Preparation Work

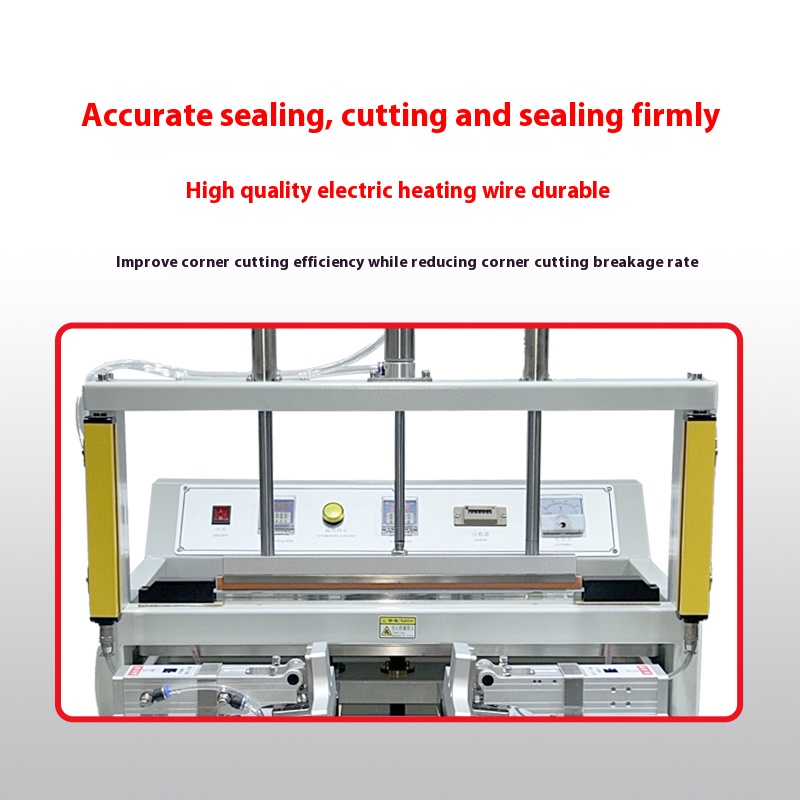

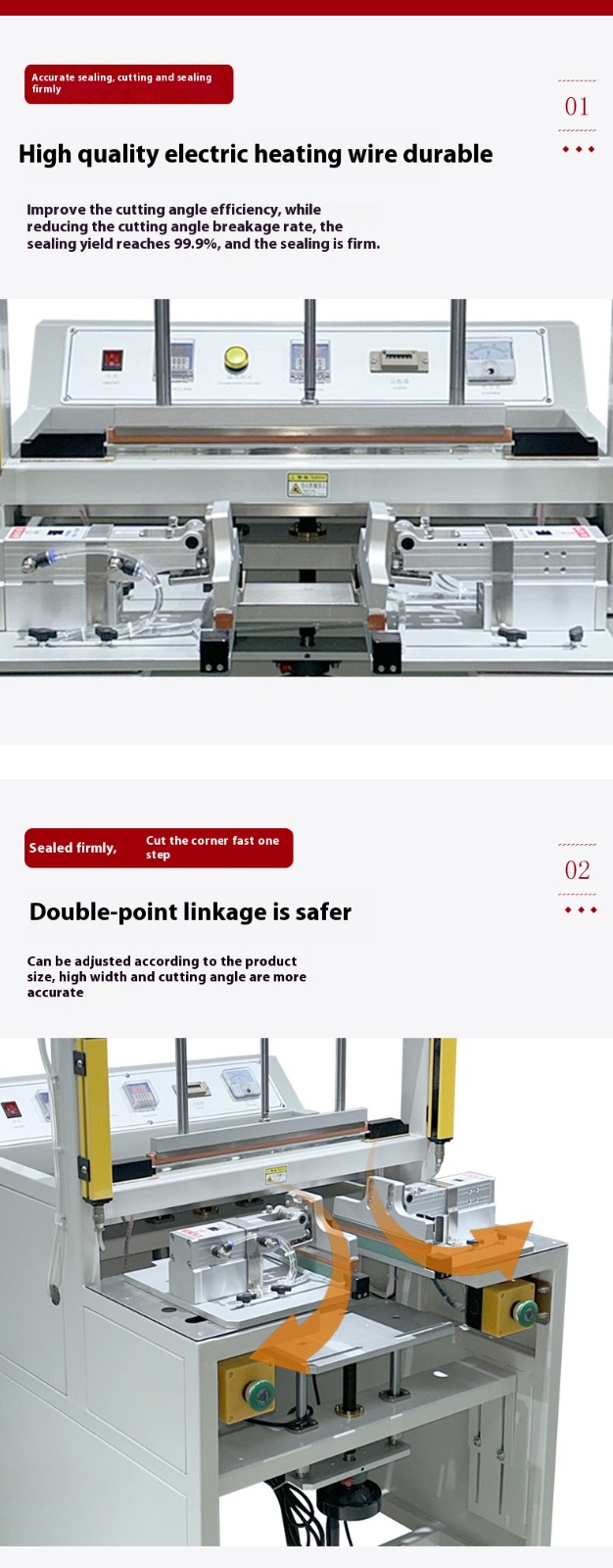

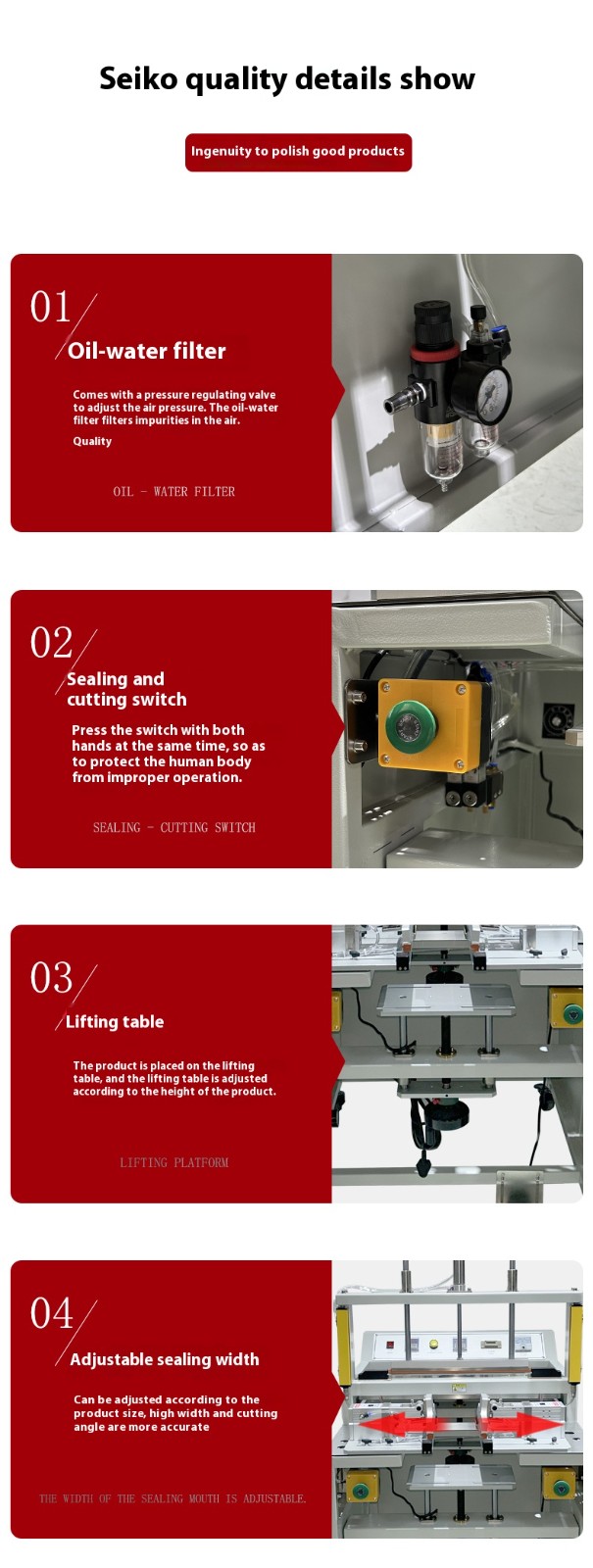

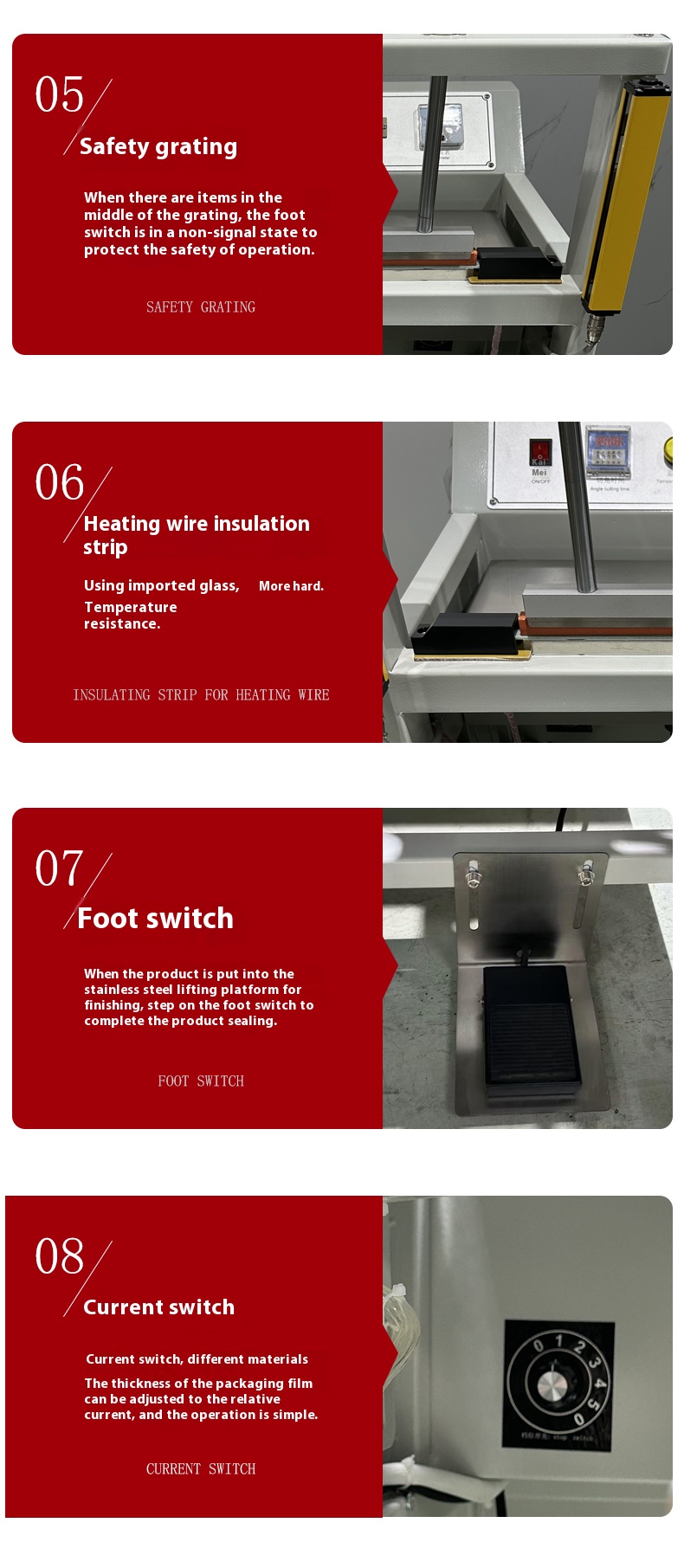

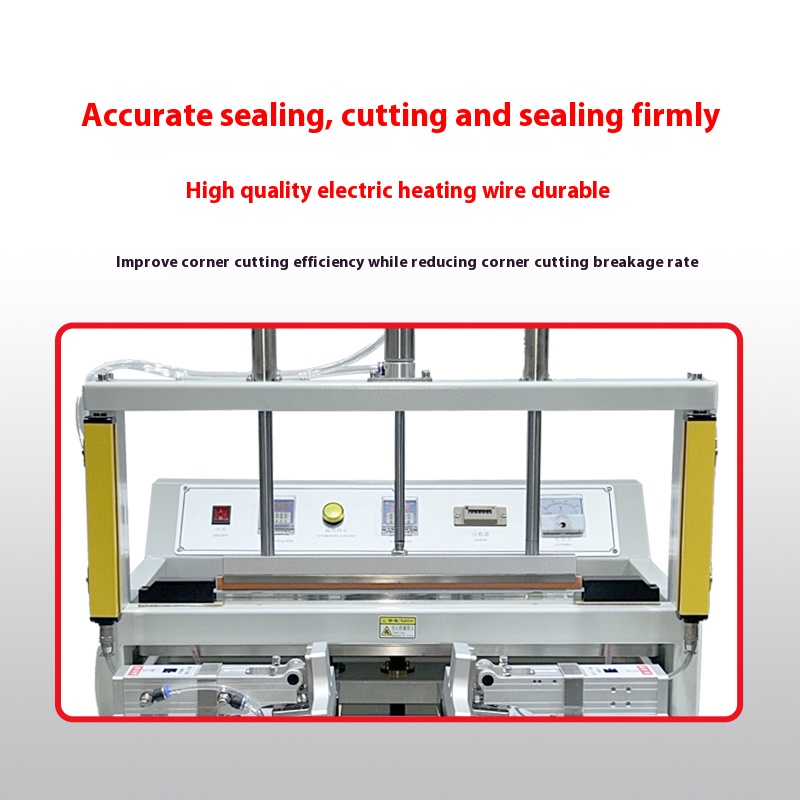

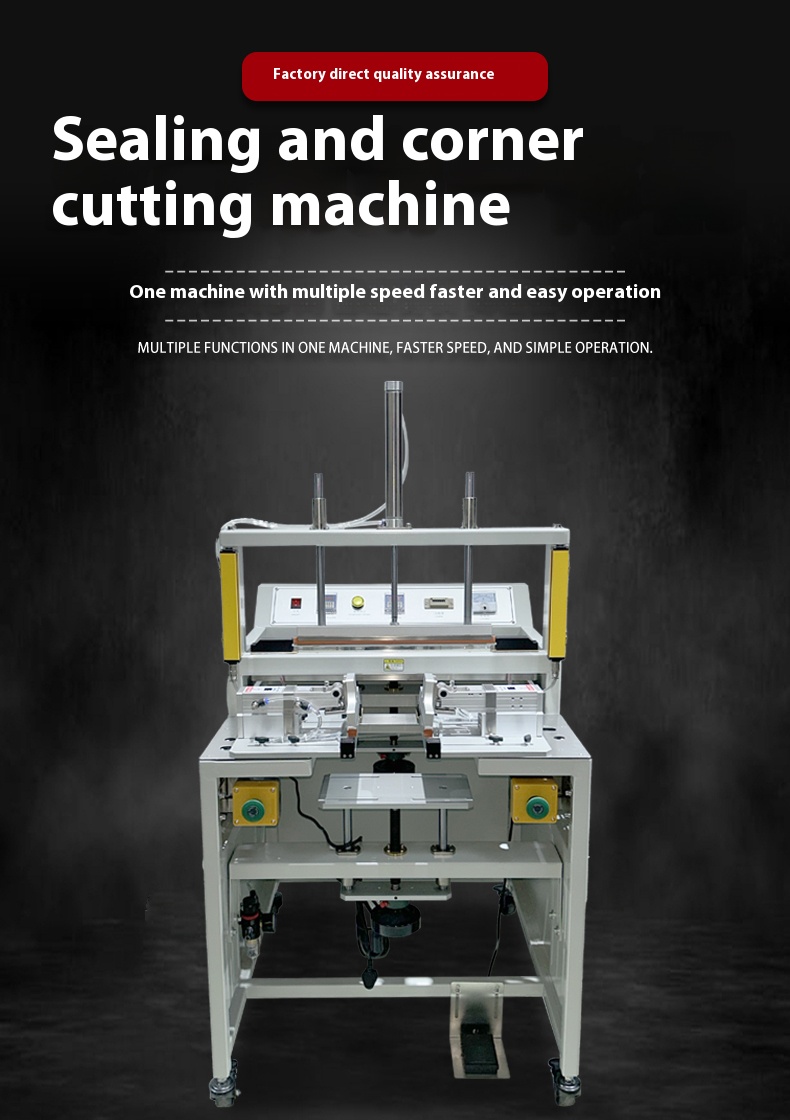

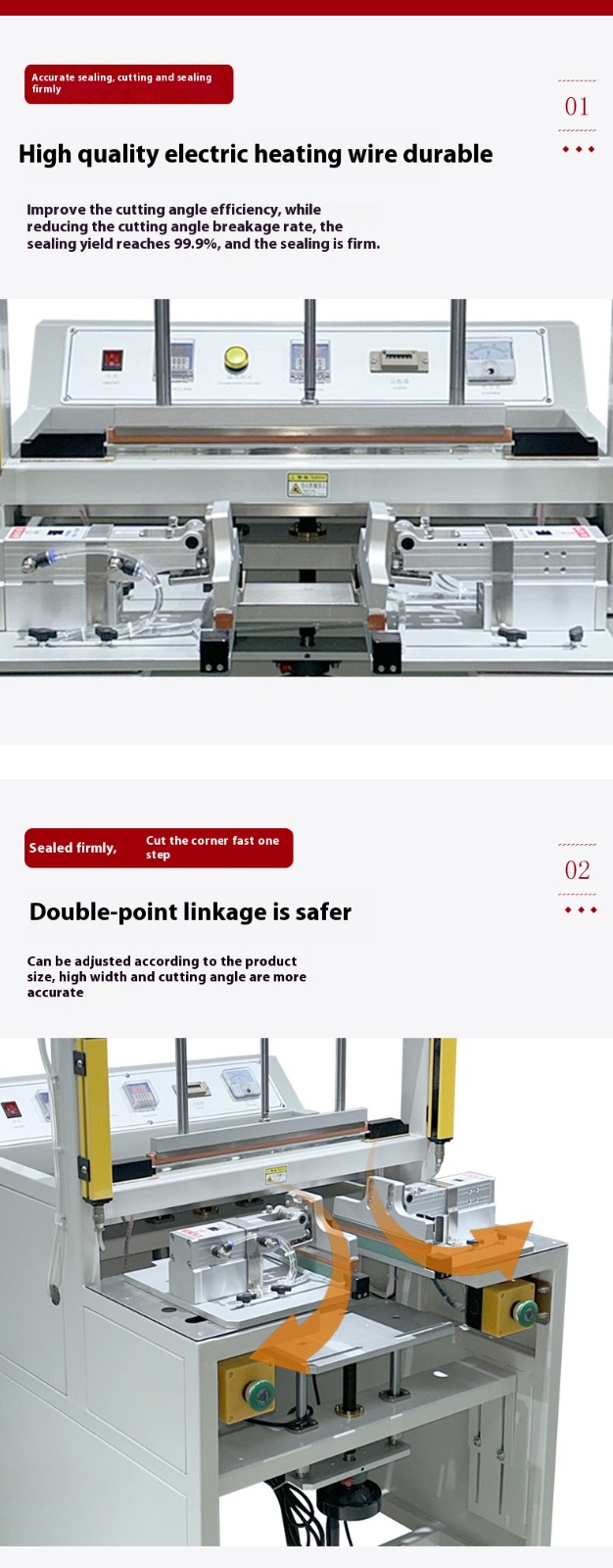

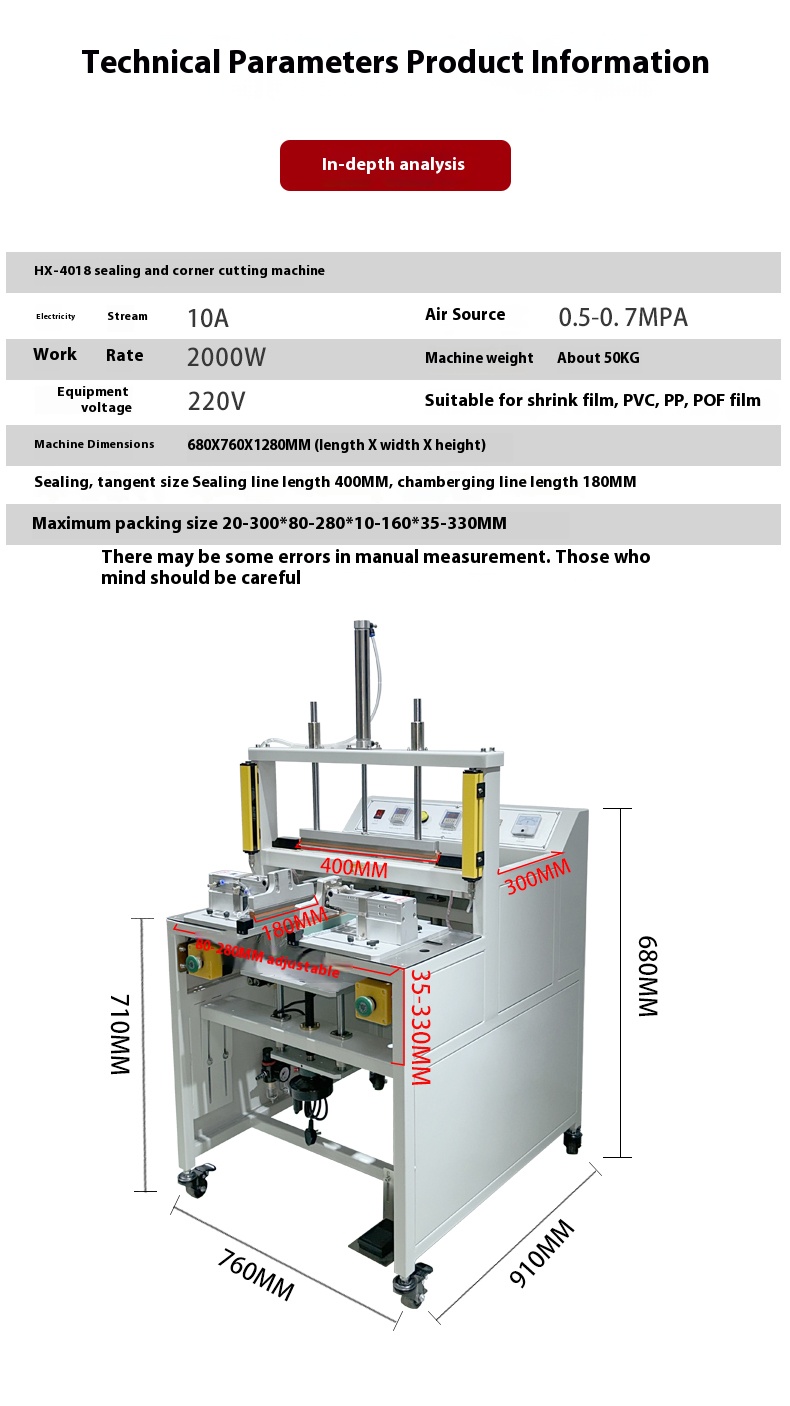

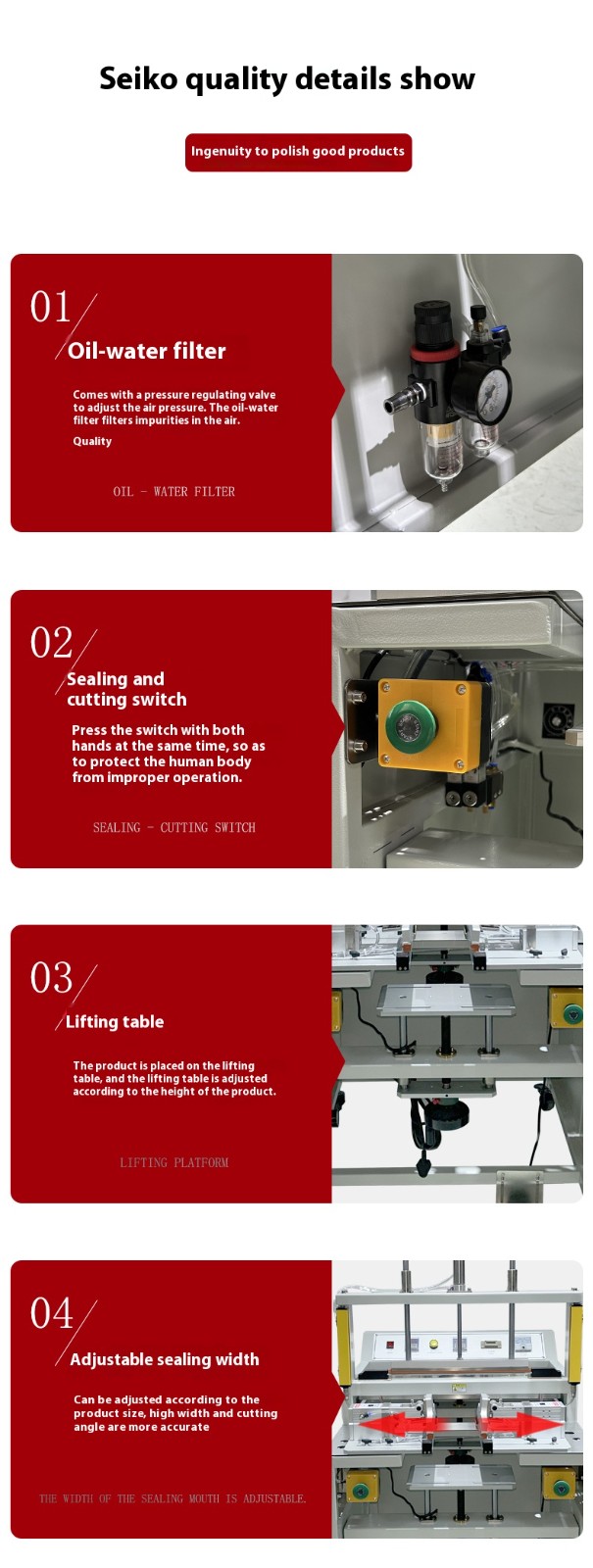

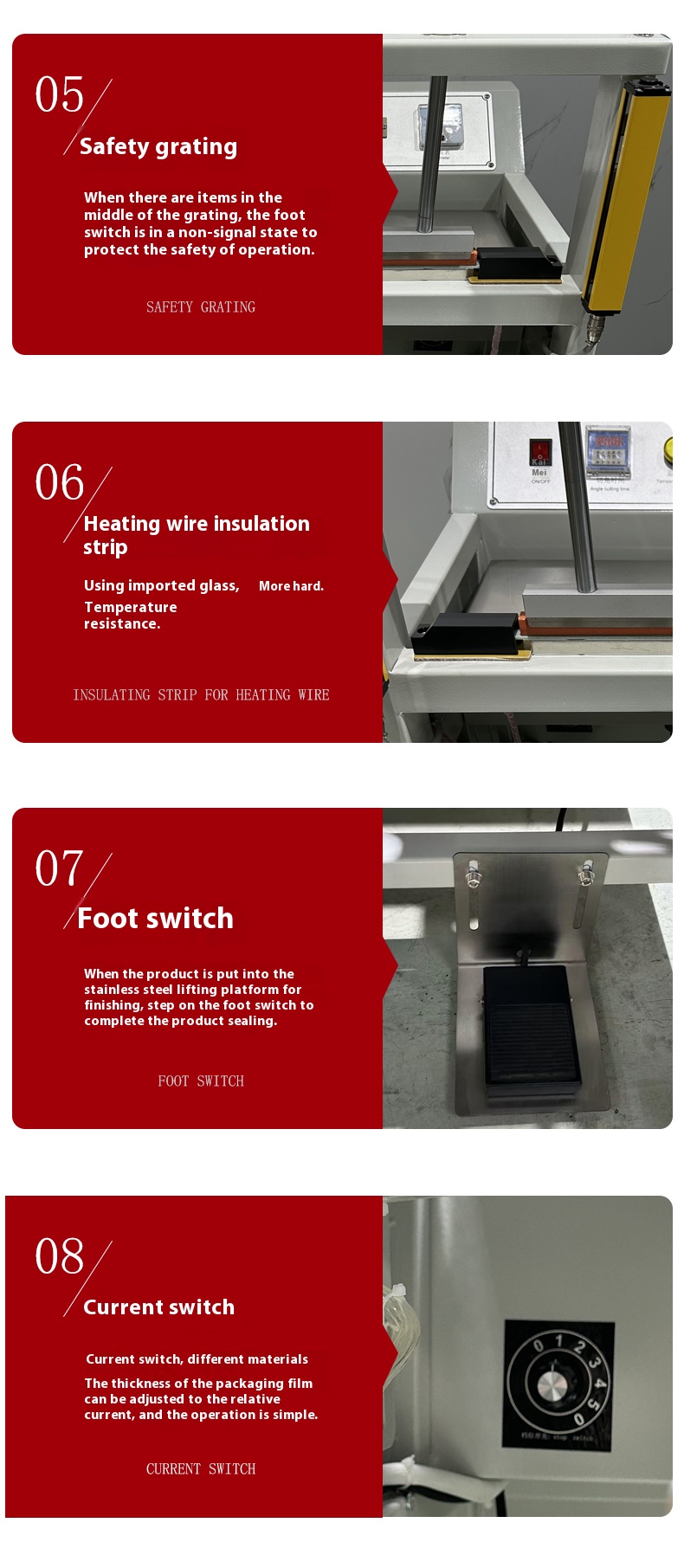

Inspect the Equipment: Check whether all components of the equipment are in normal condition, including the sealing module, corner cutting module, conveying and positioning system, etc., to ensure there is no damage or malfunction. Examine key components such as heating elements, cutting tools or laser cutting systems to see if they are in good condition. If there is any wear or damage, replace them in a timely manner.

Clean the Equipment: Use a clean cloth to wipe the workbench surface, conveyor belt and other parts of the equipment to remove debris and dust, so as not to affect the packaging quality.

Prepare Materials: According to the packaging requirements, prepare corresponding packaging materials, such as plastic films, paper materials, aluminum foil composite materials, etc., and ensure that the specifications and quality of the materials meet the requirements of the equipment. At the same time, prepare the products to be packaged.

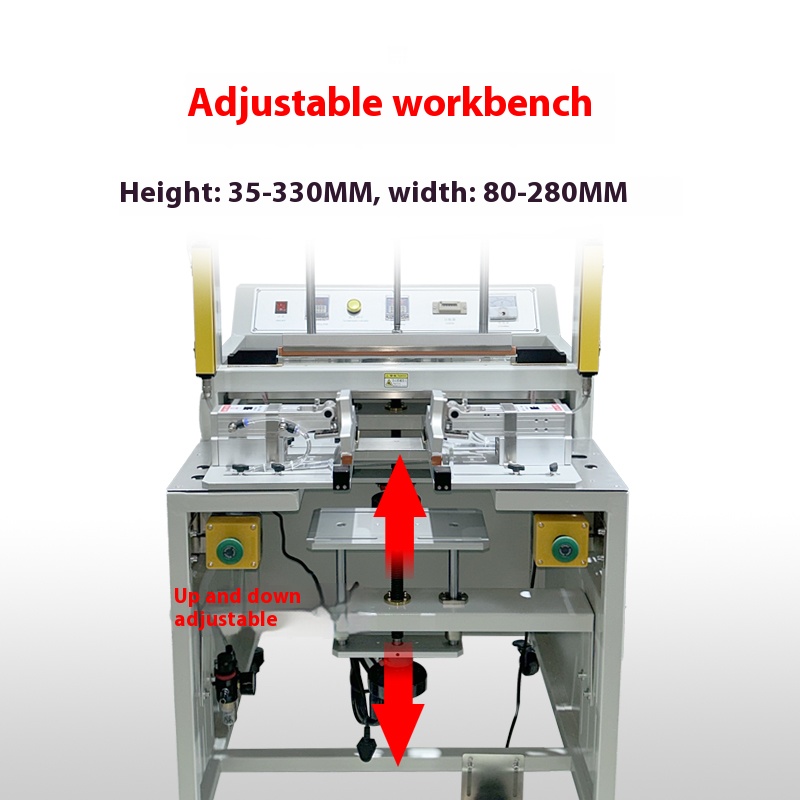

Install the Mold (if necessary): If it is necessary to replace the corner cutting mold of a different shape or size, correctly install and fix the mold according to the instructions of the equipment. Ensure that the mold is firmly installed and in the correct position to avoid affecting the corner cutting effect.

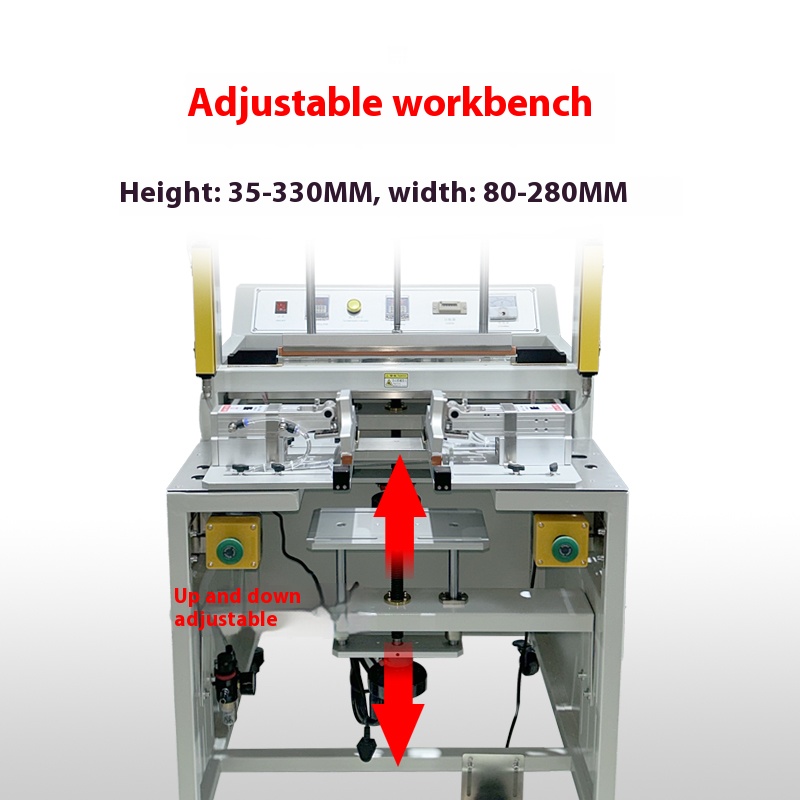

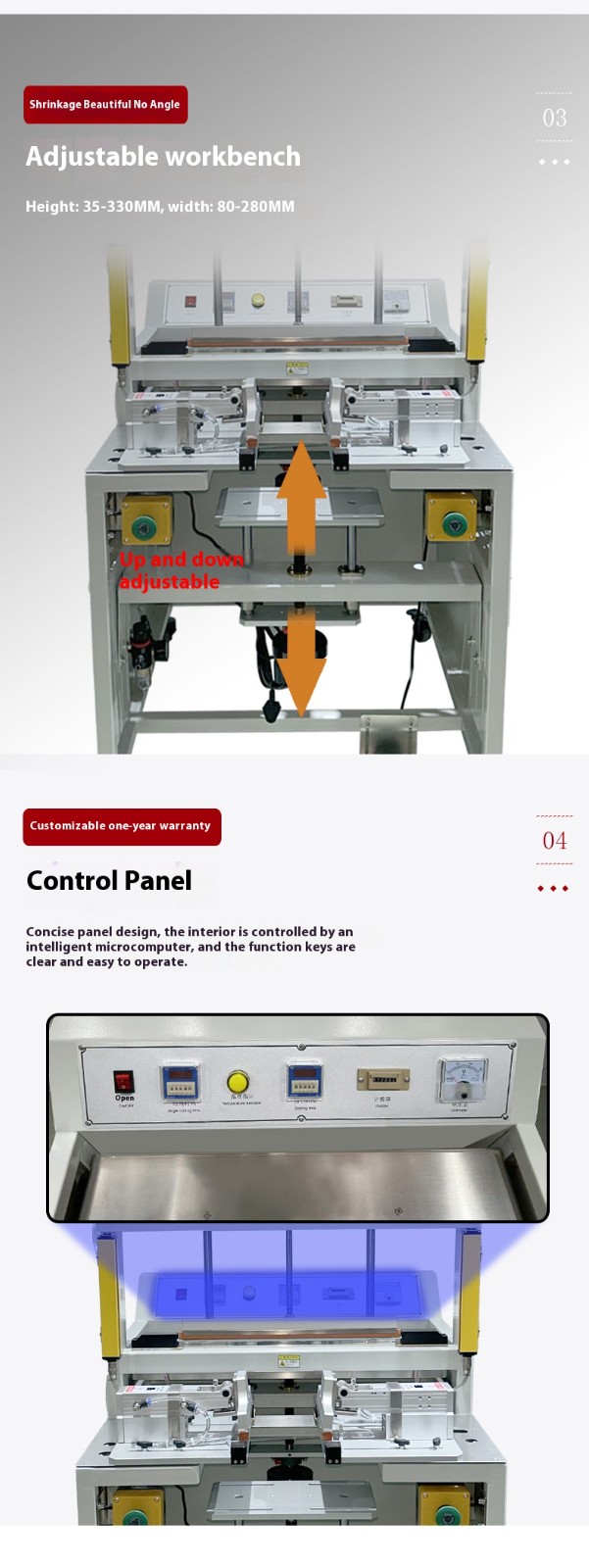

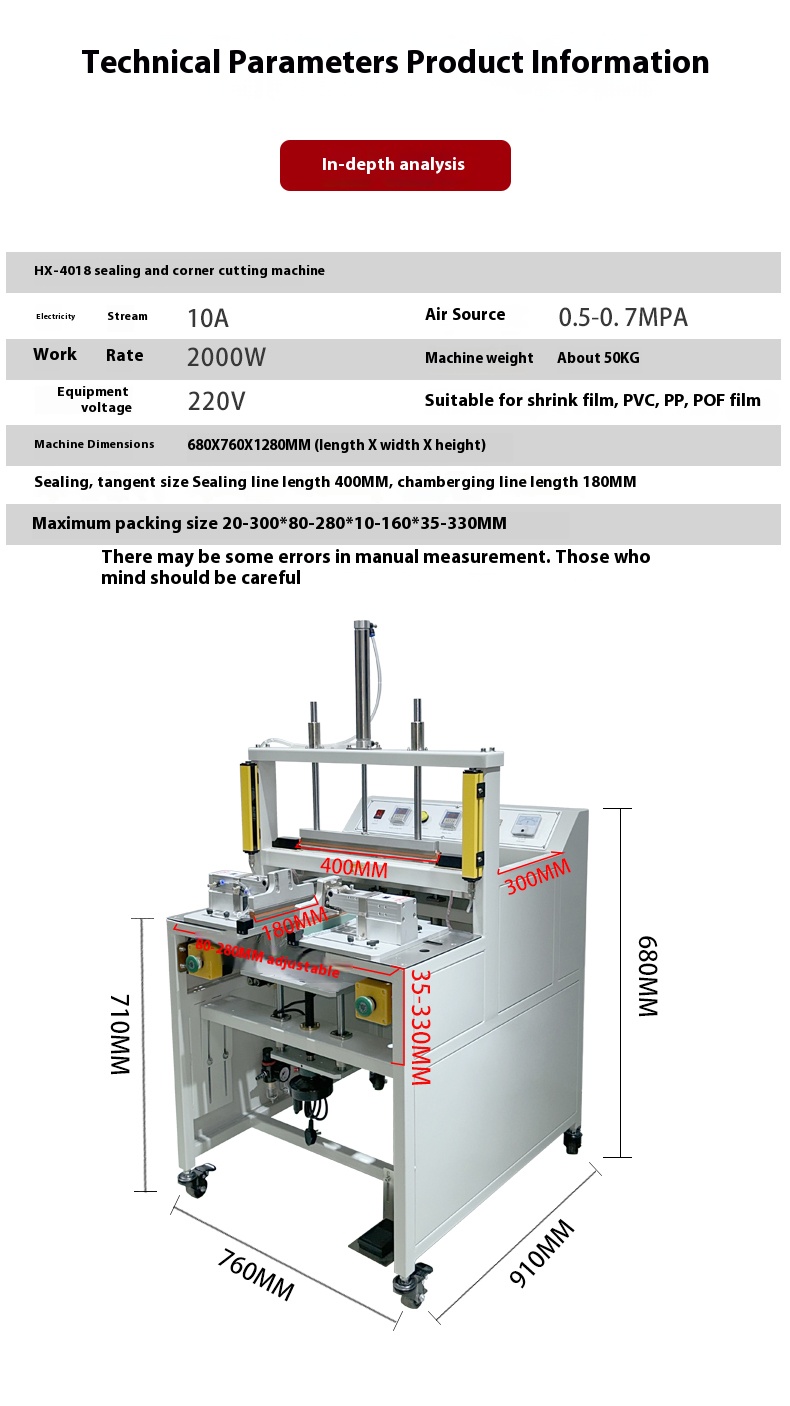

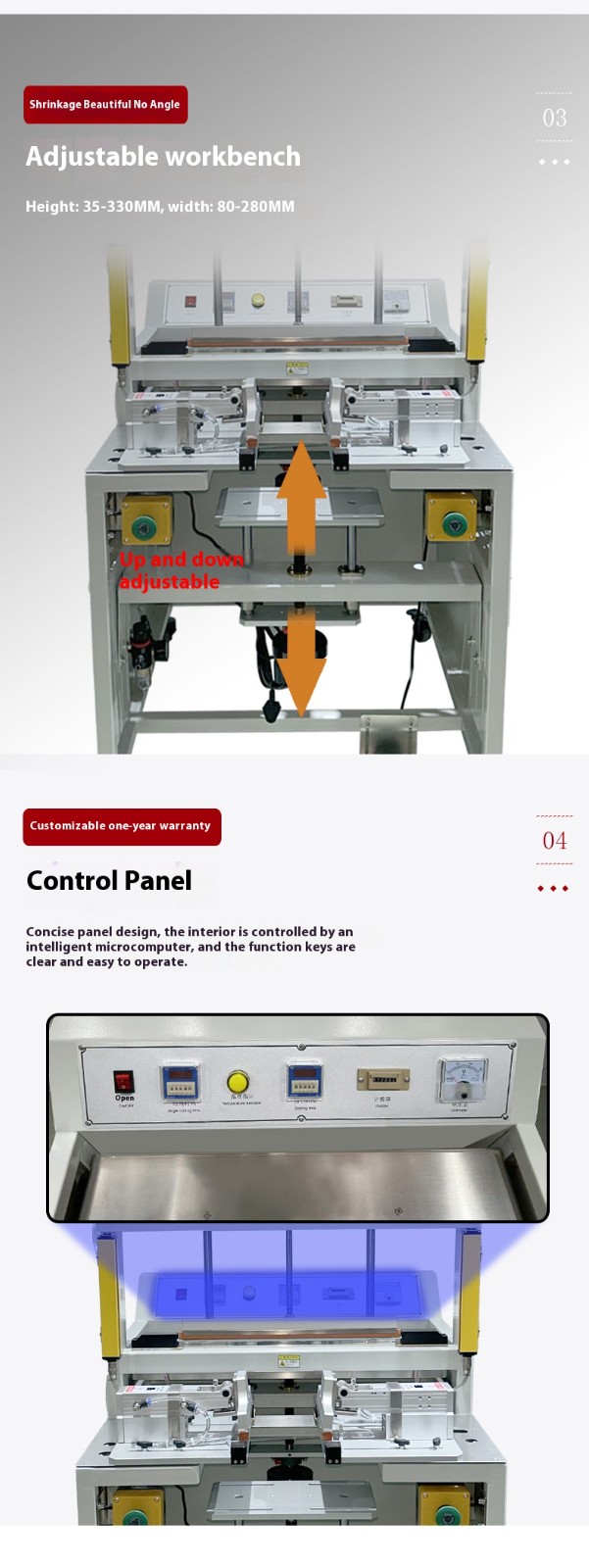

Set Parameters: Through the operation interface of the equipment, set the relevant parameters for sealing and corner cutting. This includes the sealing temperature, pressure, time, as well as the angle, size and position of corner cutting. These parameters are usually adjusted according to the material, thickness of the packaging material and the packaging requirements of the product. Generally, thicker materials require higher sealing temperature and pressure, as well as a longer sealing time.

Material Loading and Debugging

Place the Packaging Material: Place the prepared packaging material at the inlet of the equipment, ensuring that the placement position of the material is correct and it can smoothly enter the conveying system. For equipment that requires roll-type packaging materials, install the roll correctly and adjust the tension of the material.

Place the Product (if applicable): If the product needs to be placed in the packaging material before the sealing and corner cutting operation, accurately place the product at the designated position of the packaging material. Some equipment may have an automatic feeding function, and the product should be placed in the corresponding feeding device according to the requirements of the equipment.

Conduct Debugging Operation: Before the formal production, carry out several debugging operations. First, perform an unloaded operation to observe whether the conveying system, sealing module and corner cutting module of the equipment operate normally, and whether the actions of all components are coordinated. Then, conduct a trial packaging, put a small amount of packaging material and products, and check the effects of sealing and corner cutting. If it is found that the parameter setting is unreasonable or there are problems with the operation of the equipment, adjust and repair it in a timely manner.

Formal Production

Start the Equipment: After confirming that the debugging is correct, start the equipment for formal production. Continuously put the packaging materials and products into the inlet, and the equipment will automatically complete a series of operations such as conveying, positioning, sealing and corner cutting. During the production process, pay attention to observing the operation of the equipment to ensure that the packaging materials are smoothly conveyed and the packaging quality of the products meets the requirements.

Quality Inspection: Regularly conduct quality inspection on the packaged products, mainly checking whether the sealing is firm and flat, and whether there are situations such as leakage sealing and false sealing; whether the angle and size of the corner cutting are accurate and whether the edges are neat. If packaging quality problems are found, stop the machine in a timely manner to check the reasons, and adjust the equipment parameters or operation.

Material Replenishment and Cleaning: During the production process, replenish the packaging materials and products in a timely manner to ensure that the equipment will not stop due to material shortages. At the same time, regularly clean the waste and debris around the equipment to keep the working environment clean.

Ending Work

Turn off the Equipment: After the production task is completed, first close the inlet of the equipment to stop the conveying of packaging materials and products. Then, according to the operation instructions of the equipment, turn off each module and power supply of the equipment in sequence. Wait until the equipment completely stops running and cools down before carrying out subsequent cleaning and maintenance work.

Clean the Equipment: Use appropriate tools and cleaning agents to clean the residual packaging materials, glue and other debris on the equipment. Pay special attention to cleaning the dirt on the sealing module and corner cutting module to avoid affecting the performance and service life of the equipment. For some vulnerable parts, check and maintain them, such as adding lubricating oil and replacing worn parts.

Organize the Working Area: Organize and put the remaining packaging materials, products and tools in place to keep the working area clean and orderly. Classify and process the waste and defective products generated during the production process for recycling or proper disposal.

Record and Report: Record information such as the running time of the equipment, production quantity, packaging quality situation, as well as the problems and treatment methods of the equipment. These records are helpful for evaluating the performance of the equipment and providing a reference for subsequent maintenance and improvement. At the same time, report the relevant situation to the superior according to the production needs and the operation status of the equipment.