The working efficiency of a pagination labeling machine is affected by various factors, as follows:

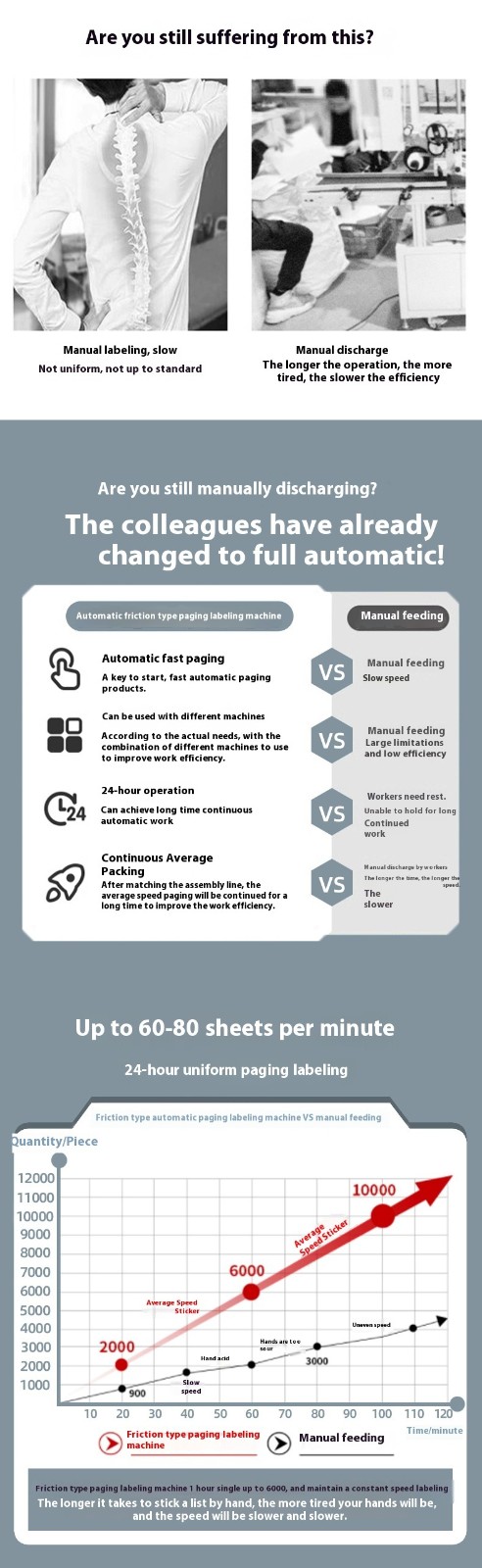

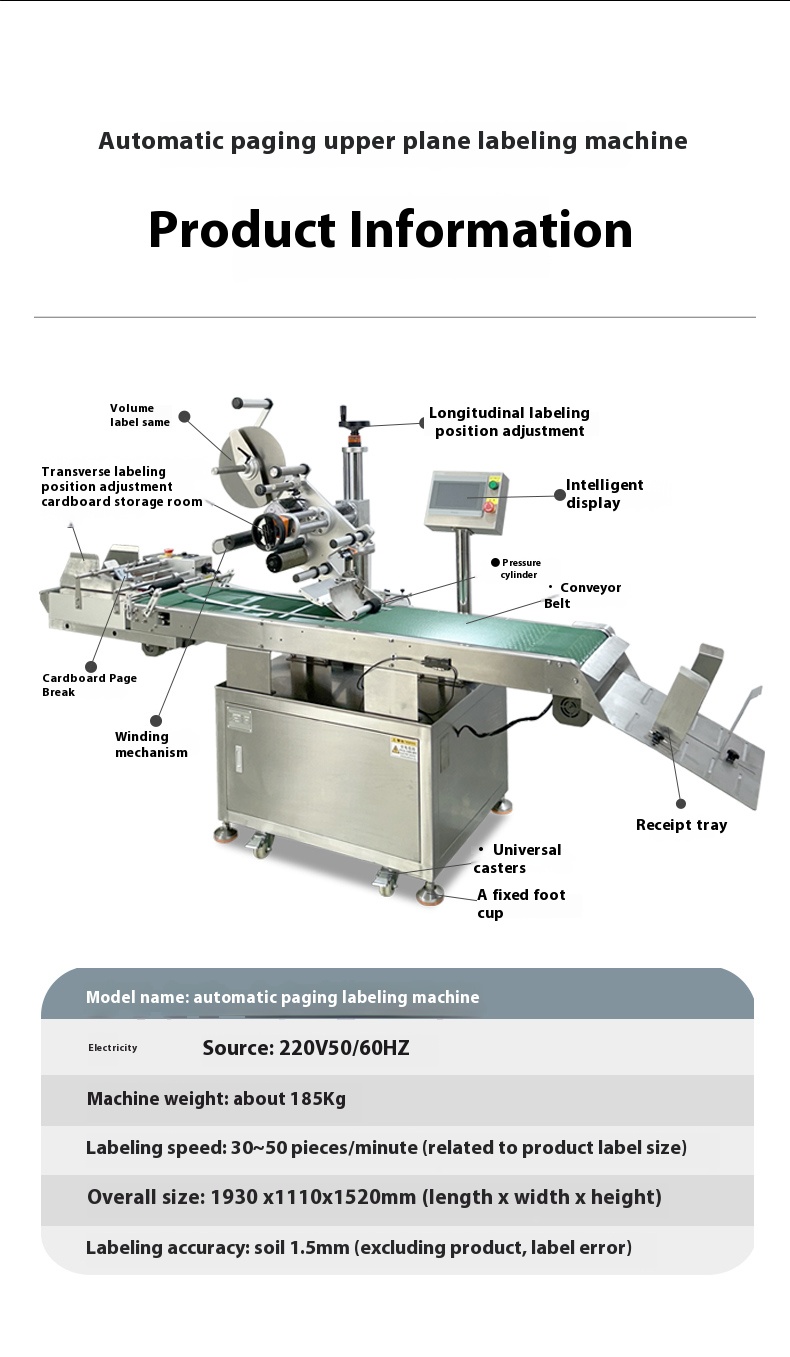

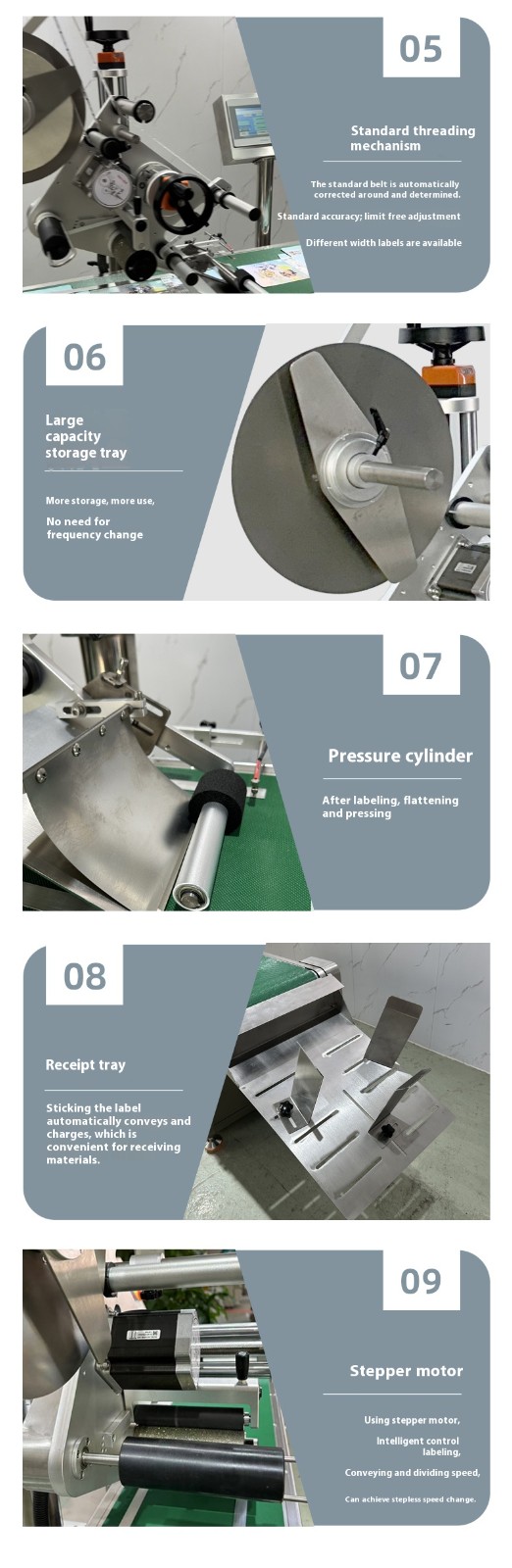

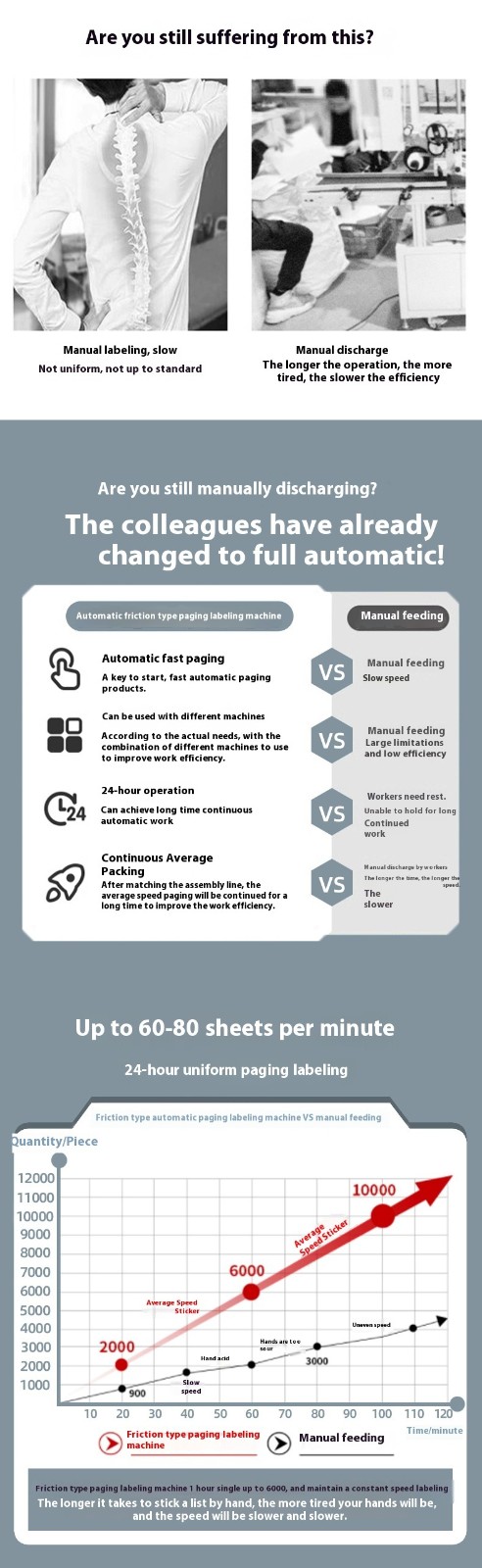

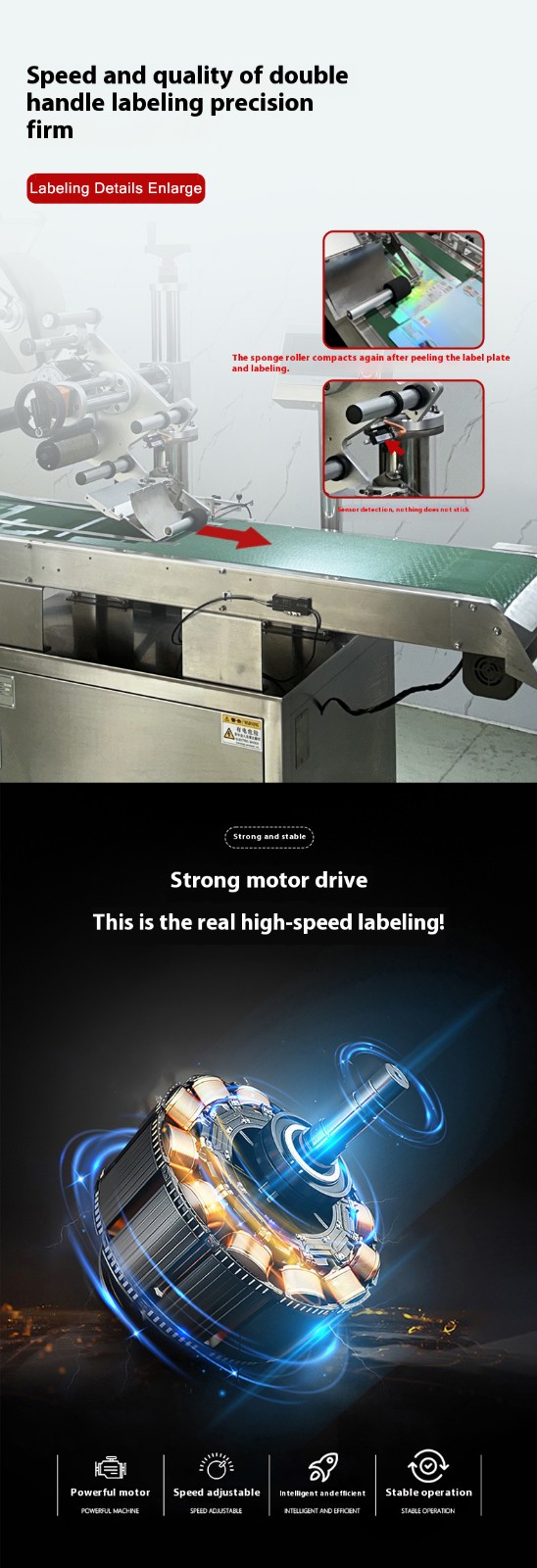

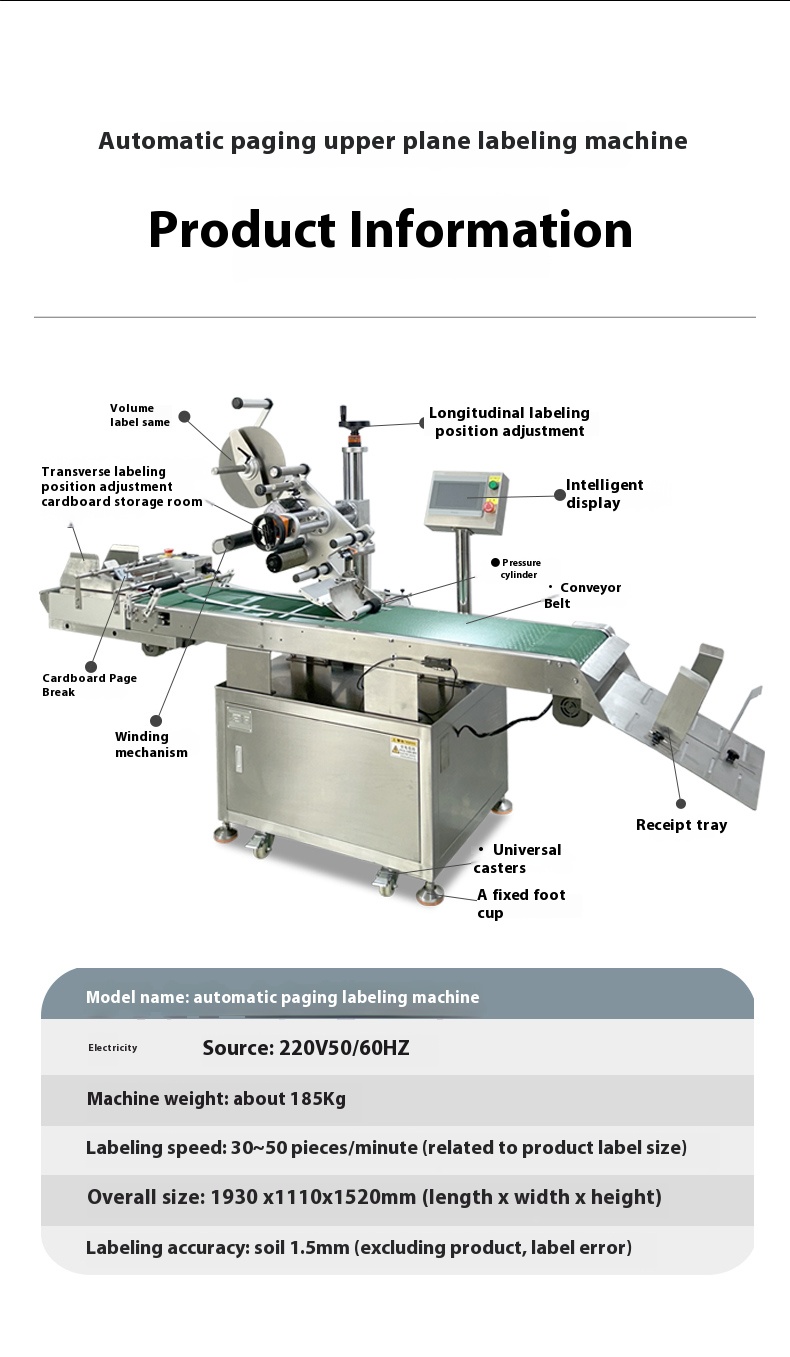

- Labeling speed: This is a crucial indicator for measuring the working efficiency of a labeling machine, which is usually determined by the performance of the motor, the accuracy of the transmission system, and the response speed of the control system. High - speed labeling machines can complete hundreds or even more labeling operations per minute, while low - speed ones may only complete dozens of operations per minute.

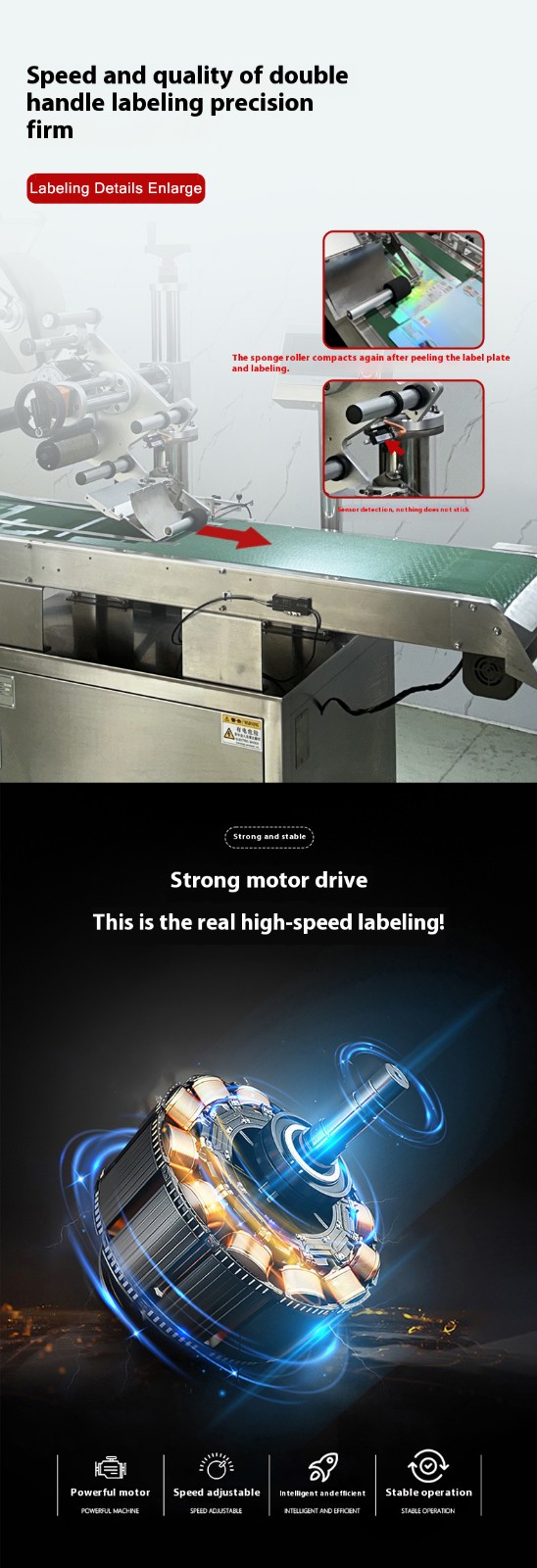

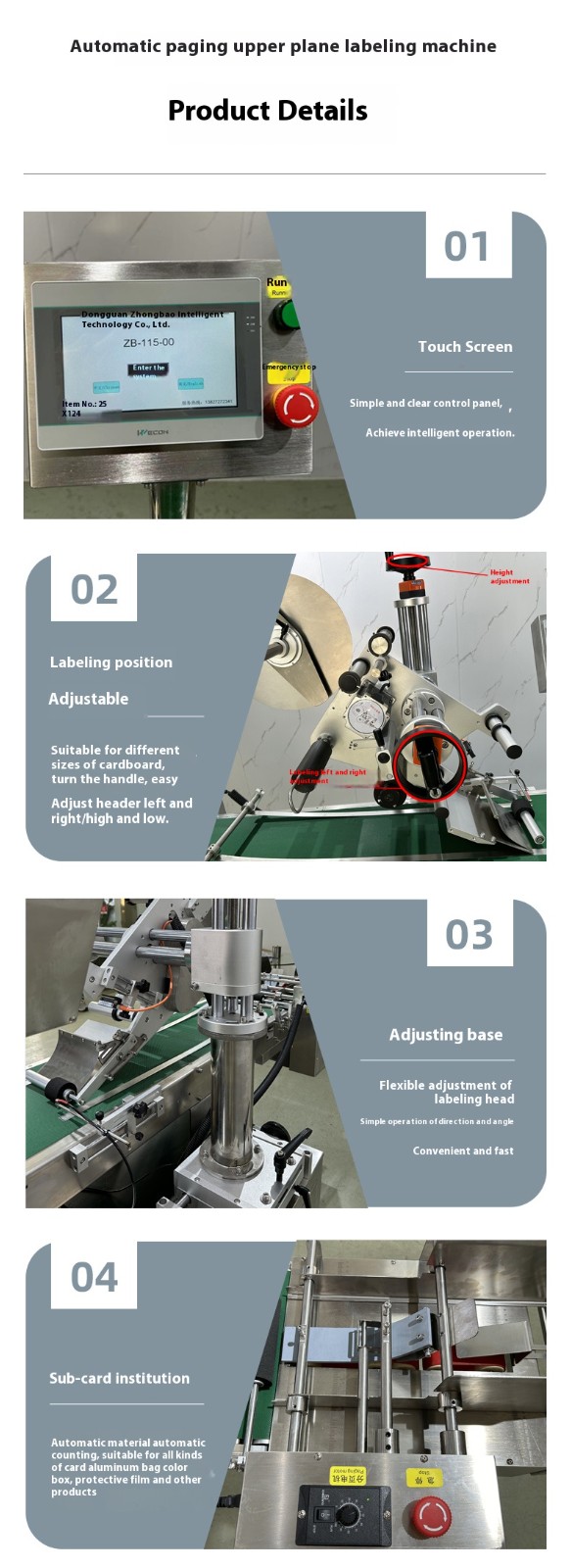

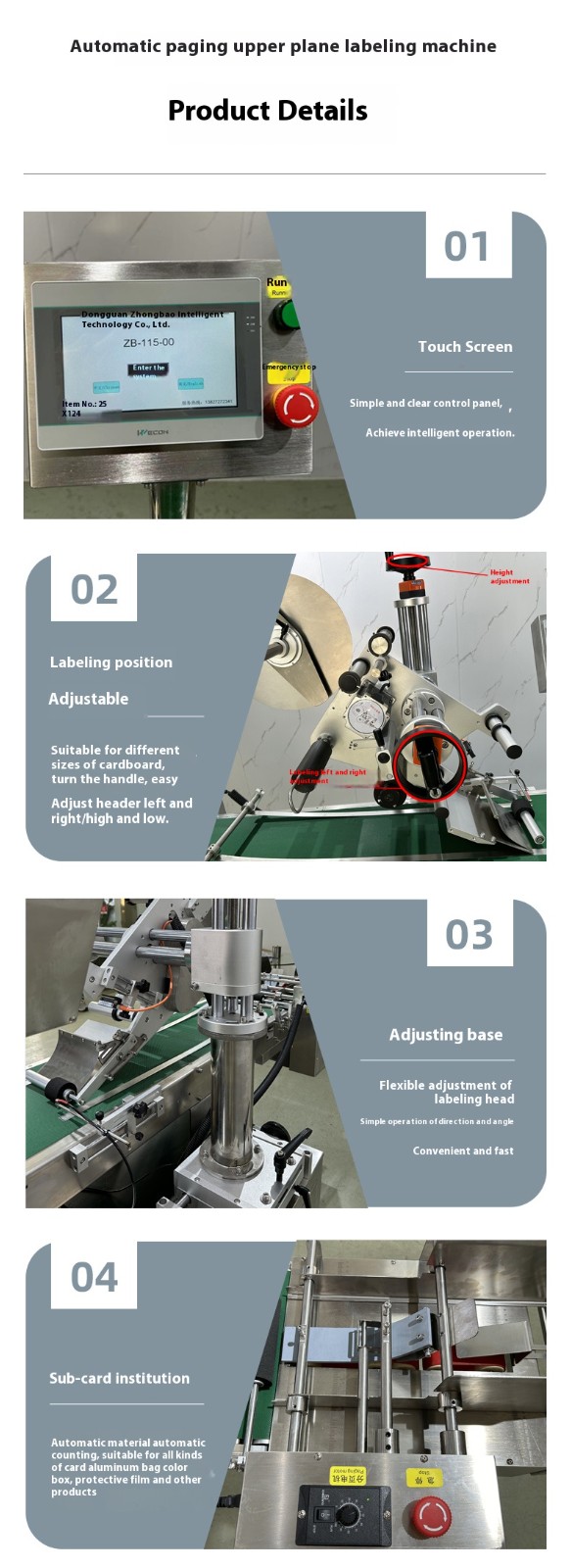

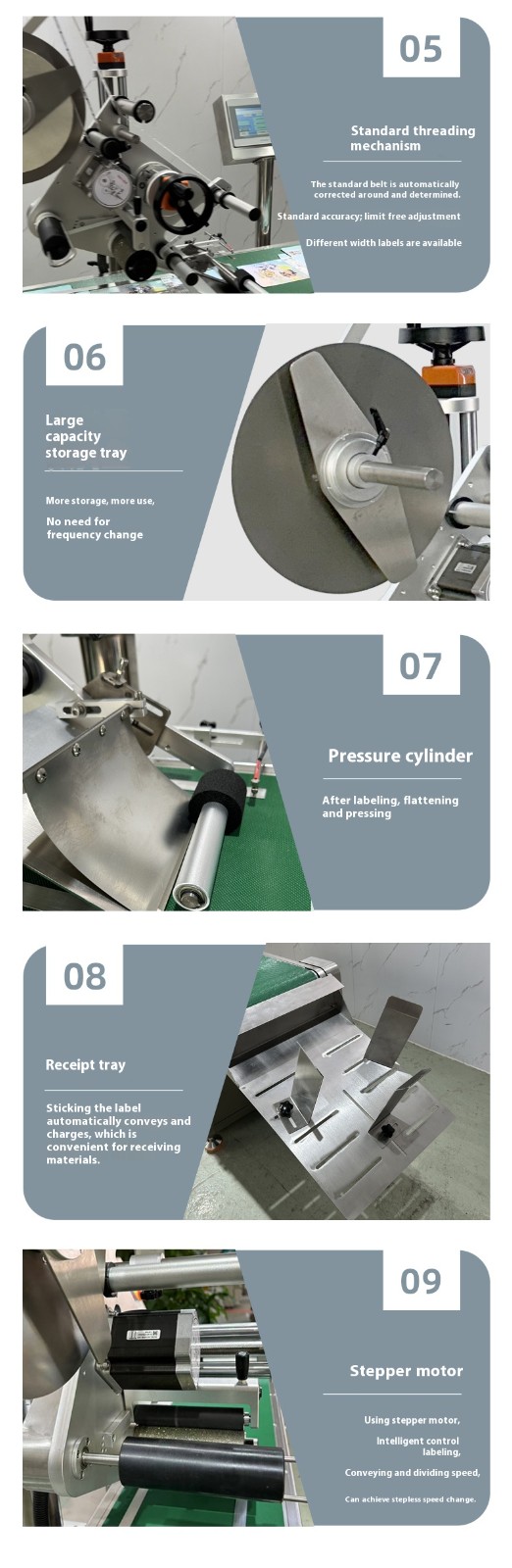

- Stability of the pagination mechanism: A stable pagination mechanism ensures the accurate and rapid separation of labels and their delivery to the labeling mechanism. If there are problems such as paper jams or poor label separation in the pagination mechanism, the labeling process will be frequently interrupted, reducing the working efficiency.

- Labeling accuracy: High labeling accuracy means that the labeling machine can accurately paste labels on products, reducing rework or the rejection rate caused by inaccurate labeling positions. High - precision labeling machines usually require more advanced sensors and control systems, as well as more precise mechanical components, thus improving efficiency while ensuring labeling quality.

- Material and shape of labels: Labels made of different materials, such as paper, plastic, and metal foil, have different flexibilities, viscosities, and surface smoothness, which affect the pagination and attachment effects of labels. For example, paper labels are prone to deformation due to moisture, affecting the pagination accuracy; if the viscosity of plastic labels is insufficient, the labels may not adhere firmly. In addition, the shape of the label is also crucial. Irregular - shaped labels require more complex positioning and labeling processes, which will reduce the labeling efficiency.

- Shape and size of products: The diversity of product shapes and sizes poses requirements for the adjustment and adaptability of the labeling machine. If the product is a regular cuboid or cylinder, it is easy for the labeling machine to position and label; however, if the product has a complex shape, such as with curved surfaces, unevenness, or large size variations, the labeling machine may require more time to adjust parameters and perform precise labeling, thus affecting the working efficiency.

- Equipment debugging ability: Skilled operators can quickly adjust the parameters of the labeling machine according to the characteristics of labels and products, such as label spacing, labeling speed, and roller pressure, to make the equipment reach the optimal working state. Novices, however, may take a long time to figure out and debug, resulting in the equipment not running efficiently in the initial stage.

- Troubleshooting ability: During the labeling process, some faults are inevitable, such as label blockages, poor labeling, and equipment crashes. Experienced operators can quickly determine the cause of the fault and take effective solutions to quickly restore the equipment operation, reducing the downtime. On the contrary, inexperienced operators may spend a lot of time dealing with faults, affecting the working efficiency.

- Temperature and humidity: Changes in environmental temperature and humidity can affect the viscosity and material of labels. For example, in a high - temperature environment, the viscosity of labels may increase, leading to difficult pagination; in a humid environment, paper labels are prone to becoming soft due to moisture, affecting the pagination accuracy and labeling quality. Therefore, maintaining a suitable production environment temperature and humidity is crucial for improving the working efficiency of the labeling machine.

- Dust and impurities: Dust and impurities in the production environment may enter the interior of the labeling machine, affecting the accuracy of sensors, blocking the pagination mechanism, or contaminating the surfaces of labels and products, resulting in poor labeling. Regularly cleaning the production environment and maintaining the labeling machine can reduce faults caused by dust and impurities and improve the working efficiency of the equipment.