Here are the maintenance methods for pneumatic sealing, corner-cutting and heat-shrink packaging machines, categorized into daily, regular and special-scenario maintenance based on key components and systems:

- Surface Cleaning: Wipe the machine shell and operation panel with a dry soft cloth to remove dust, debris and residual packaging material scraps.

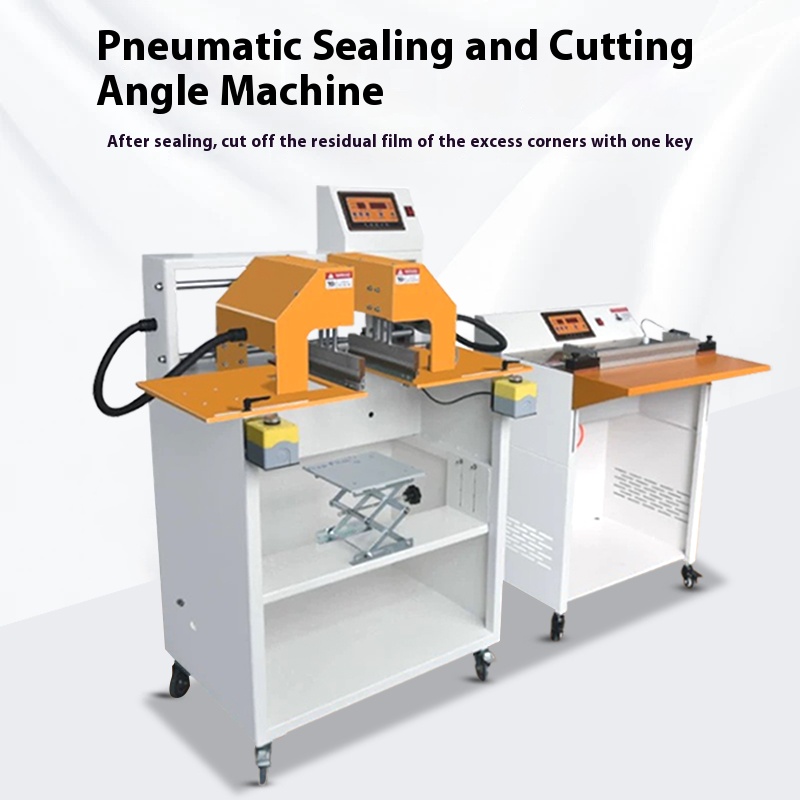

- Sealing/Corner-Cutting Components Cleaning:

- Use alcohol pads or specialized cleaning agents to wipe the sealing heating strips and cutter surfaces, removing adhered packaging material slag or stains to avoid affecting sealing quality and cutter sharpness.

- Note: Power off and wait for components to cool completely before cleaning to prevent burns.

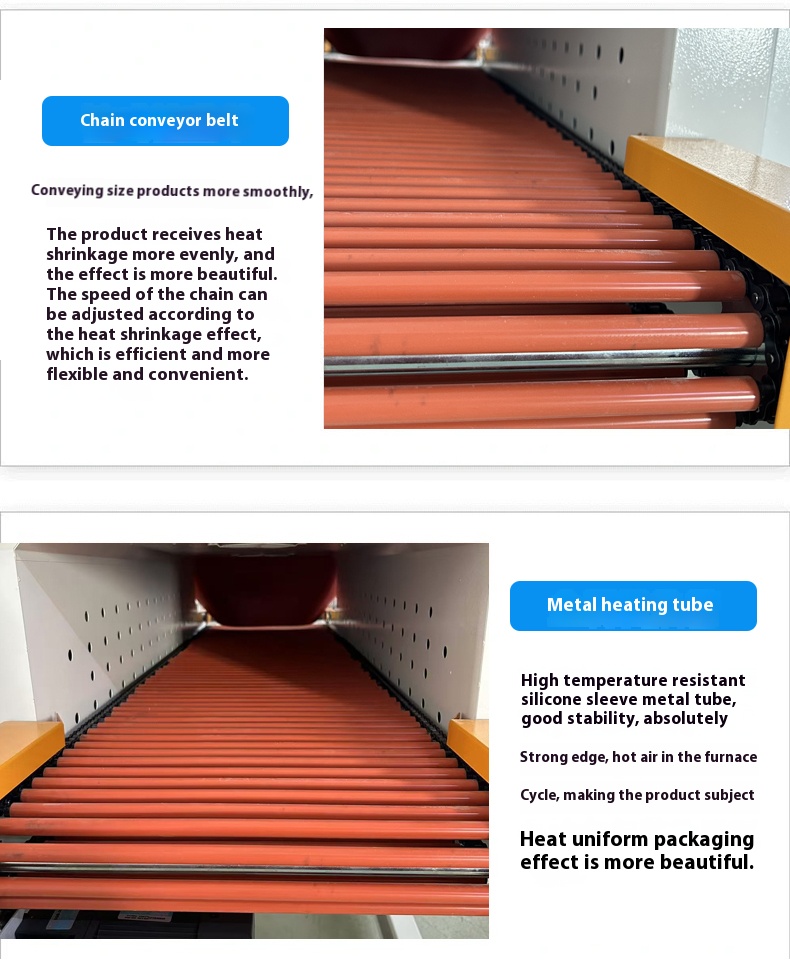

- Heat-Shrink Tunnel Cleaning:

- Clean the interior of the tunnel with a long-handled soft brush to remove dust and debris, avoiding dust accumulation that may affect heating uniformity or cause short circuits.

- Check and remove any residual packaging material fragments in the tunnel.

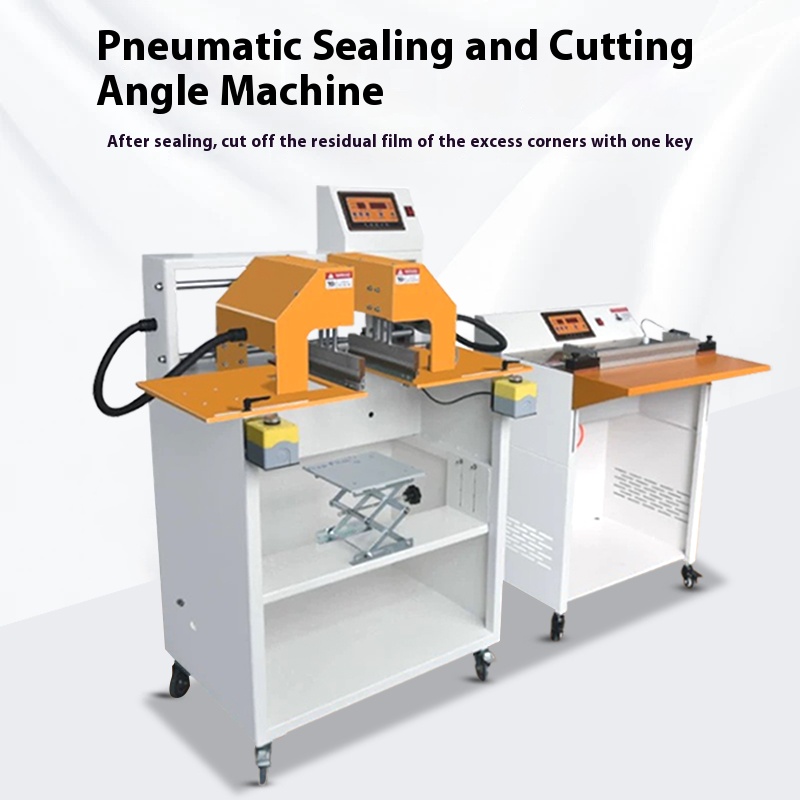

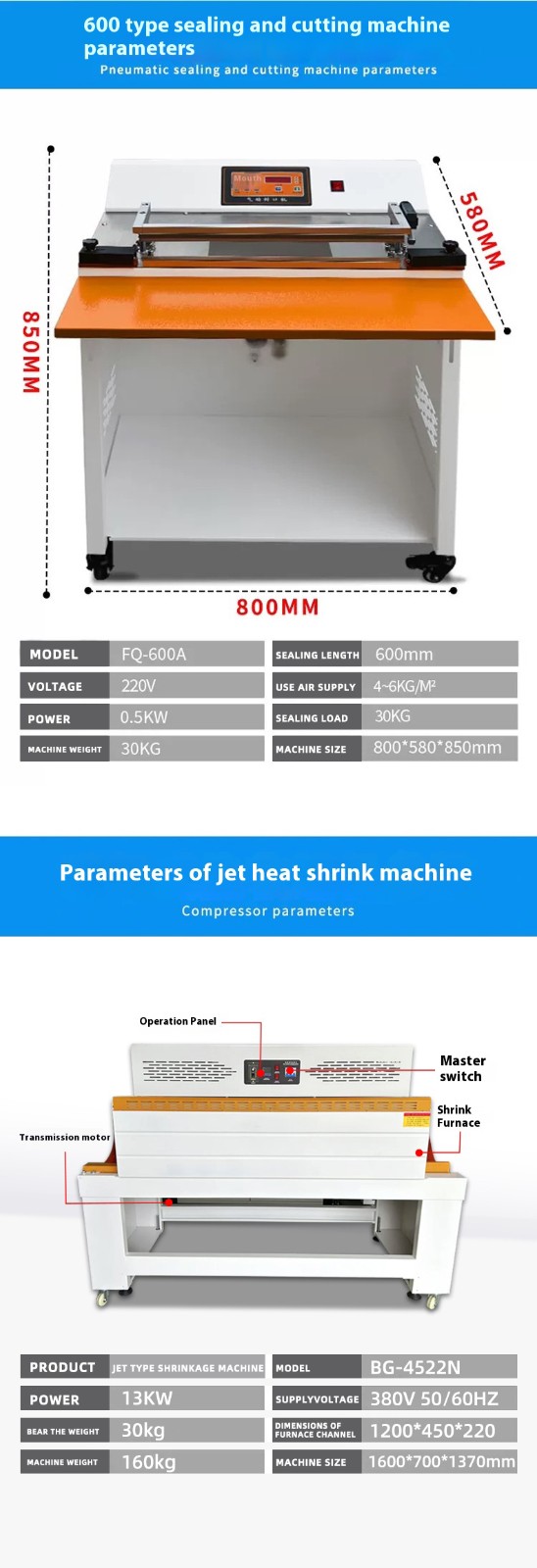

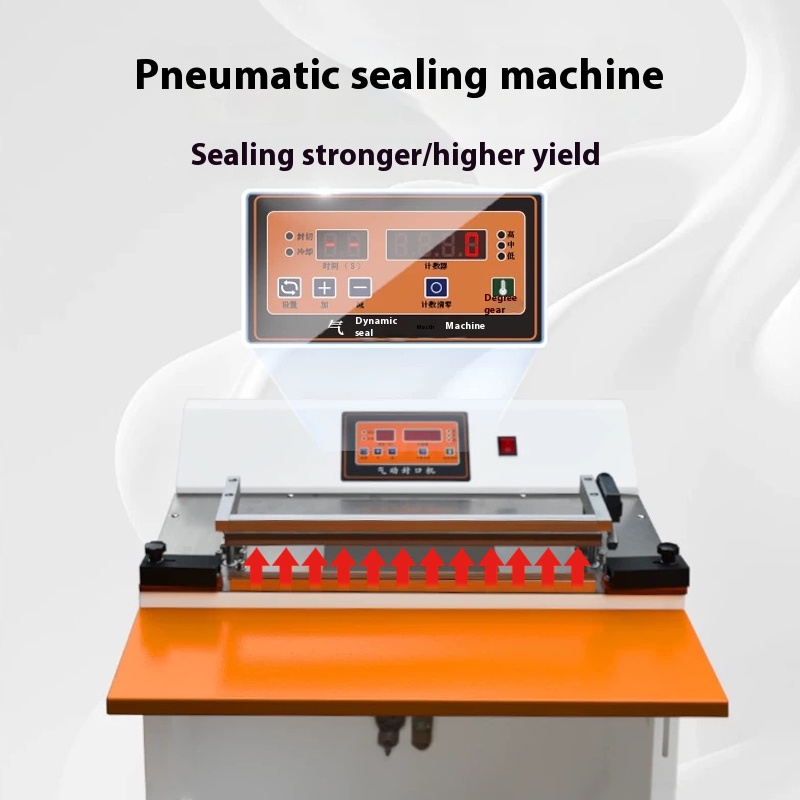

- Pneumatic System:

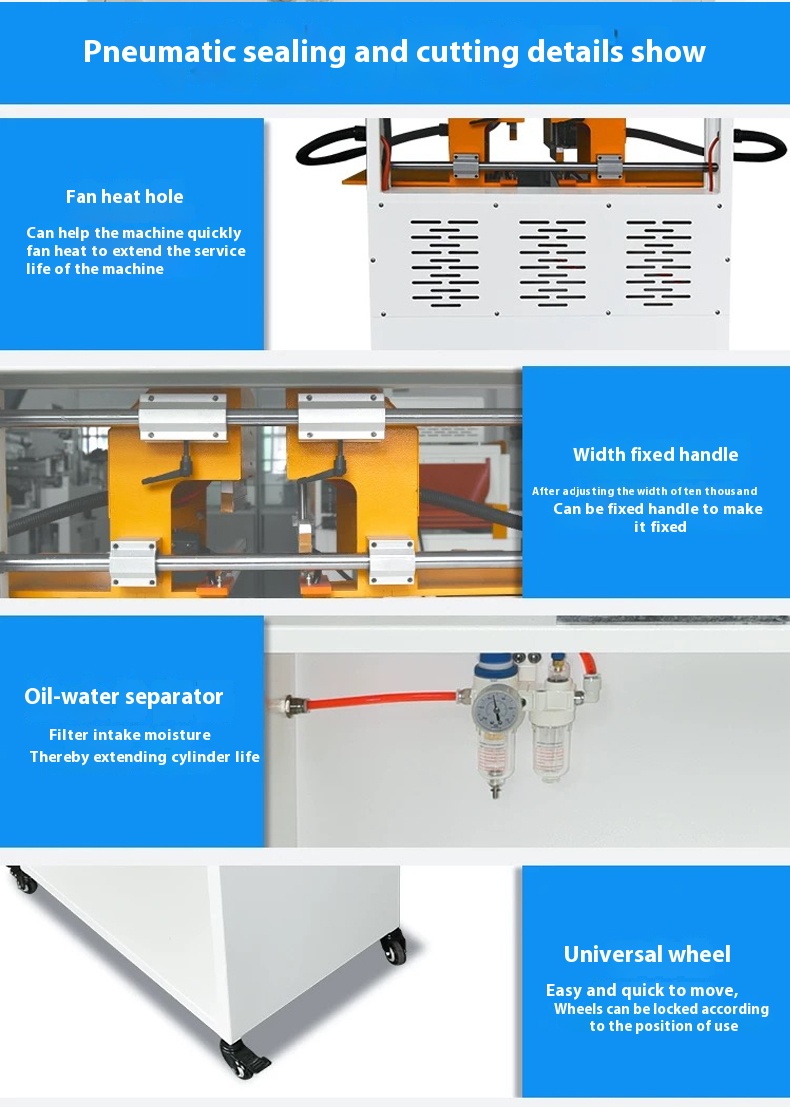

- Observe pneumatic components (cylinders, air pipes) for air leaks, looseness or abnormal noise, and tighten connections promptly.

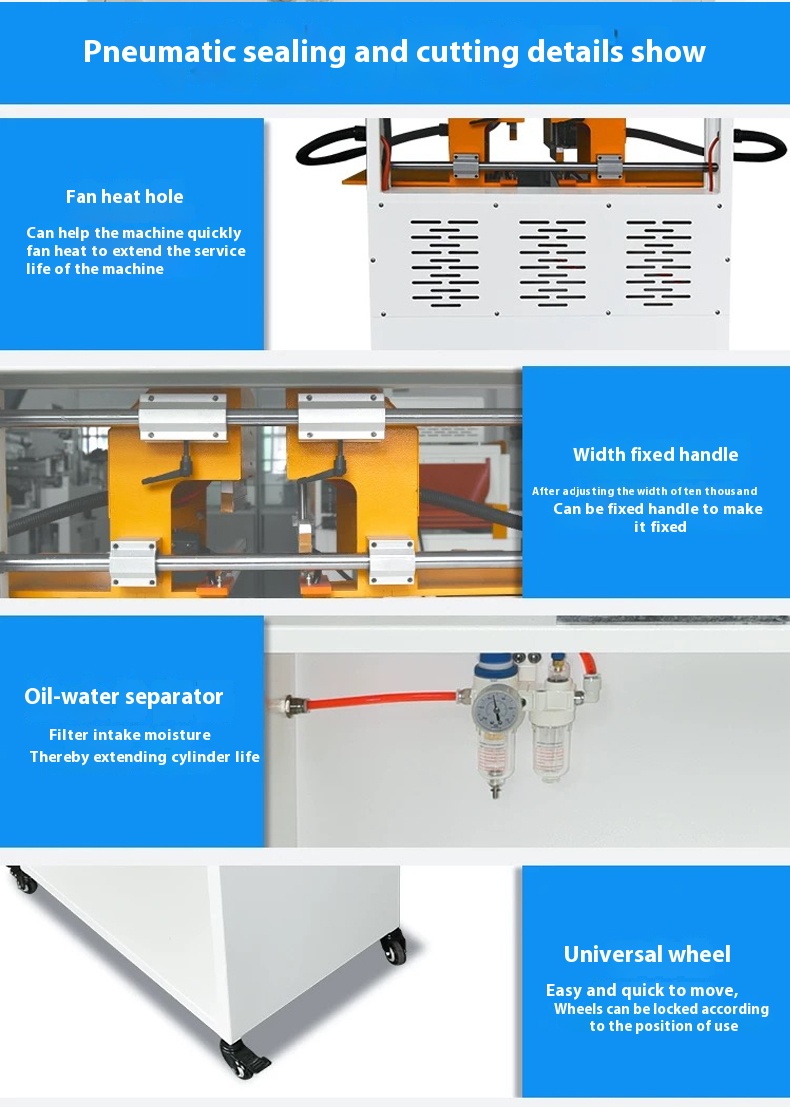

- Check the air filter (water-separating filter). Drain accumulated water in time and clean or replace the filter element if dirty.

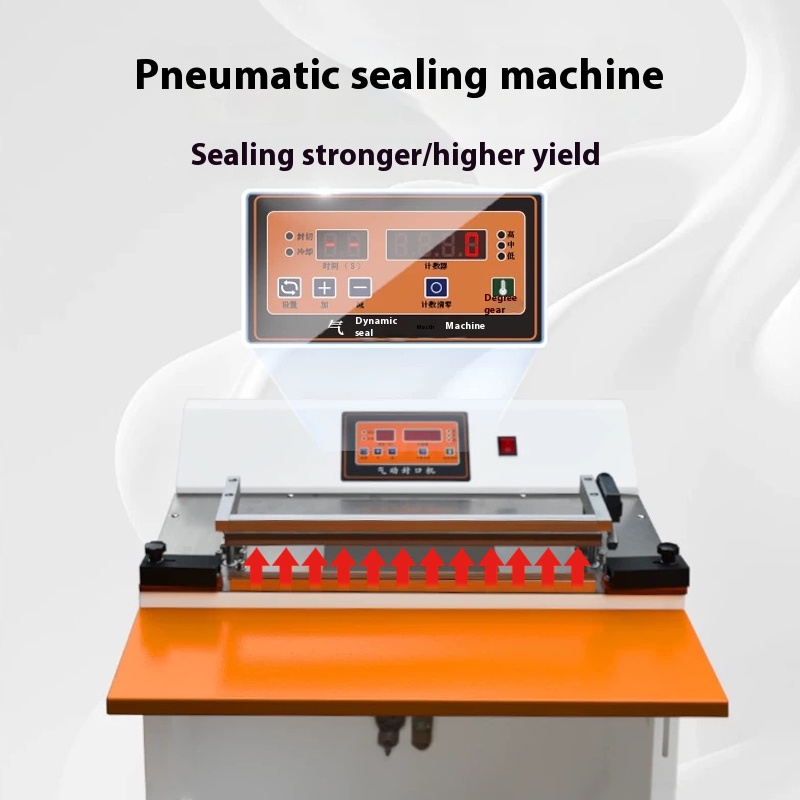

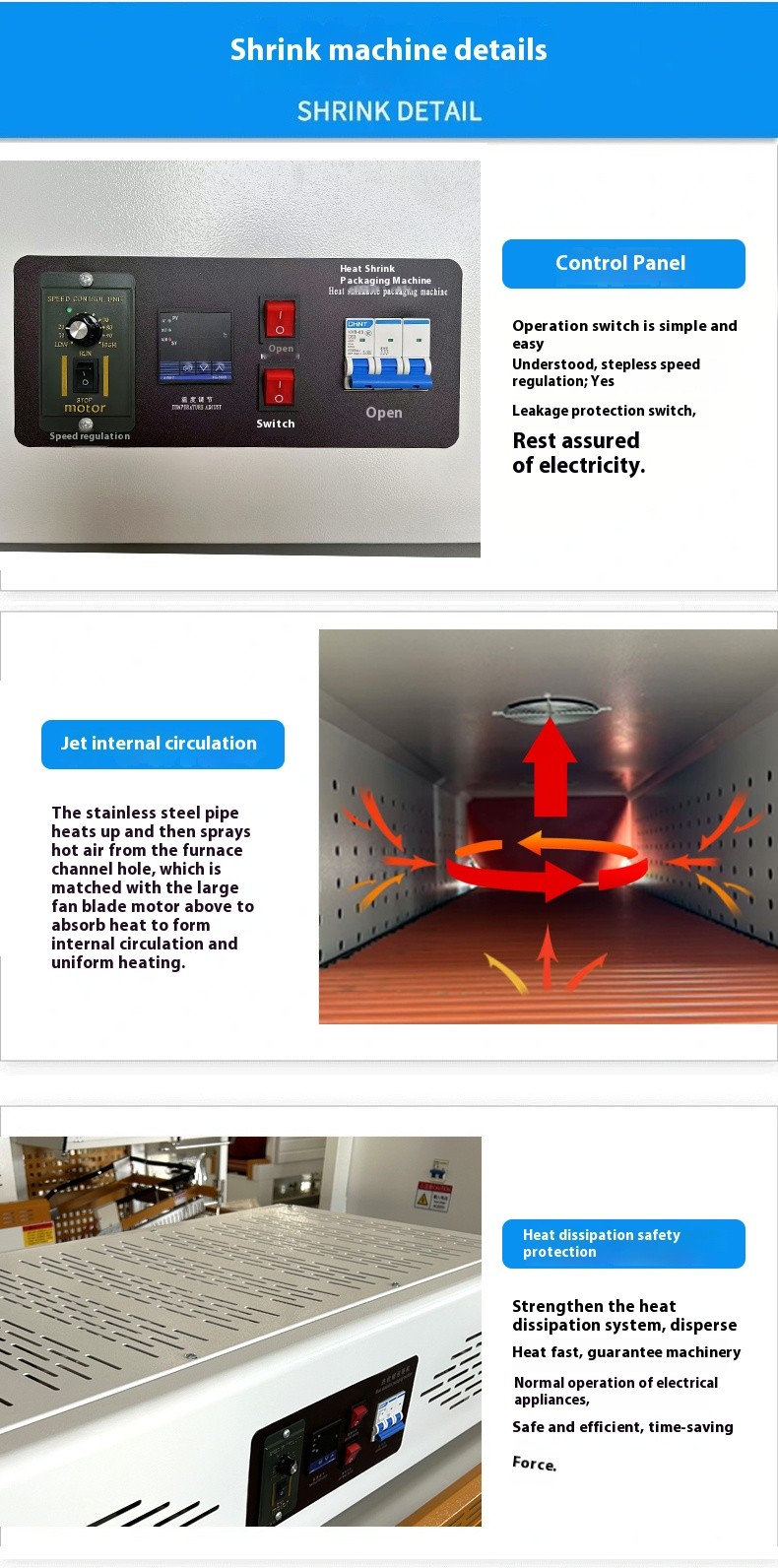

- Heating System:

- Inspect sealing heating strips and heat-shrink tunnel heating tubes for breakage, aging or poor contact to ensure normal temperature display.

- Test the temperature controller to ensure the set temperature matches the actual temperature (assisted by an infrared thermometer).

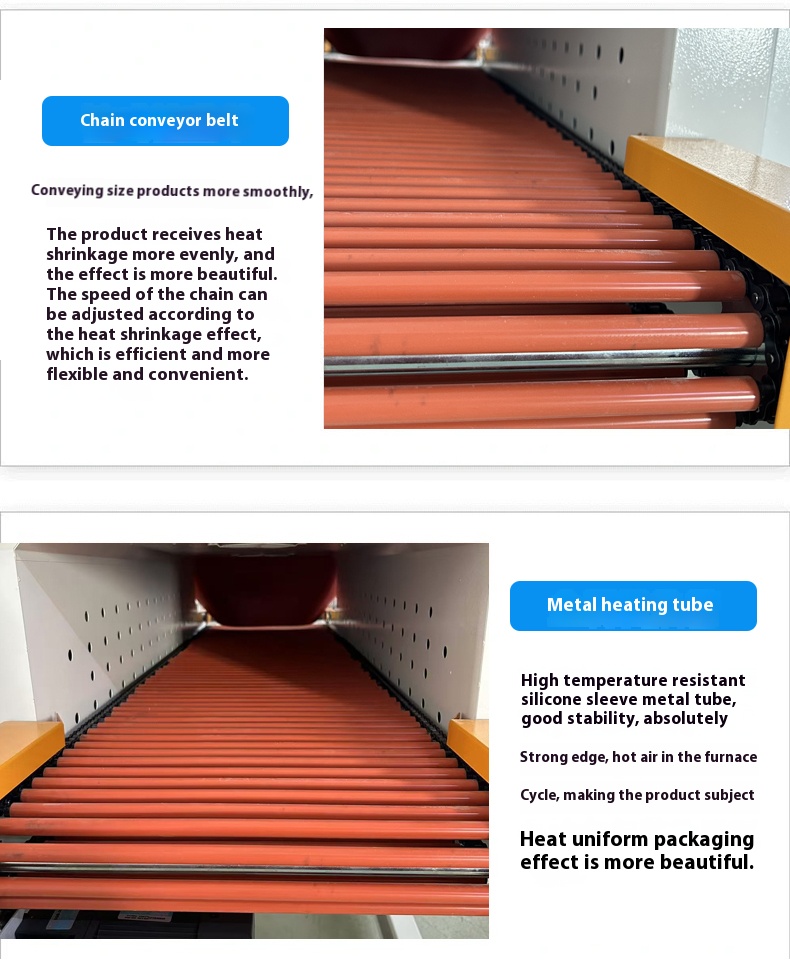

- Transmission System:

- Check transmission components (conveyor belts, chains, gears) for looseness, deviation or wear, and adjust to normal operation.

- Clean adhesions on the conveyor belt to maintain a flat surface.

- Apply appropriate lubricating oil (such as sewing machine oil or specialized grease) to moving parts (e.g., cylinder shafts, transmission chains, gears) as per the equipment manual to reduce friction and wear.

- Note: Avoid contaminating packaging materials or products with lubricants.

- Air Pipeline Inspection:

- Thoroughly check air pipes for aging, cracks or damage, and replace damaged pipes.

- Test the sensitivity of pneumatic valves, clean debris in the valve cores, and ensure precise pneumatic actions.

- Air Compressor Maintenance (if externally connected):

- Drain condensed water from the air compressor storage tank, and clean or replace the air filter element.

- Check the lubricating oil level of the air compressor and add or replace it if insufficient.

- Heating Element Detection:

- Measure the resistance value of heating strips and tubes with a multimeter (compared to the standard values in the equipment manual), and replace aging or damaged elements promptly.

- Check the terminals of heating elements for looseness or oxidation, and clean and tighten connections.

- Temperature Control System Calibration:

- Calibrate the temperature controller display with a high-precision thermometer to ensure temperature control accuracy (error typically within ±2°C).

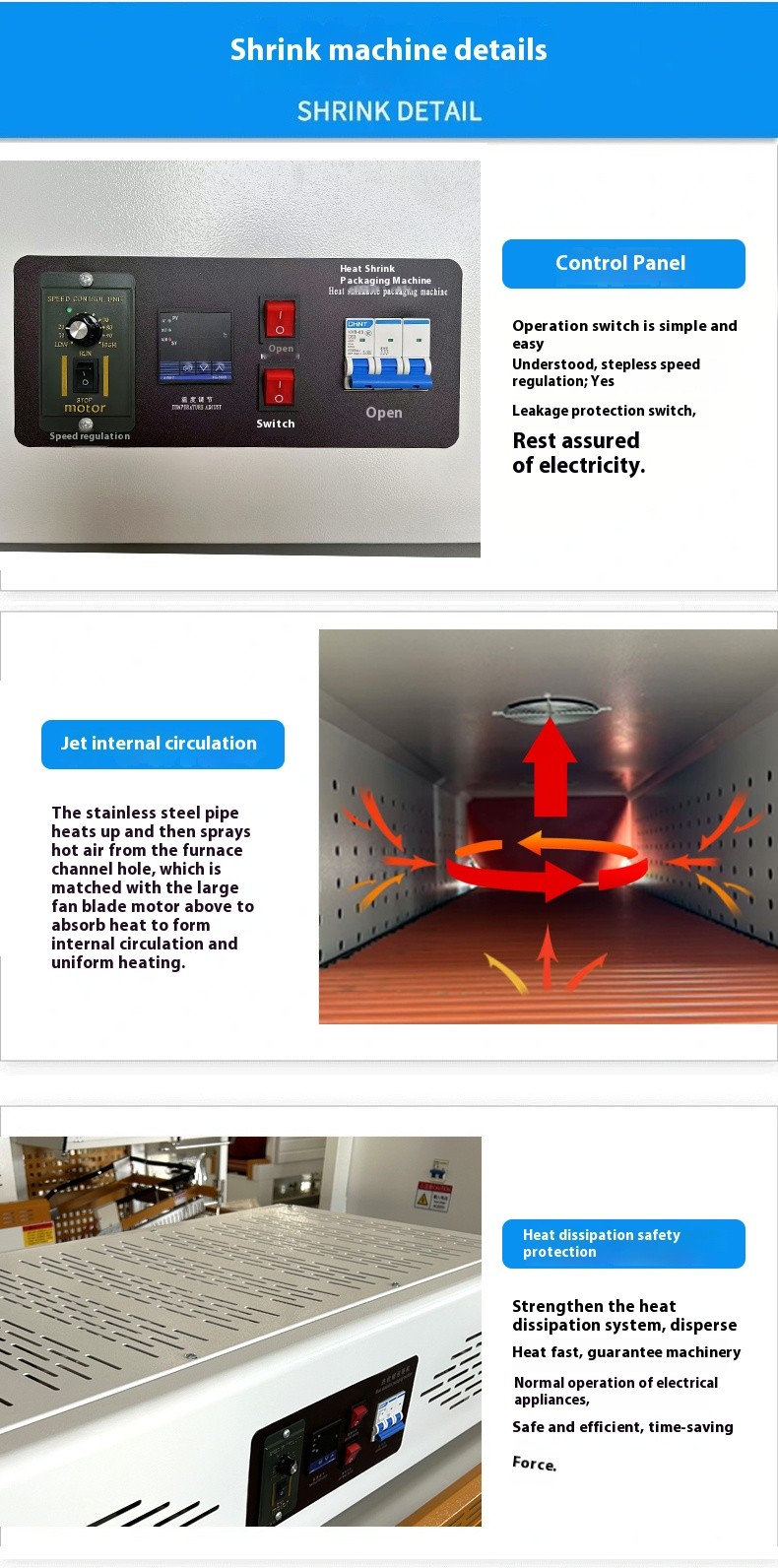

- Test the over-temperature protection function (e.g., temperature controller alarm, automatic power-off function) for sensitivity.

- Cutter Maintenance:

- Inspect the cutter blade for wear. Grind or replace it if dull to ensure neat and burr-free corner cutting.

- Adjust the clearance between the cutter and sealing components to ensure accurate corner-cutting position.

- Sealing Rubber Strip Replacement:

- Replace deformed, aged or damaged sealing rubber strips (heat-resistant silicone strips) promptly to avoid affecting sealing tightness.

- Transmission Component Tightening:

- Check the mounting bolts of motors, reducers, sprockets and other components for looseness, and retighten them.

- Adjust the tension of the conveyor belt to prevent slipping or deviation.

- Electrical System Inspection:

- Clean dust in the electrical control cabinet, check wires for looseness or aging, and repair or replace damaged wiring harnesses.

- Test the functions of emergency stop buttons, safety switches, etc., to ensure safe operation.

- Thorough Cleaning: Conduct a comprehensive cleaning of the equipment, especially for sealing, corner-cutting and heating components, to prevent residual stains from corroding the machine.

- Rust Prevention: Apply rust-proof oil to metal components (such as cutters and guide rails) to avoid rusting.

- Moisture and Dust Protection: Cover the equipment with a dust-proof cover and store it in a dry, ventilated place. Place moisture-proof agents in the electrical control cabinet if necessary.

- Regular Power-On: Power on and run the machine empty at least once a month to prevent electronic components from aging due to moisture.

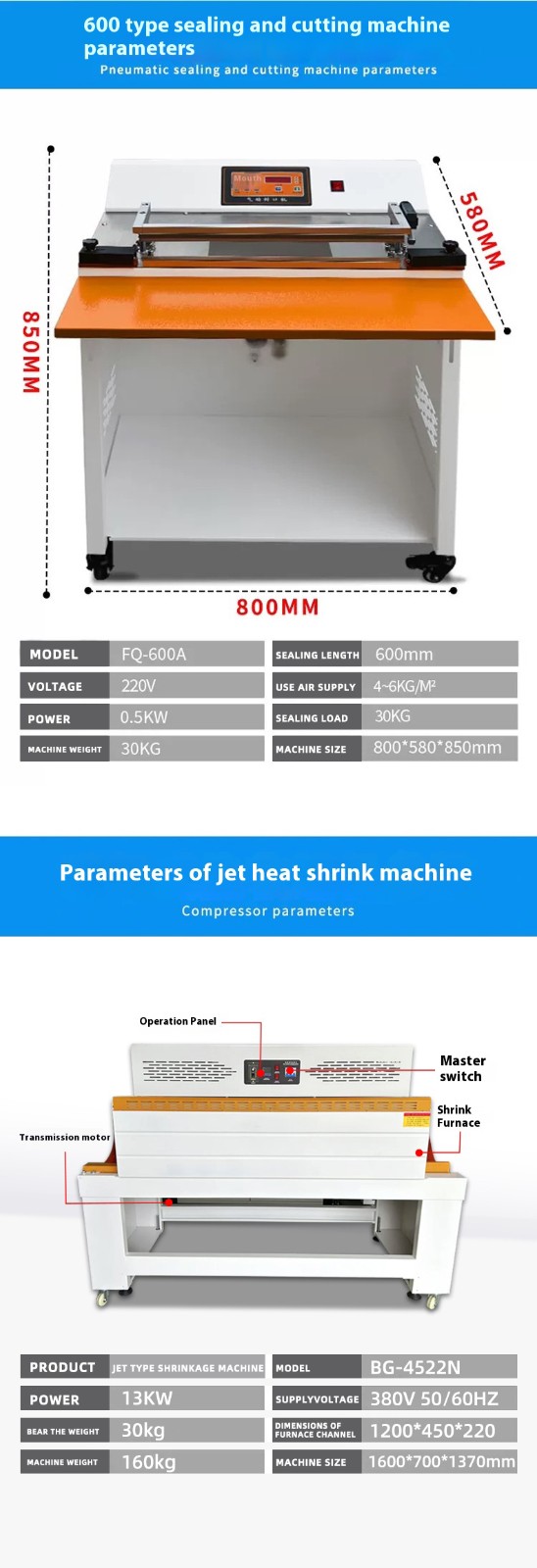

- After equipment repair or component replacement, readjust parameters such as pneumatic pressure, heating temperature and transmission speed to ensure normal coordination of all systems.

- Record the cause of the fault and maintenance details, and establish a maintenance file for follow-up tracking.