+86 13827272341

Release date:2025-05-09

Before replacement:

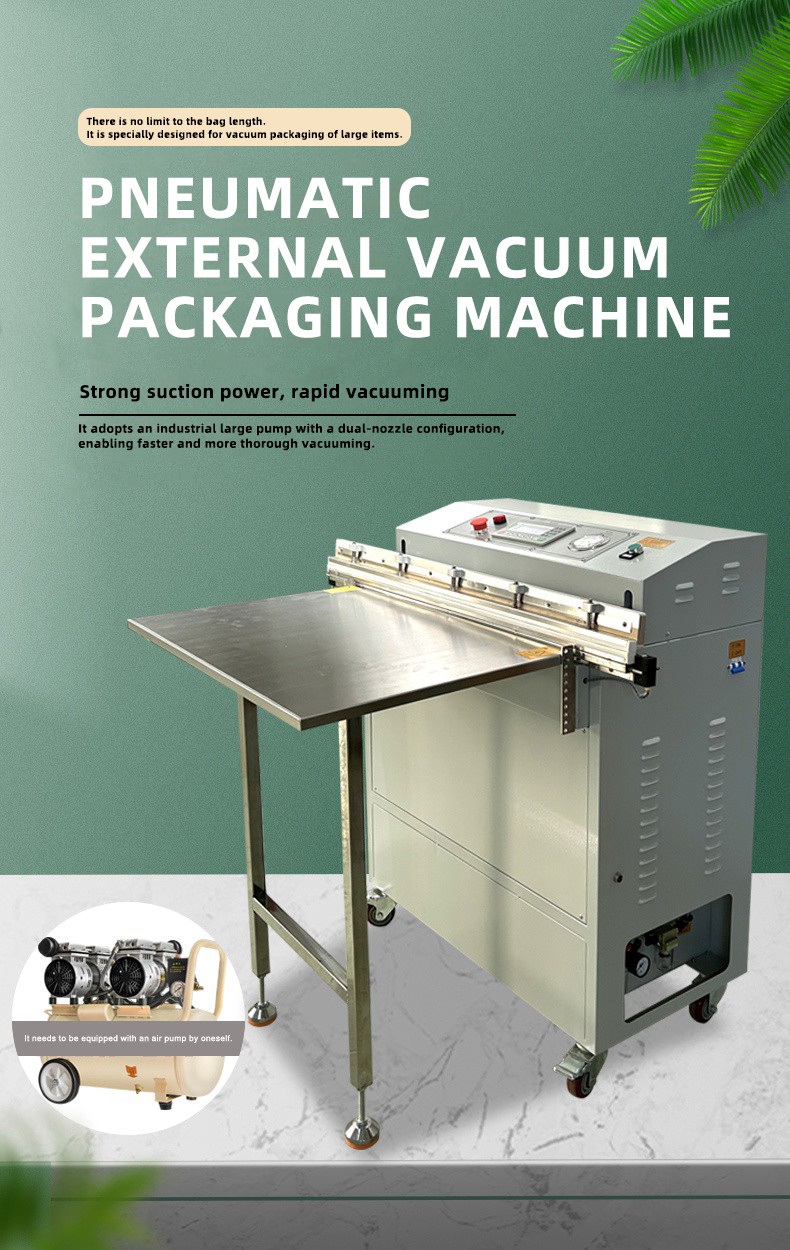

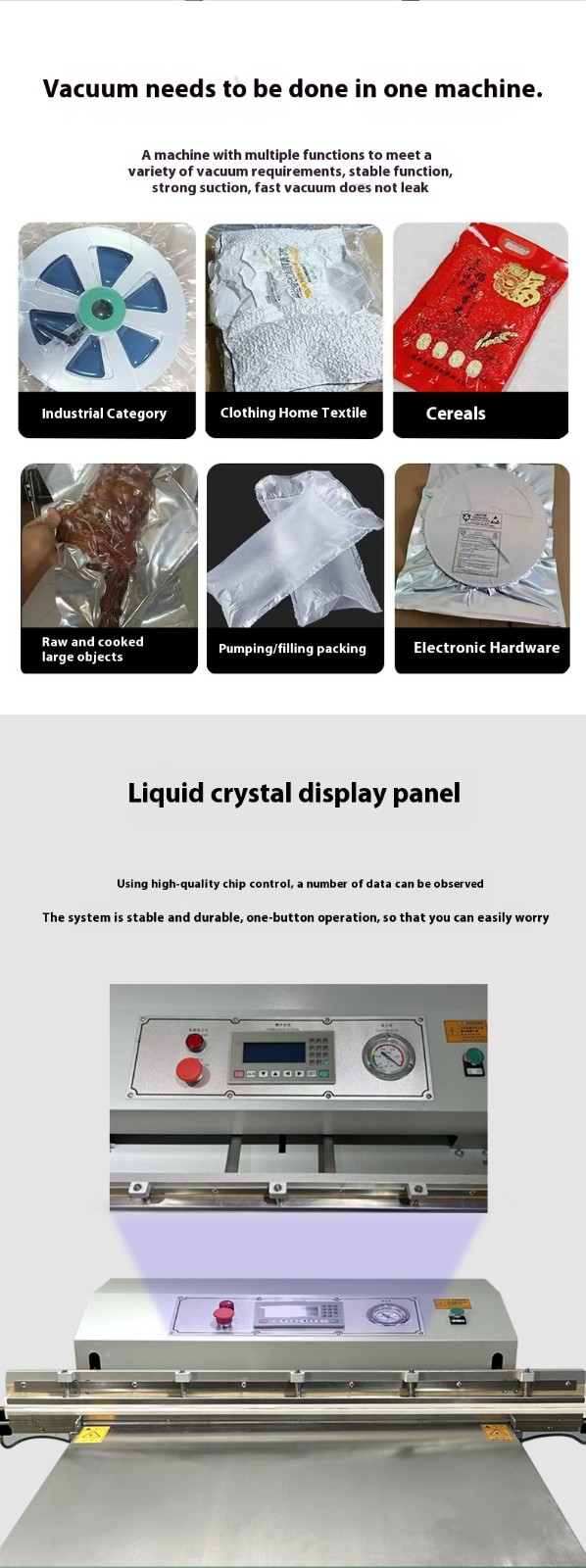

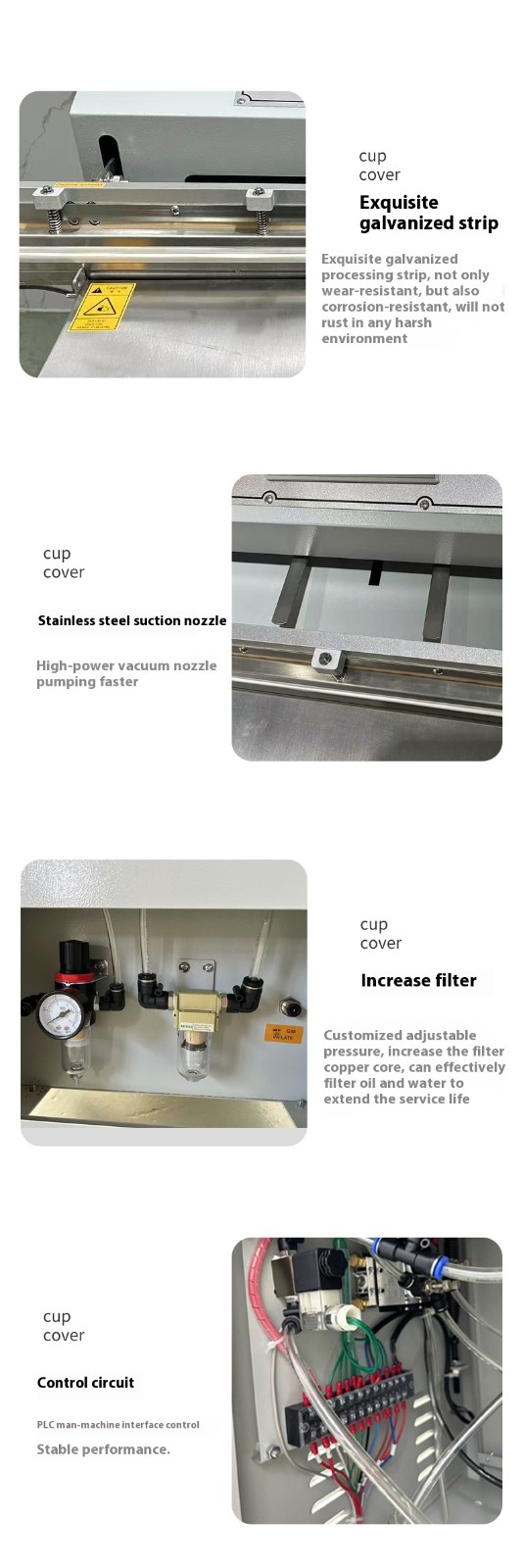

Prepare suitable accessories: According to the equipment model, prepare genuine vulnerable parts of corresponding specifications. If you are unsure of the accessory model, you can check the equipment instruction manual or consult the manufacturer's customer service. For example, for different models of pneumatic external vacuum packaging machines, the length, width and power of the heating strip may be different, and accurate matching is required.

Cut off the power supply: To prevent electric shock and misoperation of the equipment, be sure to cut off the power supply of the packaging machine before replacing the vulnerable parts, and ensure that the power plug has been pulled out of the socket.

Release the pressure: For the pneumatic system, use the corresponding valve or device to release the pressure in the system. Avoid replacing parts under pressure to cause safety accidents.

During replacement:

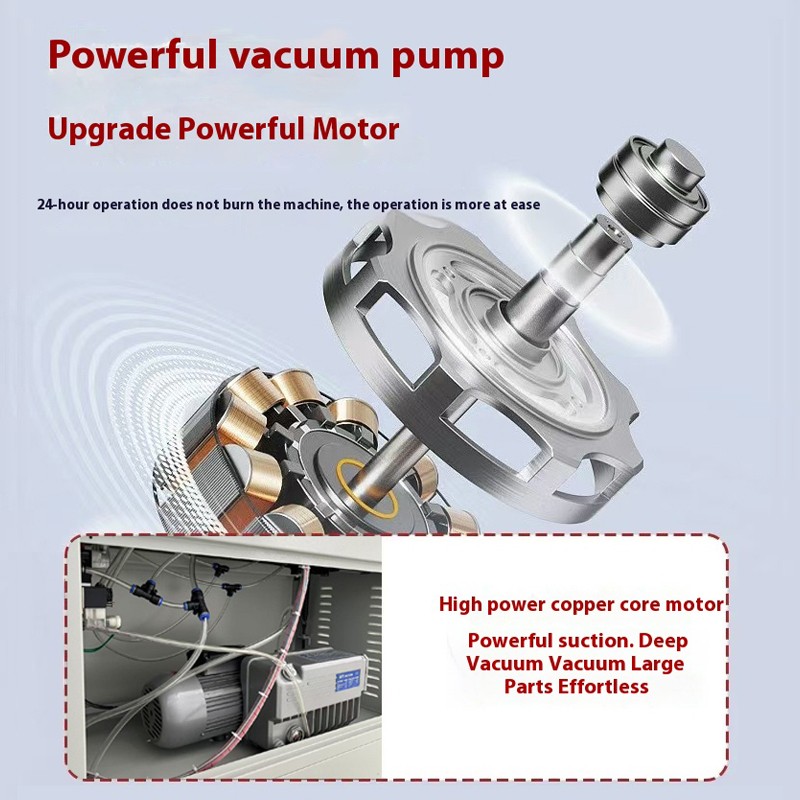

Operate in a standardized manner: Follow the steps in the equipment instruction manual for replacement operations. For example, when replacing the vacuum pump oil, drain the old oil first, and then use special tools to add the new oil to the specified oil level scale line; when replacing the heating strip, pay attention to the installation position and connection method of the heating strip to ensure firm installation and correct circuit connection.

Clean the installation part: Before installing the new vulnerable part, use a clean cloth or special cleaner to clean the installation part to remove dust, oil stains and other impurities. For example, when replacing the silicone strip, clean the residue at the sealing part first to ensure that the silicone strip fits tightly with the equipment and has a good seal.

Check related components: While replacing the vulnerable parts, also check whether other related components are damaged or abnormal. For example, when replacing the airbag, check whether the connecting pipeline of the airbag is cracked, aged, etc., and deal with or replace it in time if there are problems.

After replacement:

Test run: After the replacement is completed, connect the power supply and start the equipment for a test run. Observe whether the performance of the equipment is normal, such as whether the vacuum degree meets the requirements, whether the seal is firm, and whether the heating temperature is accurate. If there are any abnormalities, stop the machine immediately for inspection and find and solve the problem.

Record replacement information: Record the replacement time, model, specification of the vulnerable parts and the information of the replacement personnel, and establish an equipment maintenance file. This helps to track the maintenance situation of the equipment, provide a reference for future maintenance and repair, and also facilitates the statistics of the service cycle and cost of the vulnerable parts.