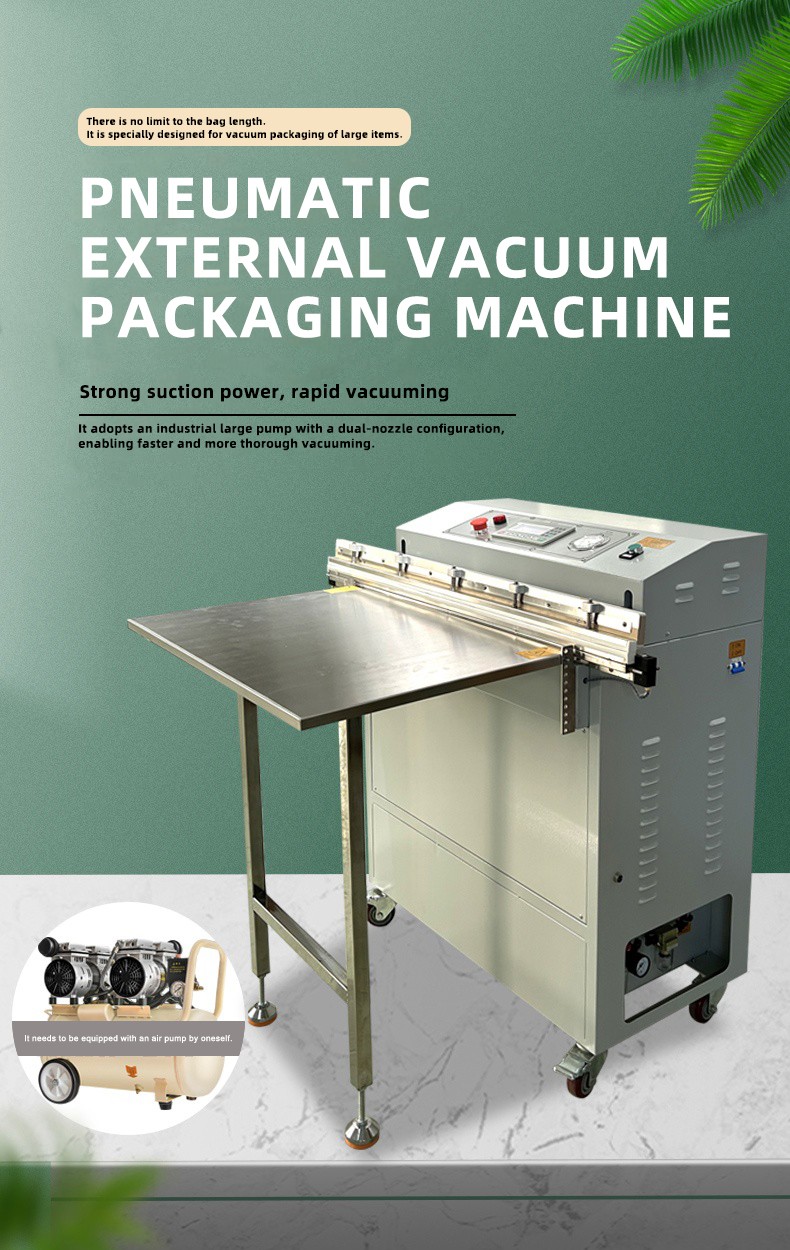

Before operating the pneumatic external vacuum packaging machine, preparations need to be made in terms of equipment inspection, material preparation, and environmental cleaning to ensure the smooth progress of the packaging work. The details are as follows:

Equipment Inspection

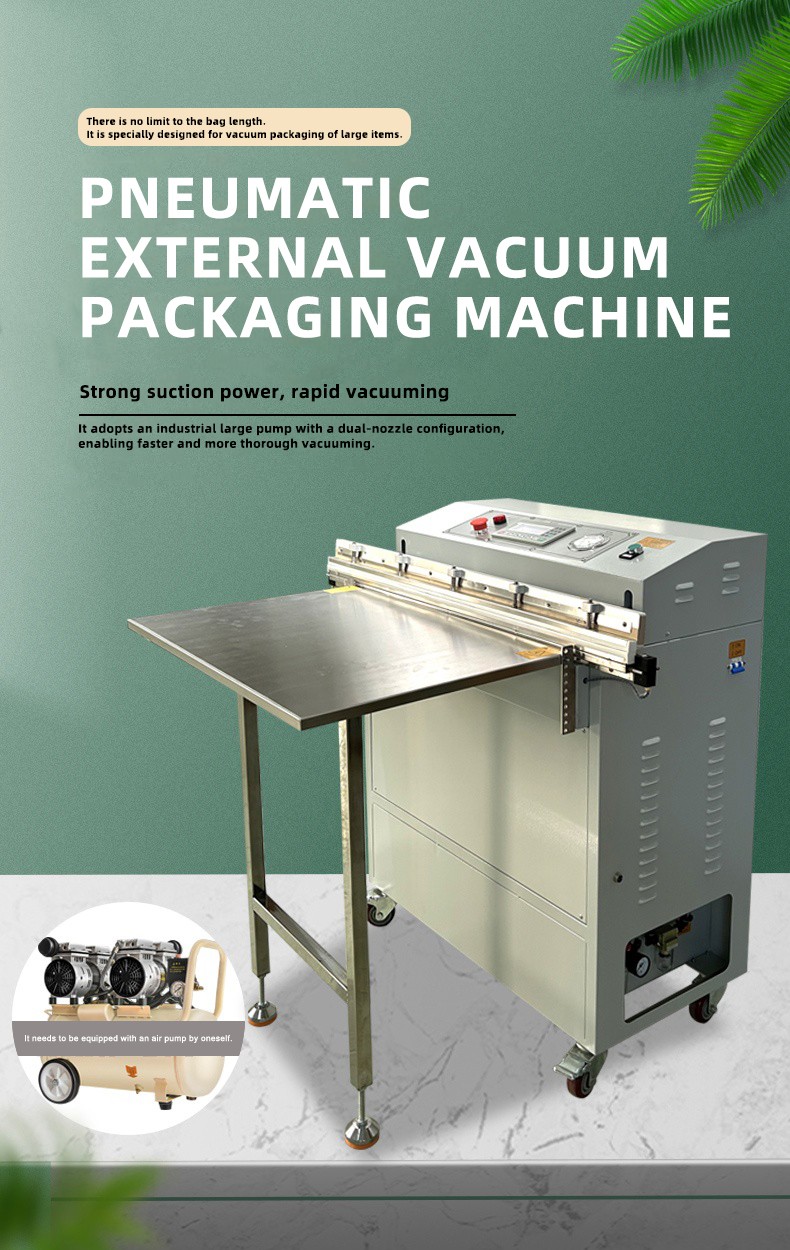

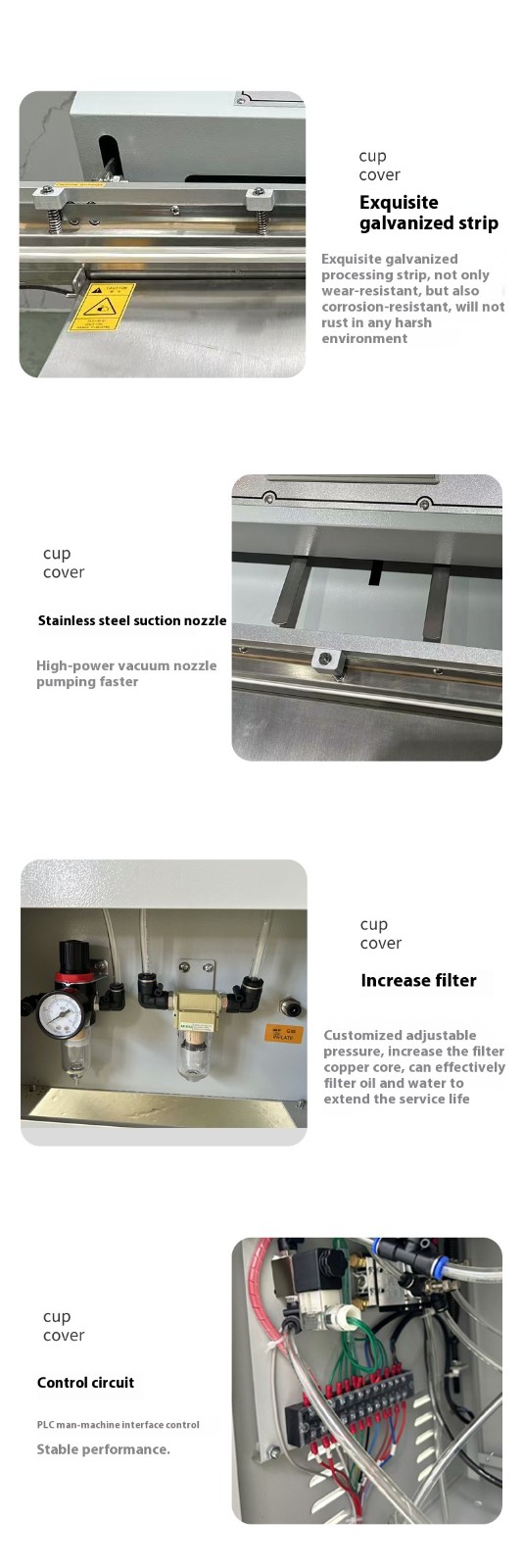

Air Source Inspection: Check whether the air compressor is running normally and whether the air source pressure is stable within the range required by the equipment, generally 0.5 - 0.8MPa. Inspect the air pipes for any air leakage. If air leakage is found, repair or replace the air pipes in a timely manner.

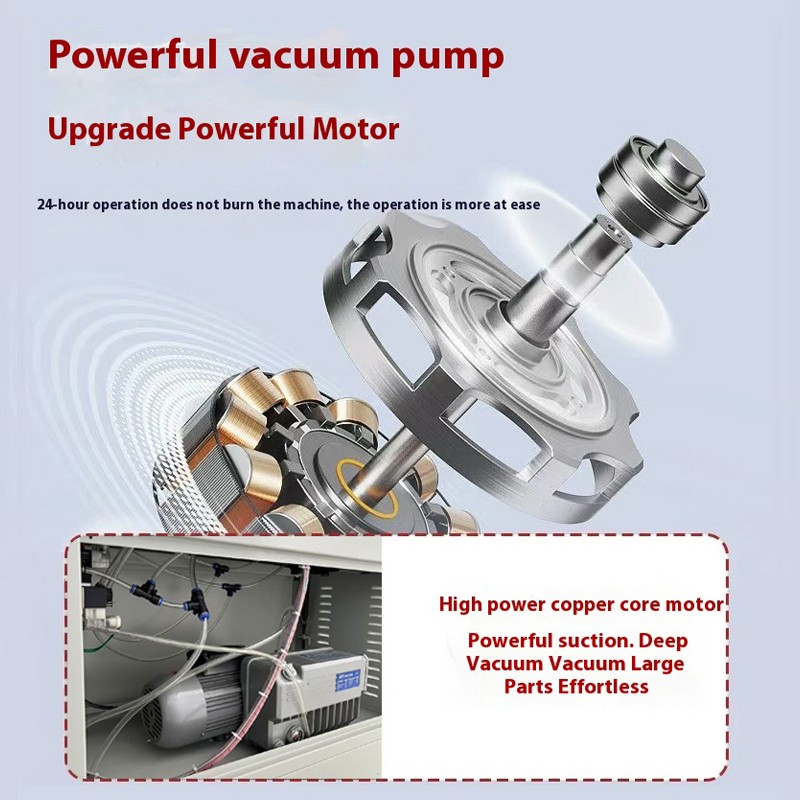

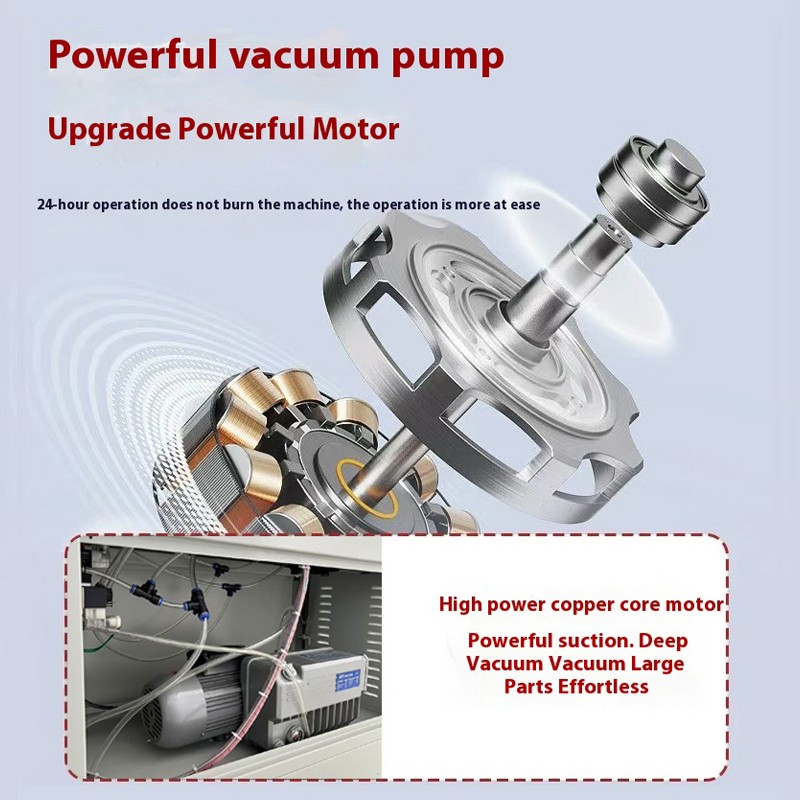

Vacuum Pump Inspection: Check the oil level of the vacuum pump to ensure that the oil level is within the normal scale range. If the oil level is too low, add special vacuum pump oil. At the same time, check whether the power cord of the vacuum pump is firmly connected. Start the vacuum pump and check whether it runs smoothly and there is no abnormal noise.

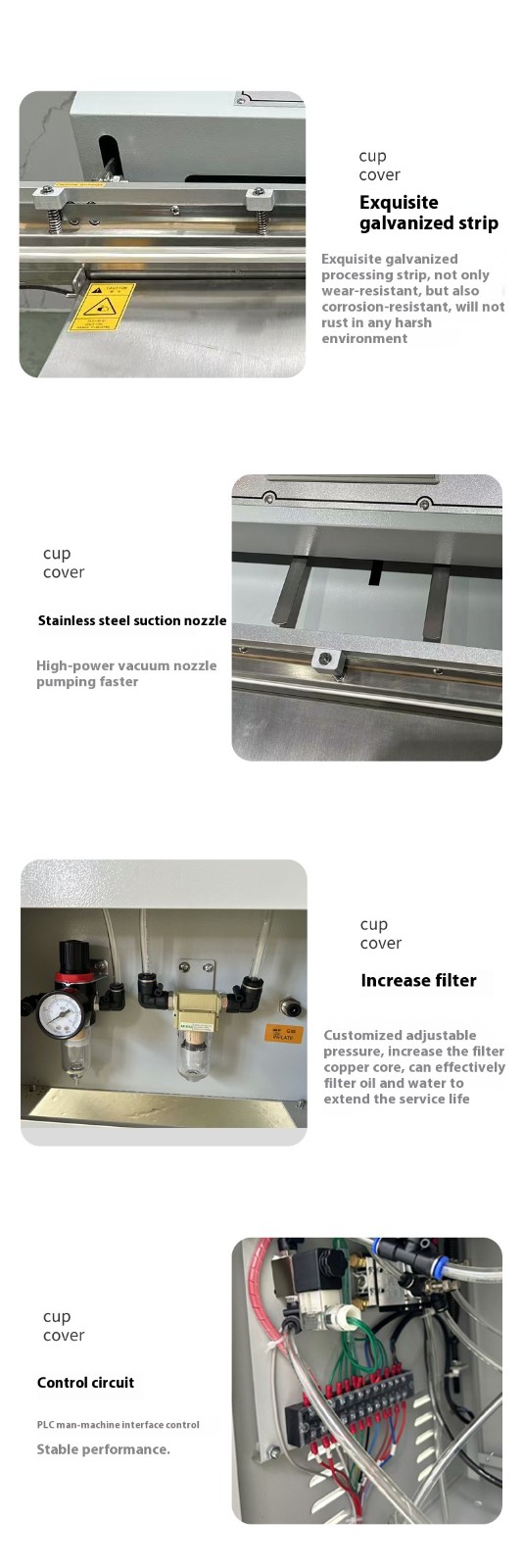

Sealing Component Inspection: Check whether the sealing heating strip is damaged, deformed or aged. If there are any problems, replace it in a timely manner. Clean the dirt and debris on the surface of the heating strip to ensure uniform heating. Check whether the sealing pressure device is normal. You can manually operate the cylinder to check whether the pressing down and lifting actions of the sealing strip are flexible.

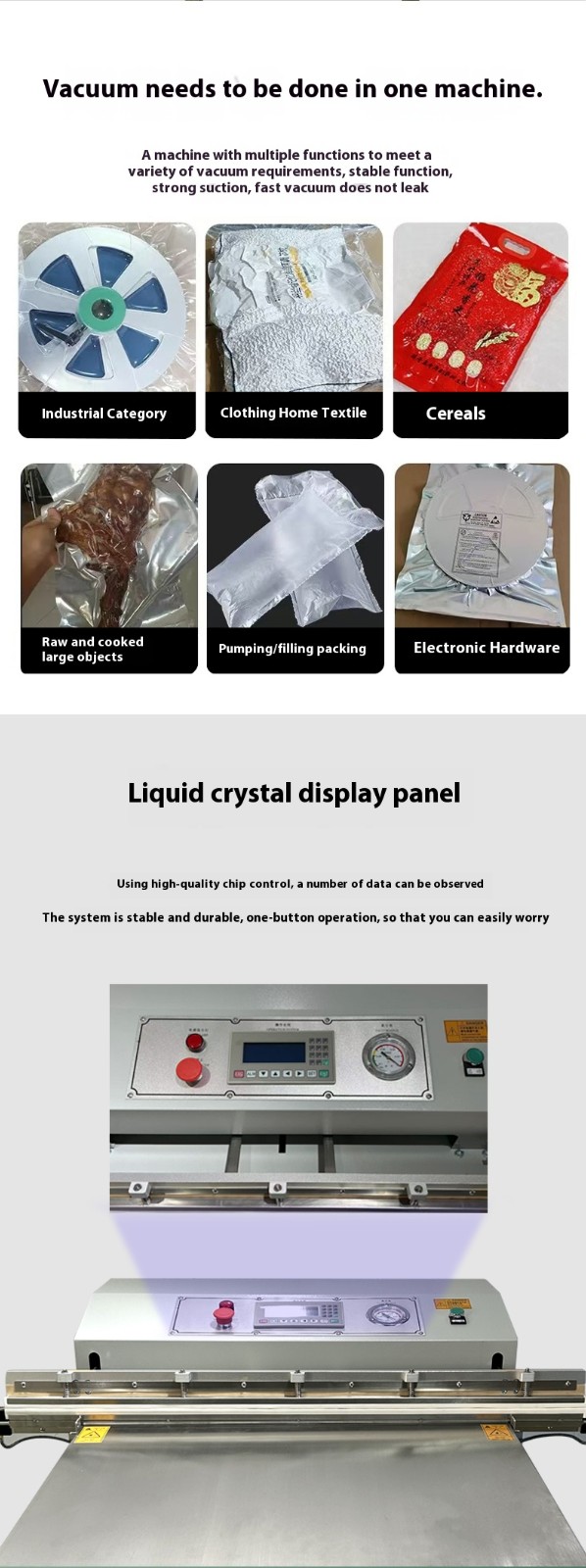

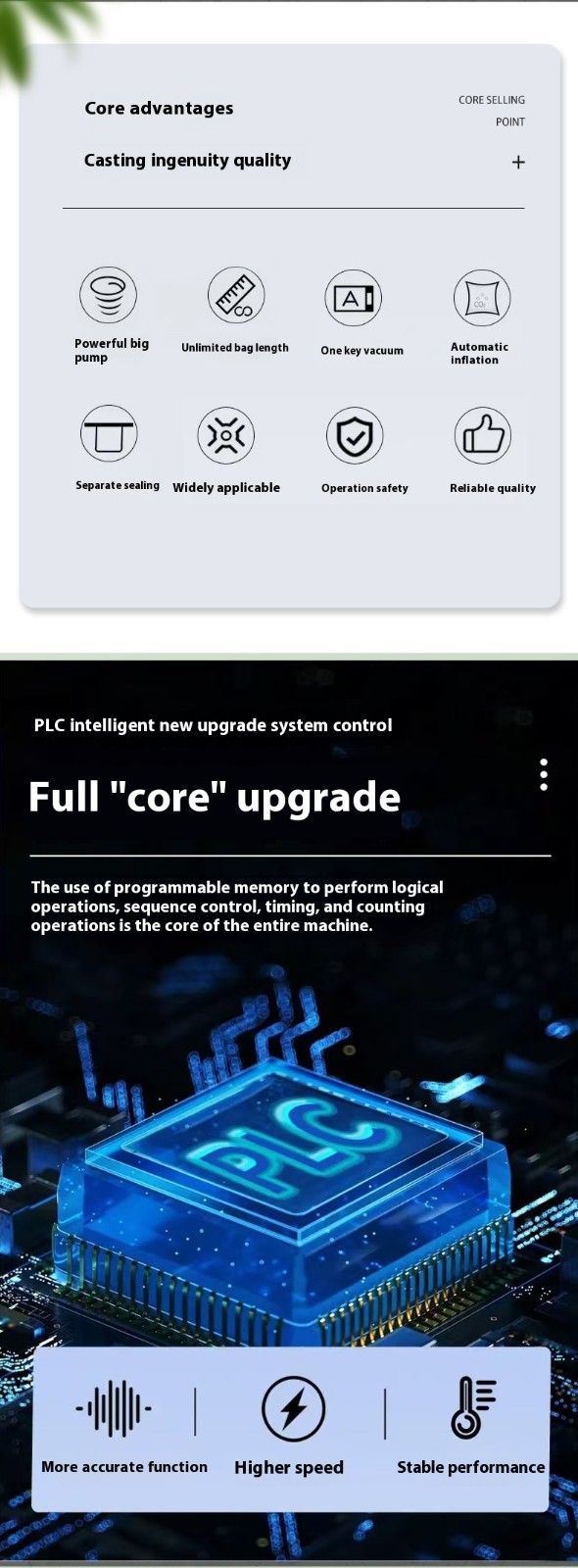

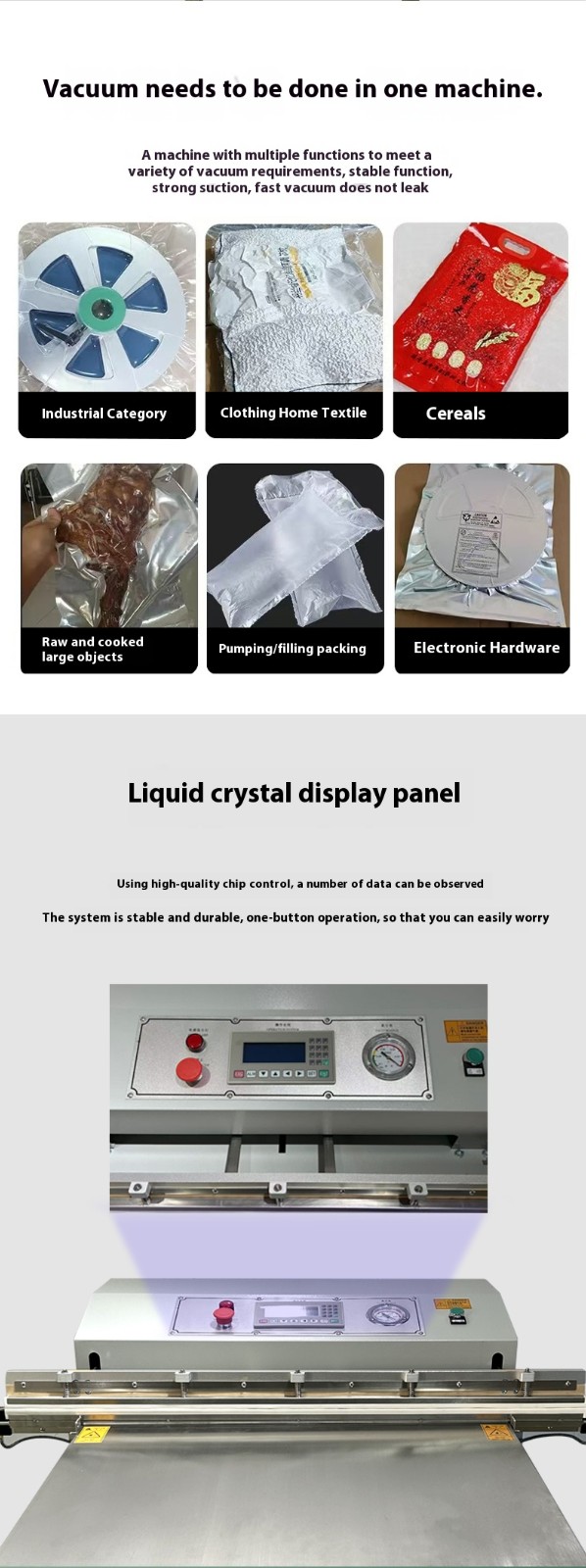

Control System Inspection: Turn on the power of the equipment, check whether the display screen of the control system is displaying normally, and whether the settings of various parameters are correct. Check whether the operation components such as buttons and switches are sensitive and effective.

Air Extraction Nozzle Inspection: Check whether the air extraction nozzle is in good condition, and whether there is any blockage or damage. Ensure that the telescopic action of the air extraction nozzle is flexible. You can manually operate the pneumatic valve to check the extending and retracting conditions of the air extraction nozzle.

Material Preparation

Packaging Bag Selection: According to the characteristics, size and packaging requirements of the items to be packaged, select packaging bags of appropriate materials and specifications. Common packaging bag materials include polyethylene (PE), polypropylene (PP), polyester (PET), etc. Ensure that the packaging bags have good sealing performance and pressure resistance.

Item Arrangement: Arrange the items to be packaged to ensure that they are clean, dry, and free of sharp edges or foreign objects to avoid damaging the packaging bags. For some items that are easily broken or deformed, appropriate protective measures can be taken, such as adding cushioning materials.

Working Environment Cleaning

Tabletop Cleaning: Clean up the sundries, dust and stains on the workbench of the packaging machine to keep the workbench clean and tidy, providing a good working platform for the packaging operation.

Surrounding Environment Arrangement: Remove the obstacles around the equipment to ensure that the operator has enough operating space, and the ventilation around the equipment is good to facilitate the heat dissipation of the equipment.