Here are the advantages of double-chamber vacuum packaging machines, along with detailed explanations:

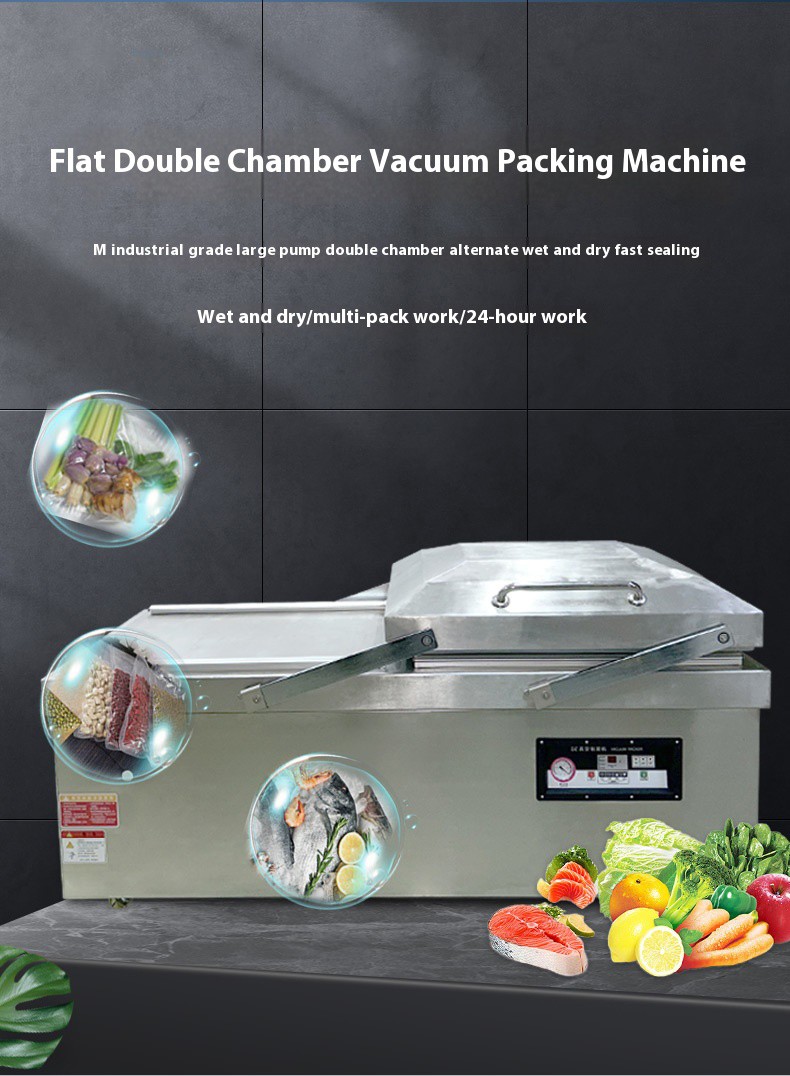

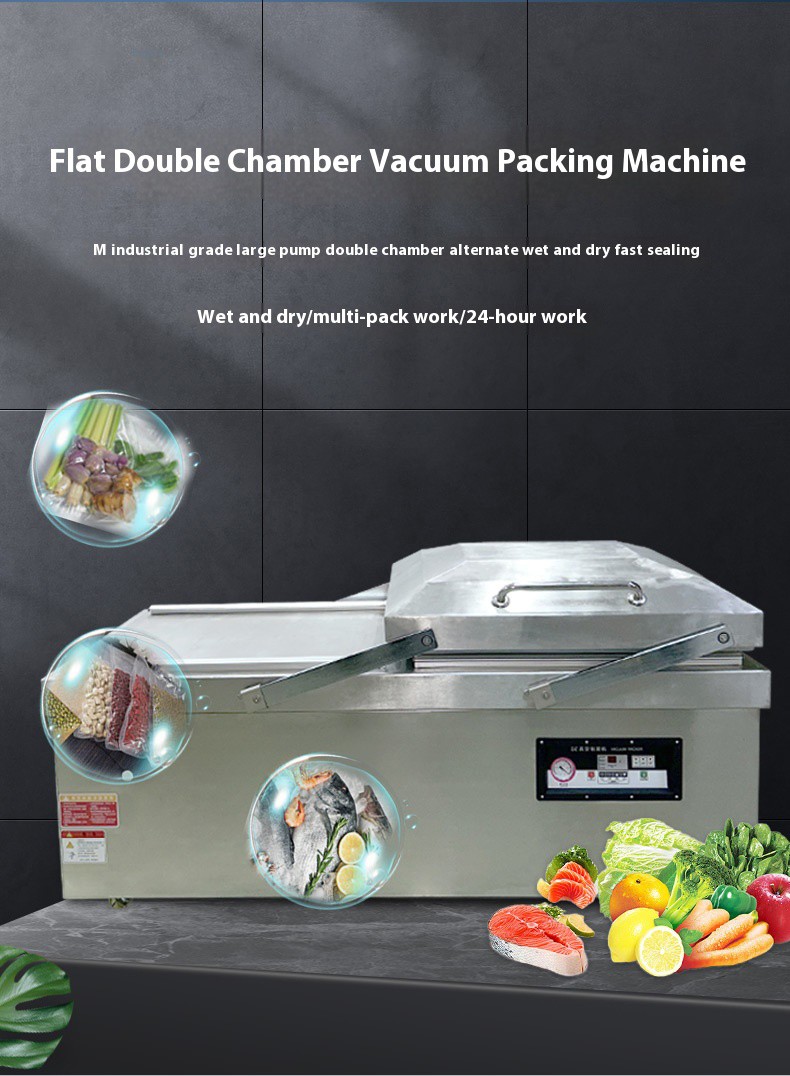

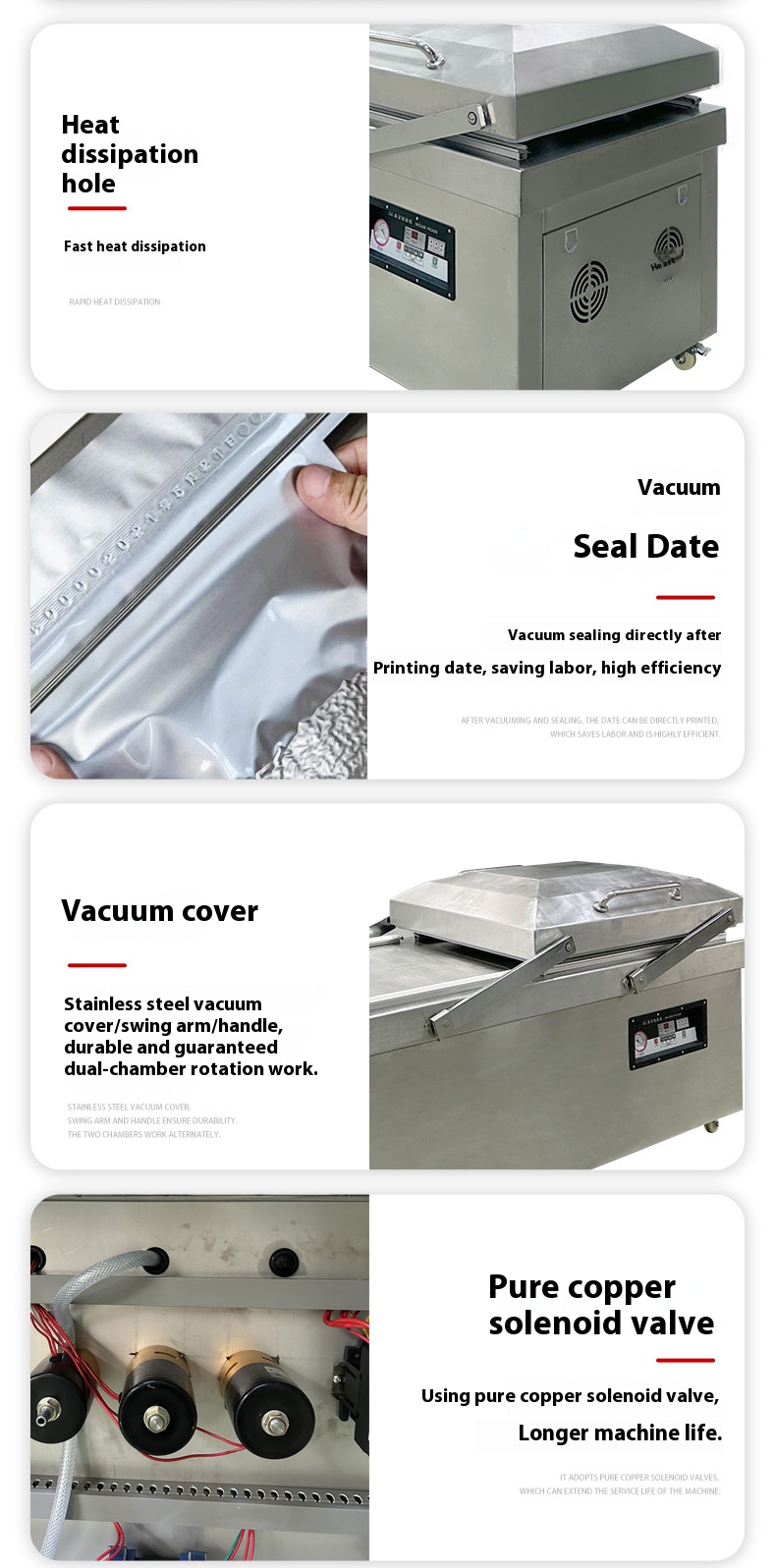

- The two chambers work alternately. While one chamber is performing vacuuming and sealing, the other can be used for placing materials, significantly improving packaging efficiency. This makes it especially suitable for large-scale production enterprises.

- Capable of packaging various types of materials, including solids, powders, granules, pastes, and liquids.

- Widely used in multiple industries such as food, electronics, hardware, chemicals, and pharmaceuticals.

- By evacuating air and filling inert gases (such as nitrogen, carbon dioxide, etc.), it effectively removes oxygen from the packaging container.

- Inhibits the growth and reproduction of microorganisms, prevents food from spoiling, oil from oxidizing, and thus extends the product's shelf life.

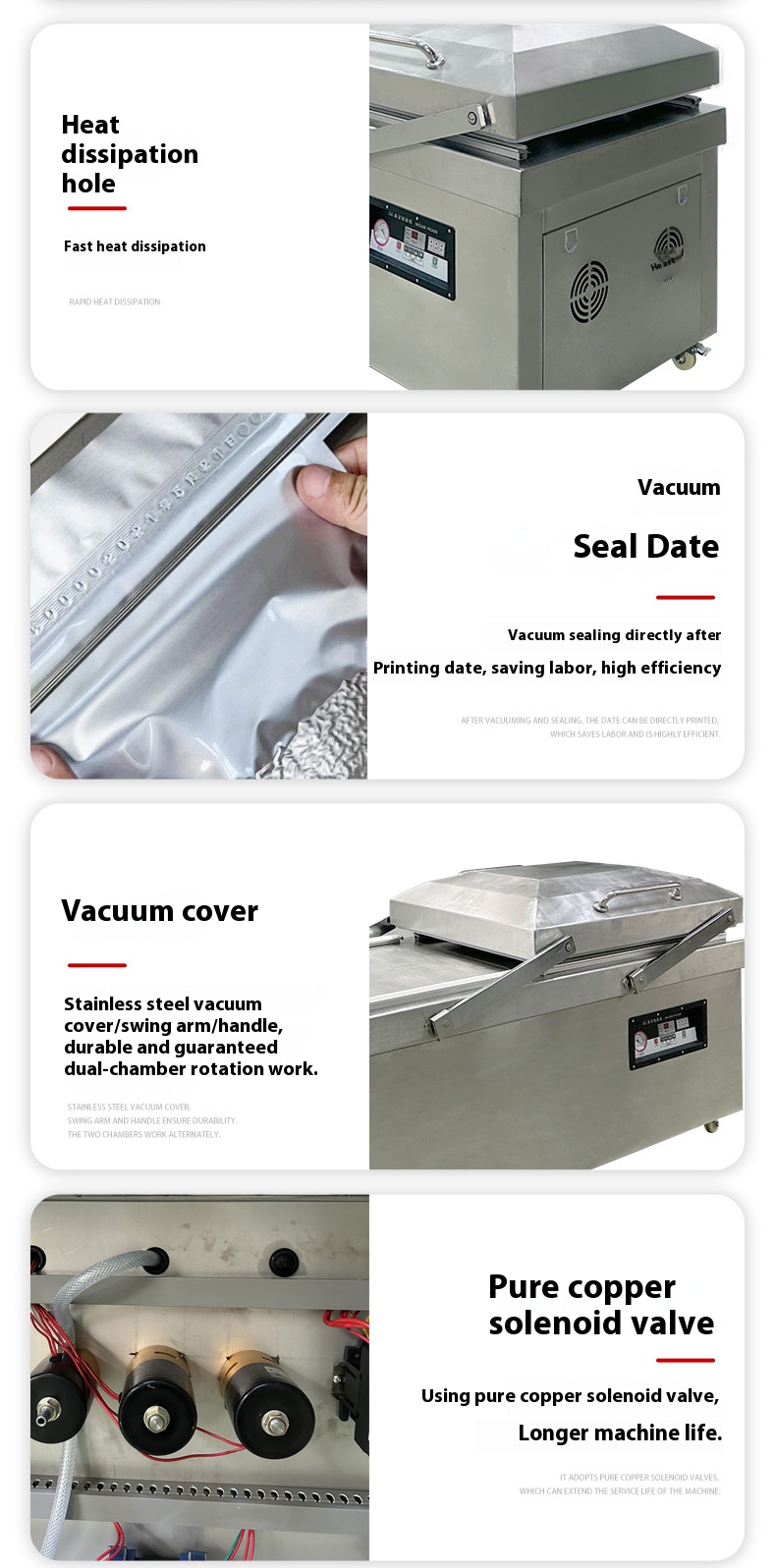

- Equipped with V-shaped sealing strips made of high-density materials, combined with strict sealing technology and standards.

- Ensures good airtightness during daily operation, preventing the exchange of packaged contents and secondary pollution.

- Typically controlled by microcomputers or PLC (Programmable Logic Controllers), paired with a color touch-screen operation interface.

- Makes the setting of packaging parameters (such as vacuuming time, heat-sealing time, etc.) more intuitive and simple, allowing new employees to quickly master the operation.