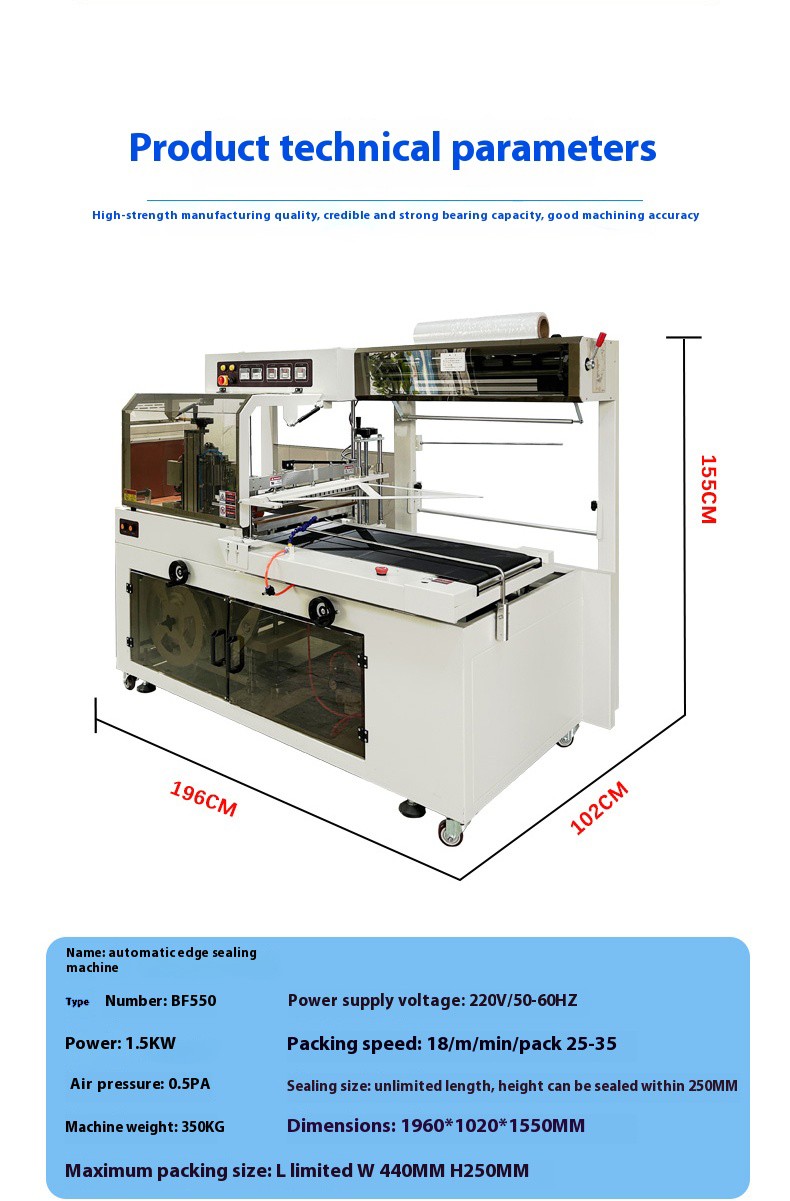

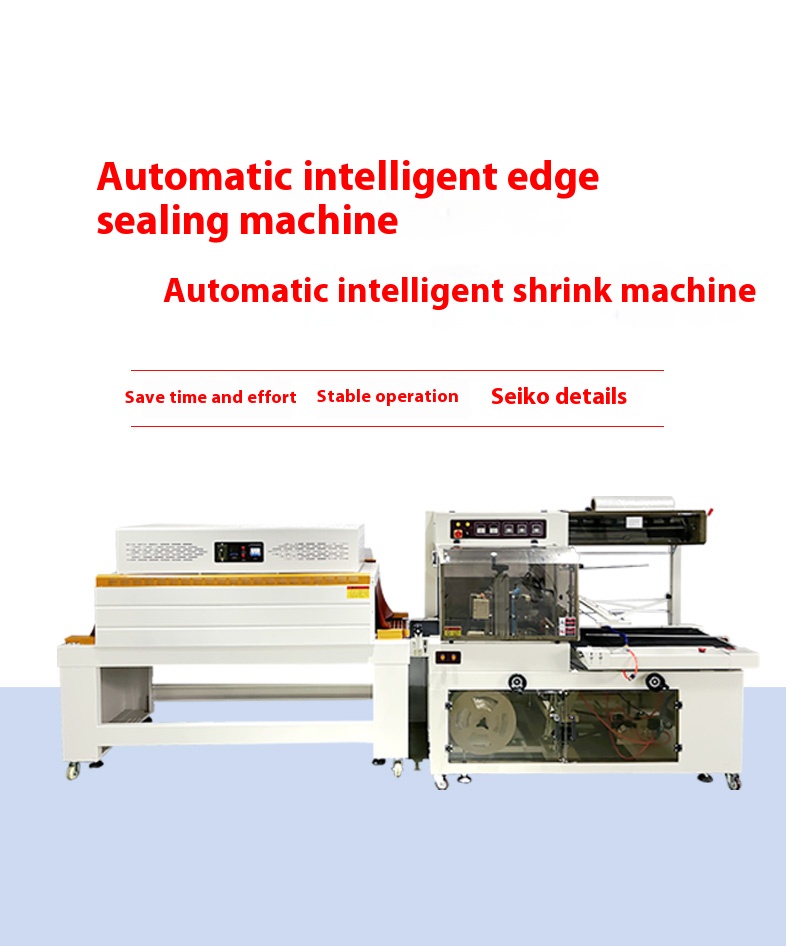

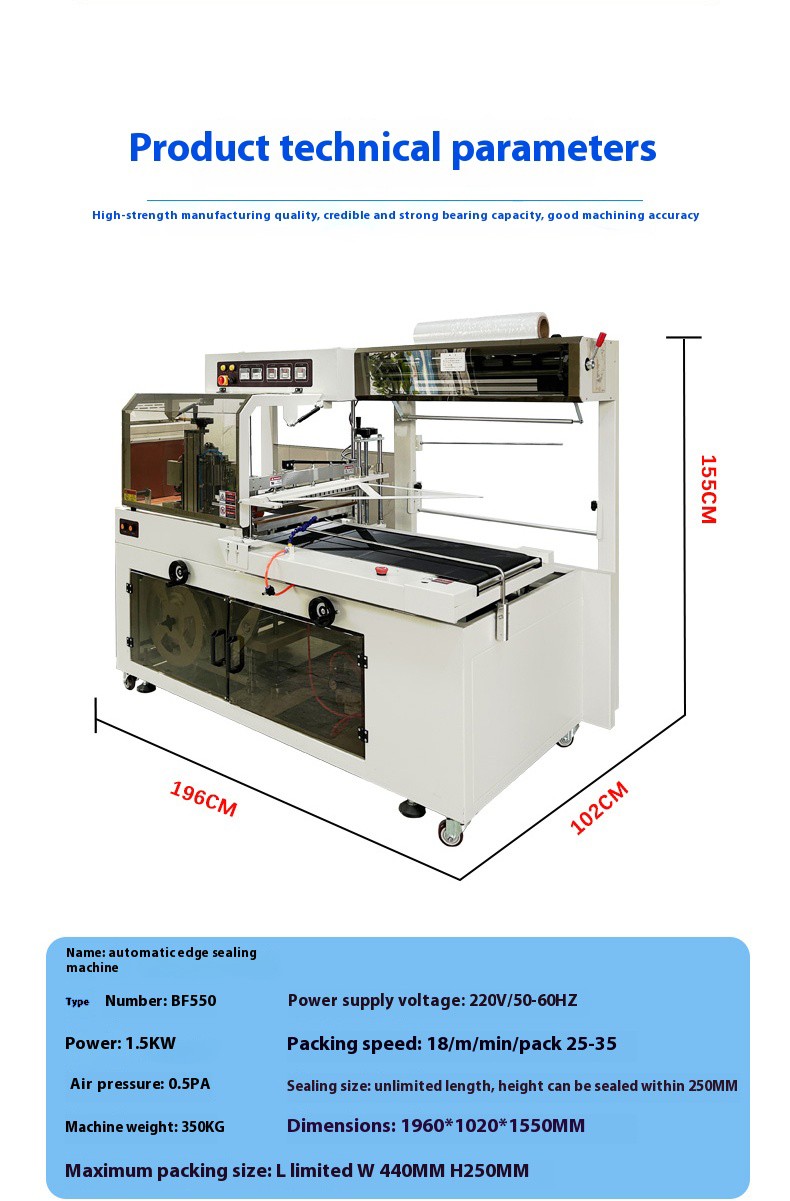

Automatic Sealing, Cutting and Heat Shrink Packaging Machine: Core Advantages of High Efficiency, Automation, and Production Line Adaptability

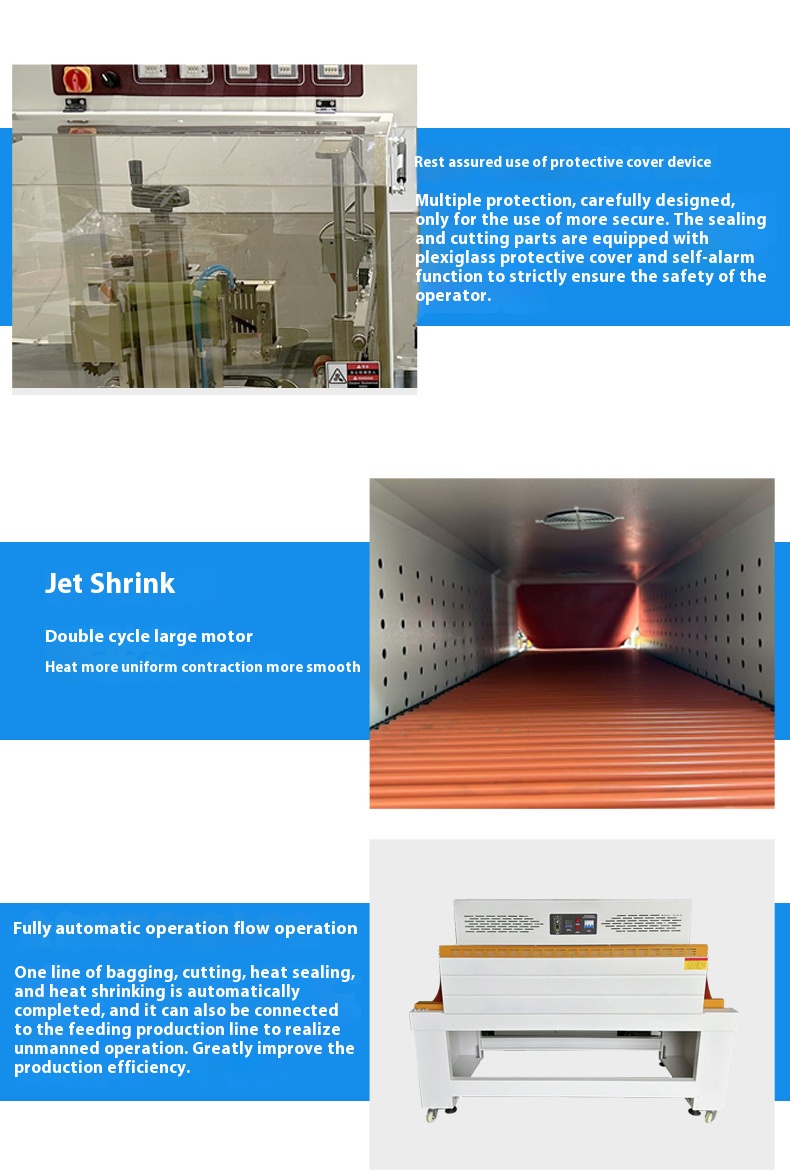

As a key equipment in the field of packaging automation, the automatic sealing, cutting and heat shrink packaging machine has become a "standard configuration" in assembly line production across industries such as food, pharmaceuticals, electronics, and daily necessities, thanks to its features of high efficiency, intelligence, and strong adaptability. By integrating the two core functions of sealing-cutting and heat shrinking, it realizes full-process automation from product feeding to final packaging formation, significantly improving production efficiency while reducing errors caused by manual intervention.

The equipment can complete the entire packaging process without manual intervention:

- Products are automatically conveyed to the sealing and cutting area, with positioning via photoelectric sensing to ensure precise packaging alignment;

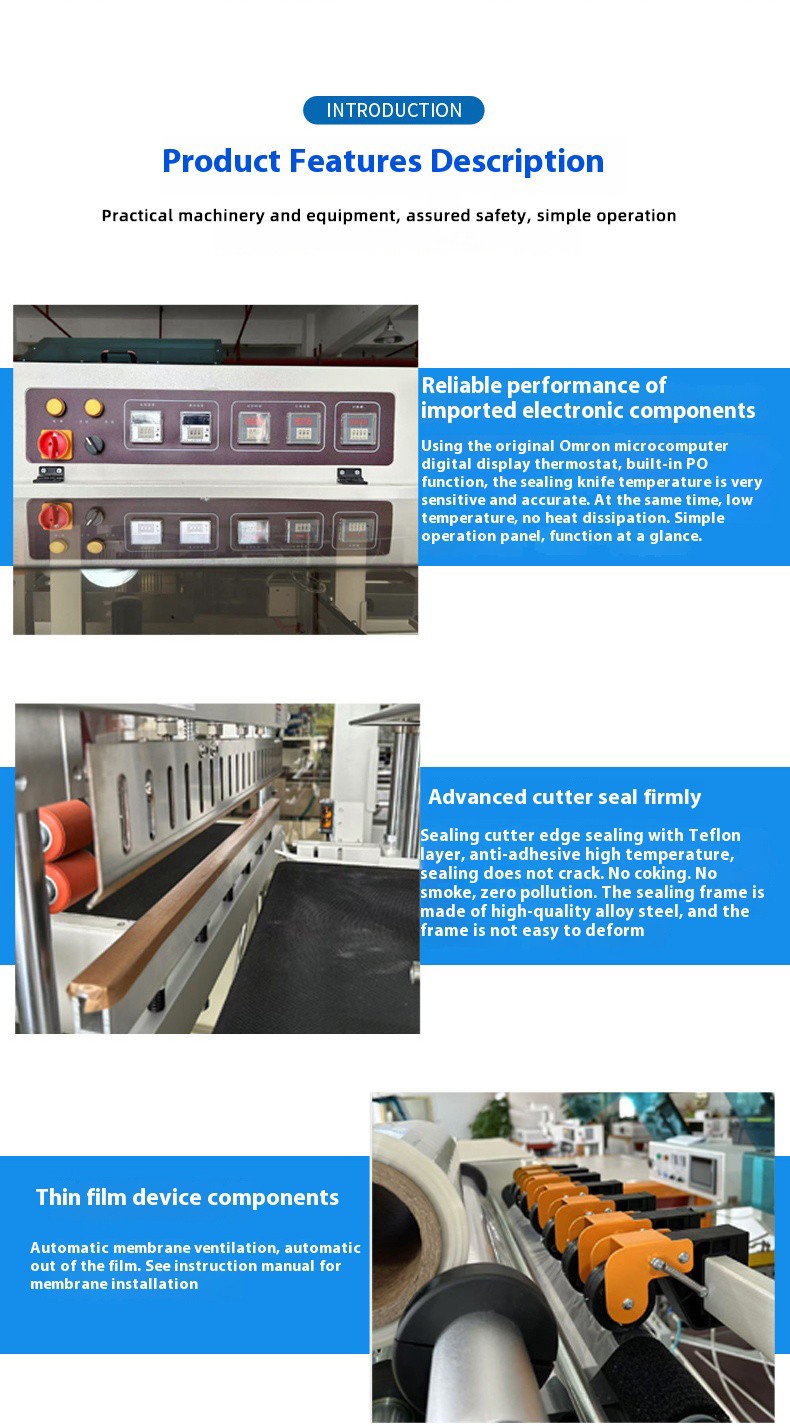

- The sealing and cutting knife quickly completes film sealing and cutting, resulting in flat, burr-free sealed edges, avoiding issues like sealing leakage or misalignment common in traditional manual operations;

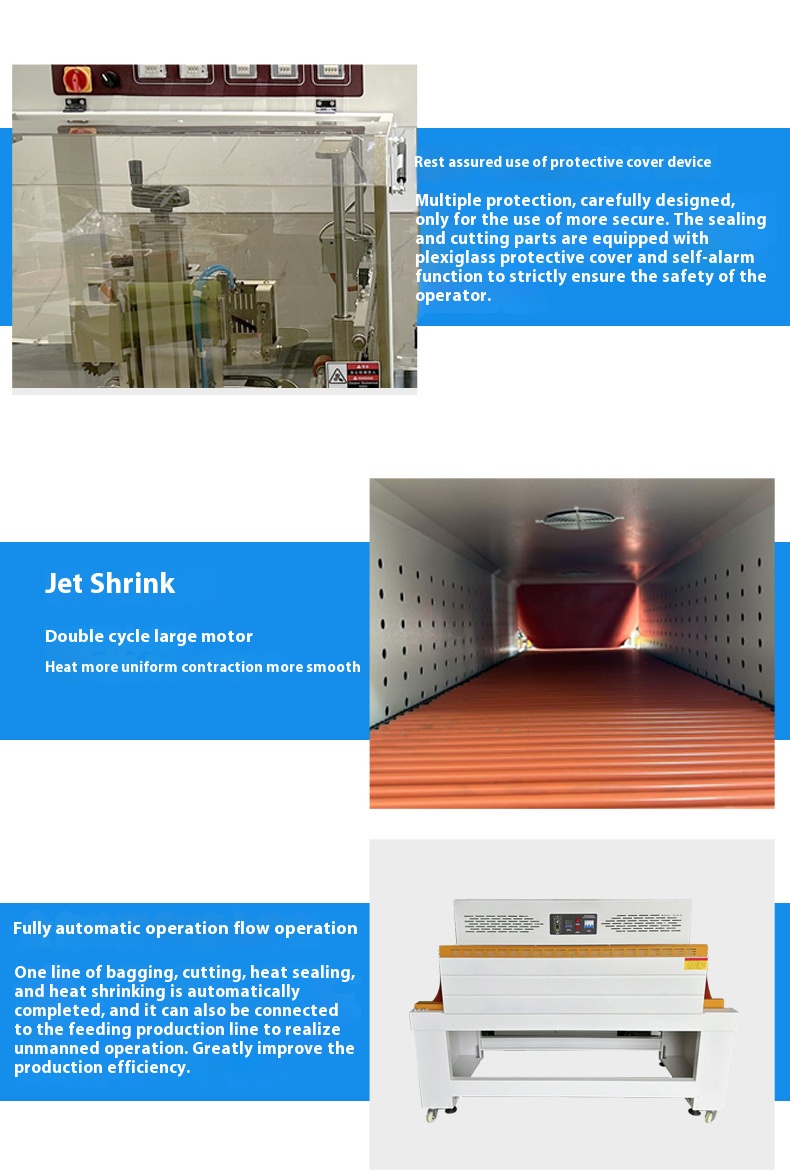

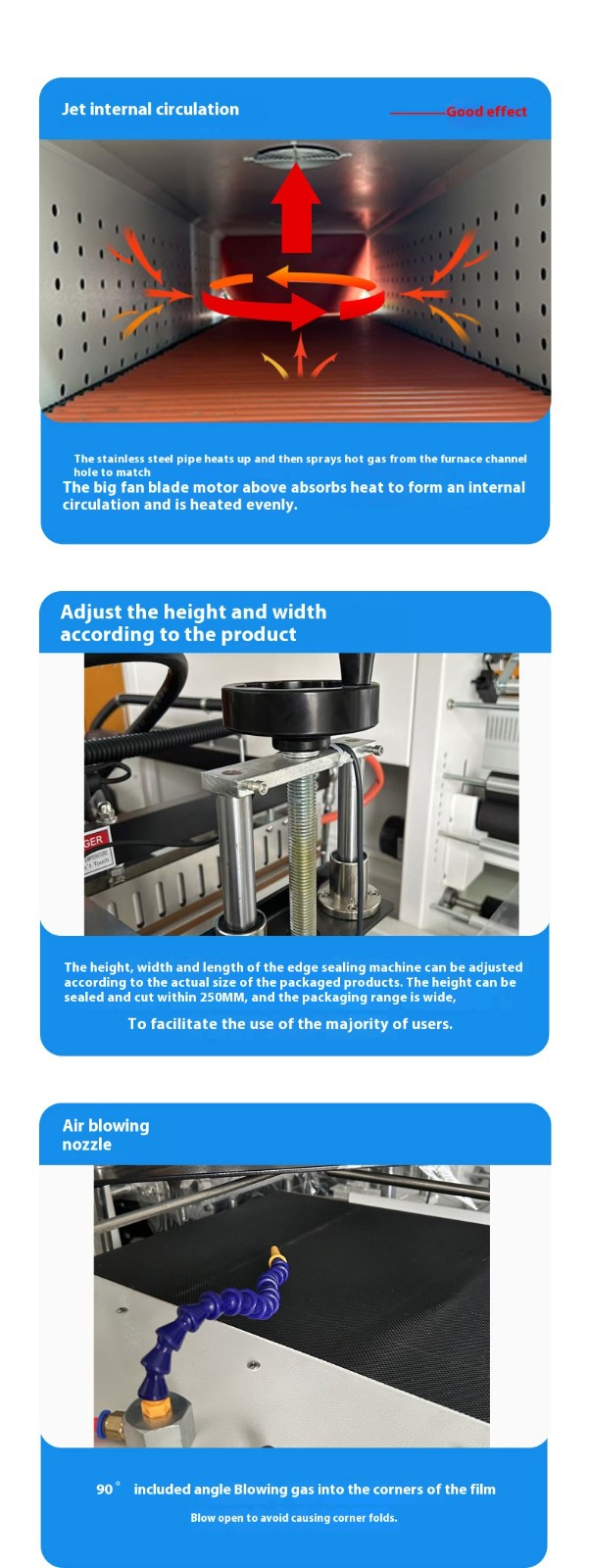

- After sealing and cutting, products automatically enter the heat shrink channel, where constant-temperature hot air circulation makes the film tightly adhere to the product, forming a compact and attractive packaging effect.

The entire process is coherent and efficient. A single device can handle 30-100 products per minute (adjusted based on model and product size), far exceeding the efficiency of manual packaging.

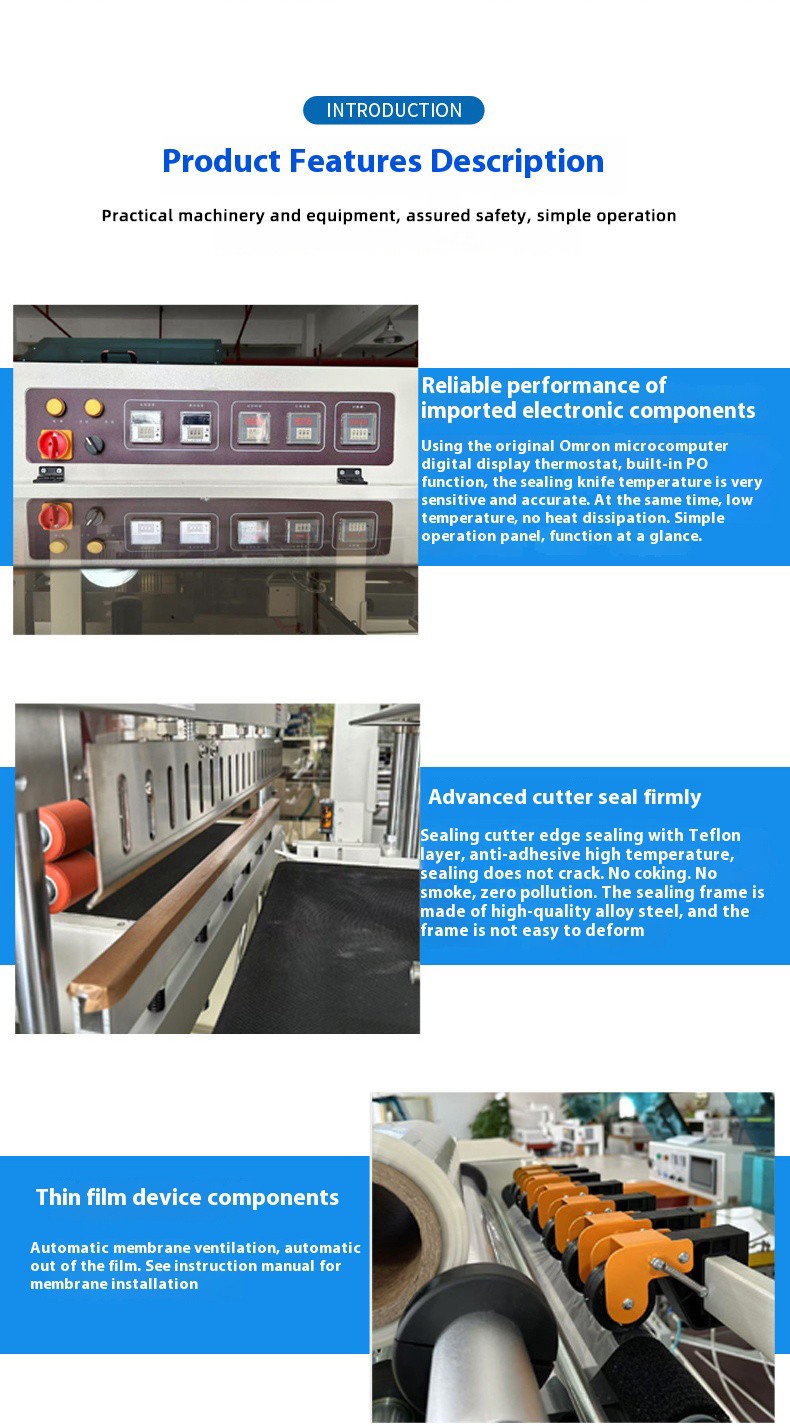

Equipped with a PLC control system and a touchscreen operation interface, it allows quick setting of packaging parameters (such as sealing temperature, shrinking time, and conveying speed). It supports storing multiple sets of recipes, which can be recalled with one click during product changeover, significantly reducing debugging time.

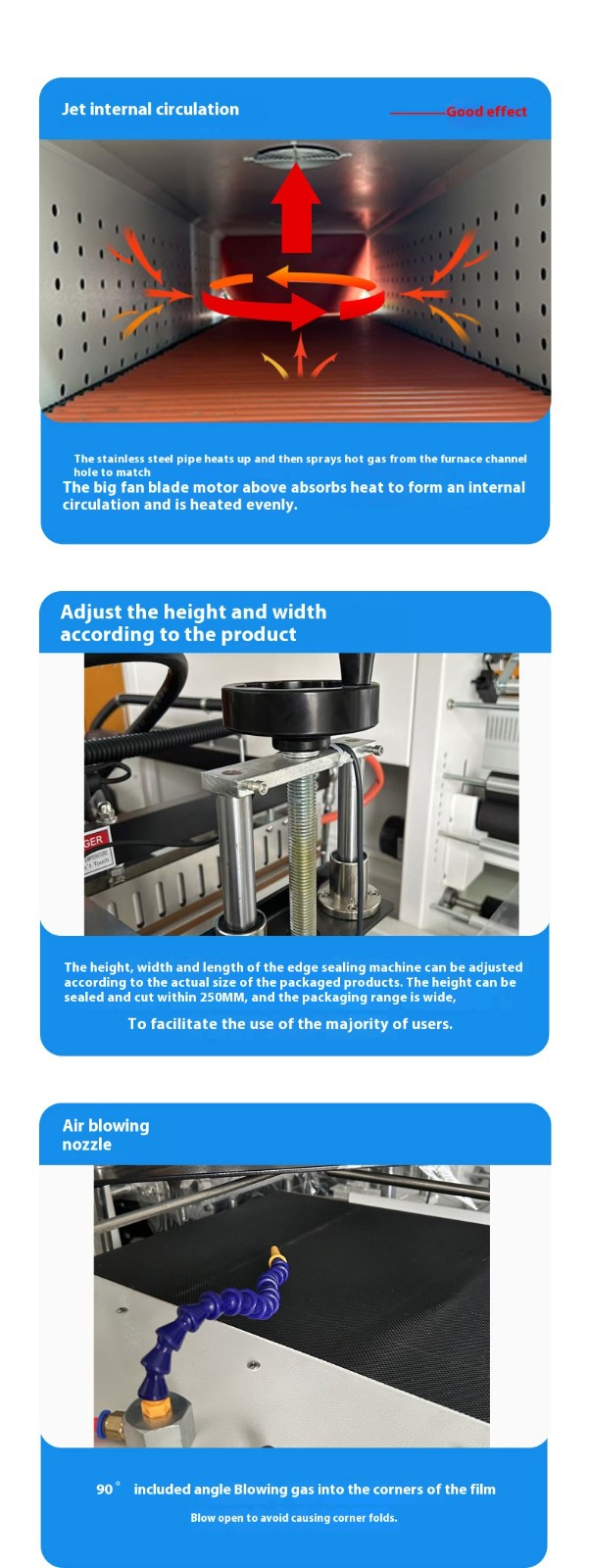

The inlet and outlet ends of the equipment can be adjusted according to the height and speed of the production line. It supports seamless connection with front-end filling and sorting equipment or back-end palletizing and warehousing systems, forming a continuous production closed loop and reducing time waste in intermediate transfer links.

- It is adaptable to packaging films of different materials (e.g., POF, PVC, PE), meeting the hygienic standards of industries such as food and pharmaceuticals;

- It can handle single-product packaging and multi-product collective packaging (e.g., whole cases of bottled water, cosmetic sets). By changing molds, it enables quick switching between products of different specifications, offering high versatility.

Adopting wear-resistant conveyor chains, high-precision sealing and cutting knives, and constant-temperature heating systems, it ensures stability during long-term continuous operation, reduces the frequency of shutdowns for maintenance, and guarantees the overall productivity of the production line.

- Reducing labor costs: It replaces traditional manual sealing, cutting, and film wrapping processes, reducing 3-5 operators, making it especially suitable for mass production scenarios;

- Enhancing packaging quality: Standardized sealing, cutting, and shrinking effects result in neater product appearance and tighter sealing, reducing damage and contamination during transportation;