The maintenance of the can and box adhesive tape sealing machine is crucial for ensuring its normal operation, extending its service life, and guaranteeing the sealing quality. The following are some key points for its maintenance:

Daily Cleaning: After the end of each working day, the power supply should be cut off. Use a clean soft cloth to wipe off the dust, debris, and adhesive tape scraps on the surface of the equipment. For the interior of the machine body, compressed air can be used to blow away the accumulated dust. Pay special attention to cleaning key parts such as the sealing part, transmission components, and sensors to prevent the accumulation of debris from affecting the performance of the equipment.

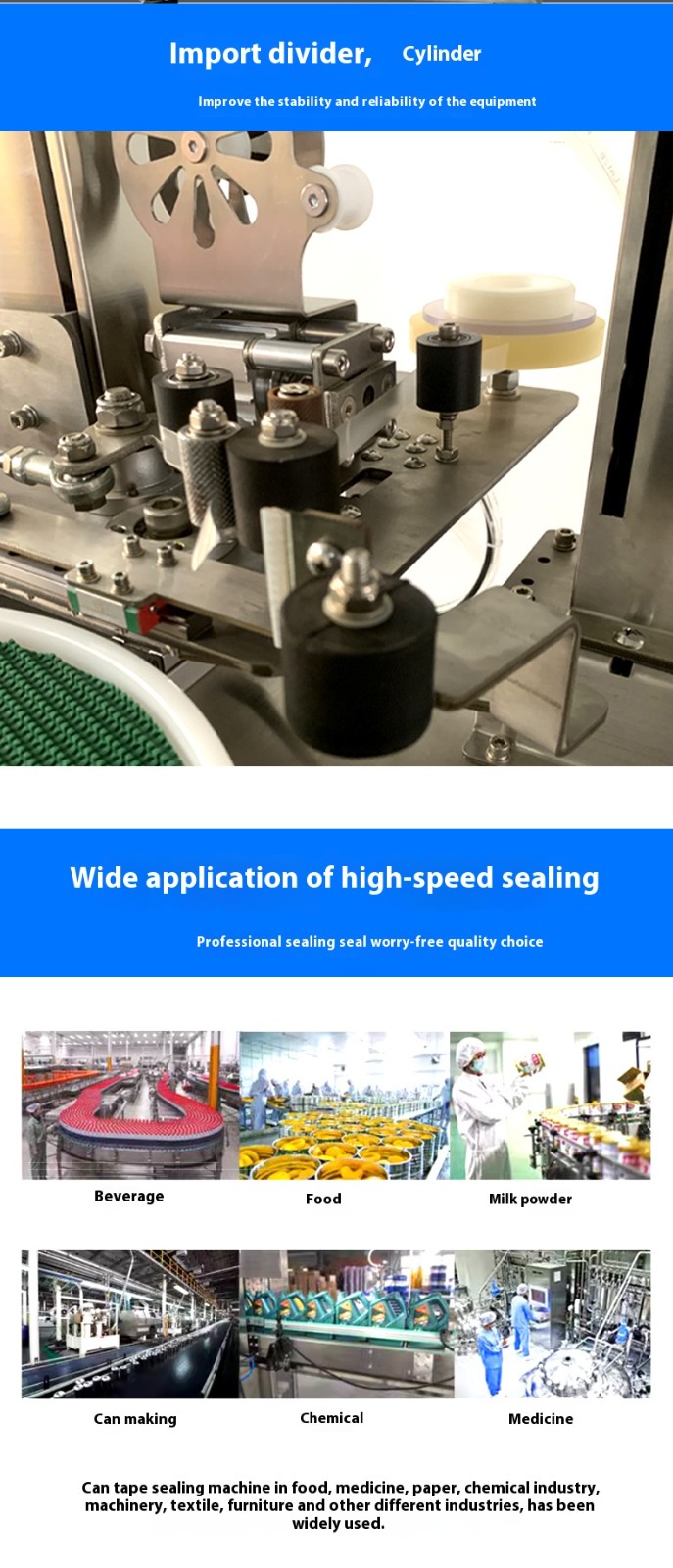

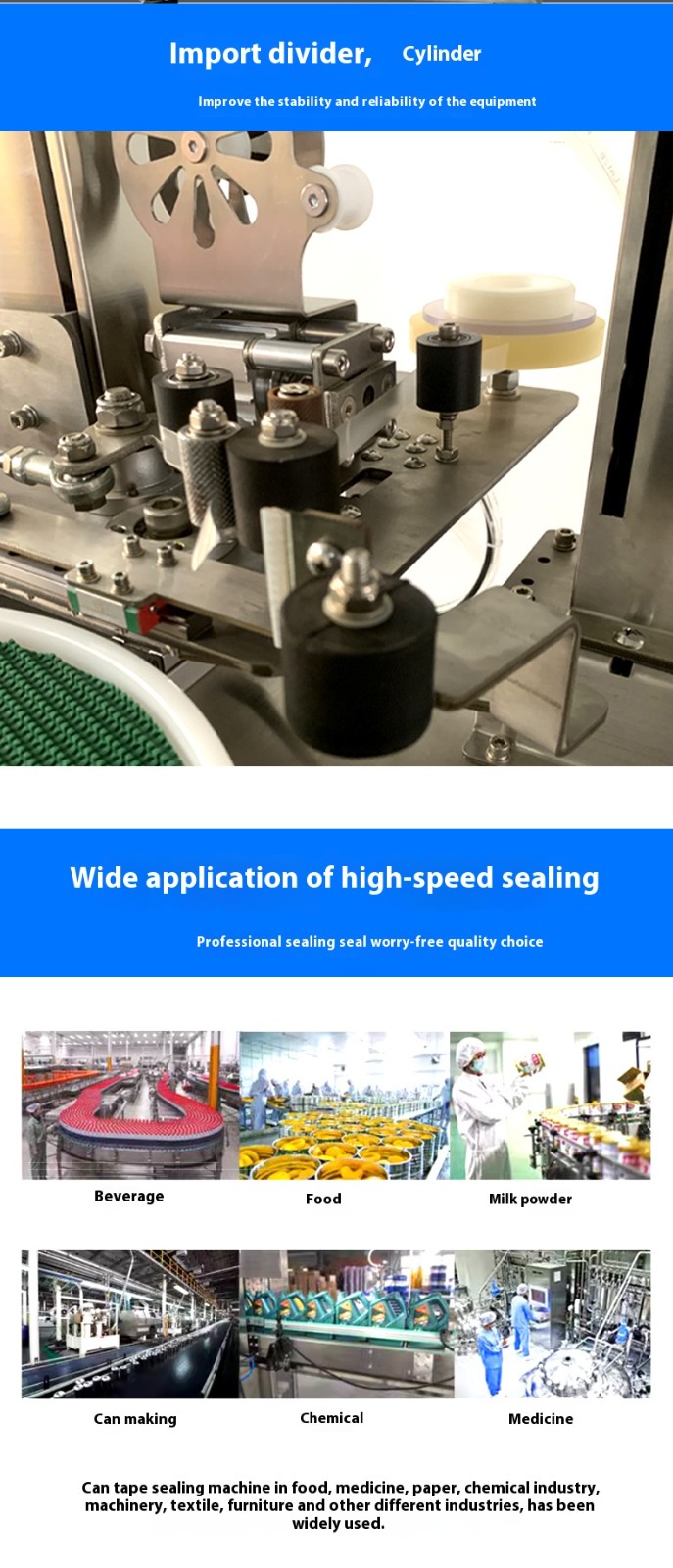

Maintenance of Adhesive Tape Installation Components: Regularly check components such as the adhesive tape installation shaft, guide wheels, and tension adjustment device. Ensure that the adhesive tape installation shaft rotates flexibly without any jamming; the surface of the guide wheels should be smooth without any wear or deformation. If there is wear, it should be replaced in a timely manner to ensure that the adhesive tape can be guided and tensioned correctly. Check whether the tension adjustment device is working properly to ensure that the adhesive tape maintains an appropriate tension during the sealing process.

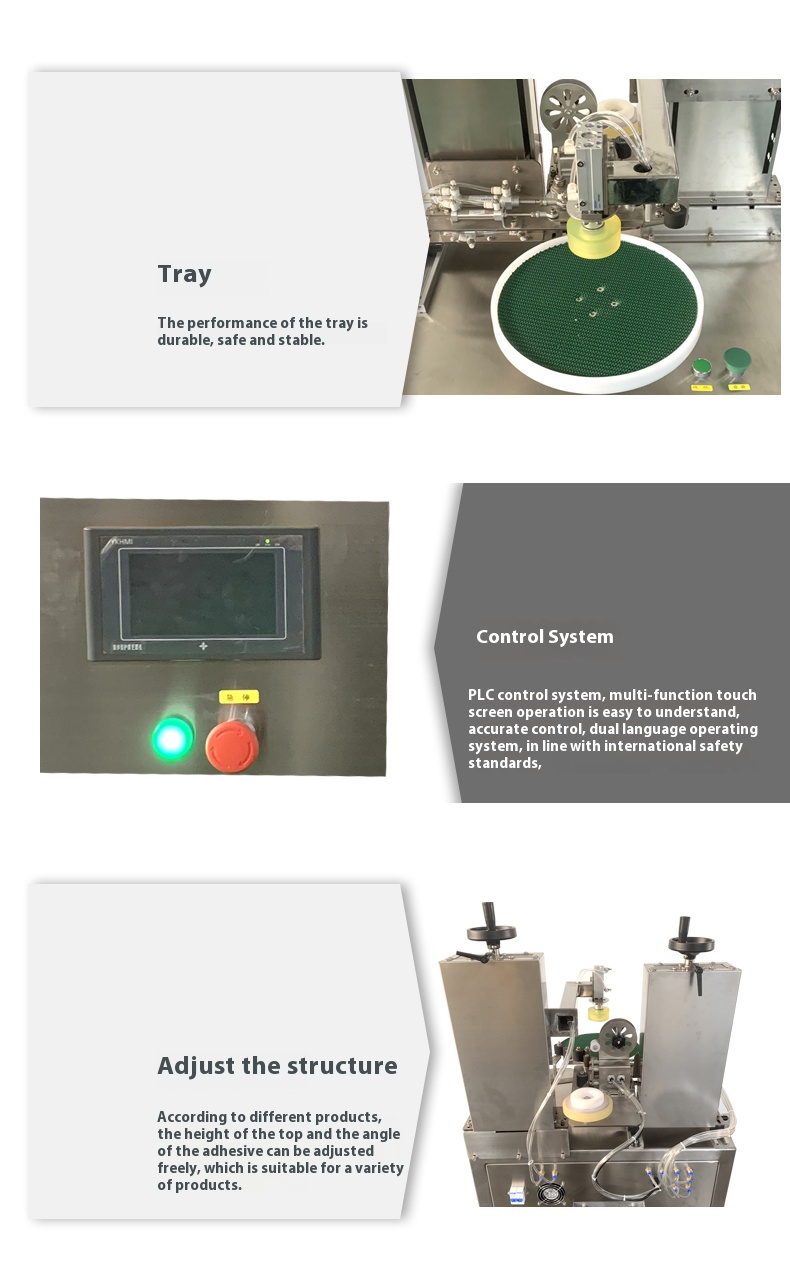

Maintenance of the Pressing Device: The pressing device is a key component for ensuring the sealing quality. Regularly check the surface condition of the pressing rollers or pressing plates. If there is wear, deformation, or foreign matter adhesion, it should be repaired or cleaned in a timely manner. At the same time, check whether the pressure adjustment mechanism of the pressing device is accurate and reliable to ensure that an appropriate pressing pressure can be provided for different packaging materials and sizes of cans and boxes.

Inspection of the Temperature Control System: If the sealing machine has a heating function, regularly check the temperature control system. This includes checking whether the temperature sensor is accurate, whether the heating element is working properly, and whether there is any dirt or damage on the surface of the heating plate. If there is any inaccuracy in temperature control, the relevant components should be calibrated or replaced in a timely manner to avoid poor sealing caused by abnormal temperatures.

Lubrication of Transmission Components: Transmission components of the equipment such as chains, gears, lead screws, and guide rails need to be regularly lubricated with lubricating oil or grease. Generally, lubrication should be carried out once every certain working period (such as weekly or monthly) to reduce friction, lower wear, and ensure the smoothness and accuracy of transmission. At the same time, promptly clean the excess lubricating oil on the transmission components to prevent the oil stain from contaminating the packaging materials or products.

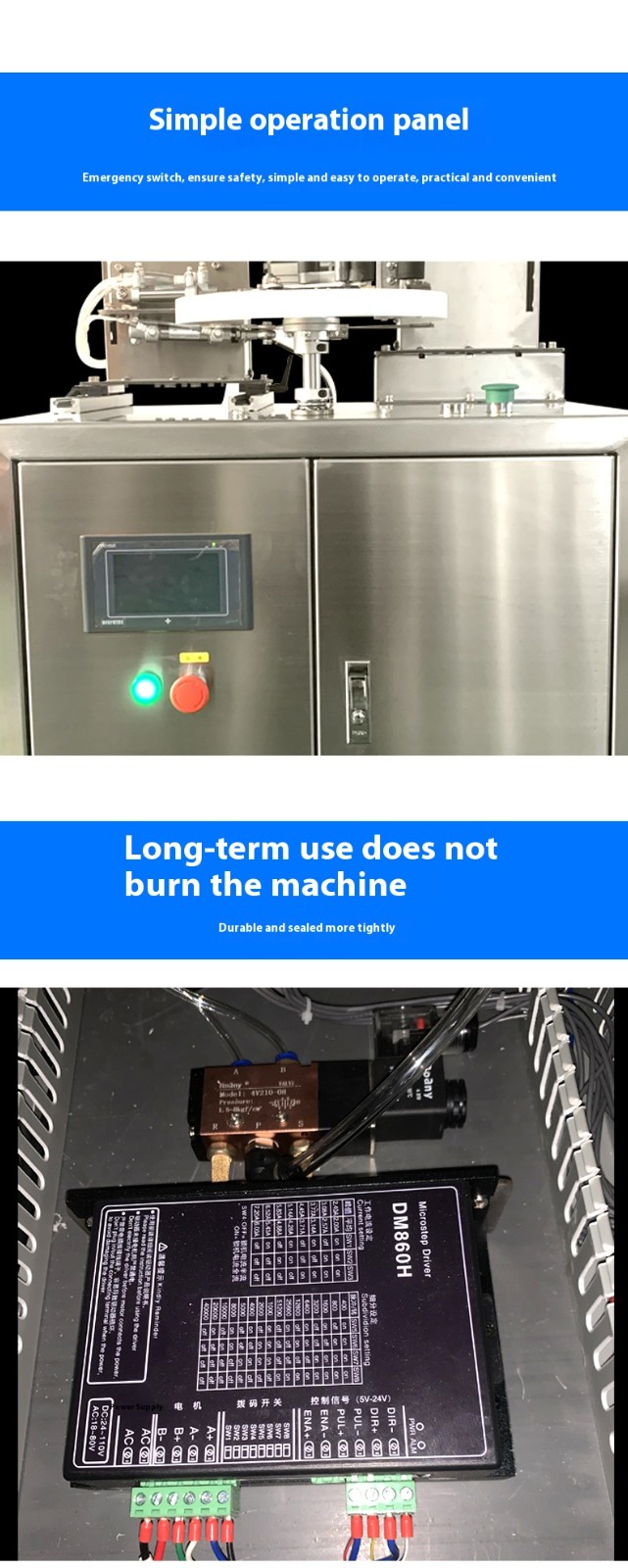

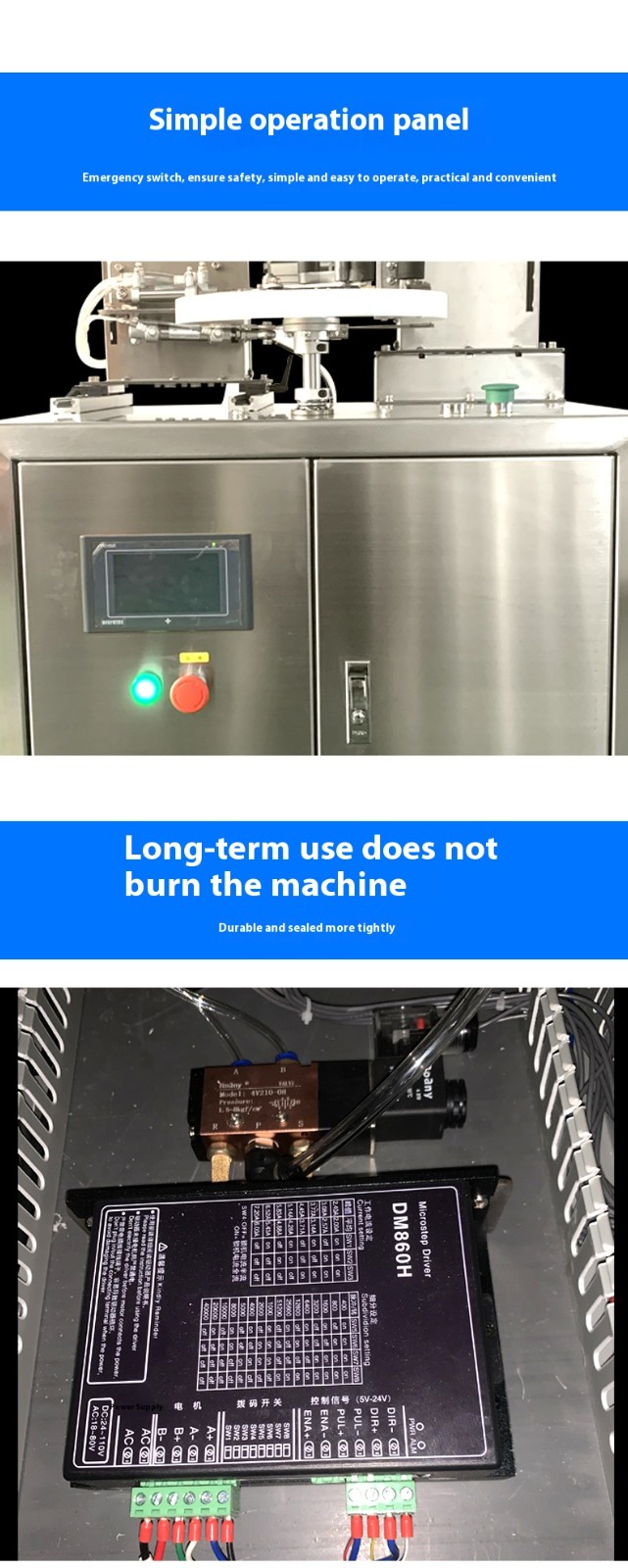

Inspection of the Electrical System: Regularly check the connection of the electrical system, including power cords, plugs, sockets, switches, relays, and other components to ensure that the connections are firm without any looseness, poor contact, or short-circuit phenomena. Check the working status of the electrical components. If there are abnormal phenomena such as overheating, arcing, or peculiar smell, the machine should be shut down immediately for inspection and troubleshooting. In addition, pay attention to keeping the inside of the electrical cabinet clean and dry to prevent dust and moisture from affecting the electrical performance.

Replacement of Vulnerable Parts: According to the usage frequency and actual operation situation of the equipment, regularly replace vulnerable parts such as blades, springs, and sealing rings. These vulnerable parts may experience wear, aging, or damage after long-term use, which will affect the normal operation of the equipment and the sealing quality. Replacing the vulnerable parts in a timely manner can prevent the occurrence of faults and ensure the stability and reliability of the equipment.

Regular Calibration and Debugging: Regularly calibrate and debug the can and box adhesive tape sealing machine to ensure that all parameters and performance indicators of the equipment meet the requirements. For example, check the accuracy of the sealing position, whether the length and width of the adhesive tape pasting are accurate, and adjust the running speed of the equipment and the coordination among various actions. Through regular calibration and debugging, potential problems can be discovered and solved in a timely manner to ensure that the equipment is always in the best working condition.

Requirements for the Storage Environment: If the equipment needs to be shut down and stored for a long time, it should be placed in a dry and well-ventilated environment to avoid the influence of humidity, dust, and corrosive gases. At the same time, conduct a comprehensive cleaning and maintenance of the equipment, and take appropriate protective measures, such as covering it with a dust cover, to prevent the equipment from being damaged during the storage period.