The working efficiency of fully automatic cuff-type packaging machines is affected by factors such as equipment models, product specifications, packaging materials, and the degree of automation.

Release date:2025-06-24

Conventional Efficiency Range:

The packaging speed of most fully automatic cuff-type packaging machines is 20-120 packs/minute, specifically determined by equipment configuration and product dimensions.

- Small-scale equipment (for single-product packaging): Approximately 20-50 packs/minute (e.g., single cosmetic box packaging).

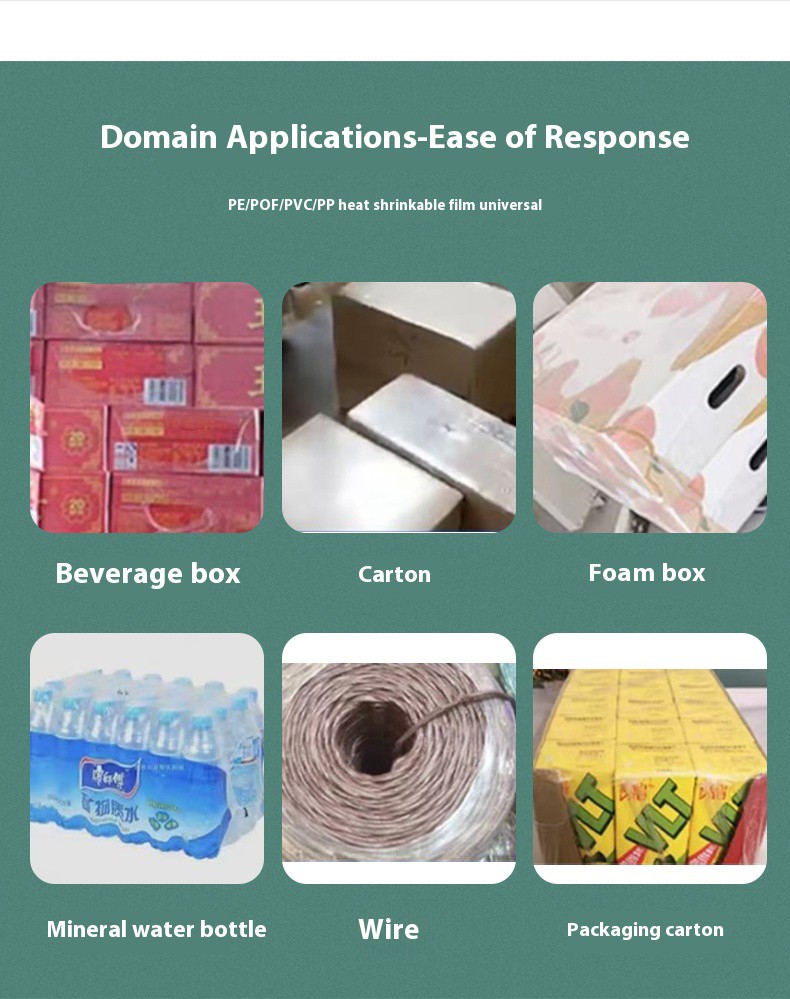

- Medium-scale equipment (for multi-bottle beverage combination packaging): Approximately 50-80 packs/minute (e.g., 6-bottle beverage sets).

- Large high-speed equipment (supporting production lines): Up to 80-120 packs/minute (e.g., full-package packaging for bottled water).

Case Reference:

When a certain brand of cuff-type packaging machine processes 500ml mineral water (6 bottles/set), the capacity reaches 60 sets/minute, i.e., 360 bottles packaged per minute—equivalent to 10-20 times the efficiency of traditional manual labor.

- Fully automated process:

The equipment integrates full processes including automatic feeding, positioning, film sleeving, heat shrinkage, and cooling, requiring no manual intervention and reducing downtime. For example, high-end models can achieve end-to-end automation of "product conveying → automatic film sleeving → shrinkage → sorting," with efficiency increased by over 50% compared to semi-automatic equipment. - Manual intervention scenarios:

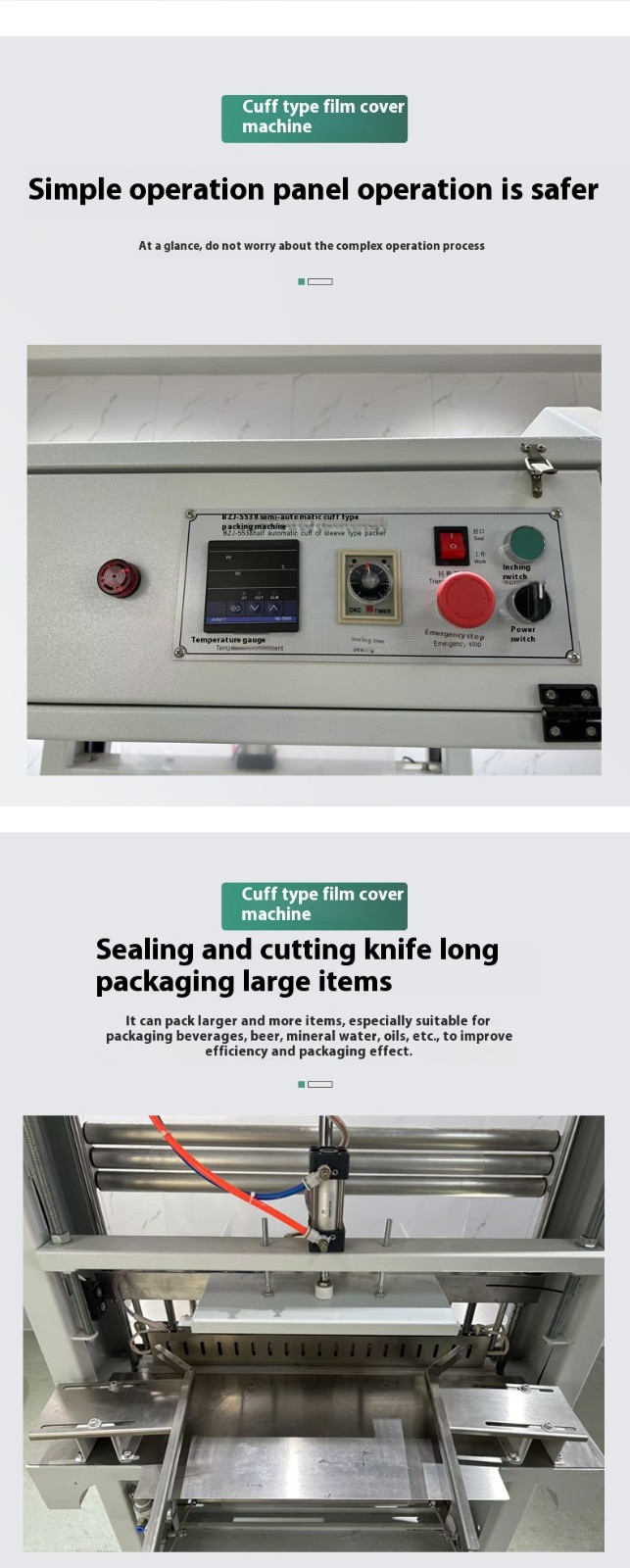

Some semi-automatic models require manual feeding or film adjustment, with packaging speed typically below 40 packs/minute—suitable for small-batch, multi-specification product switching.

- Product size and shape:

- Regular shapes (e.g., square boxes, cylindrical bottles): Higher packaging efficiency, with precise equipment positioning and film sleeving. For example, the packaging speed of rectangular medicine boxes can reach 70 packs/minute.

- Irregular products (e.g., toys, irregular tools): Require customized molds or parameter adjustment, potentially reducing packaging speed by 10%-30%. For example, plush toys are packaged at approximately 40 packs/minute.

- Number of packaging layers and film materials:

- Single-layer film packaging: Faster speed (e.g., common POF film); multi-layer or thickened films (e.g., anti-static PE film): Prolonged shrinkage time, reducing efficiency by approximately 10%-20%.

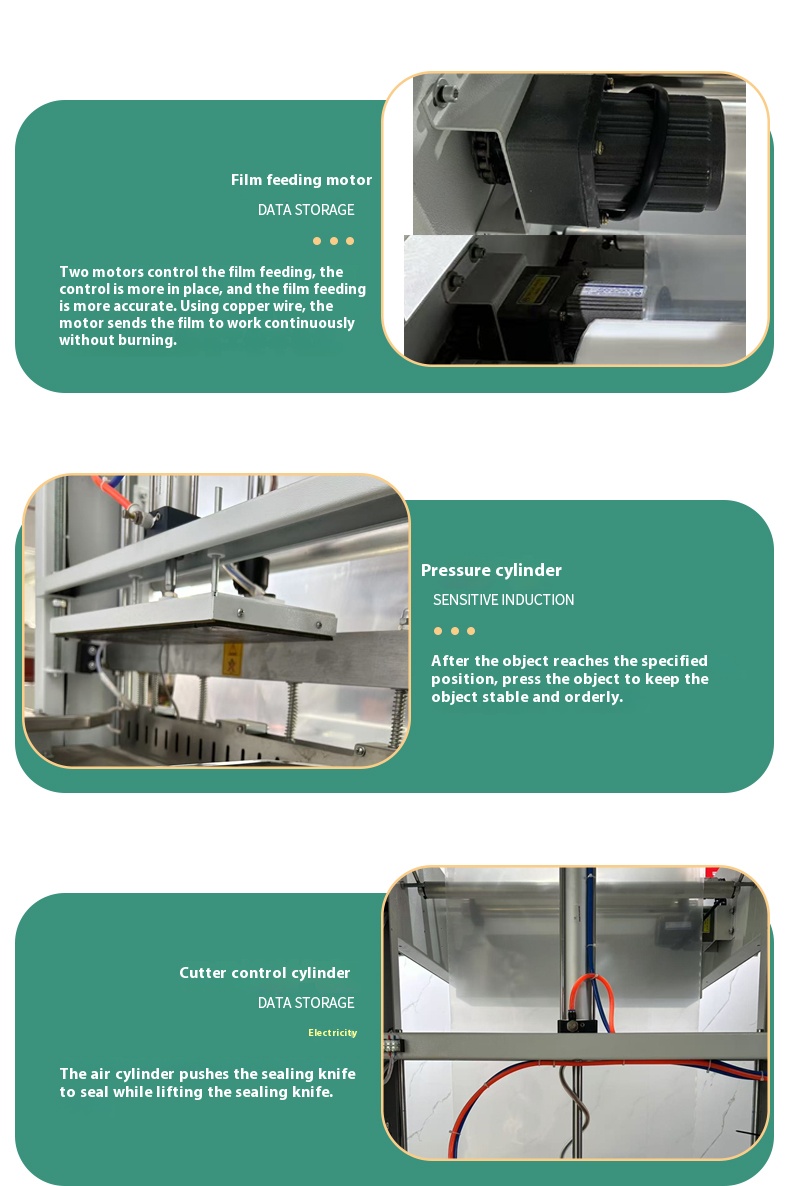

- Motor and transmission system:

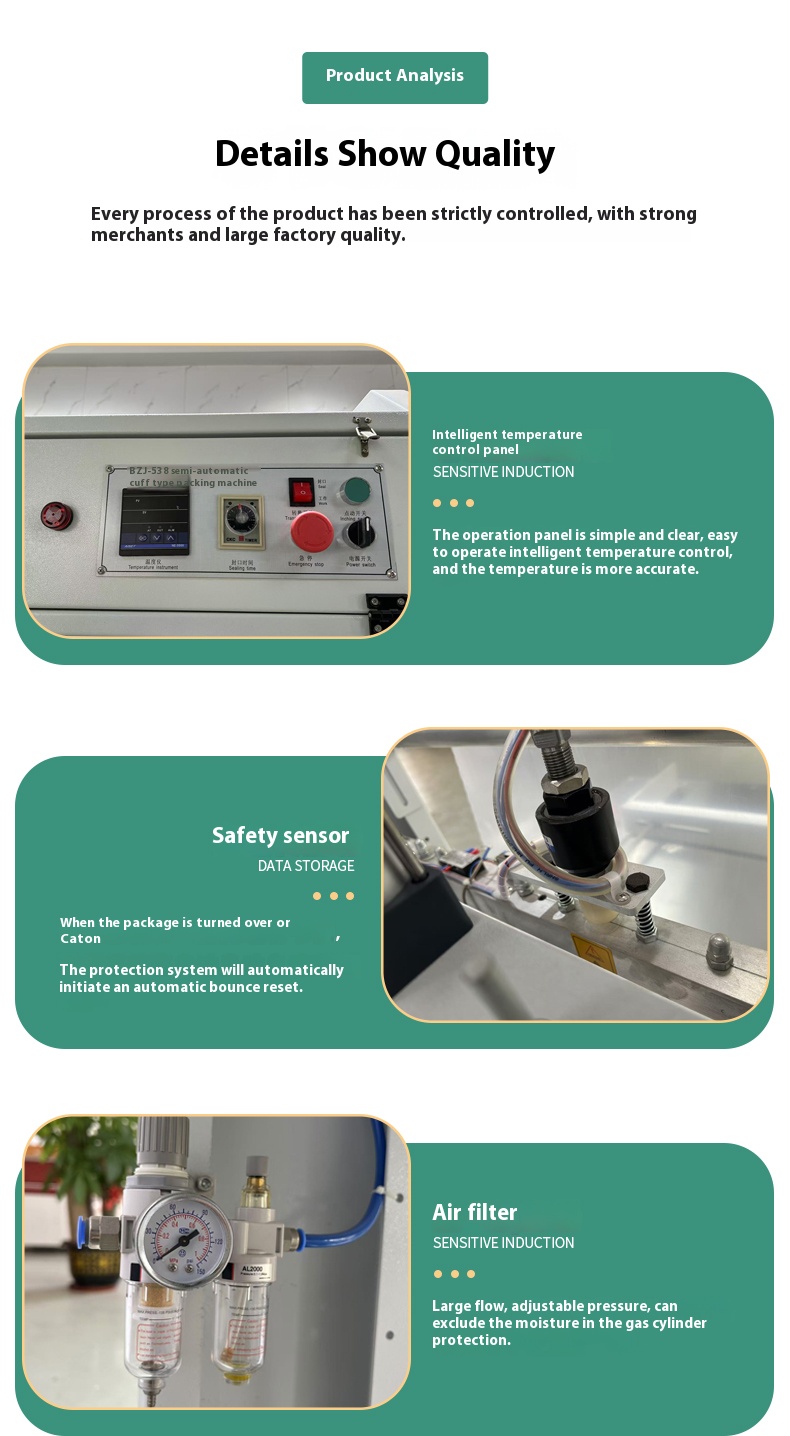

Equipment driven by servo motors features more precise positioning and stable speed, with 15%-30% higher efficiency than models with ordinary motors. - Heat shrinkage furnace power:

High-power heat shrinkage furnaces (e.g., over 12kW) provide uniform heating and fast shrinkage, suitable for high-speed production lines; low-power equipment (e.g., 6kW) may cause bottlenecks due to slow heating, affecting overall efficiency. - Intelligent control system:

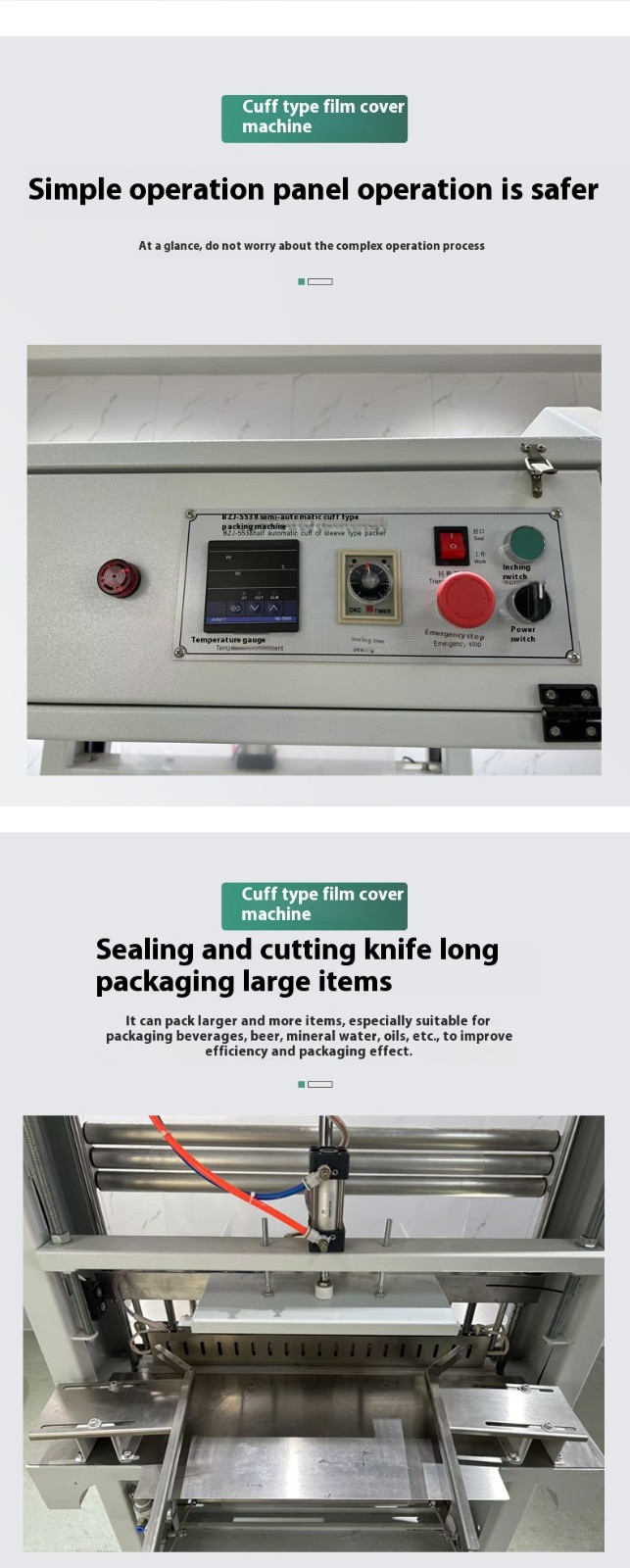

Equipment equipped with PLC intelligent control and touchscreens can store multiple product parameters, eliminating manual debugging during specification switching. The model changeover time is shortened from the traditional 30 minutes to 5-10 minutes, reducing downtime losses.

- Front-end conveyor line matching:

If the conveyor line speed does not match the packaging machine (e.g., slow feeding or jamming), the packaging machine will idle or stop frequently, with efficiency decreasing by over 20%. - Stability of film supply:

Improper installation, insufficient tension, or breakage of rolled film will interrupt the packaging process. The automatic deviation correction and tension control systems of high-quality equipment can reduce such failures and extend continuous operation time.