The "high packaging efficiency" and "high packaging flexibility" of pneumatic external suction vacuum packaging machines are their core advantages. These two characteristics endow them with strong practicality in multiple industries and scenarios, which can be understood in depth from the following perspectives:

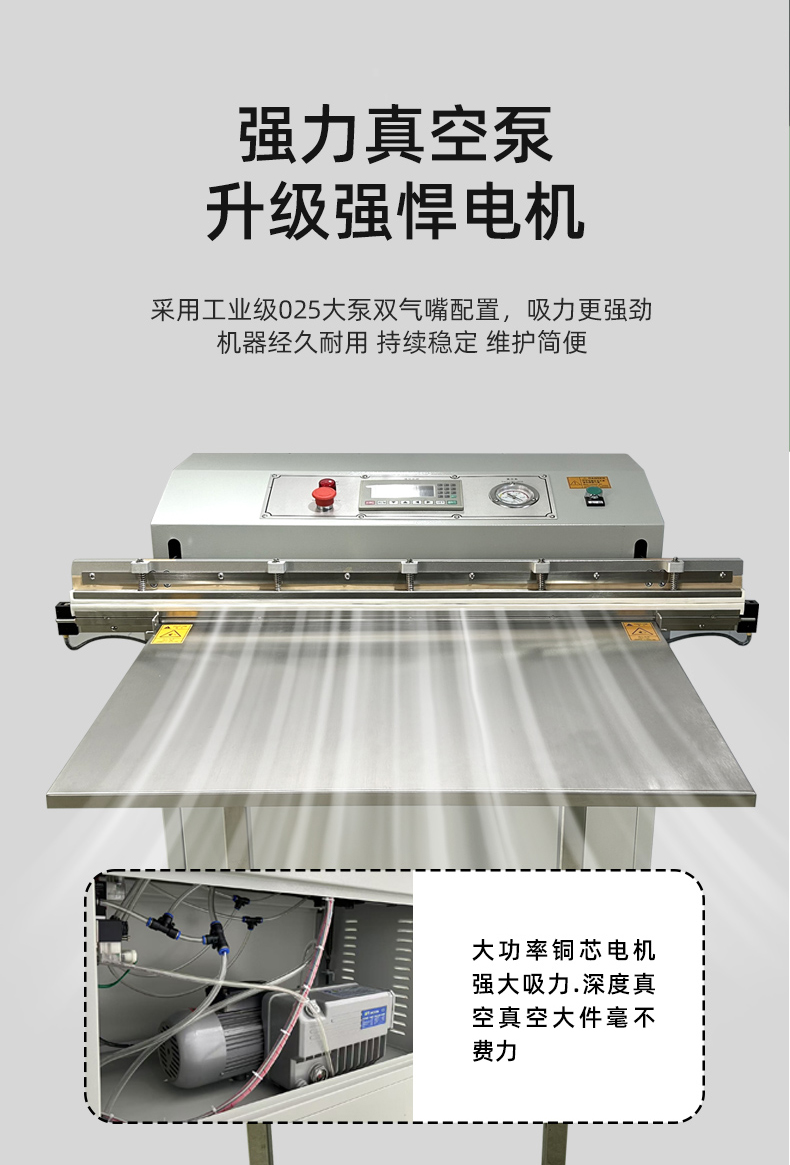

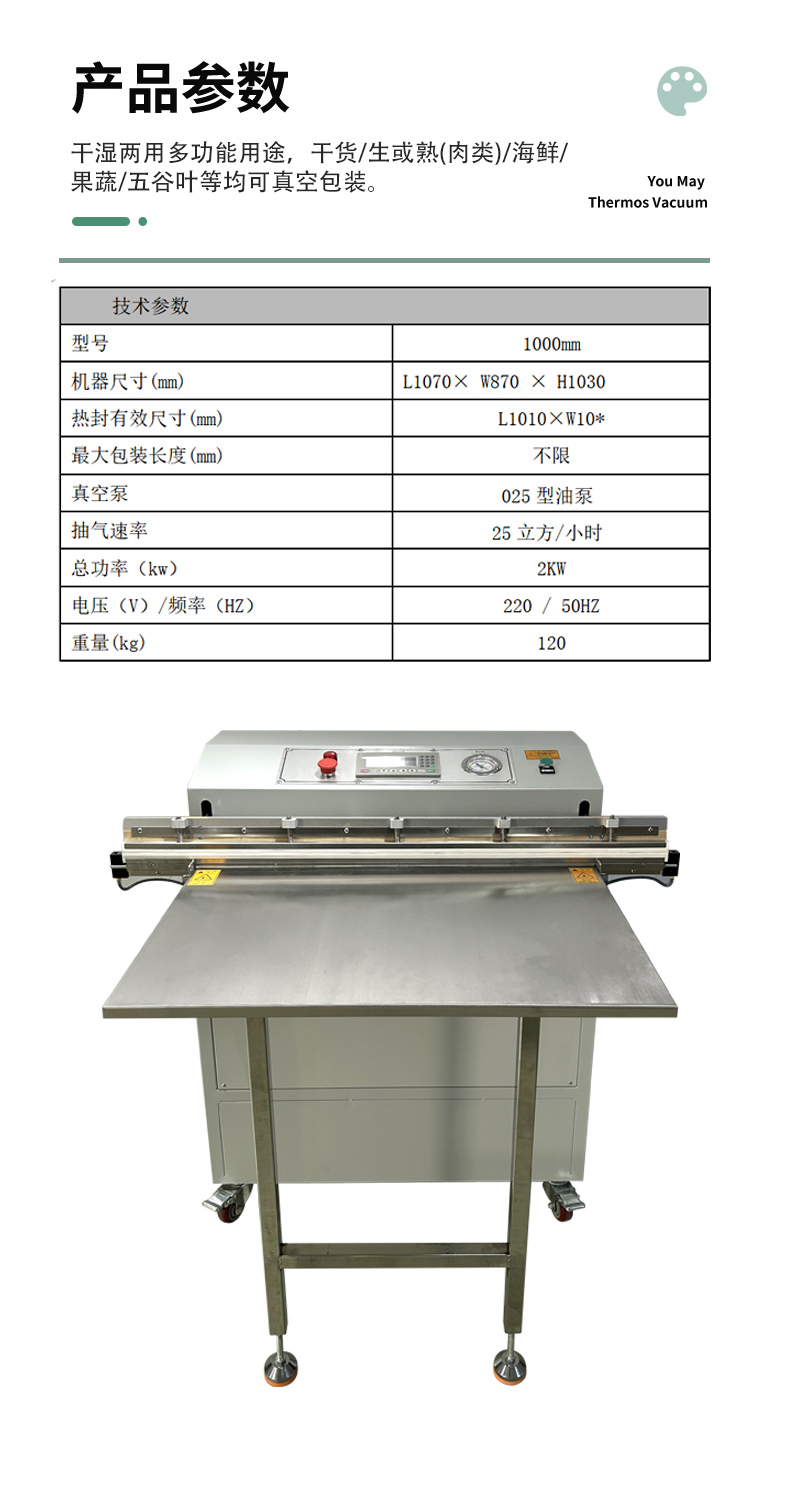

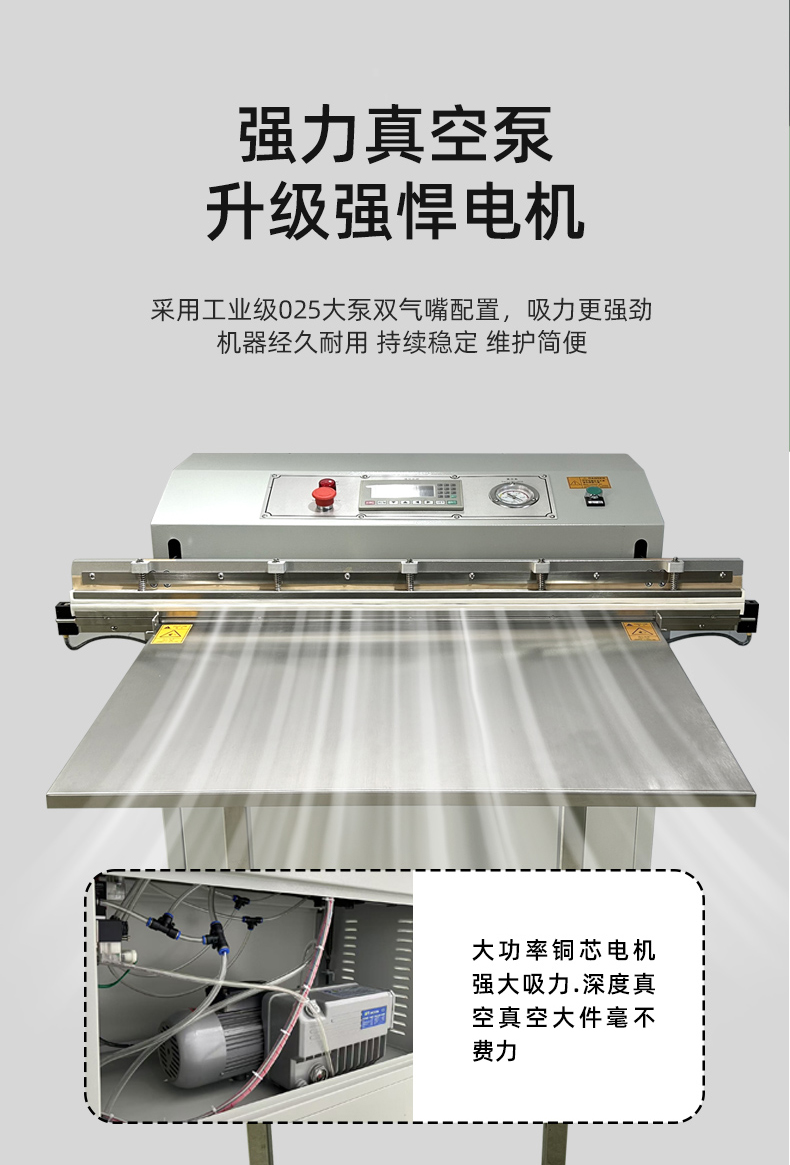

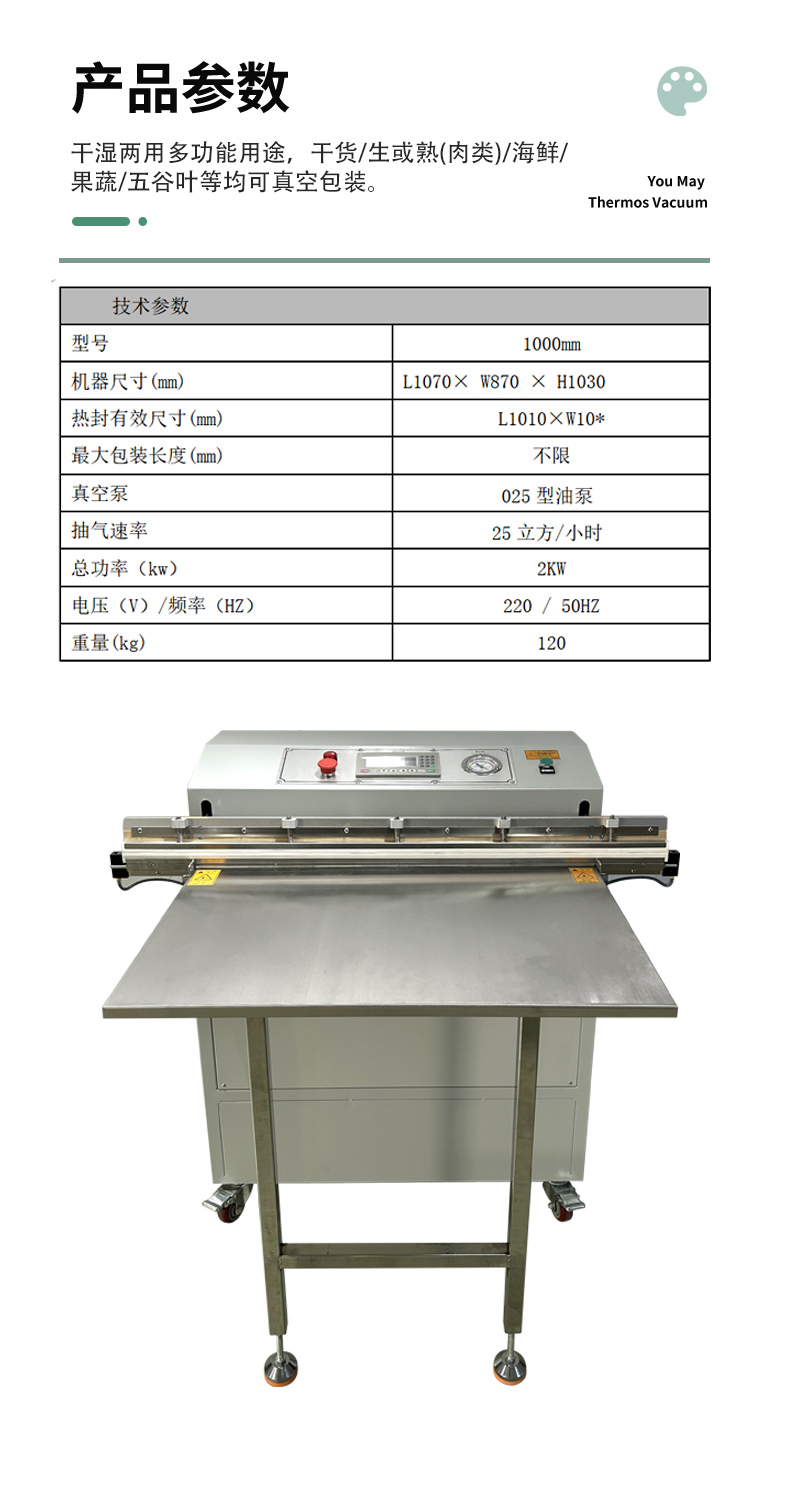

The core advantage of the pneumatic system lies in its "fast response and stable power": During the air extraction phase, the pneumatic valve can open instantly, and when paired with a high-power vacuum pump (such as a rotary vane vacuum pump with an air extraction rate of 100-500 L/min), it can quickly extract air from the packaging bag. In the heat-sealing phase, the pneumatic cylinder drives the heat-sealing strip to press precisely, with stable pressure and a short action time (usually heat-sealing time can be controlled within 0.5-3 seconds). The transition between air extraction and heat-sealing has almost no delay.

Compared with internal suction vacuum machines (which rely on air extraction from a vacuum chamber and require waiting for the complete cycle of chamber sealing, air extraction, and deflation), the external suction type eliminates steps such as "placing the product into the vacuum chamber" and "sealing the chamber". As a result, the single-cycle time can be reduced by 30%-50%.

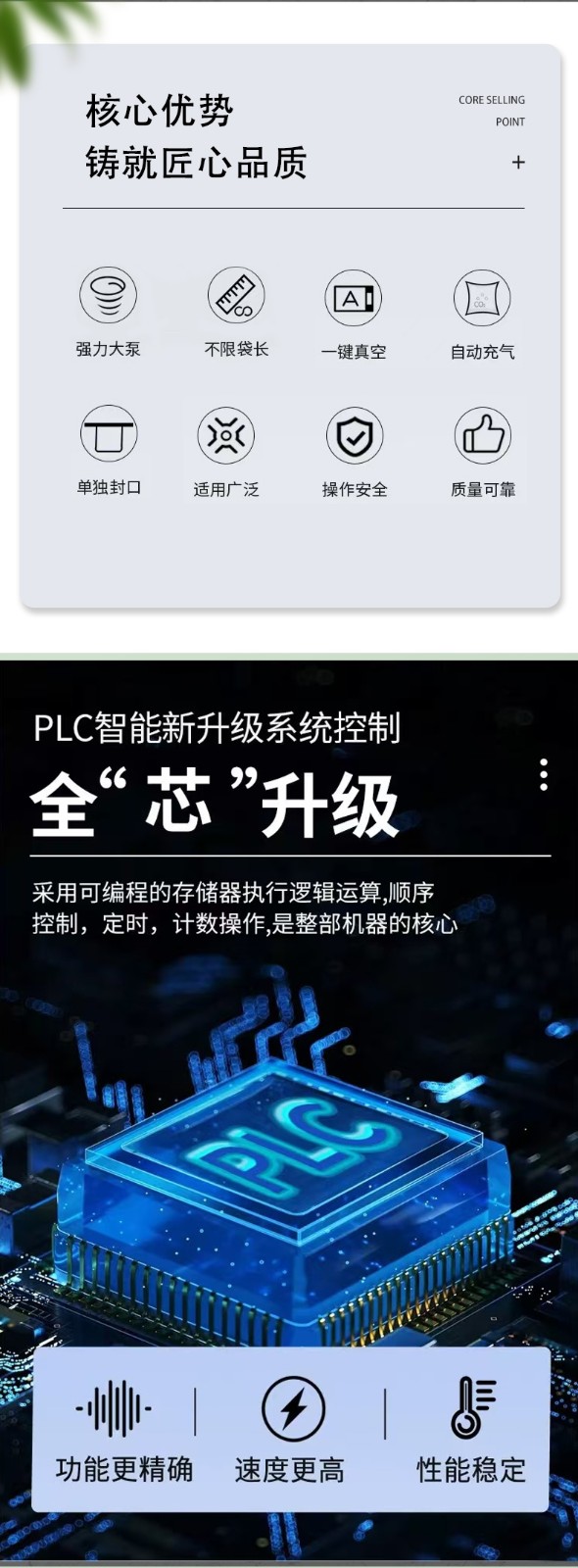

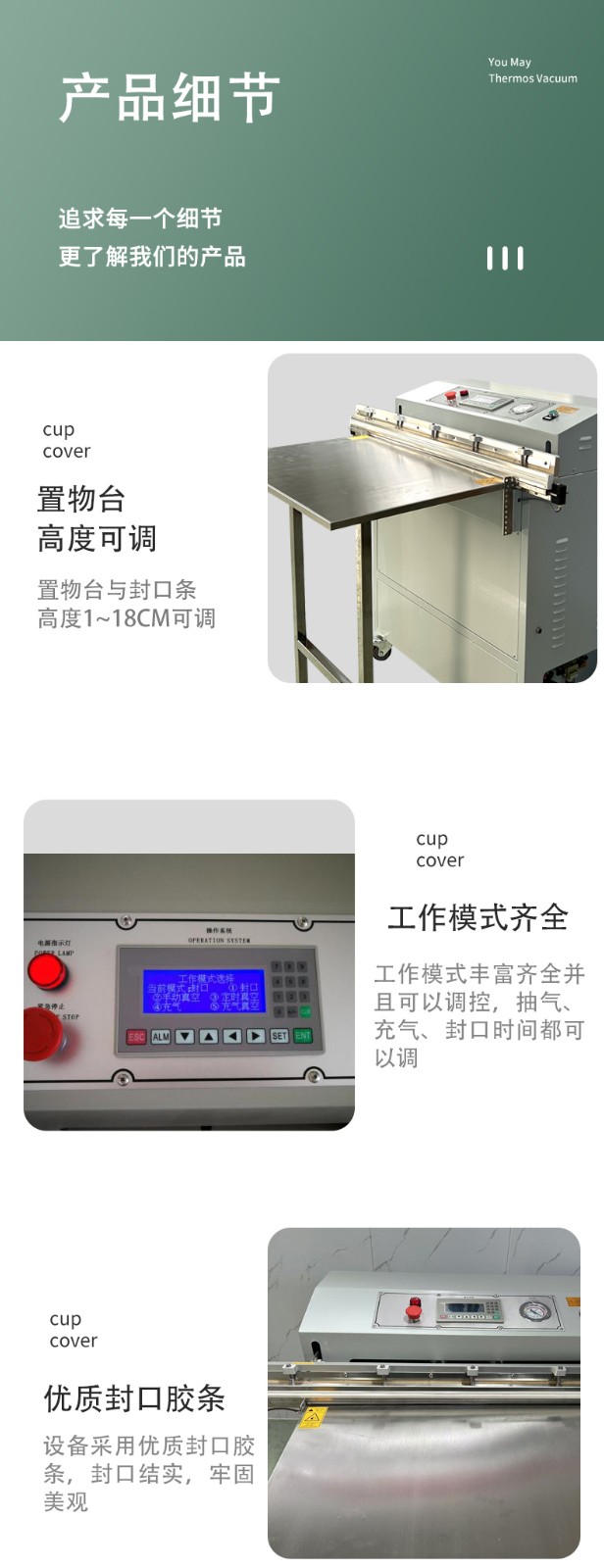

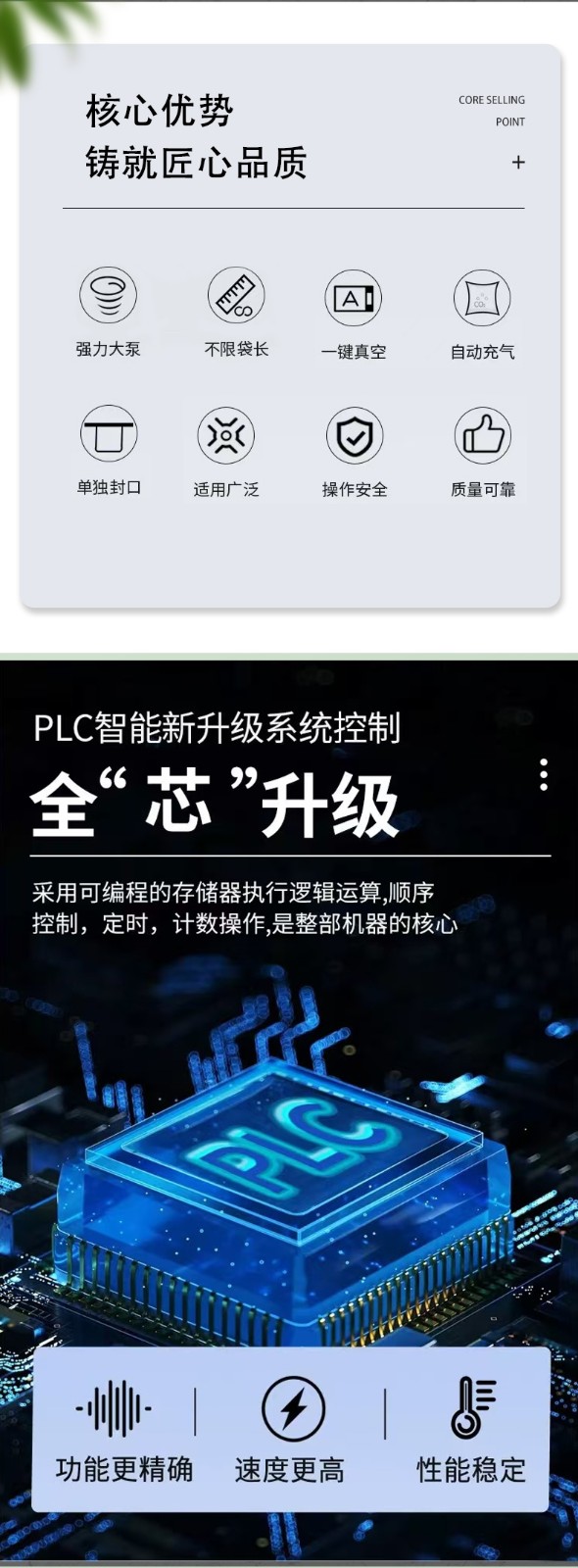

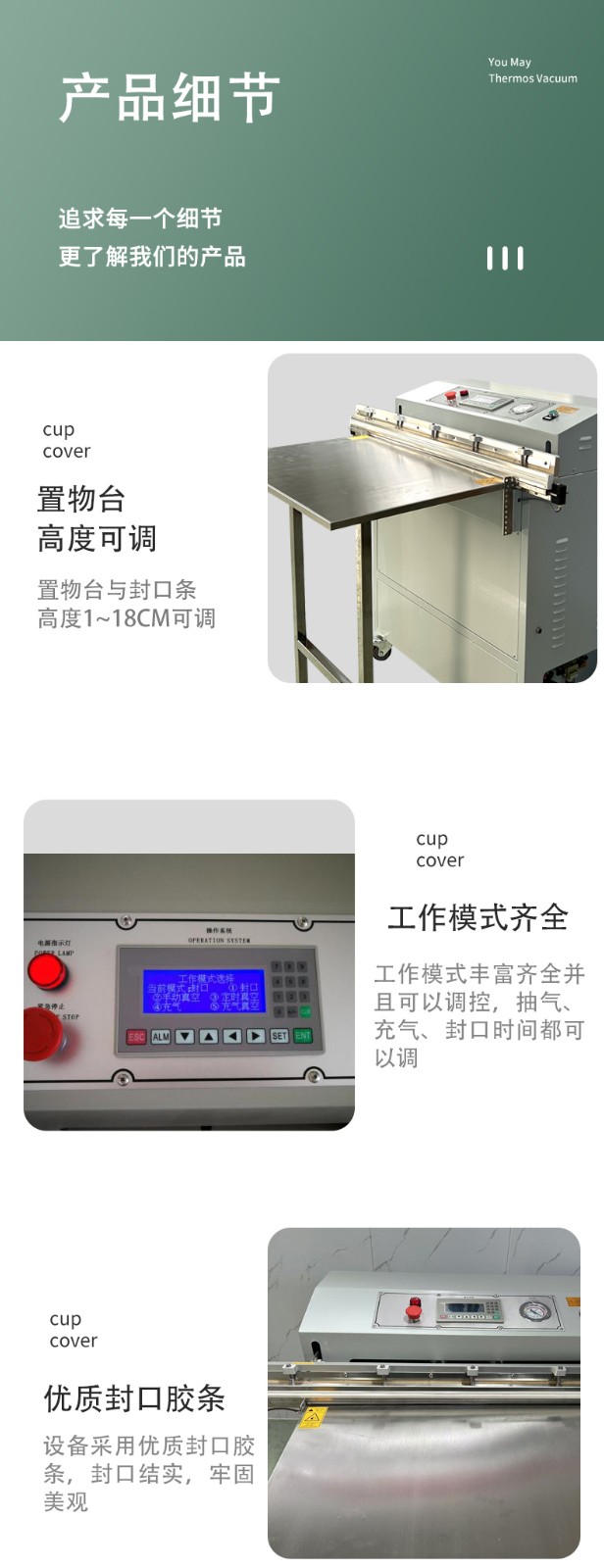

Equipped with a PLC or microcomputer control system, parameters such as vacuum degree, air extraction time, and heat-sealing settings can be preset, eliminating the need for repeated adjustments during mass production. Some models also support automatic feeding, automatic bag cutting, and even linkage with production lines, realizing full-process automation from "bag placement - air extraction - sealing - discharge".

For example: In food processing plants, a medium-sized pneumatic external suction machine can complete 800-1500 packages per hour (depending on the size of the product), far exceeding manual packaging (about 100-300 times/hour). Moreover, it features high stability, avoiding efficiency fluctuations caused by manual operations.

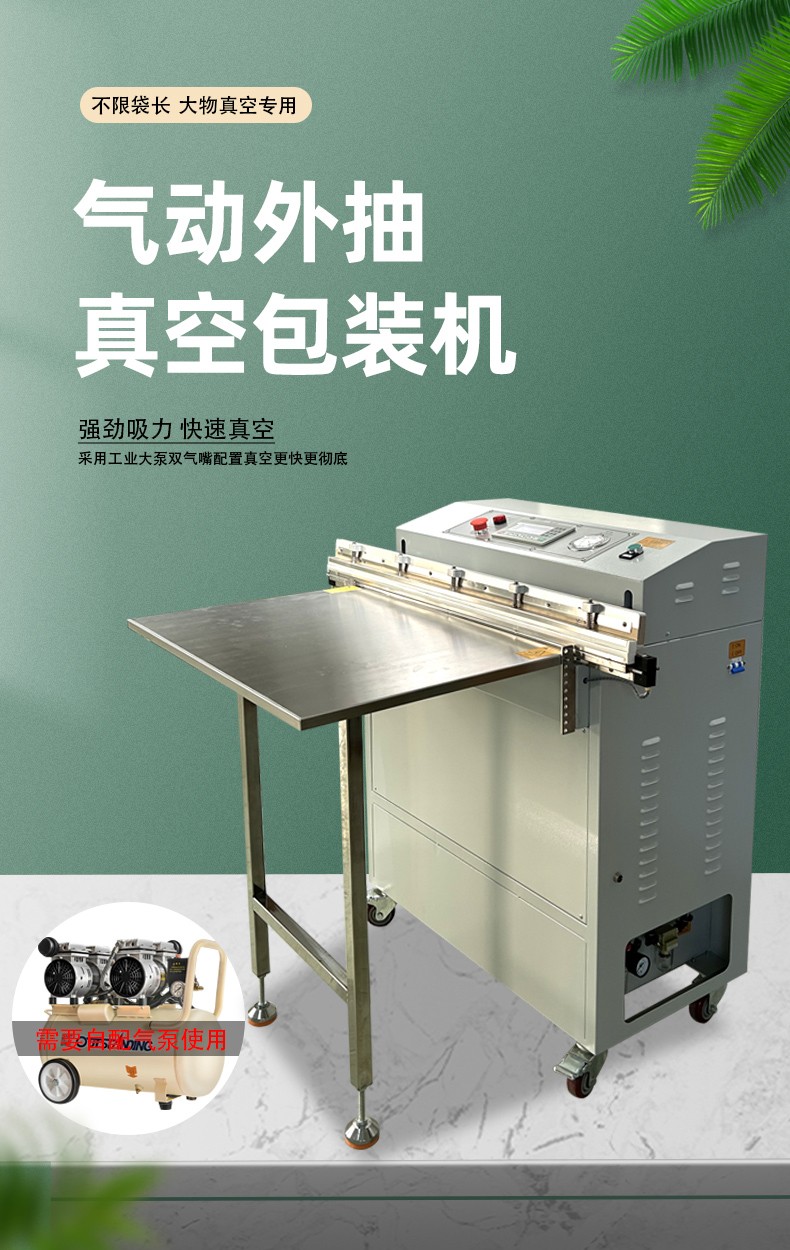

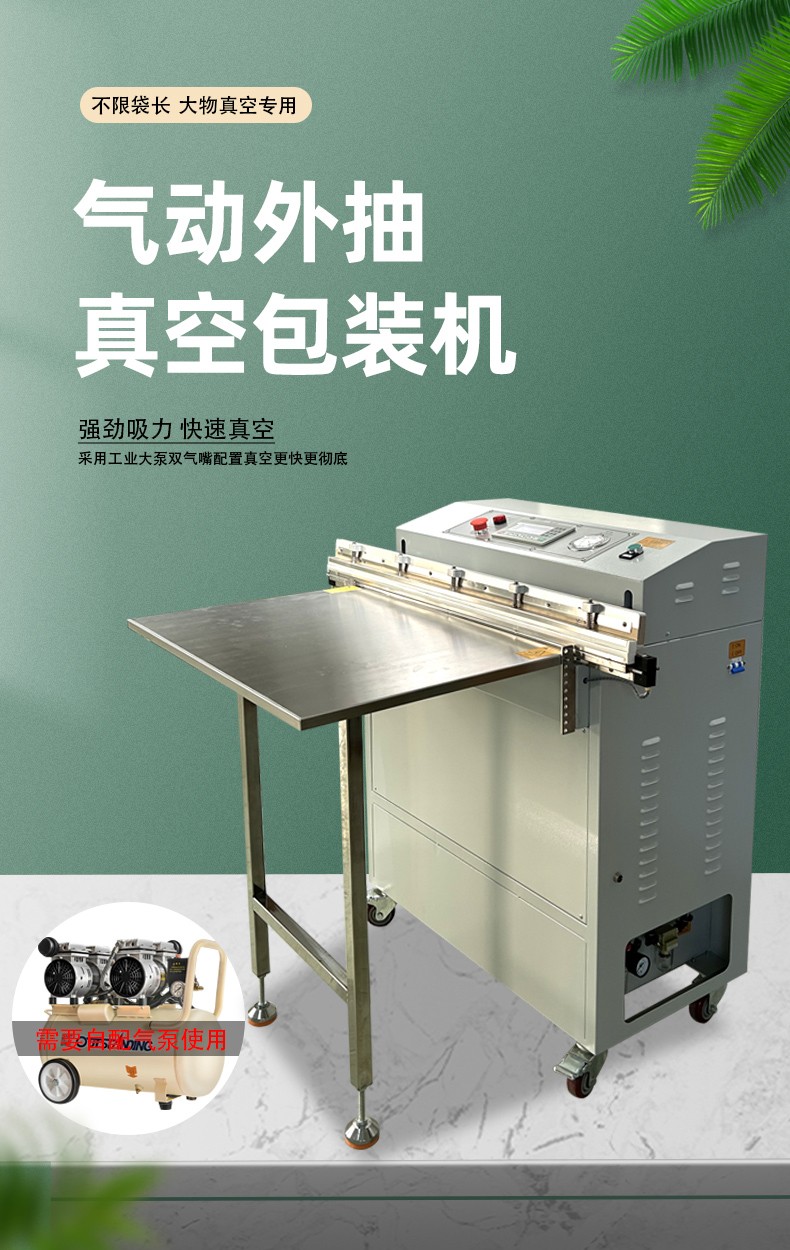

The core design of the external suction type is "external placement of the air extraction component"—the suction nozzle is connected to the vacuum pump via a pipeline, eliminating the need to place the product in a closed vacuum chamber. Therefore:

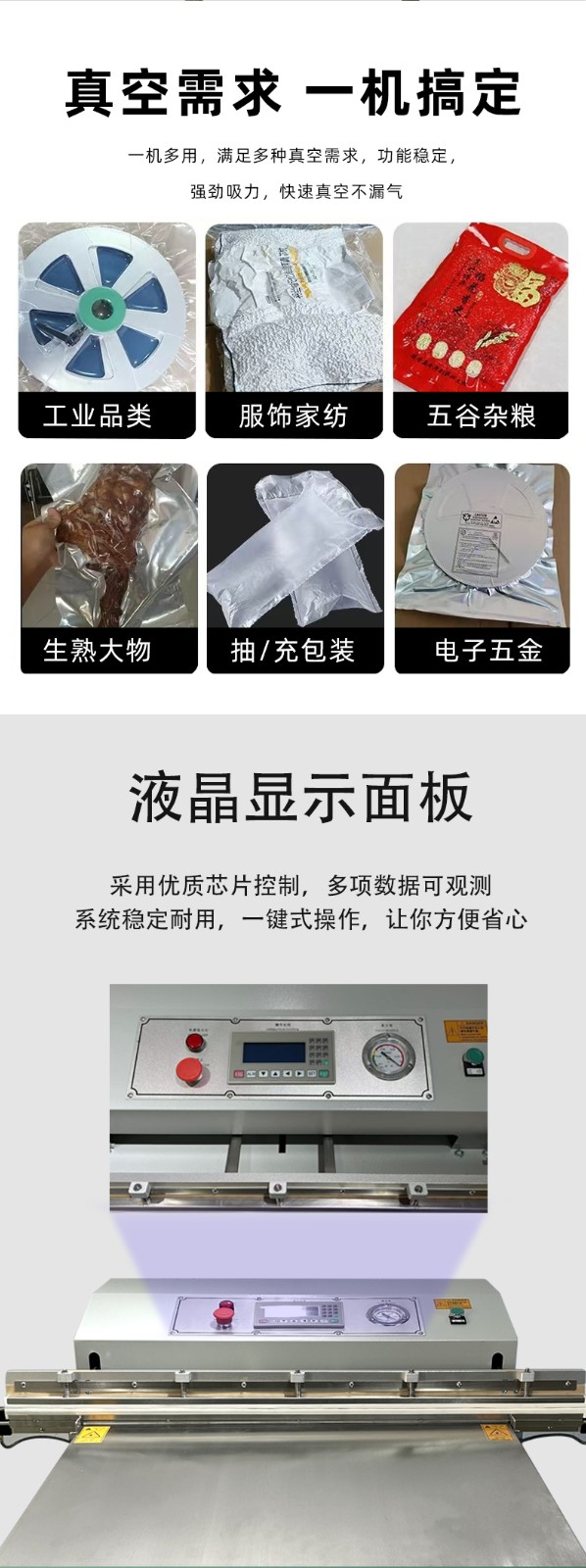

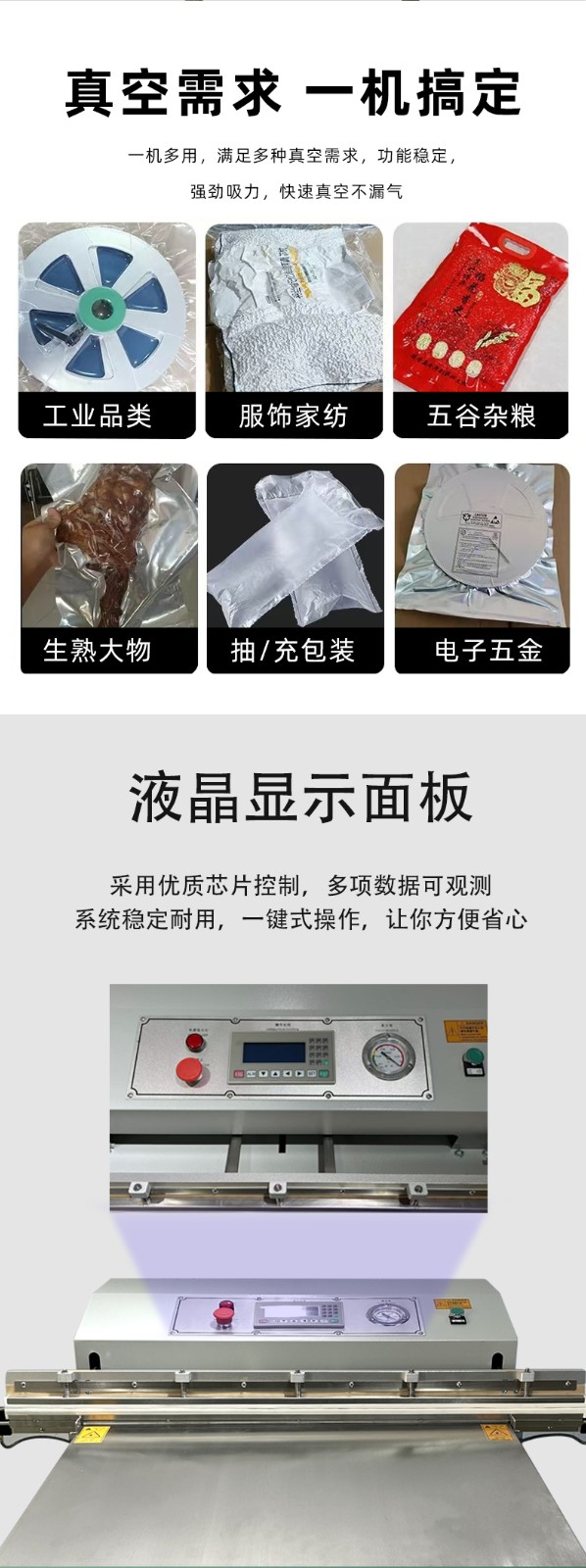

- Large products (such as mattresses, quilts, large hardware parts) can be directly covered with large-sized packaging bags, and the suction nozzle only needs to be aligned with the bag opening;

- Irregularly shaped products (such as seafood, meat, special-shaped electronic components) do not need to be deliberately arranged. During air extraction, it can exhaust air along the contour of the product, avoiding the packaging limitations of internal suction types due to insufficient vacuum chamber space.

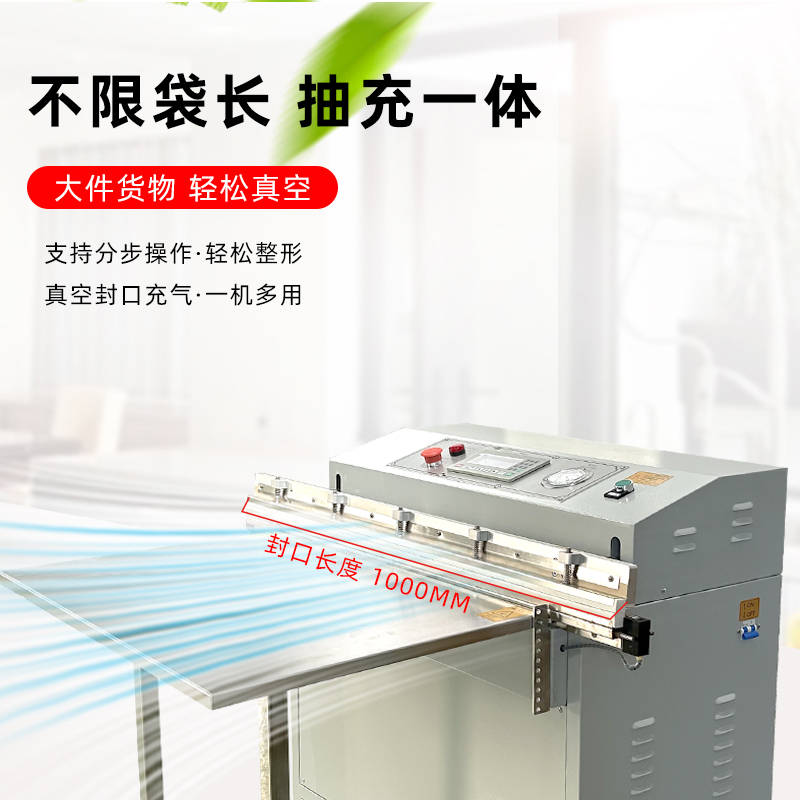

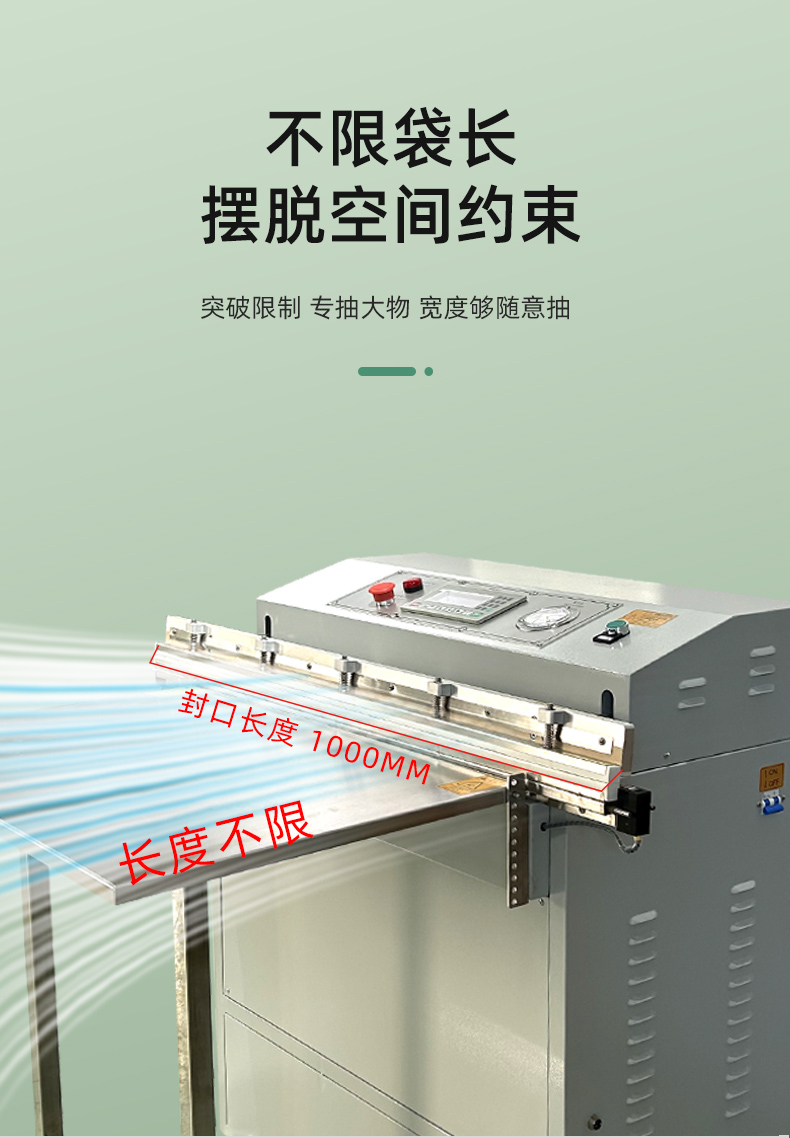

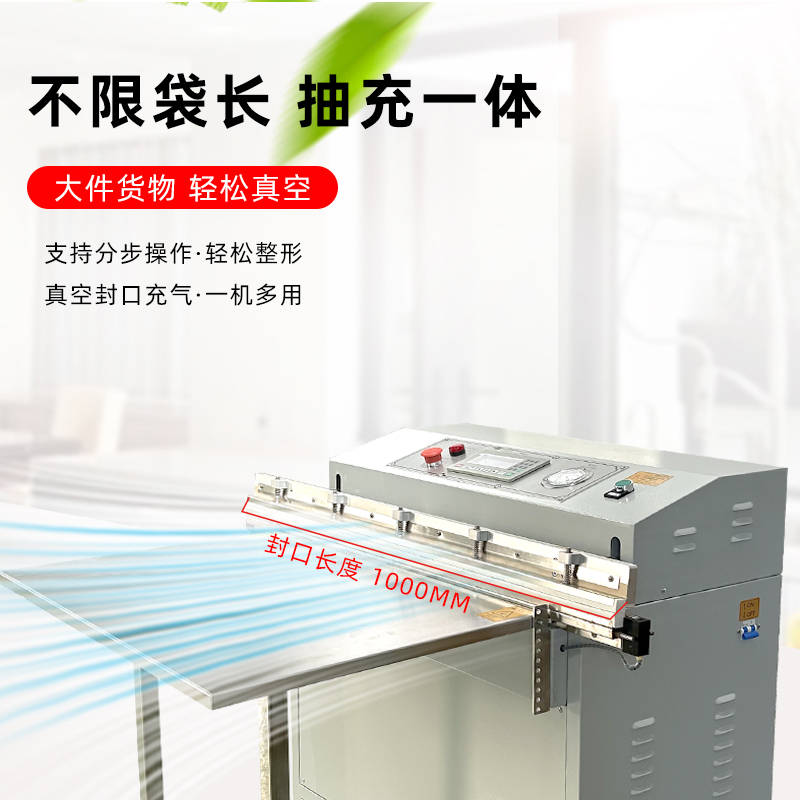

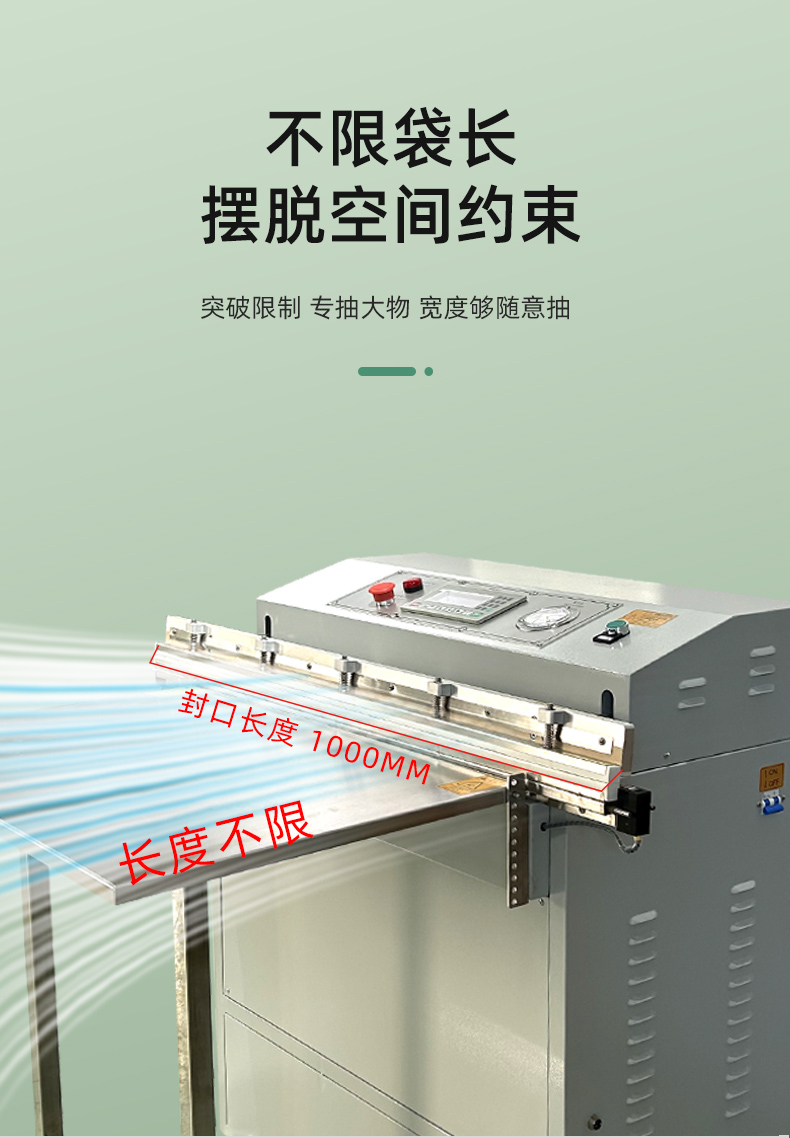

Whether it is pre-made bags, roll film bags, aluminum foil bags, composite film bags, or even special packaging bags with valves, the external suction type can adapt to them. There is no need to replace the vacuum chamber mold according to product size; only the position of the suction nozzle or the width of the heat-sealing strip needs to be adjusted (some models support adjustable heat-sealing strips) to quickly switch packaging specifications.

For example: In e-commerce warehouses, it can package both small jewelry (using small bags) and large household items (using large bags) without replacing equipment, greatly reducing the equipment investment cost for multi-category production.