I. Core Logic of Docking: Achieving a Full-Process Automated Closed-Loop Between "Production Line and Side-Sealing Machine"

The essence of docking is to form a seamless, labor-free connection between the "output" of the production line and the "input" of the side-sealing machine. The core objectives include:

- Enabling automatic transfer of products between the production line and the side-sealing machine to avoid efficiency losses and errors caused by manual handling;

- Matching the operation rhythm of the side-sealing machine (e.g., conveying speed, sealing and cutting frequency) with the production capacity of the production line to eliminate the bottleneck of "front-end congestion and back-end idleness";

- Realizing a full-process closed-loop of "product detection → automatic entry into the side-sealing machine → completion of packaging → return to the production line" through intelligent control.

II. Key Docking Technologies: Ensuring "Smooth Connection and Precise Synchronization"

- Synchronous Control of Conveying System: Avoiding Stalls Caused by "Speed Differences"

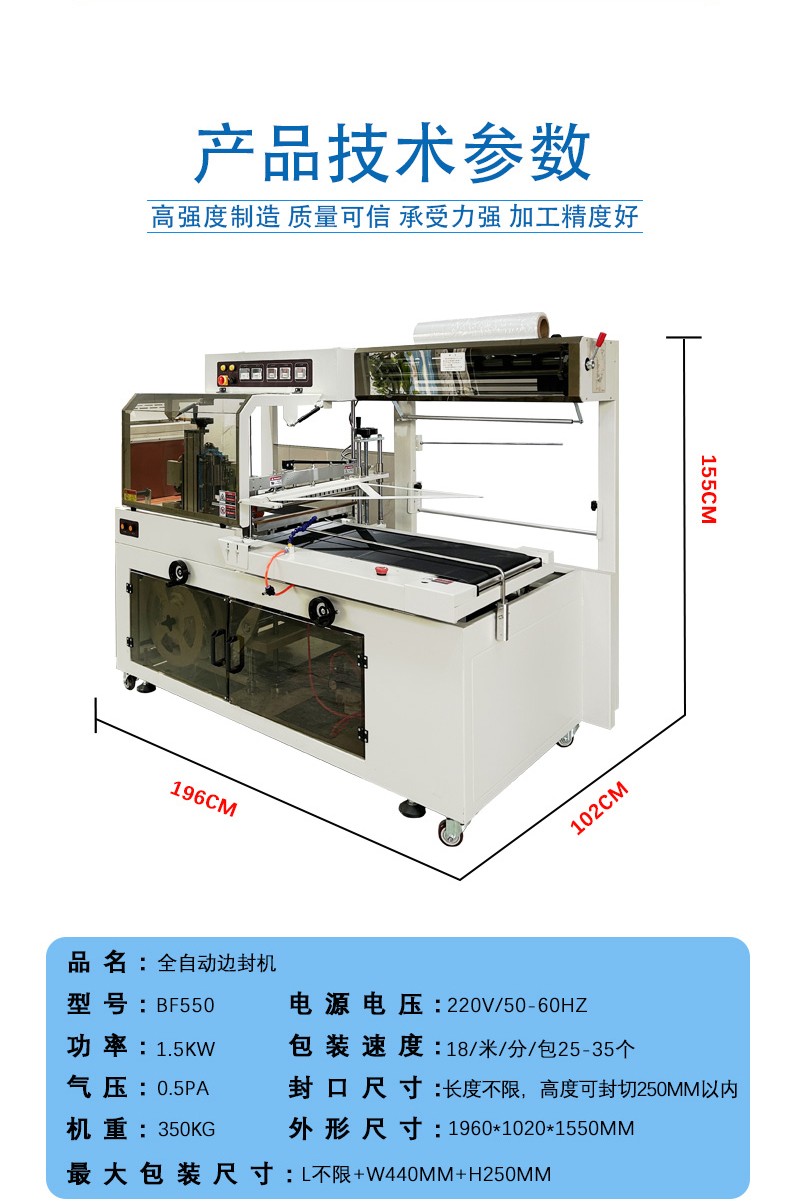

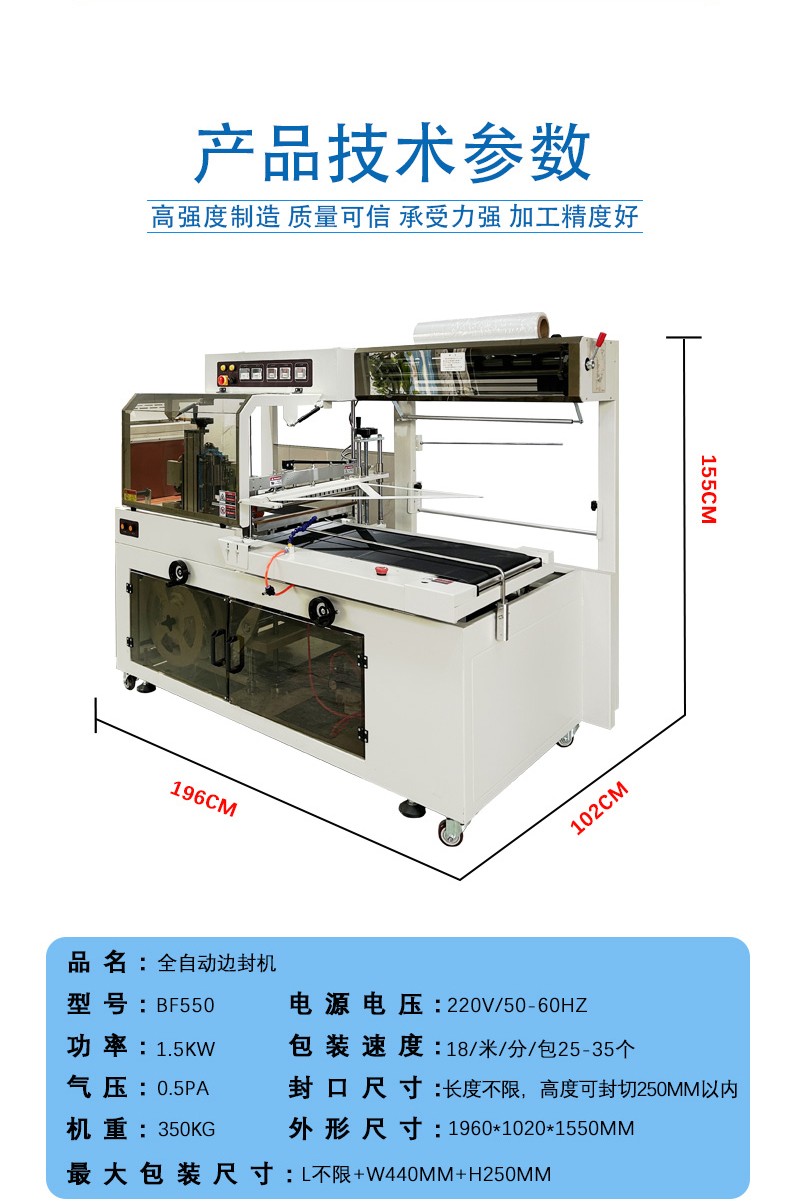

- Speed matching: Through a PLC control system or servo drive, the conveying speed of the production line (e.g., 10-30 meters per minute) is linked to the feeding speed of the side-sealing machine to ensure real-time synchronization (with an error ≤±5%). For example, when the production line speed increases, the film feeding, sealing and cutting, and shrinking furnace conveying speeds of the side-sealing machine automatically increase proportionally, and vice versa.

- Flexible transition: A "buffer transition section" (such as a powered short conveyor belt or roller conveyor line) is added between the production line and the side-sealing machine. Its speed can be fine-tuned (5%-10% faster than the production line) to prevent product accumulation. If product spacing is uneven, the transition section can detect this via photoelectric sensors and automatically adjust the conveying rhythm to ensure stable spacing of products entering the side-sealing machine (e.g., maintaining a 10-20cm gap for easy sealing and cutting positioning).

- Product Positioning and Precise Feeding: Avoiding Packaging Defects Caused by "Offset"

- Position detection: Photoelectric sensors (to detect the presence of products), visual recognition systems (to detect product size/position offset), or mechanical limiting devices (to regularize product posture) are installed at the end of the production line and the entrance of the side-sealing machine, ensuring products enter the side-sealing machine in a "centered, non-tilted" state.

Example: For irregular products (such as special-shaped cartons), the visual system can identify their edges, and a "side-push correction mechanism" driven by a servo motor pushes the product to the center position before it enters the side-sealing machine. - Automatic feeding trigger: When the sensor detects that a product has reached the entrance of the side-sealing machine, it automatically triggers the feeding mechanism of the side-sealing machine (such as chain conveying or belt conveying) without manual activation, realizing continuous operation of "packaging upon arrival".

- Signal Linkage and Data Interconnection: Enabling "Intelligent Response"

The production line and the side-sealing machine are connected via industrial buses (e.g., Modbus, Profinet) or IO signals to share key information such as "product arrival, equipment failure, and shutdown signals":

- If the production line shuts down due to material shortage, the side-sealing machine automatically enters "standby mode" (sealing knife cools down, conveying pauses) to avoid idle waste;

- If the side-sealing machine experiences jamming or sealing knife failure, it immediately sends a "pause signal" to the production line to prevent continuous accumulation of subsequent products.

Equipped with an HMI touchscreen, it can display real-time data such as "production line speed, side-sealing machine packaging efficiency, and qualification rate", facilitating operators to monitor the overall rhythm.

III. Stability Assurance: Eliminating "Connection Failures" and Reducing Shutdown Risks

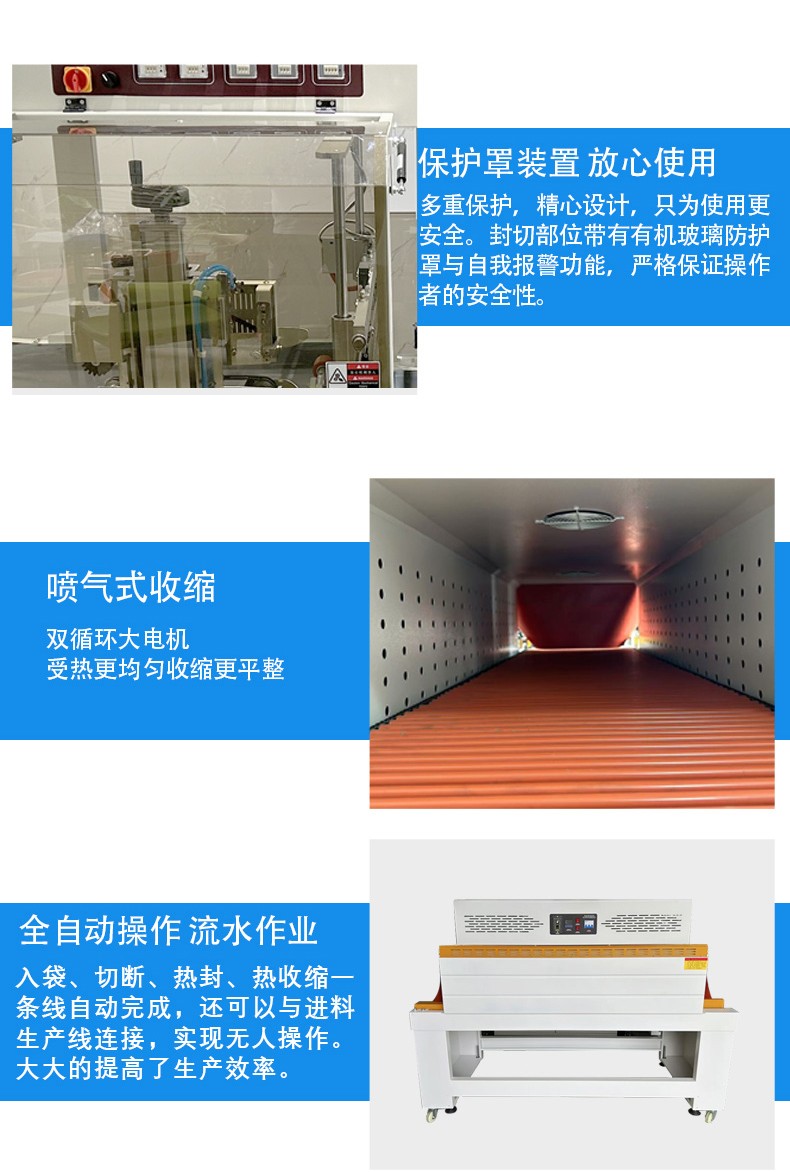

Anti-Jamming and Fault-Tolerant Design

Pressure sensors or infrared through-beam sensors are installed in the transition section and at the entrance of the side-sealing machine. If product jamming is detected (e.g., stuck for more than 2 seconds), an alarm is triggered immediately and the machine shuts down to avoid equipment overload damage;

The feed inlet of the side-sealing machine adopts a "rounded transition" design to reduce friction between product edges and the equipment; the width of the conveying track can be automatically adjusted via a motor (to adapt to products of different sizes) to avoid jamming caused by size deviations.

Equipment Compatibility and Standardization

Priority is given to selecting a side-sealing machine with the "same brand/same control system" as the production line (e.g., both using Siemens PLC) to reduce compatibility issues in signal docking;

Unify the conveying height (e.g., the height difference between the production line and the side-sealing machine's feed inlet ≤5mm) and conveying direction (maintain a straight line or 90° turn transition, with guide wheels added at the turn) to avoid product posture offset caused by "climbing/descending".

Regular Maintenance and Early Warning

Daily cleaning of impurities (such as film debris and dust) on the transition section's conveying rollers and the side-sealing machine's feed track to prevent increased friction resistance;

Regularly check the tension of synchronous belts, operating temperature of servo motors, and sensor sensitivity. Use the equipment's built-in "fault early warning system" (e.g., abnormal sealing knife temperature, insufficient film roll remaining) to pre-screen potential hazards.

IV. Efficiency Improvement Strategies: Making "Docking" a Production Capacity Amplifier

Continuous Operation and Parameter Optimization

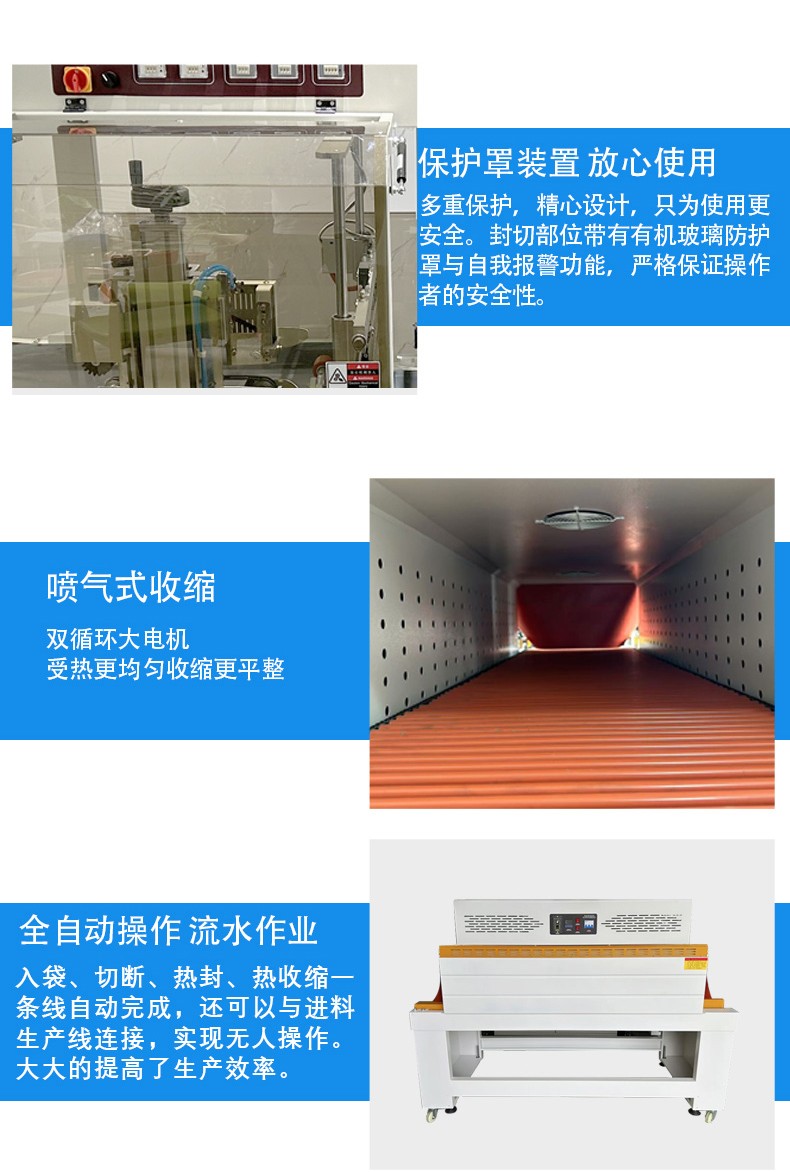

The side-sealing machine adopts an "uninterrupted film feeding" design (e.g., dual film roll switching device), which automatically switches to a standby film roll when the current roll is exhausted, eliminating the need for shutdown during film replacement;

"Quick parameter packages" are preset according to product characteristics (e.g., size, material) (e.g., "high-speed sealing + low-temperature shrinking" for small products, "low-speed sealing + high-temperature shrinking" for large products). After the production line's code scanner identifies the product, the side-sealing machine automatically calls up the parameters to reduce debugging time.

Production Capacity Adaptation and Bottleneck Breakthrough

If the production line capacity is higher than the efficiency of a single side-sealing machine (e.g., the production line produces 1000 pieces per hour, while the side-sealing machine packages 800 pieces per hour), a "one main and multiple auxiliary" design can be adopted: one main production line distributes products to 2 side-sealing machines via a shunting mechanism (e.g., pneumatic pusher) to match production capacity;

The shrinking furnace adopts a "dual-temperature zone + high-velocity air circulation" design to shorten shrinking time (e.g., from 10 seconds to 6 seconds) and improve the overall cycle of the side-sealing machine.

Data-Driven Continuous Optimization

Collect data such as "docking link failure rate" (e.g., jamming rate, positioning deviation rate) and "equipment OEE (Overall Equipment Effectiveness)" through the MES system for targeted optimization:

- If frequent jamming is caused by uneven product spacing, a "spacing regulating device" (e.g., paddle-type spacing mechanism) can be added to the production line;

- If the sealing and cutting speed of the side-sealing machine cannot keep up with the production line, upgrade the servo motor power or optimize the sealing knife structure (e.g., use a more wear-resistant Teflon coating to reduce shutdown maintenance).