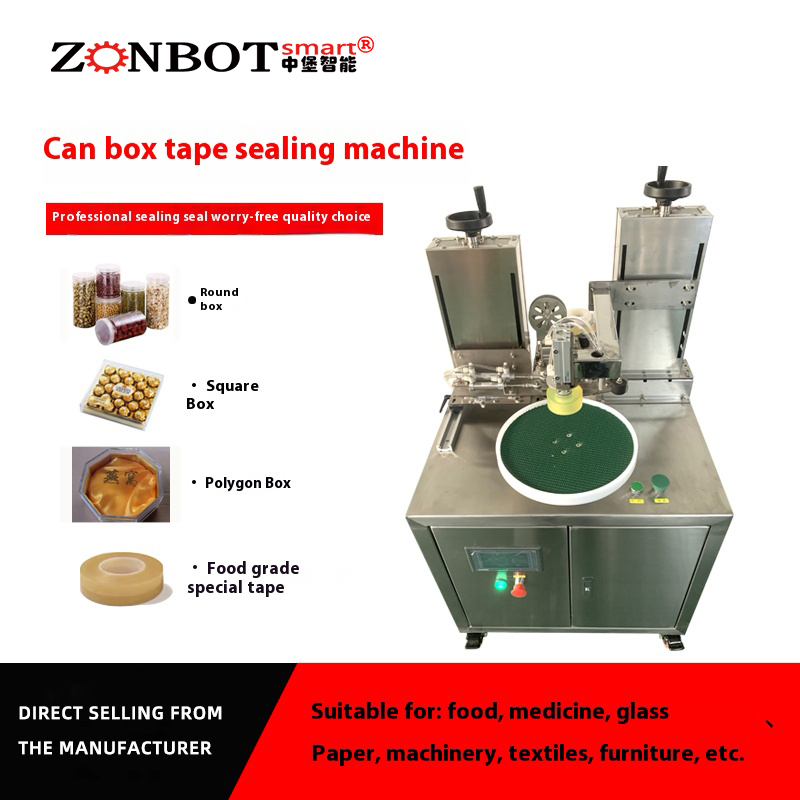

The following are some factors that affect the stability of the can box tape sealing machine:

Mechanical Structure Design

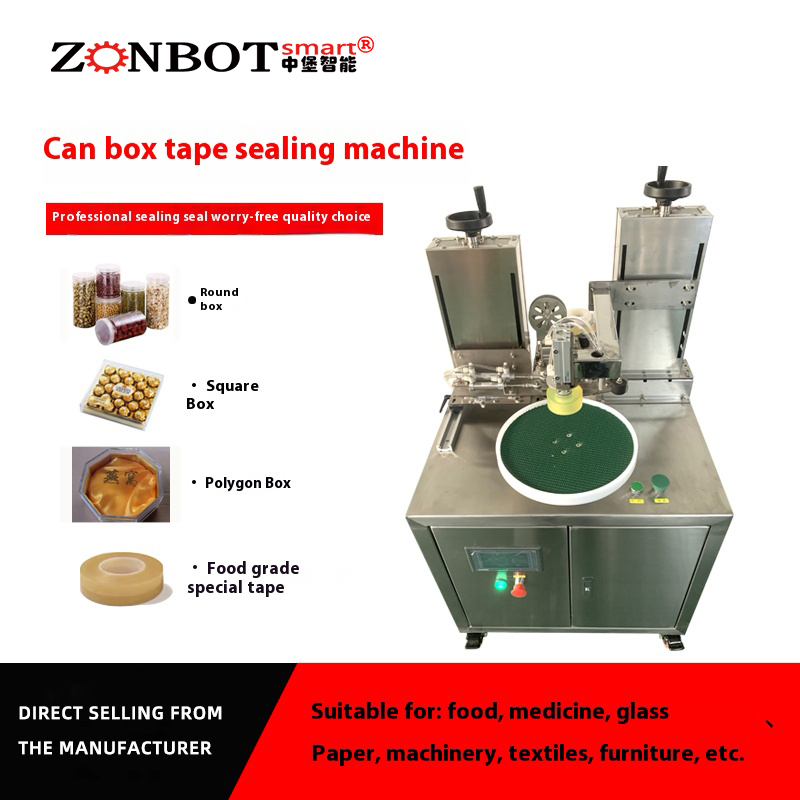

- Rationality of the Overall Structure: A reasonable mechanical structure can ensure that all components are evenly stressed and move smoothly. For example, if the strength of the machine body frame is insufficient, it may vibrate during the operation of the equipment, affecting the sealing accuracy and stability.

- Stability of Component Connections: For all components of the sealing machine, such as the conveyor belt, sealing device, cutting device, etc., if the connections are not firm, they are likely to loosen during long-term operation, resulting in deviations in the cooperation between components, which in turn affects the stability of the equipment.

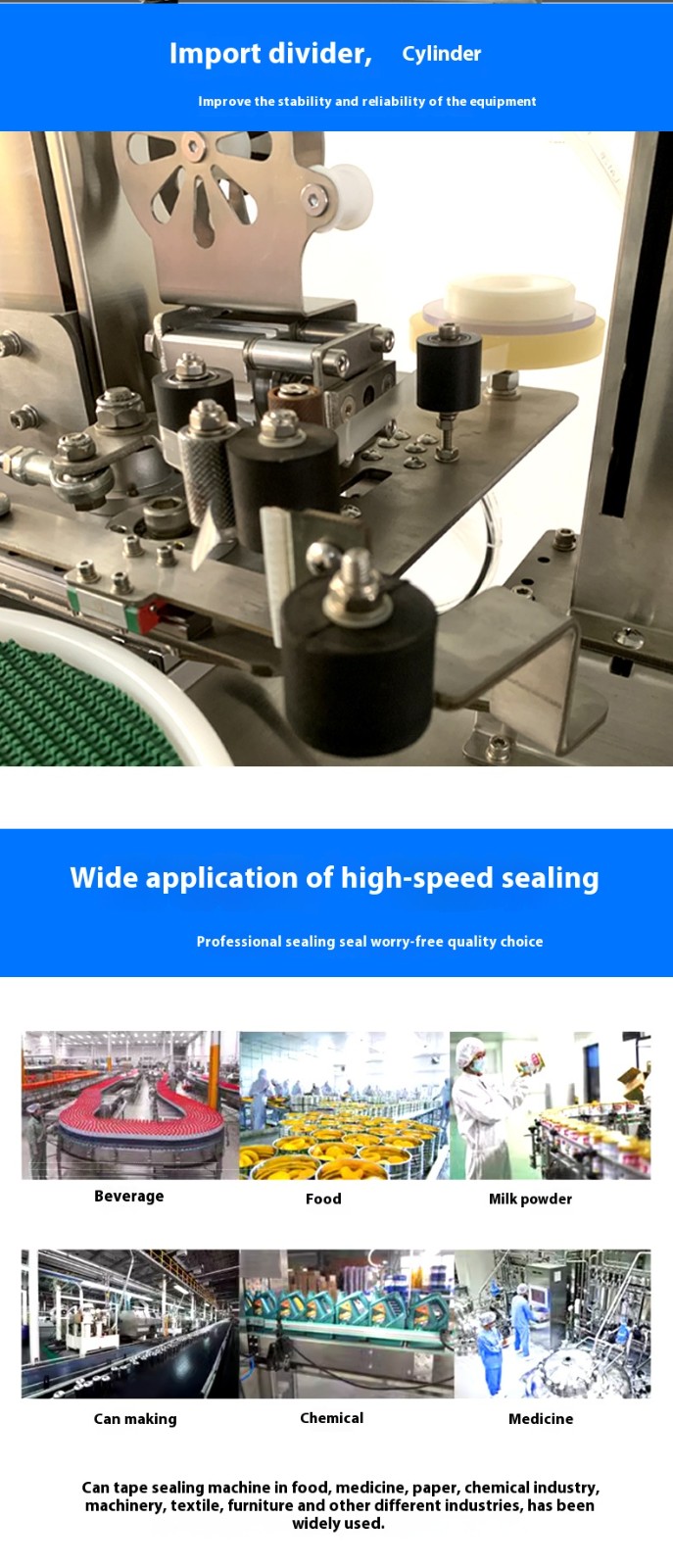

Quality of Spare Parts

- Quality of Key Components: The quality of key components such as motors, cylinders, and sensors is crucial to the stability of the sealing machine. High-quality motors run smoothly and have stable power output; high-quality cylinders act precisely and respond sensitively; reliable sensors can accurately detect the position and status of the can box. Conversely, it may trigger various failures.

- Wear Resistance of Vulnerable Parts: For vulnerable parts like conveyor belts, tape rollers, and cutting blades, if their wear resistance is poor, they need to be replaced frequently. This not only increases the maintenance cost but also causes the equipment to stop due to the replacement process, affecting production stability.

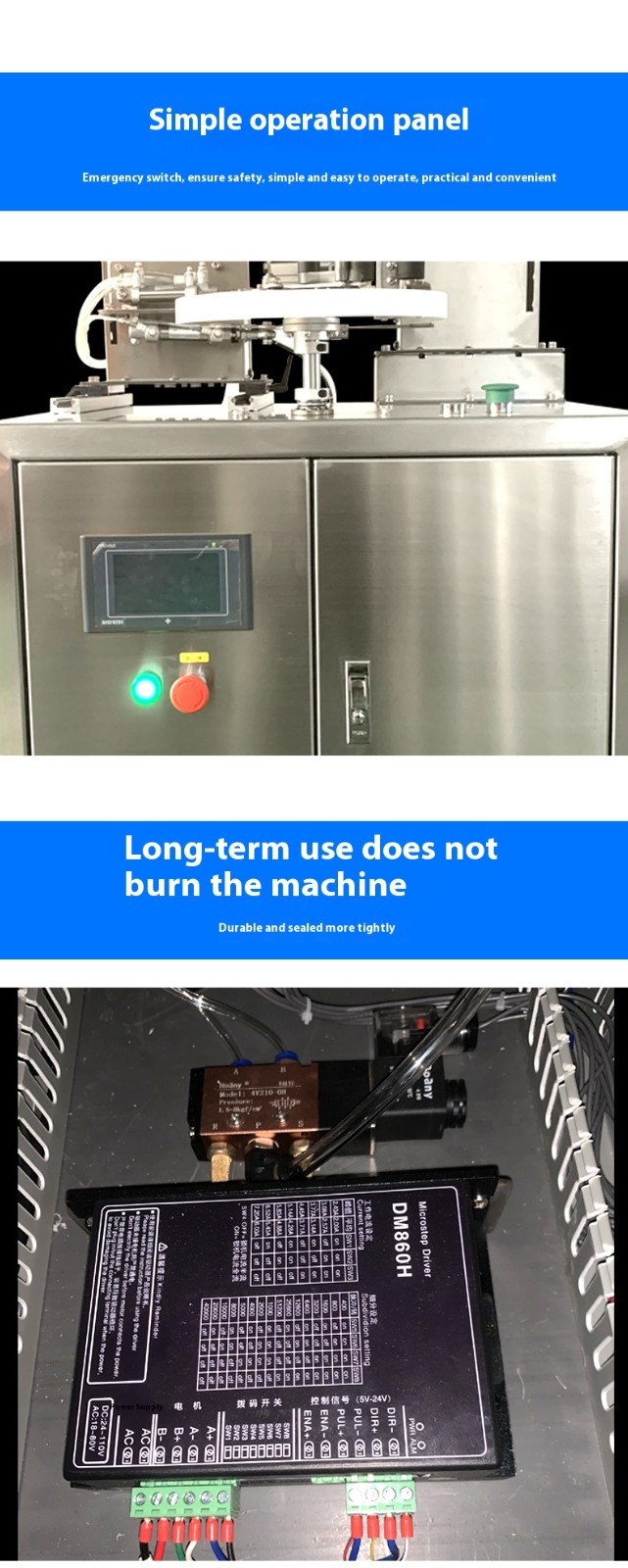

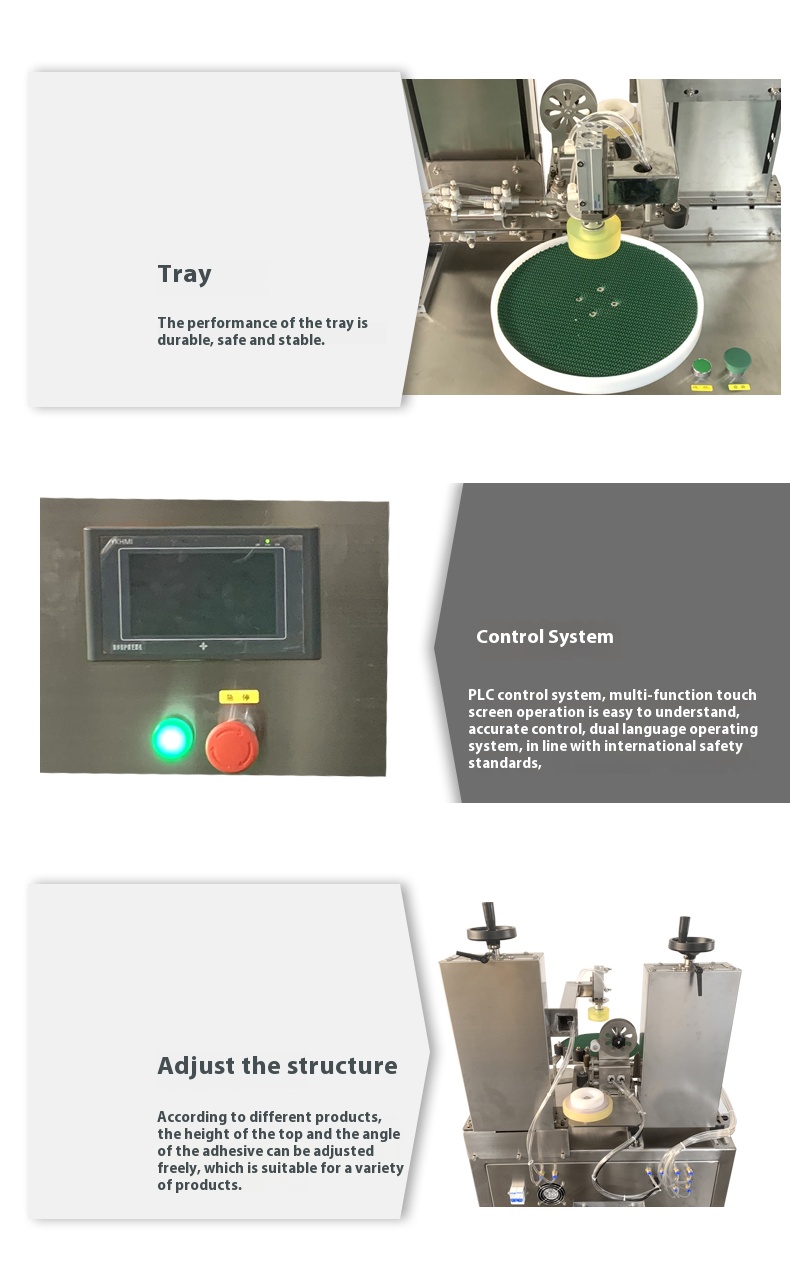

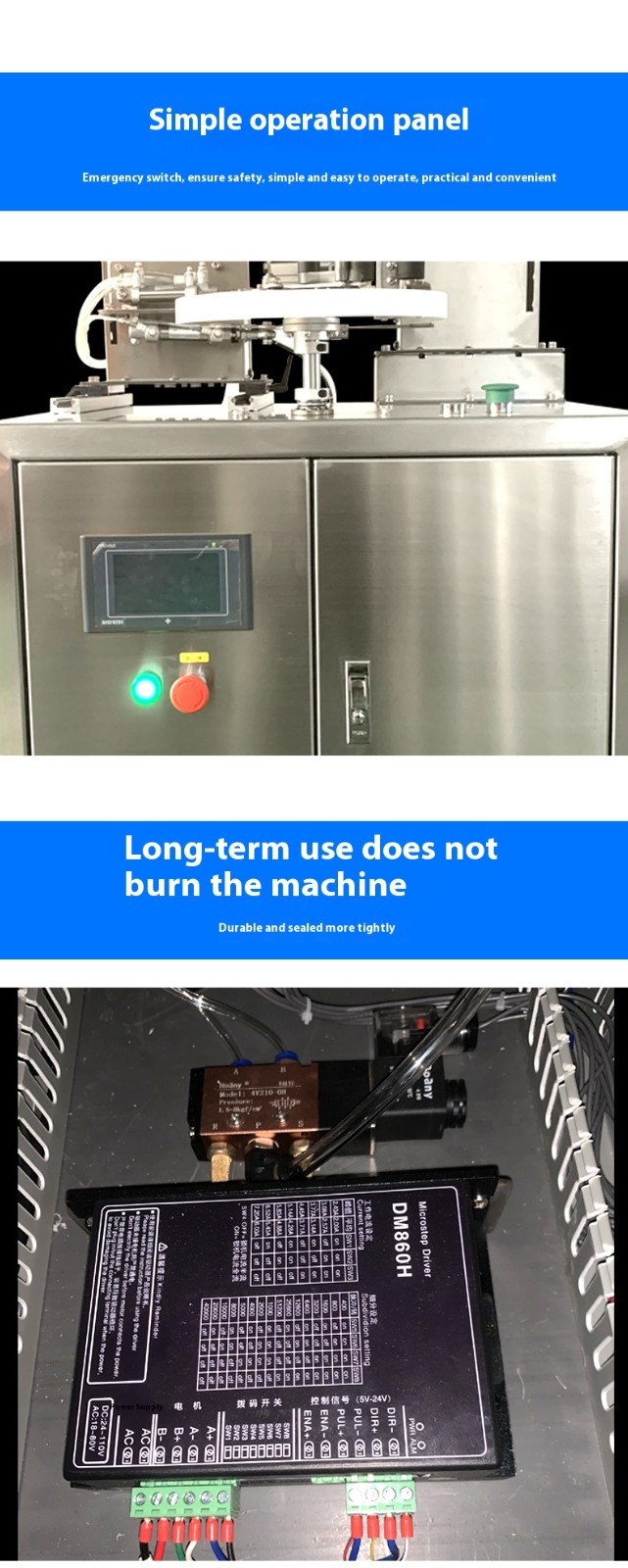

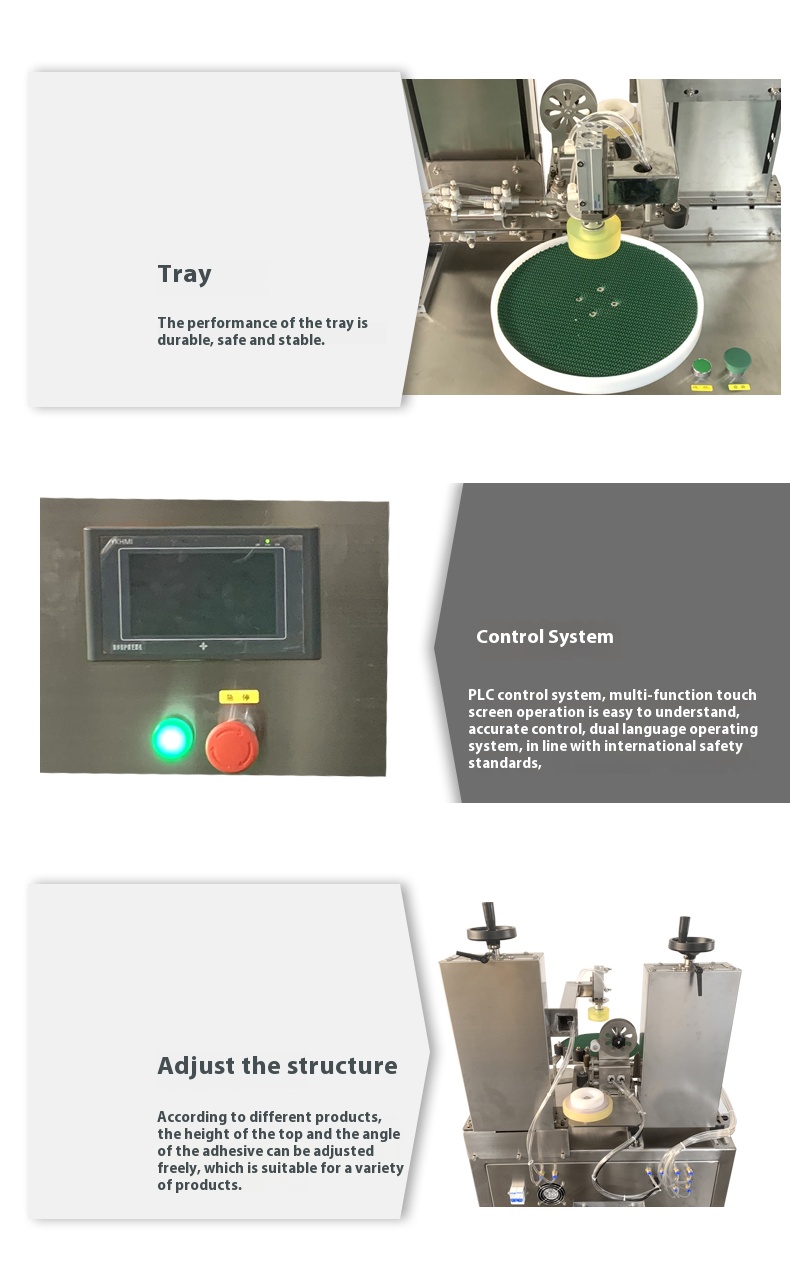

Control System

- Accuracy of the Control Algorithm: An advanced and accurate control algorithm enables the sealing machine to precisely control parameters such as the conveying length of the tape, sealing pressure, and cutting timing according to different parameters of the can box size and tape type, ensuring the stability of the sealing quality. If the control algorithm is not perfect, it may lead to inaccurate sealing parameters, affecting the sealing effect and the stability of the equipment.

- Reliability of Electrical Components: If electrical components such as PLCs, relays, and frequency converters are not reliable in quality, they are prone to failures, resulting in the failure of the control system and thus affecting the normal operation of the sealing machine.

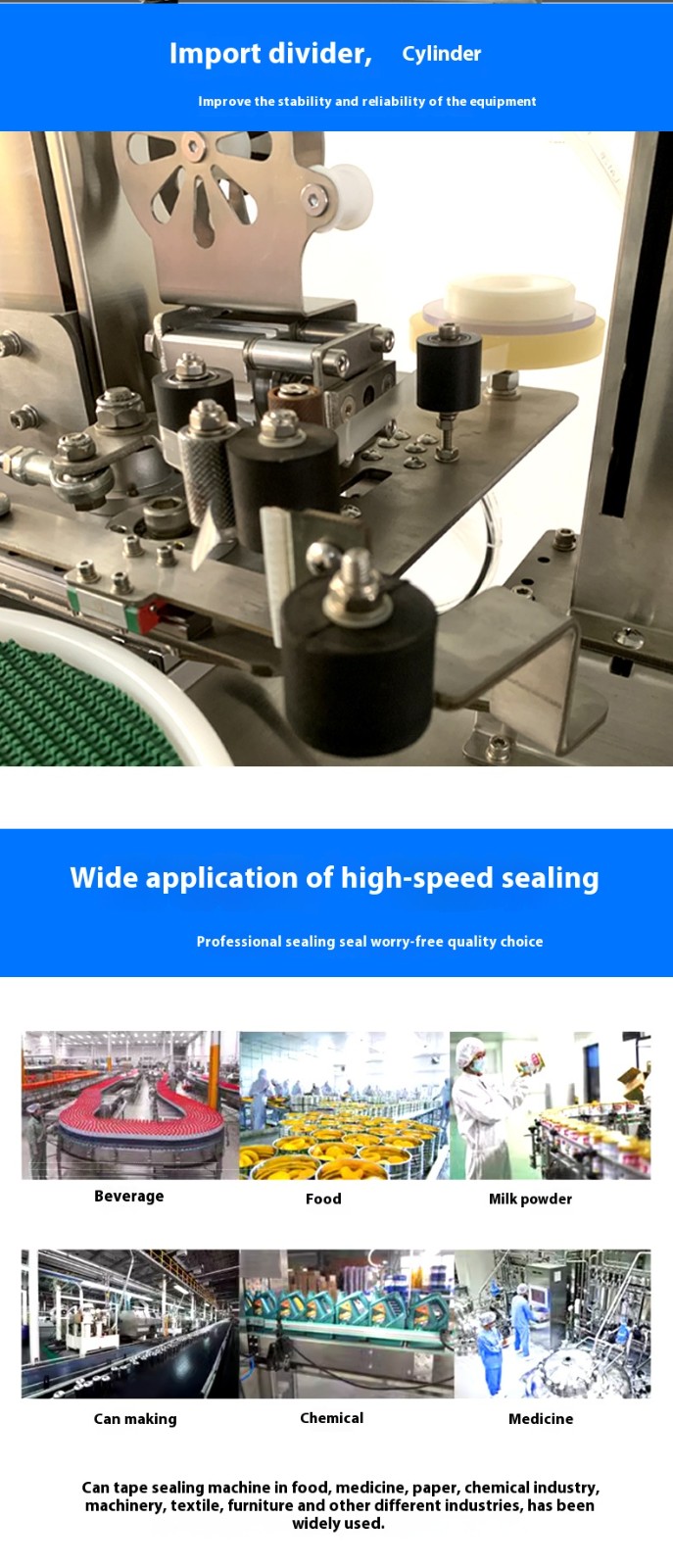

Working Environment

- Temperature and Humidity: Excessively high or low temperatures may affect the performance of the equipment's components and the physical properties of materials. For example, it may change the viscosity of the tape, and the thermal expansion and contraction of metal components may cause changes in the fit clearance. Excessive humidity may cause electrical components to get damp, triggering faults such as short circuits and reducing the stability of the equipment.

- Dust and Impurities: In a dusty environment, dust is likely to enter the interior of the equipment, contaminating sensors, affecting the lubrication and movement of mechanical components, and may even block the tape conveying channel, causing the equipment to run poorly.

Maintenance and Upkeep

- Regular Maintenance: Regularly carrying out maintenance work such as cleaning, lubricating, and tightening screws on the equipment can promptly detect and solve potential problems, extend the service life of the equipment, and ensure its stability. Conversely, a lack of maintenance will cause the equipment to gradually age and its performance to decline.

- Proper Repair: When the equipment malfunctions, the technical level and repair methods of maintenance personnel are also crucial. Incorrect repairs may exacerbate the problem, affecting the stability and reliability of the equipment