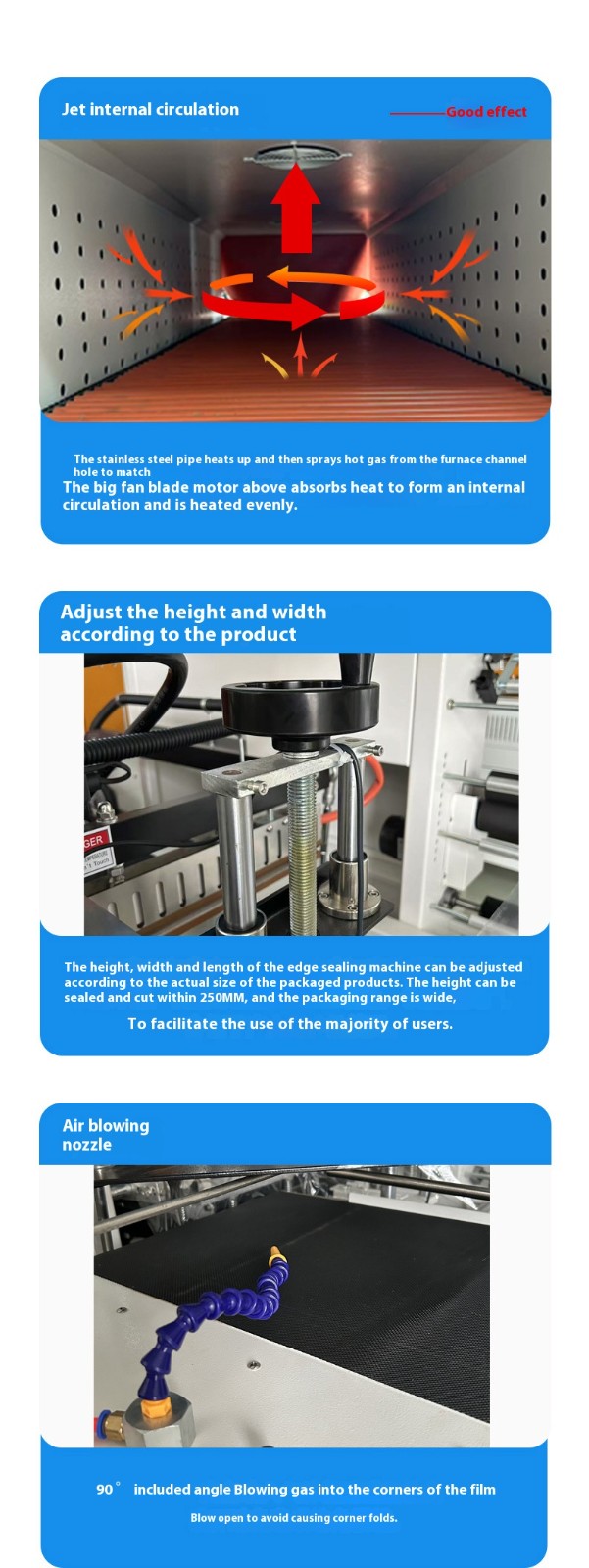

Sealing and Cutting Problems

- Unfirm Sealing and Cutting

- Reasons: The sealing and cutting temperature is too low, the sealing and cutting time is too short, the pressure of the sealing and cutting knife is insufficient, or the quality of the heat shrinkable film is poor.

- Solutions: Appropriately increase the sealing and cutting temperature, extend the sealing and cutting time, adjust the pressure of the sealing and cutting knife, and replace the heat shrinkable film with a better quality one.

- Burrs or Uneven Cuts at the Sealing and Cutting Area

- Reasons: The sealing and cutting knife is worn, the sealing and cutting temperature is too high, or the sealing and cutting speed is too fast.

- Solutions: Polish or replace the sealing and cutting knife, lower the sealing and cutting temperature, and appropriately reduce the sealing and cutting speed.

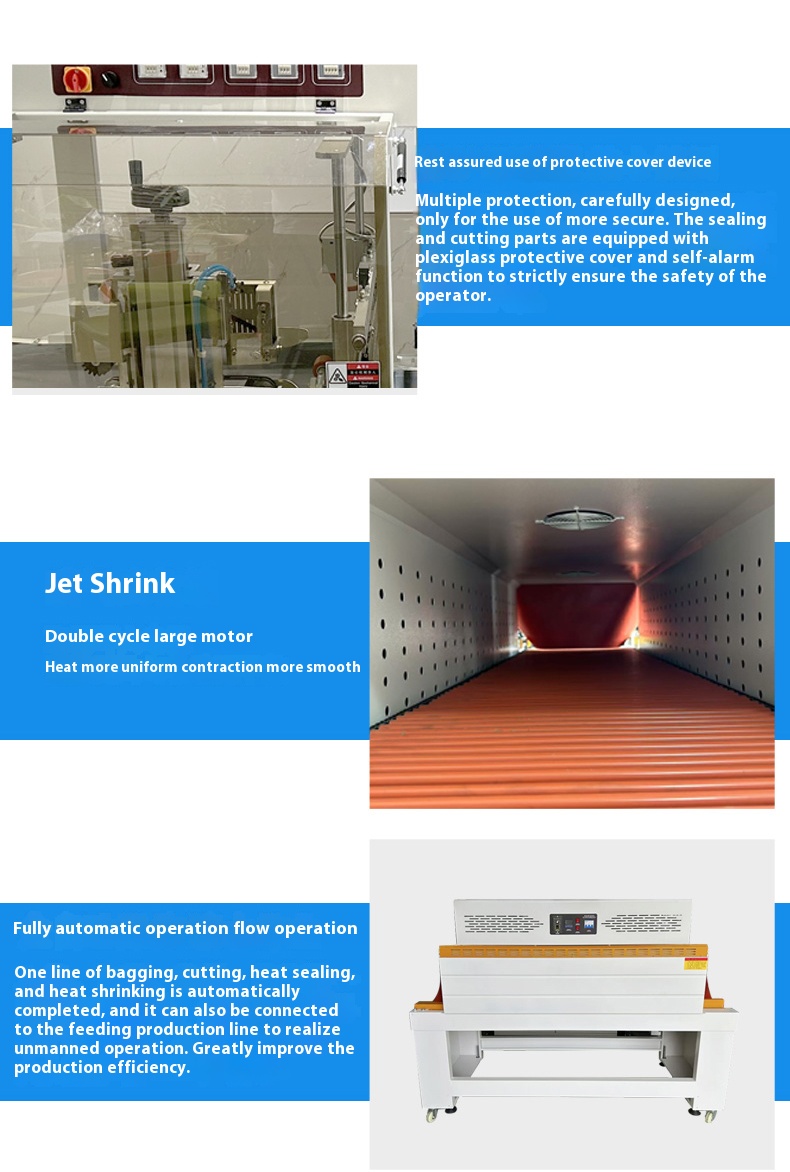

Heat Shrinkage Problems

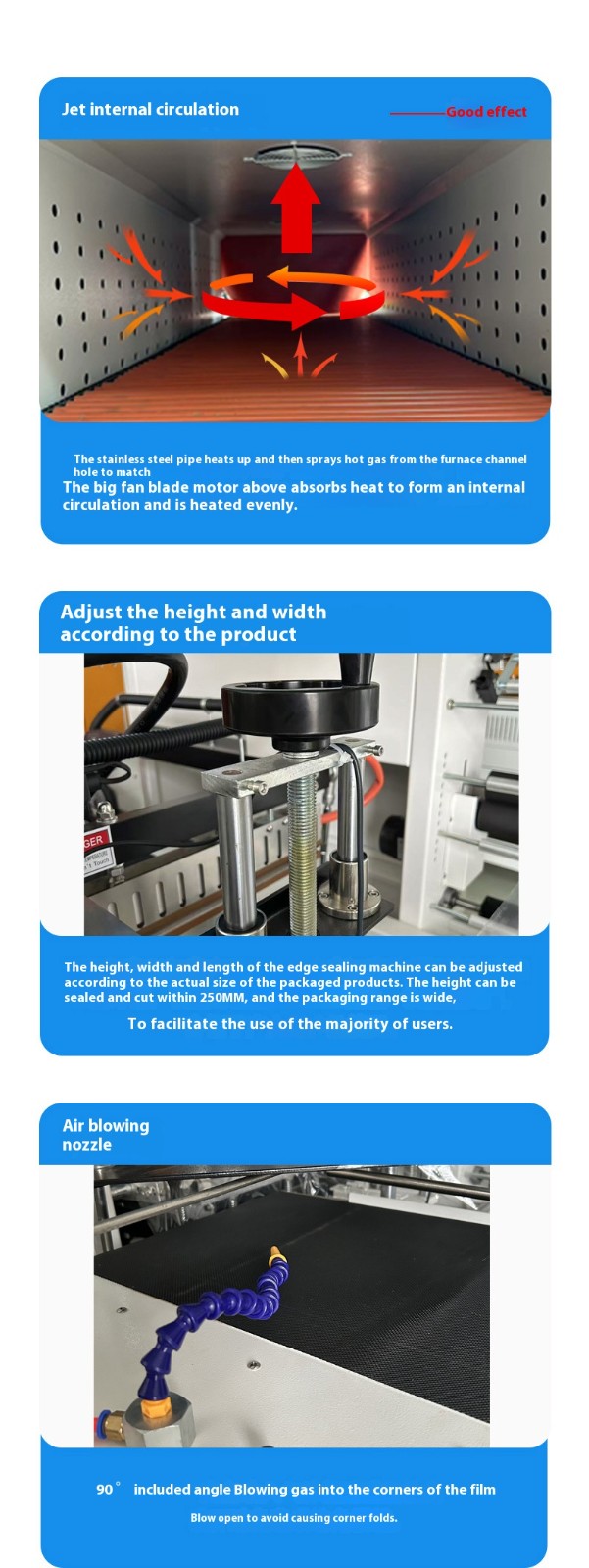

- Uneven Shrinkage

- Reasons: The temperature in the heat shrinkage channel is uneven, the product is not placed smoothly, or the thickness of the heat shrinkable film is uneven.

- Solutions: Check the distribution of the heating tubes and the operation of the fan, and adjust to make the temperature uniform; re-place the product to ensure it is smooth; replace the heat shrinkable film with an evenly thick one.

- Excessive or Insufficient Shrinkage

- Reasons: The shrinkage temperature is too high or too low, and the shrinkage time is too long or too short.

- Solutions: Reasonably adjust the shrinkage temperature and time according to the materials of the product and the heat shrinkable film.

Feeding Problems

- Unsmooth Product Conveying

- Reasons: There are foreign objects on the surface of the conveyor belt, the tension of the conveyor belt is inappropriate, or the feeding motor is faulty.

- Solutions: Clean the foreign objects on the surface of the conveyor belt, adjust the tension of the conveyor belt, check the feeding motor and the relevant circuit, and repair or replace the motor.

- Inaccurate Product Positioning

- Reasons: The positioning sensor is faulty, or the action of the pushing device is inaccurate.

- Solutions: Check the positioning sensor, clean the dust on its surface or replace the sensor; adjust the position and action parameters of the pushing device to ensure accurate pushing.

Electrical System Problems

- No Power Display on the Machine

- Reasons: The power plug is not plugged in properly, the fuse is blown, or the power switch is damaged.

- Solutions: Check whether the power plug is plugged in firmly, replace the blown fuse, and replace the damaged power switch.

- Partial Malfunction of Functions

- Reasons: Electrical components are faulty, the circuit connection is poor, or there is an error in the PLC program.

- Solutions: Check the corresponding electrical components, such as relays and contactors, and replace the damaged components; check the circuit connection and repair the loose or disconnected wires; check the PLC program, and reprogram it or restore the default program if there is an error.

Other Problems

- Abnormal Noise during Machine Operation

- Reasons: The transmission components are worn, the fan impeller is loose, or the machine is not installed stably.

- Solutions: Check and replace the worn transmission components, such as chains, gears, and bearings; tighten the fan impeller; adjust the installation position of the machine to make it placed stably.

- Wrinkling of the Heat Shrinkable Film

- Reasons: The quality of the heat shrinkable film is poor, the tension of the film is uneven, or the shrinkage speed is too fast.

- Solutions: Replace the heat shrinkable film with a better quality one, adjust the unwinding tension of the film, and appropriately reduce the shrinkage speed