Shrinkage Effect of Cuff-type Packaging Films: POF Film as the Optimal Choice

Core Advantages of POF Film:

Outstanding Shrinkage Performance

- Moderate shrinkage rate (20%-30%) with fast shrinkage speed (completing shrinkage in just 1-3 seconds), and it can initiate shrinkage at low temperatures (120-160℃), resulting in lower energy consumption.

- Uniform film thickness (typically 0.02-0.08mm) ensures even heat distribution during shrinkage, minimizing local wrinkles or cracks. It is particularly suitable for products with irregular surfaces (e.g., bottles, special-shaped boxes).

Environmental Friendliness and Safety

- Non-toxic and odorless, compliant with FDA, ROHS, and other standards. It can directly contact food and pharmaceutical products, and emits no harmful gases when burned, making it suitable for high-hygiene requirements.

Aesthetic Packaging Effect

- With a transparency of over 90%, close to glass-like texture, it significantly enhances product visual appeal when paired with color-printed films. Commonly used in branded packaging (e.g., cosmetics, premium food).

Adaptability to High-Speed Production Lines

- Stable shrinkage process matches the continuous operation of cuff-type packaging machines (speed up to 10-30 packs/minute), reducing downtime for adjustments.

Limitations:

- Higher Cost: Unit price is approximately 1.5-2 times that of PE film, which may be less friendly for budget-sensitive small enterprises.

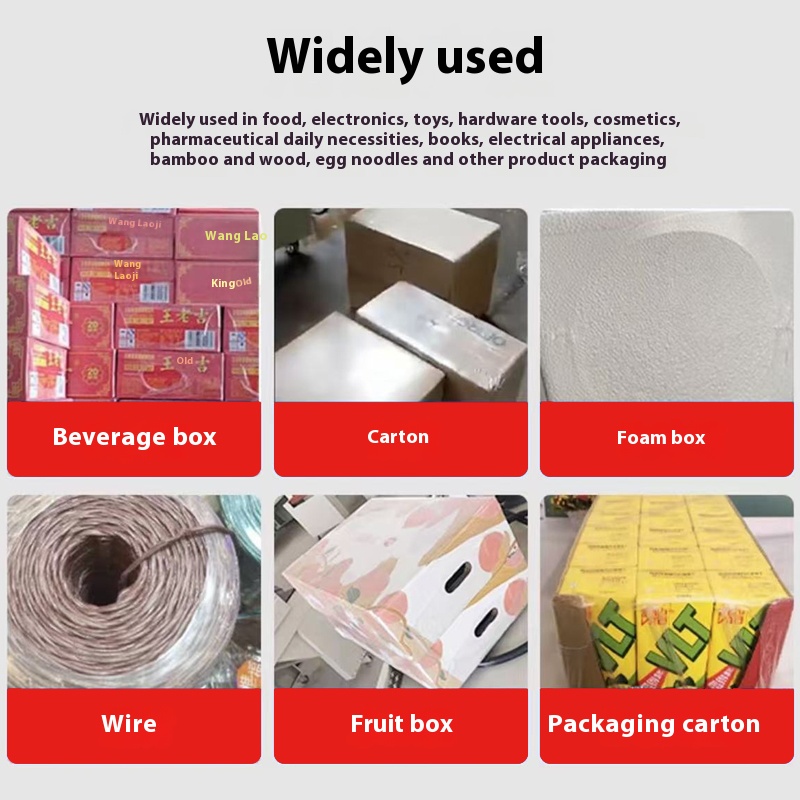

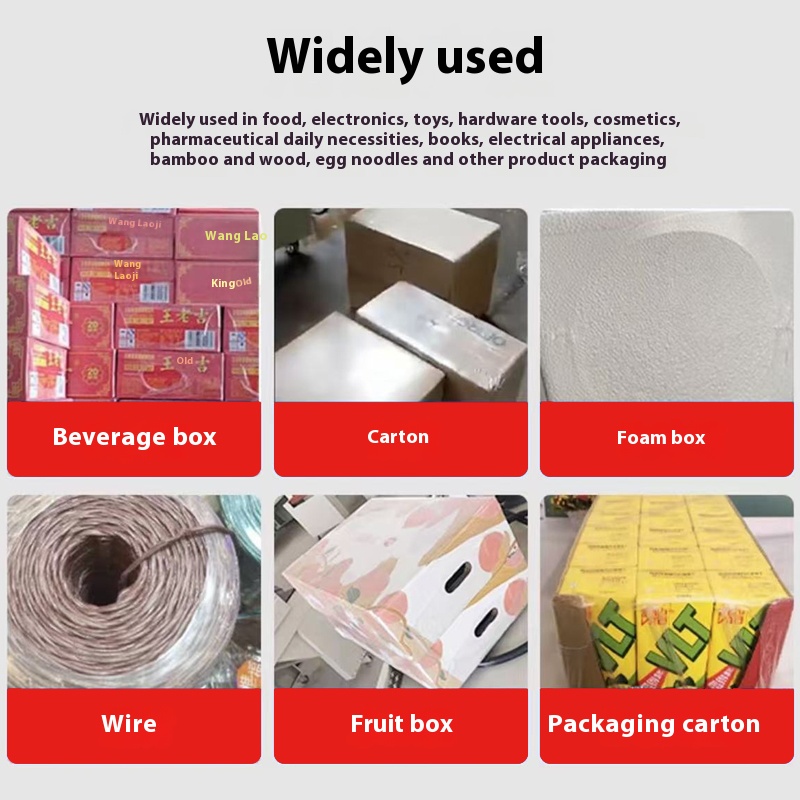

- Moderate Puncture Resistance: Prone to piercing by sharp objects when the thickness is too thin (e.g., <0.03mm), unsuitable for products with sharp edges (e.g., hardware tools).

PE Film: Cost-Effective Option

- Suitable for packaging heavy and collision-prone products (e.g., bottled beverages, barreled water), with superior flexibility and impact resistance at a lower cost (unit price: approximately 0.8-1.5 USD/m²).

- Recommended thickness: 0.05-0.15mm, suitable for medium-to-low-speed production lines (5-15 packs/minute).

PVC Film: Prioritizing Printing and Stiffness

- Ideal for enhancing product aesthetics through packaging (e.g., gifts, toys), with high printing clarity and rigidity. Note: Requires environmental compliance (limited to non-food industries).

- Recommended thickness: 0.08-0.2mm, requiring high-temperature packaging machines (temperature ≥180℃).

PP Film: Supplementary for Special Scenarios

- Only recommended for scenarios with low shrinkage requirements but high temperature resistance (e.g., kitchen utensils, electrical components), with limited practical applications.

- Prioritize POF Film: Opt for POF film if seeking superior shrinkage effect, environmental friendliness, and aesthetics, especially for premium packaging in food, daily chemicals, and 3C industries (with budget flexibility).

- Match by Product Characteristics:

- Irregular/fragile products: Choose POF or PE film (for uniform shrinkage and impact resistance).

- Flat/regular-shaped products: Consider PVC or PP film (for stiffness and printing effects).

- Test Compatibility: Due to significant process variations among film brands, request samples from suppliers to test shrinkage flatness, sealing performance, and energy consumption on your packaging machine before bulk purchasing.