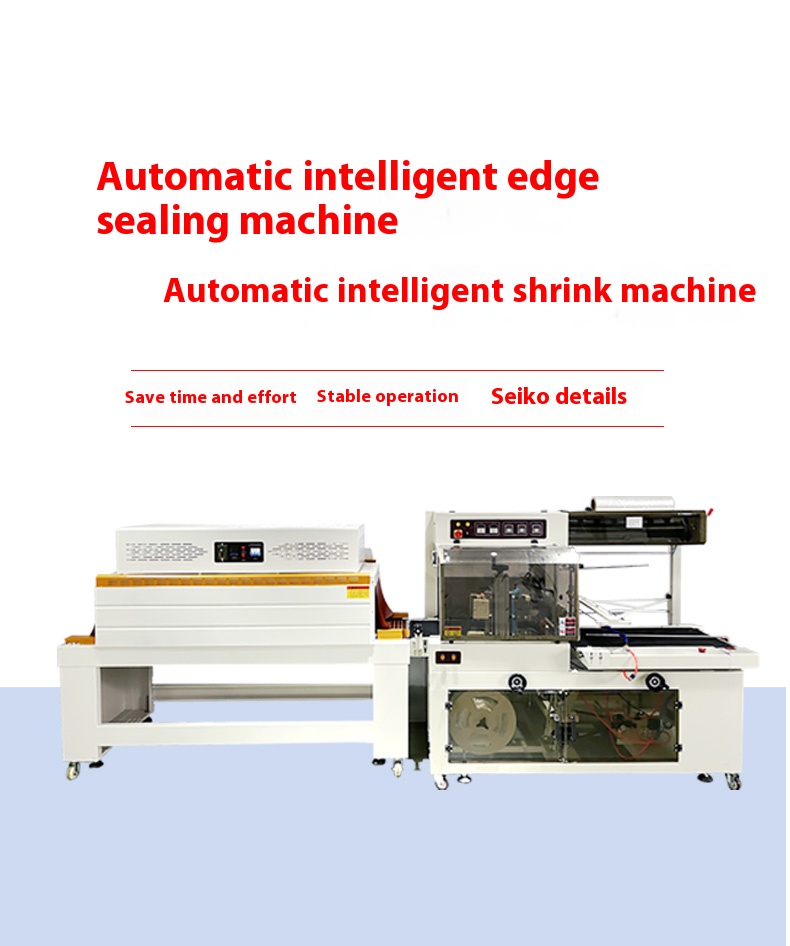

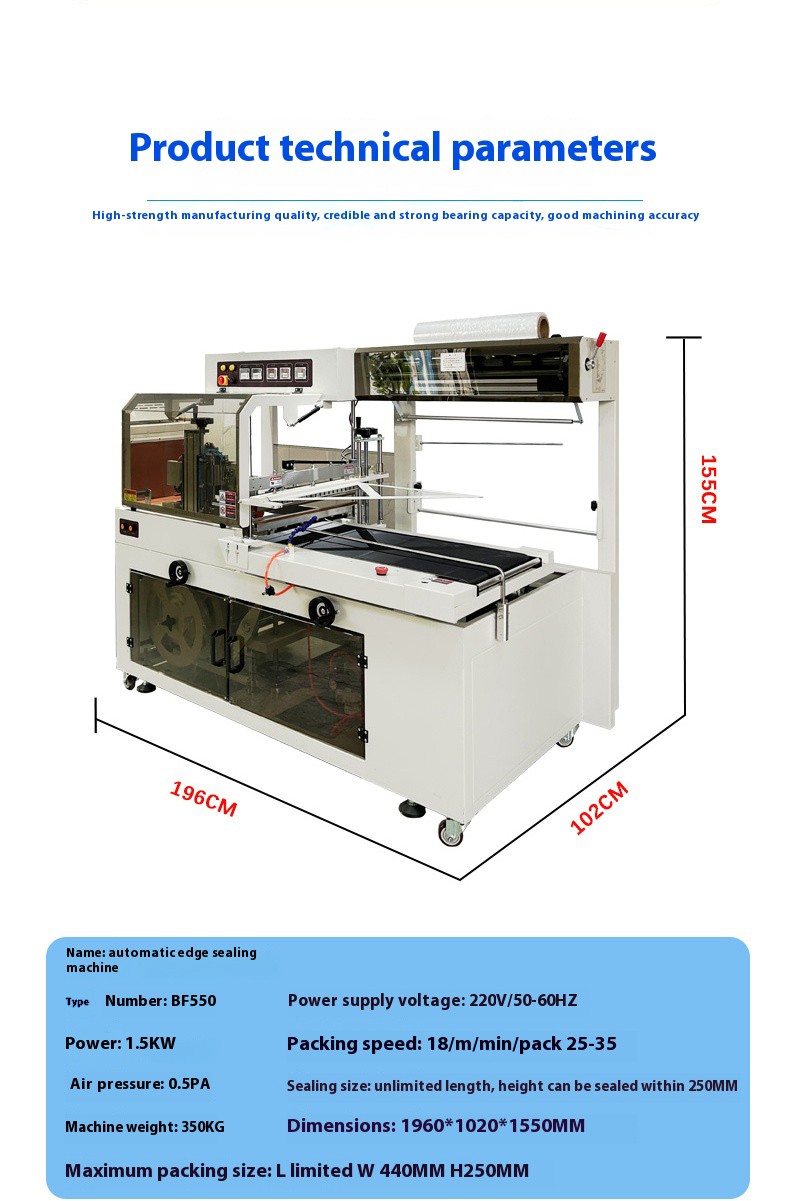

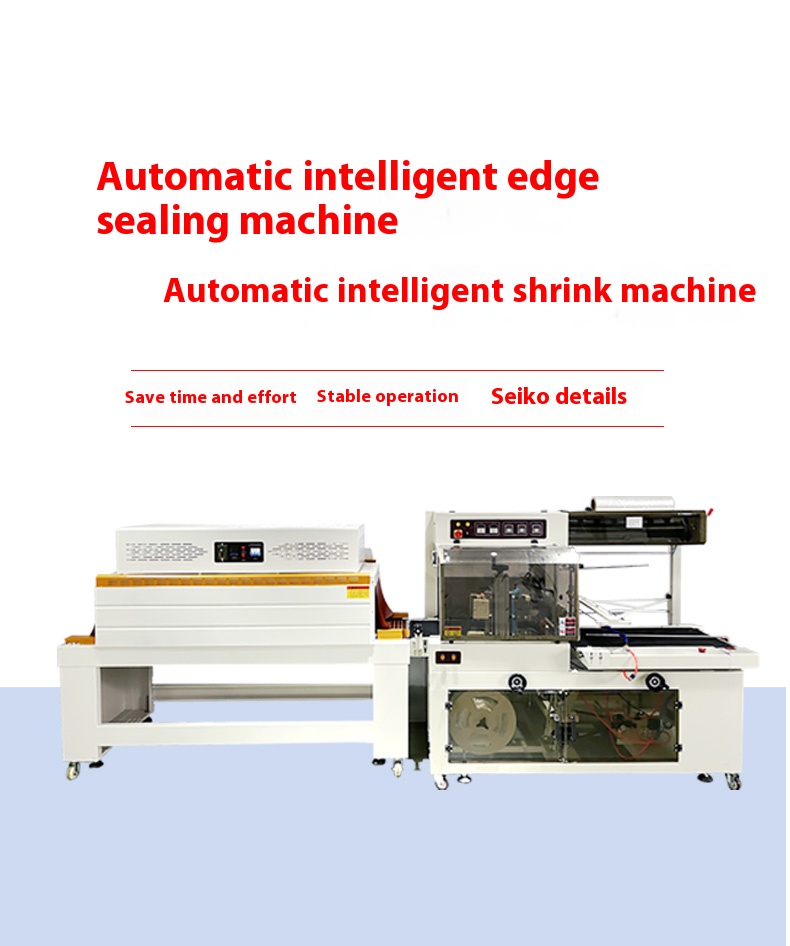

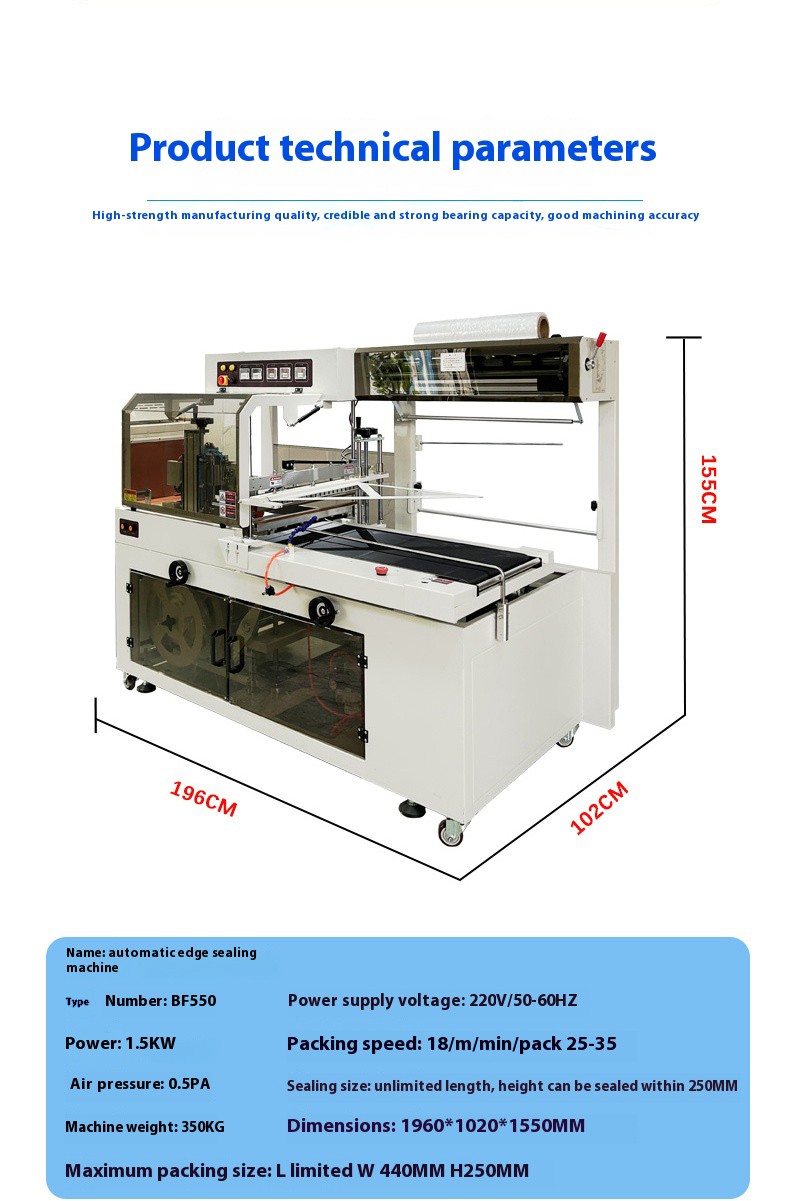

The fully automatic side-sealing shrink wrapping machine achieves full-process automated packaging through an intelligent system and precision mechanical structure, significantly enhancing production efficiency and packaging quality. The following details its technical principles and advantages:

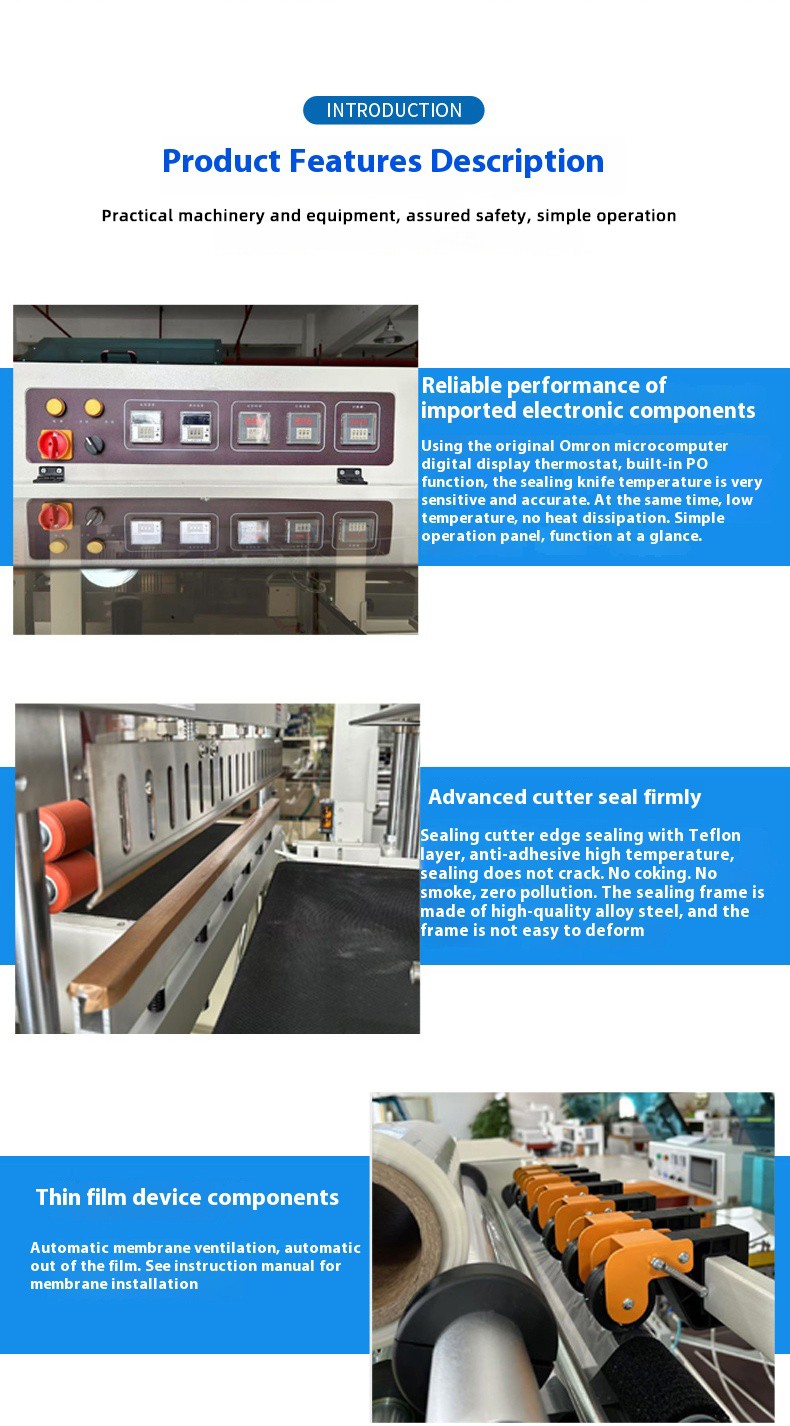

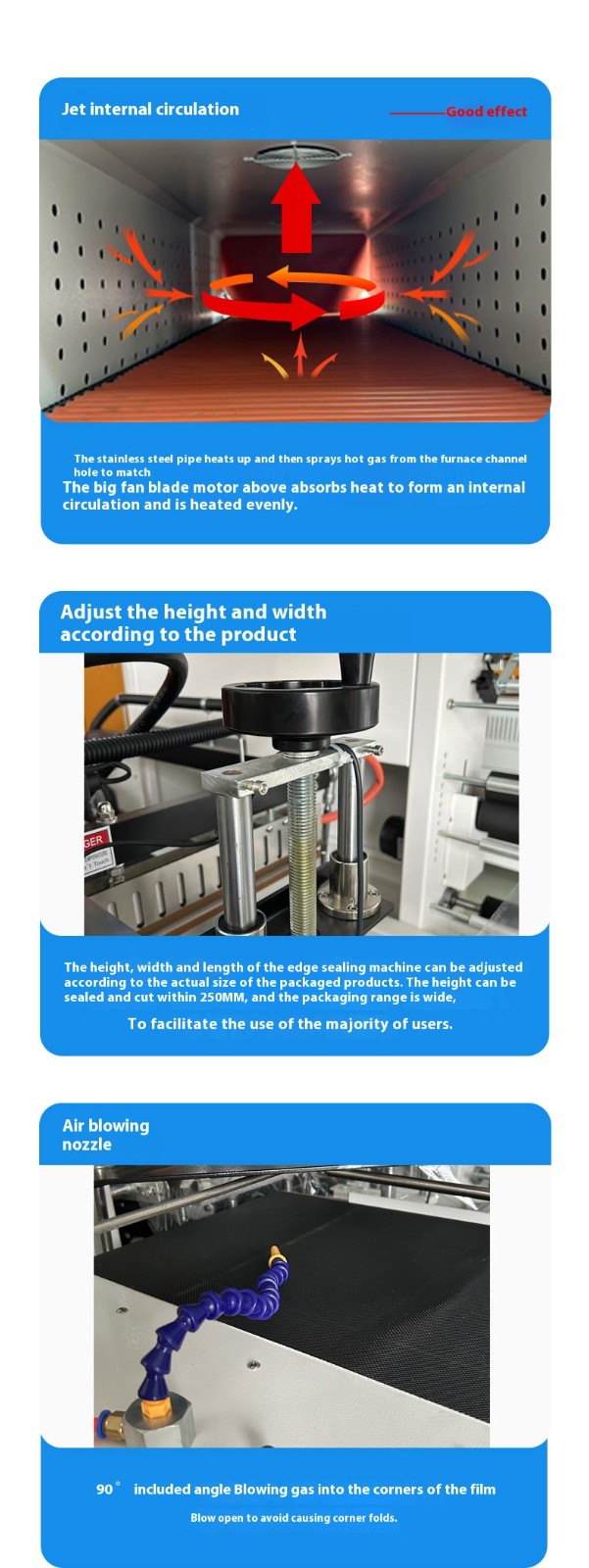

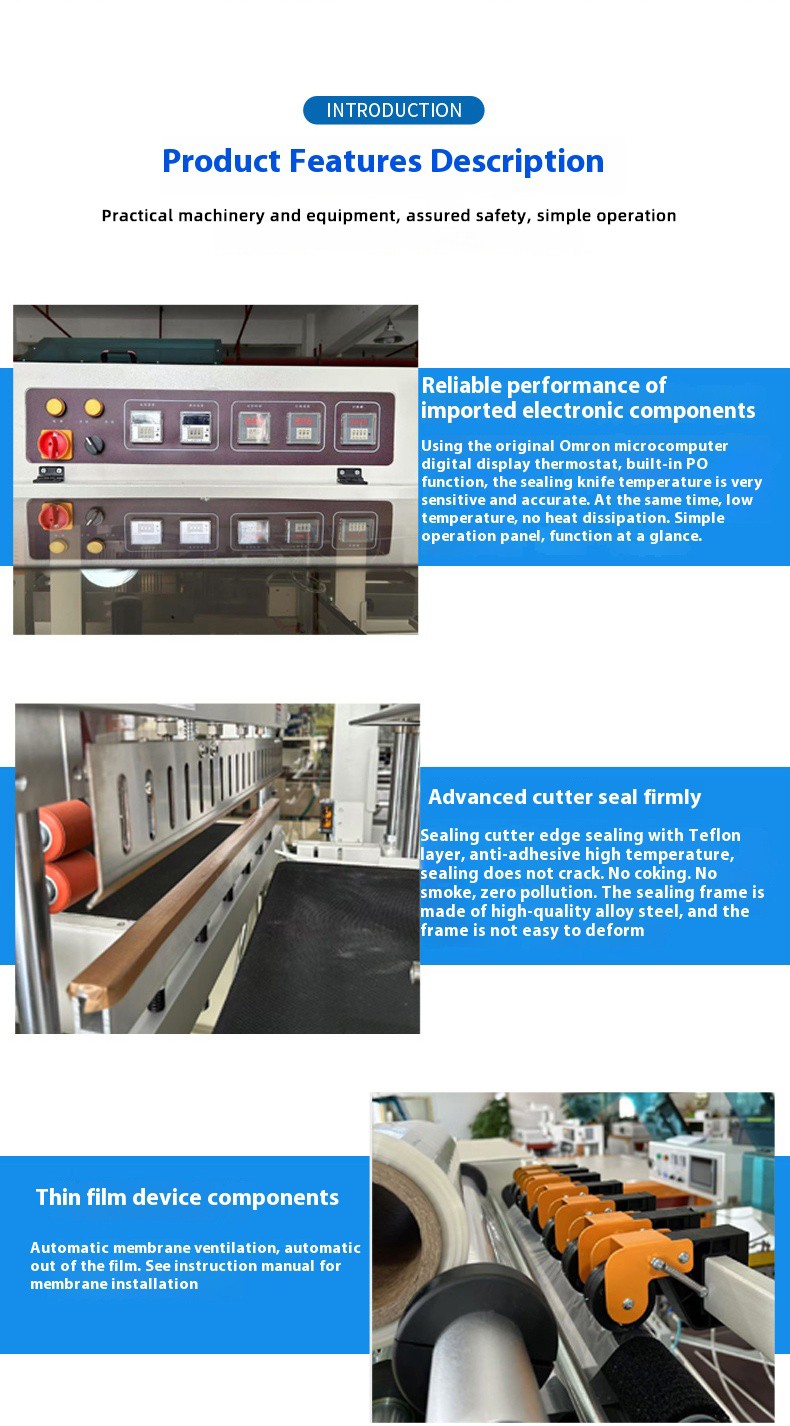

Equipped with high-precision photoelectric sensors and a PLC control system, the device continuously monitors the position and spacing of products. When sensors detect products entering the conveyor line, the system automatically controls the conveyor belt to run at a constant speed, ensuring precise delivery to designated stations. For products of different sizes, conveying speed and pause time can be adjusted via parameter settings to prevent collisions or accumulation.

A servo motor precisely controls the unwinding speed of the film roll, while an L-type or cuff-style sleeving mechanism enables accurate stretching and wrapping of the film. During sleeving, sensors continuously monitor film tension. If tension is insufficient or excessive, the system automatically adjusts the unwinding motor speed to ensure uniform film coverage and prevent wrinkles or incomplete sleeving.

The sealing and cutting process utilizes an imported temperature controller and high-temperature-resistant alloy blades, with temperature control accuracy reaching ±1℃. The system automatically matches optimal sealing temperatures and time parameters based on film materials (e.g., PE, PVC) to ensure firm and flat seals. A Teflon-coated blade effectively prevents film adhesion, reduces residual film, and improves sealing and cutting quality and efficiency.

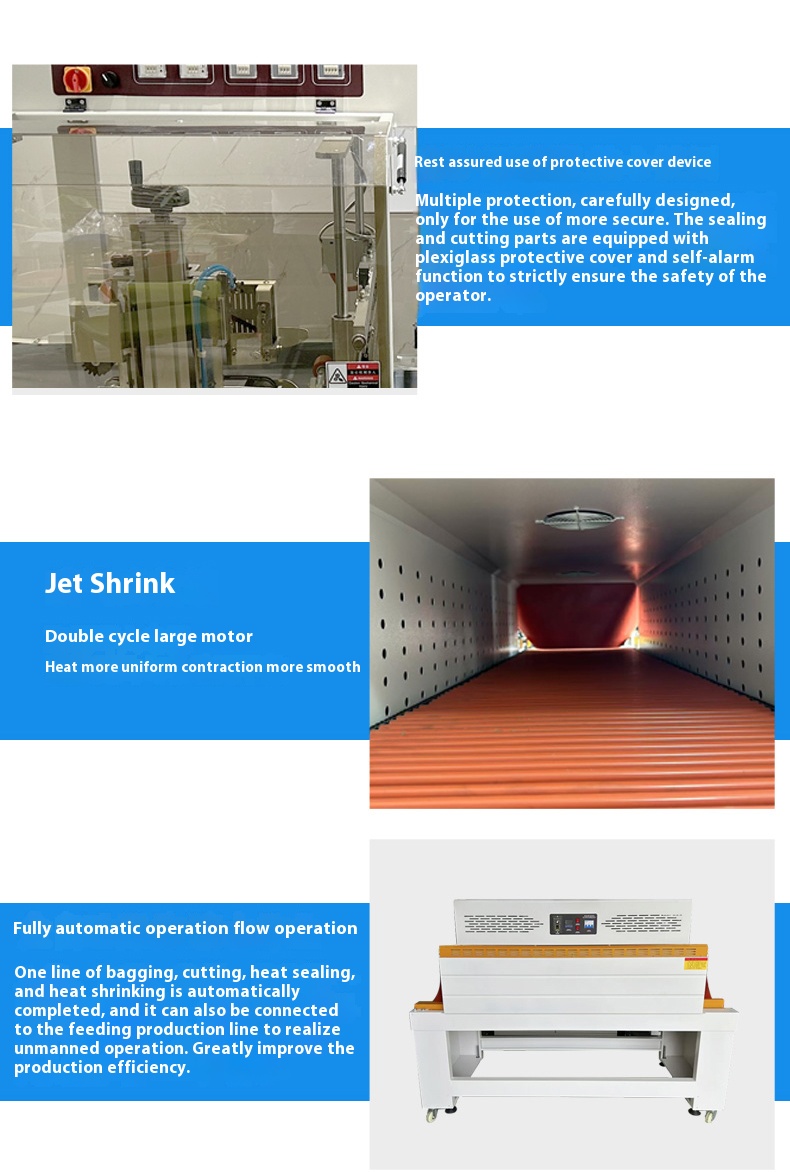

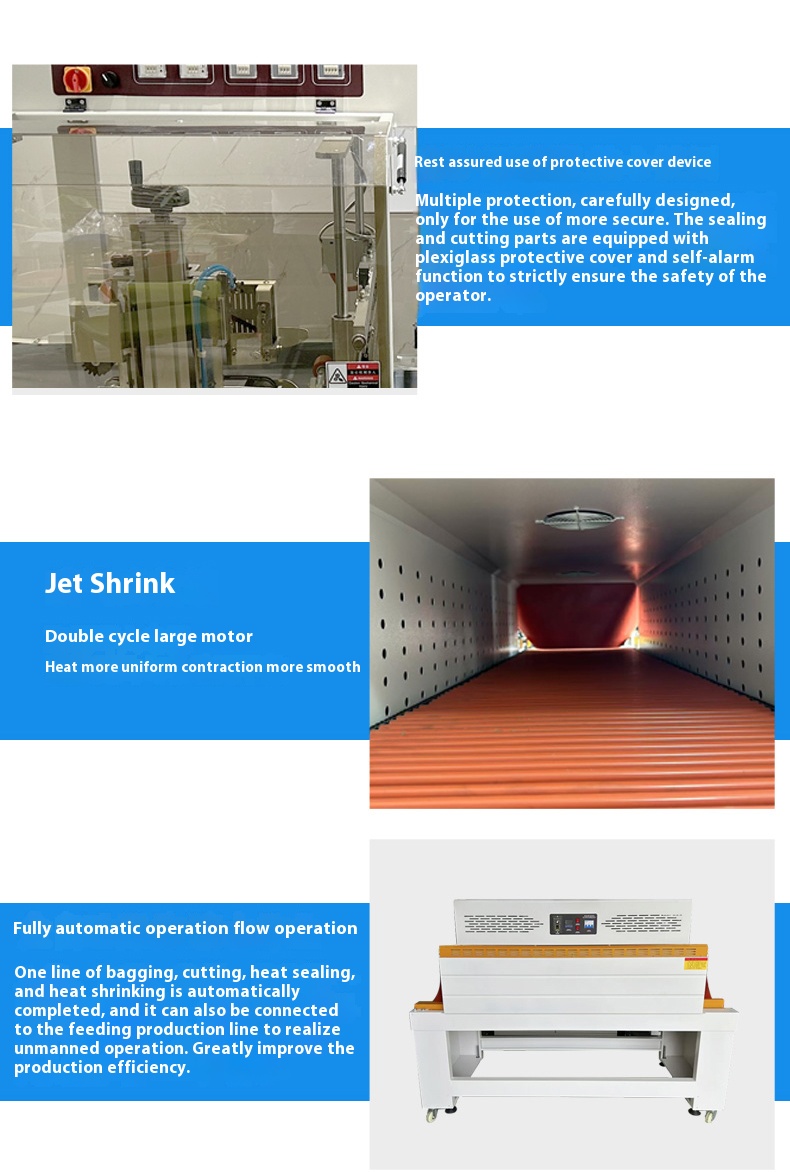

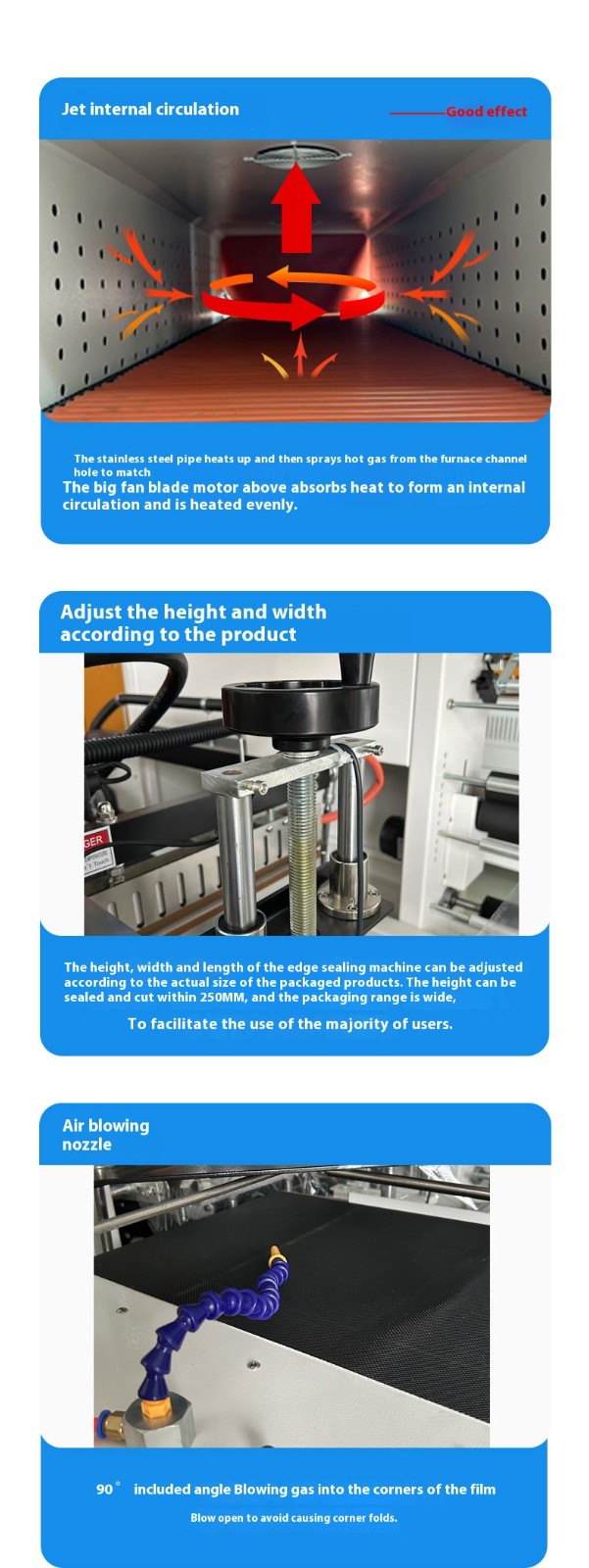

The heat shrinkage tunnel is equipped with multiple infrared heating tubes and circulating fans to form a three-dimensional hot air circulation system. The PLC intelligently adjusts heating temperature and airspeed according to product types and film characteristics, ensuring uniform film heating and shrinkage. Temperature sensors inside the tunnel provide real-time feedback, allowing the system to dynamically adjust heating power and avoid local overheating or insufficient shrinkage.

The cooling device employs a combination of air cooling or water cooling to rapidly lower the temperature of products after they exit the heat shrinkage tunnel. High-speed fans or a cooling water circulation system quickly shape the packaging film, enhancing its adhesion to the product, preventing rebound or deformation, and ensuring a tight and aesthetically pleasing final packaging effect.

Compared with traditional manual packaging, the fully automatic device can achieve a packaging speed of 10–30 pieces per minute, representing a 3–5-fold increase in efficiency. Its continuous, uninterrupted automated operation effectively meets high-volume production demands, particularly during peak seasons in industries such as food & beverage and electronics.

Precise parameter control and stable mechanical movements ensure highly uniform packaging results for each product. Indicators such as seal firmness, film shrinkage rate, and packaging appearance flatness all meet high standards, reducing defect rates and enhancing brand image and product market competitiveness.

Fully automated operation minimizes reliance on manual labor, allowing enterprises to save significant labor costs while avoiding production fluctuations caused by personnel turnover or differences in operational proficiency. Equipment operation requires only a small number of technicians for parameter setting and monitoring, reducing management complexity.