The fully automatic side-seal heat shrink machine features high work efficiency, which can meet the needs of mass continuous production. Its specific efficiency can be measured through three dimensions: packaging speed, stability and adaptability.

The packaging speed mainly depends on the machine model specifications and product size, with significant differences between different models.

- Standard models: For small and medium-sized products (such as cosmetic boxes, stationery), they can package 30-60 pieces per minute, suitable for most conventional production scenarios.

- High-speed models: For small-sized and regular products (such as CDs, small gift boxes), they can package up to 80-120 pieces per minute at maximum, which can match high-capacity production lines.

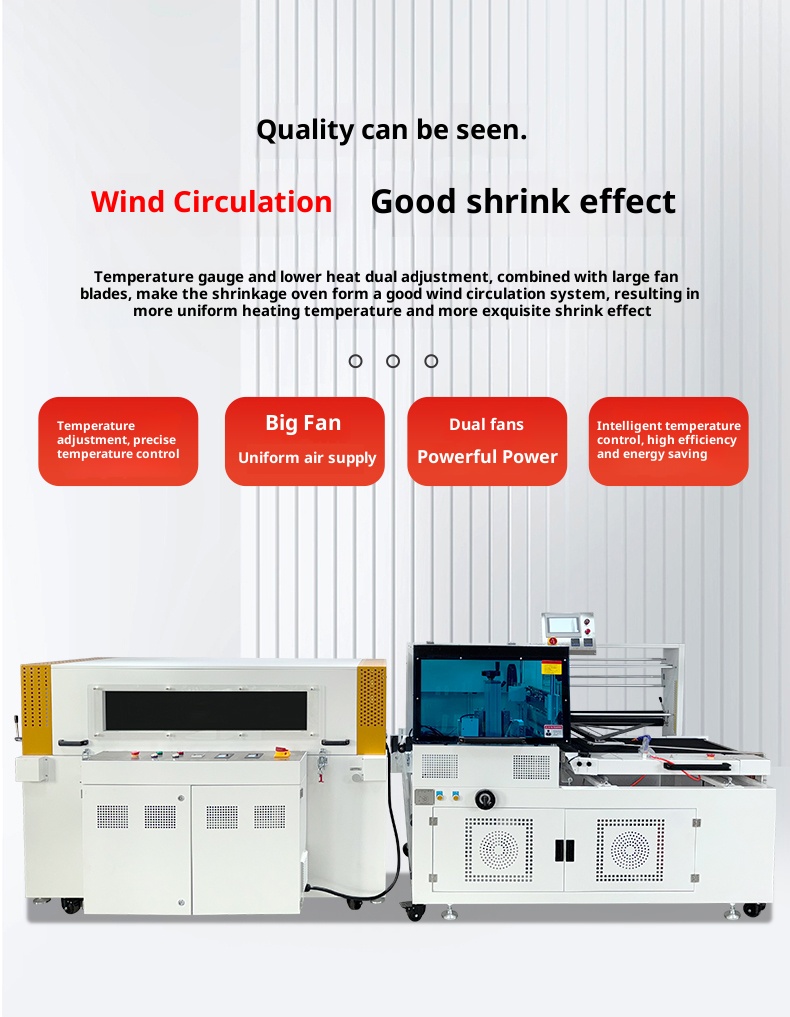

- Customized models: For long-strip or large-sized products (such as aluminum profiles, photo frames), although the speed is relatively lower (10-30 pieces per minute), it is still much higher than the efficiency of manual packaging.

The automatic design and structural characteristics of the machine further improve the actual production efficiency.

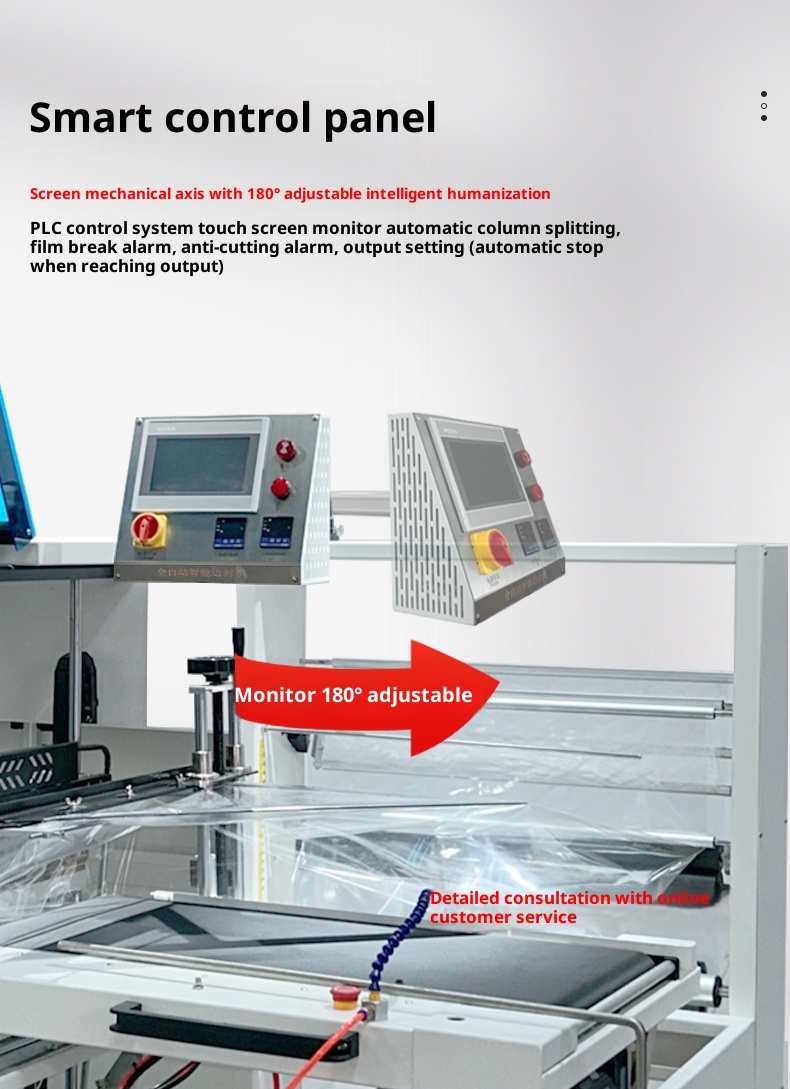

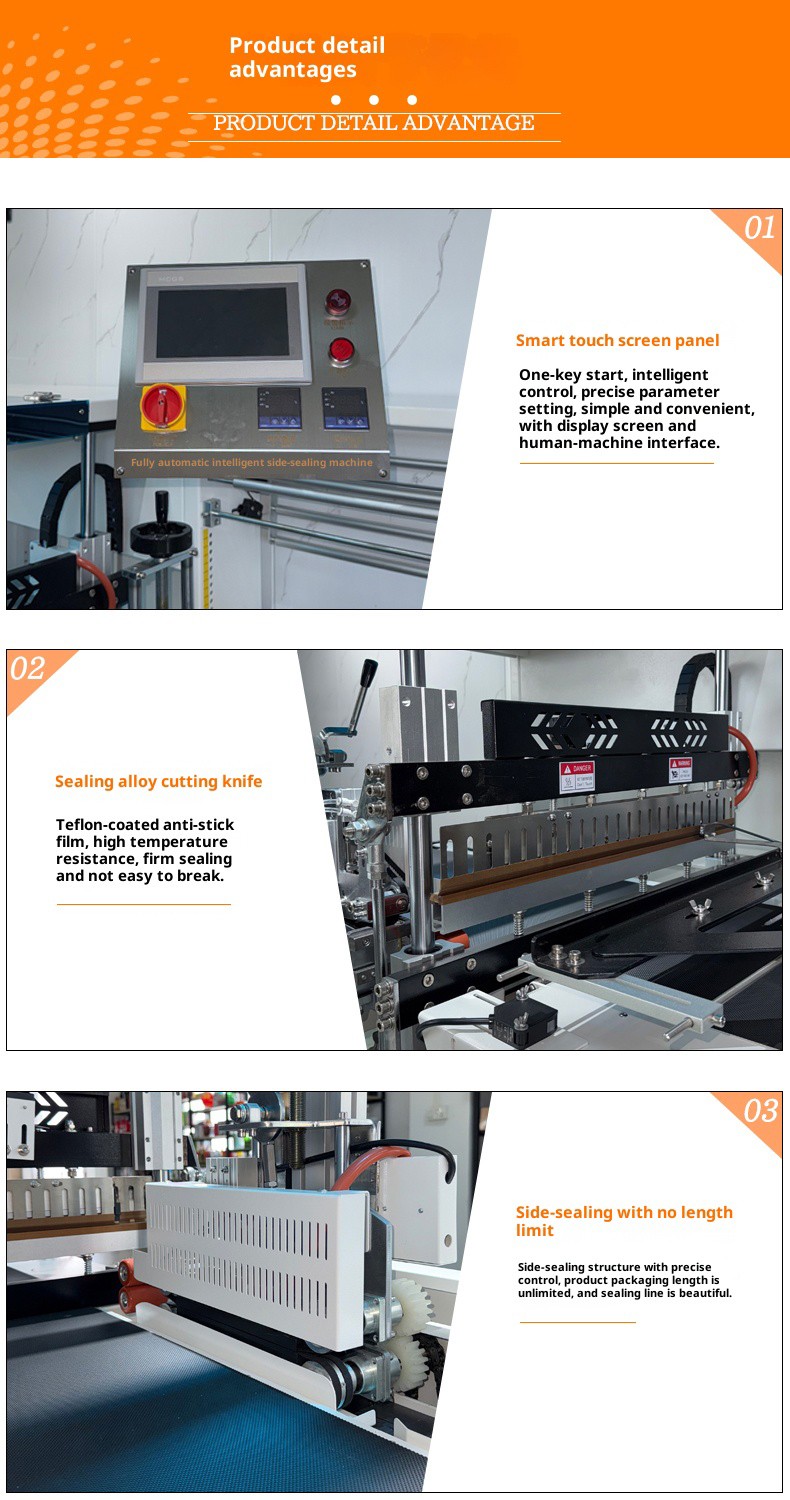

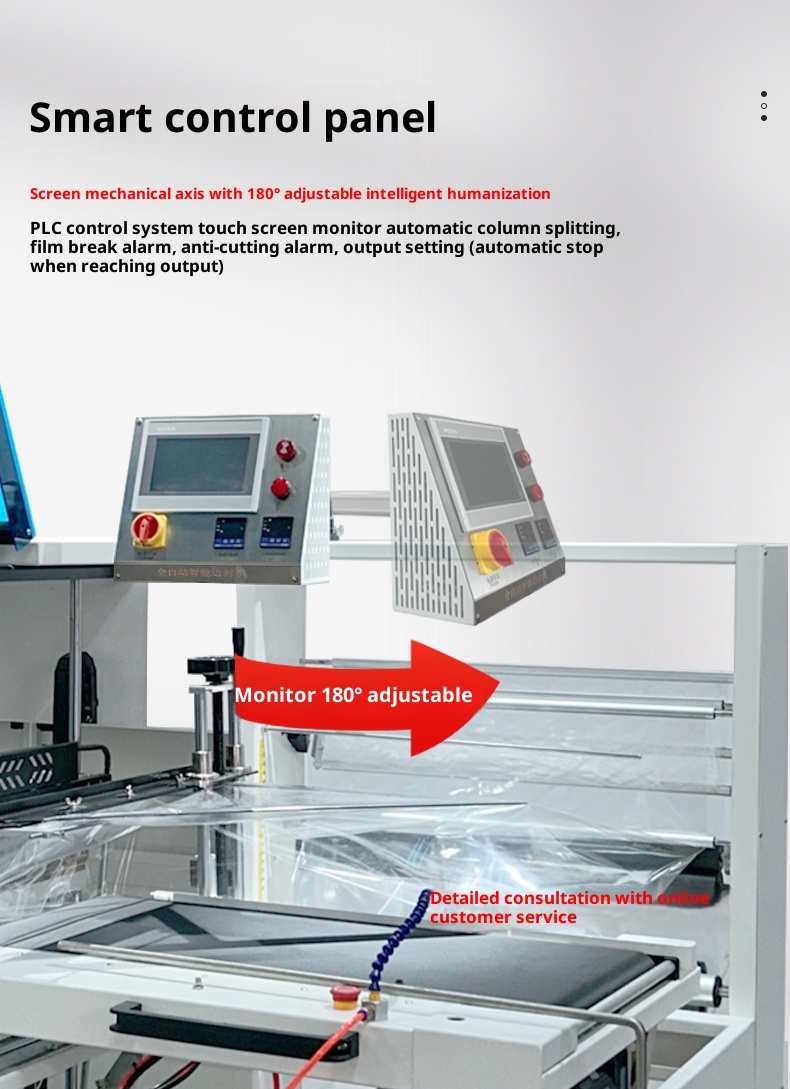

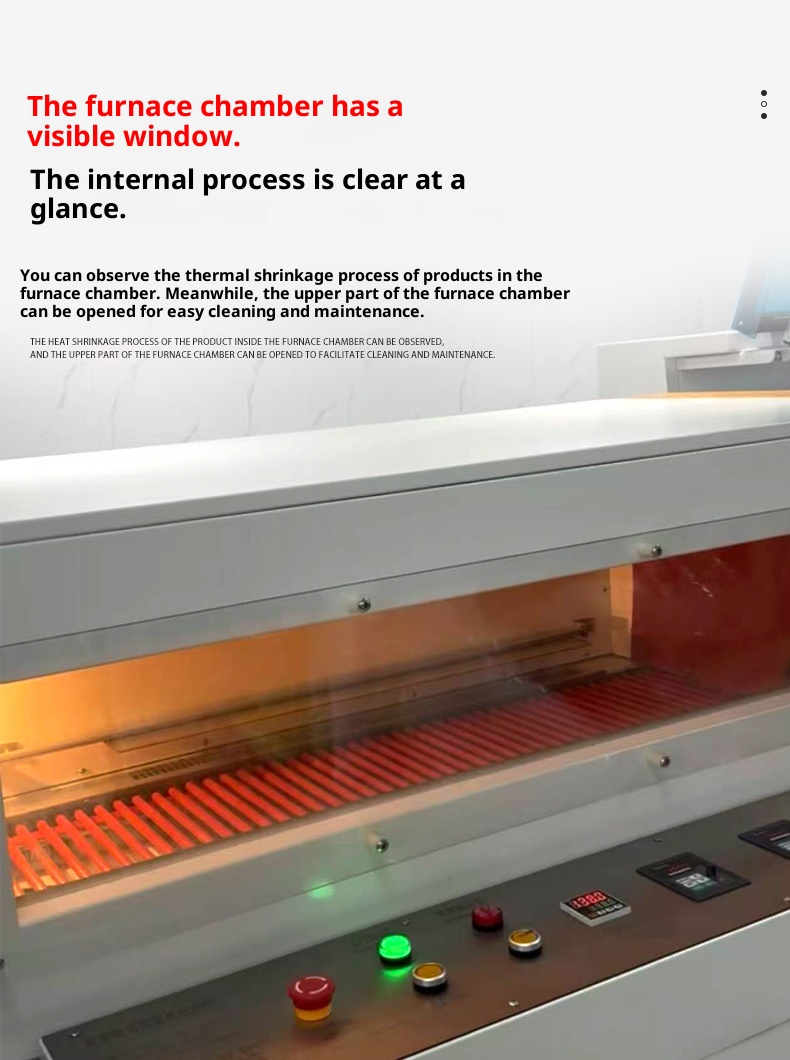

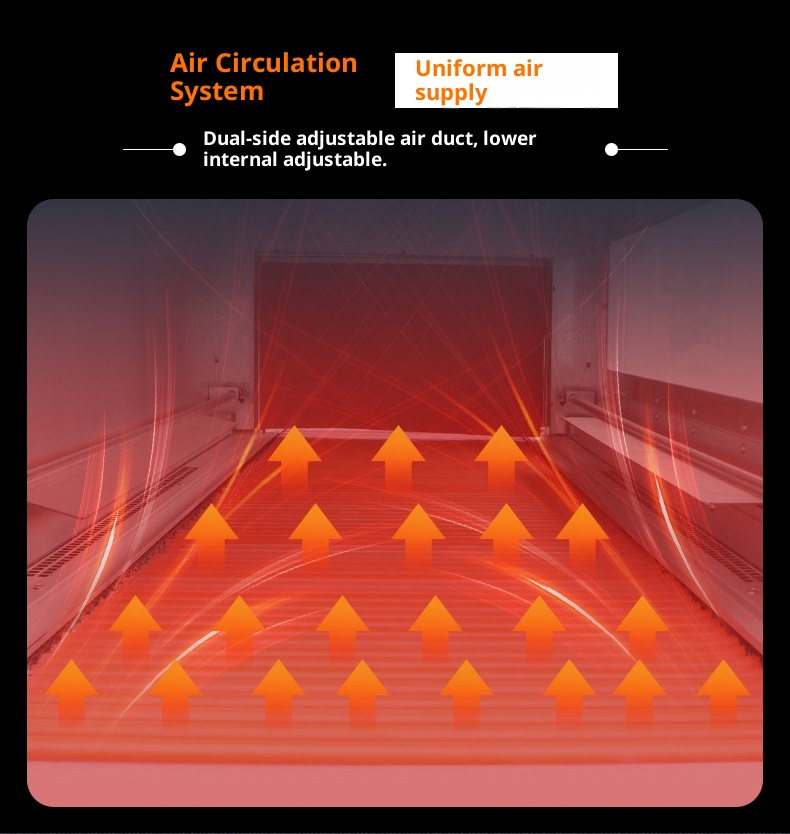

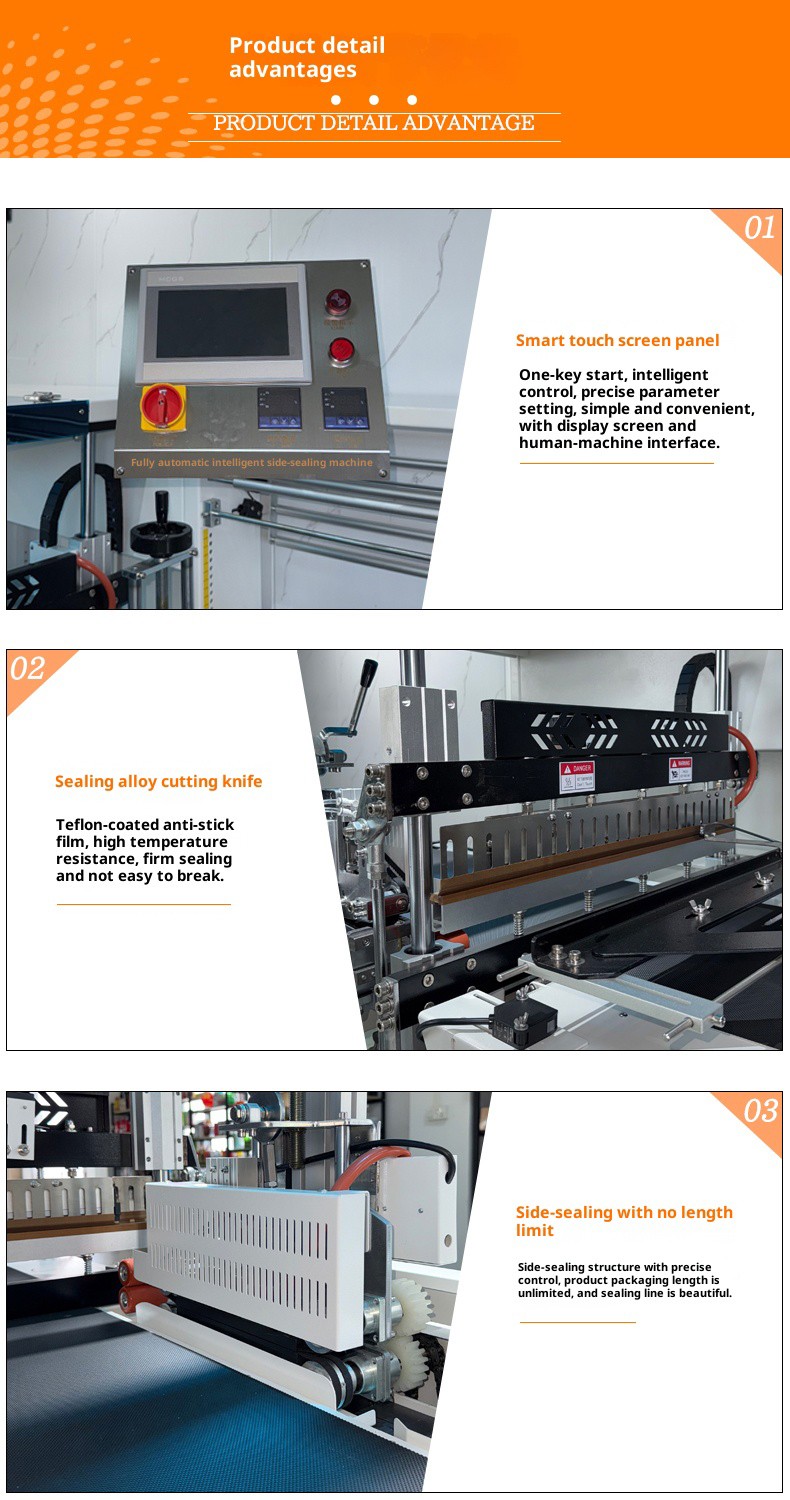

- High degree of automation: Equipped with a PLC control system and photoelectric sensing devices, it can automatically complete the entire process of film feeding, sealing, heat shrinking and discharging without manual intervention.

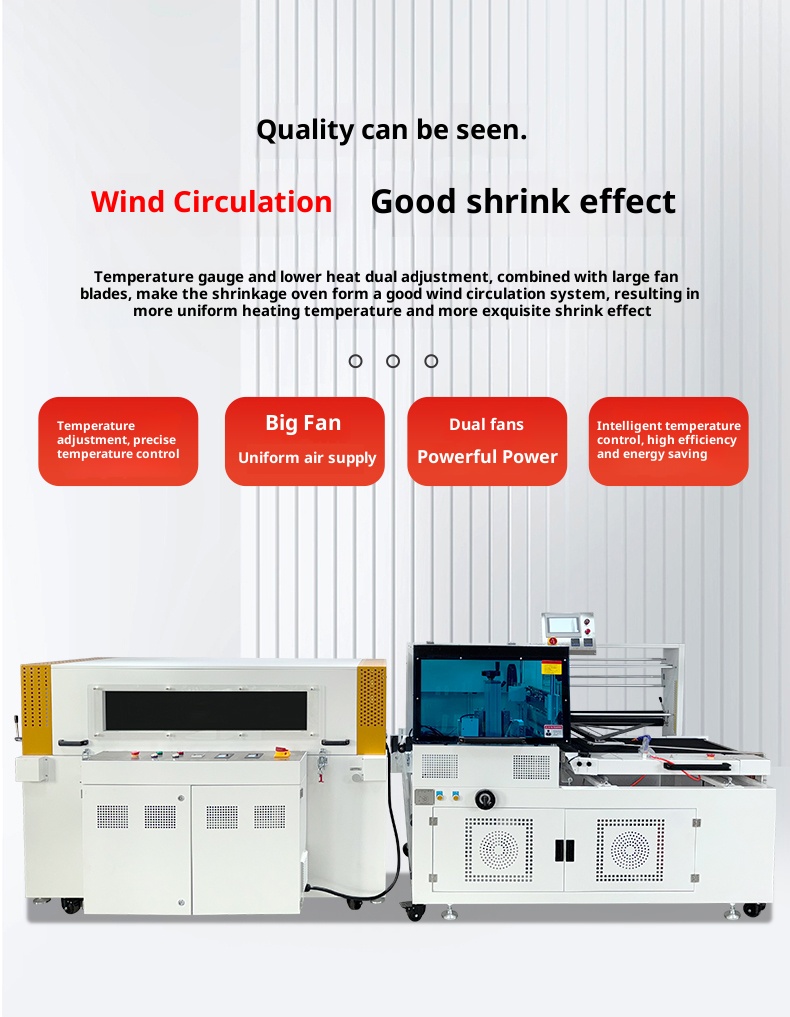

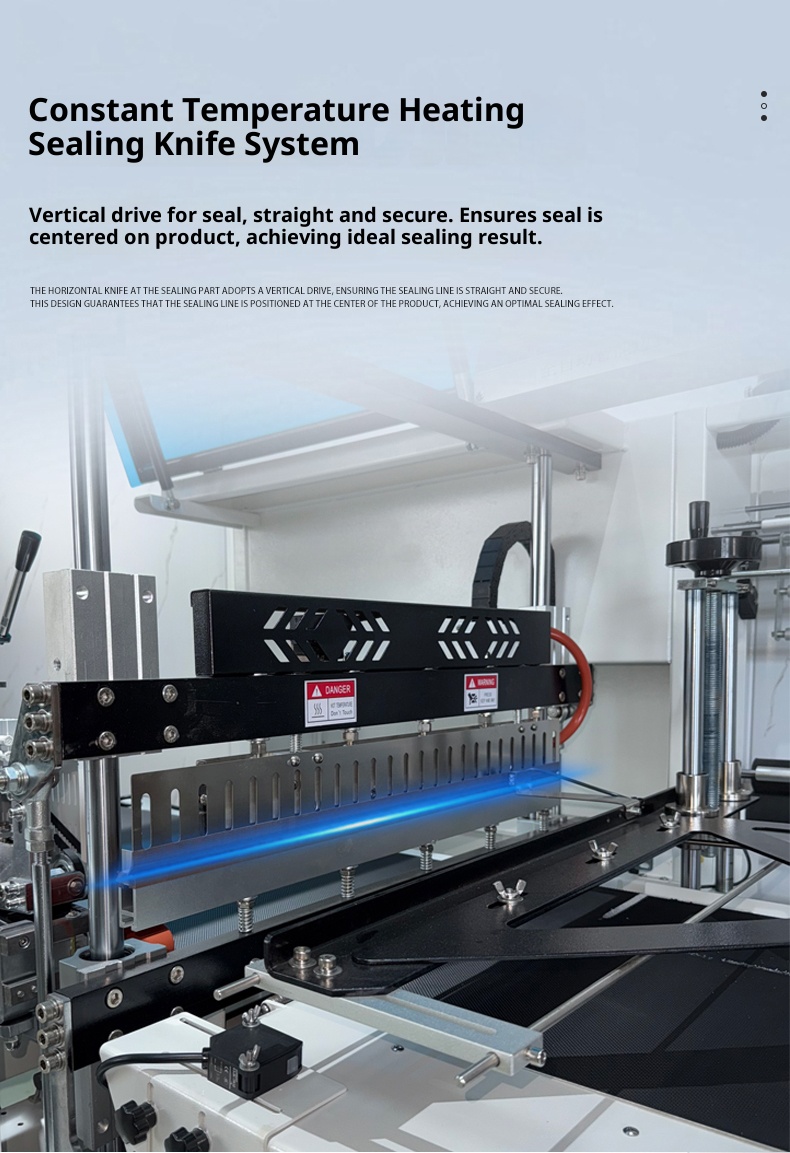

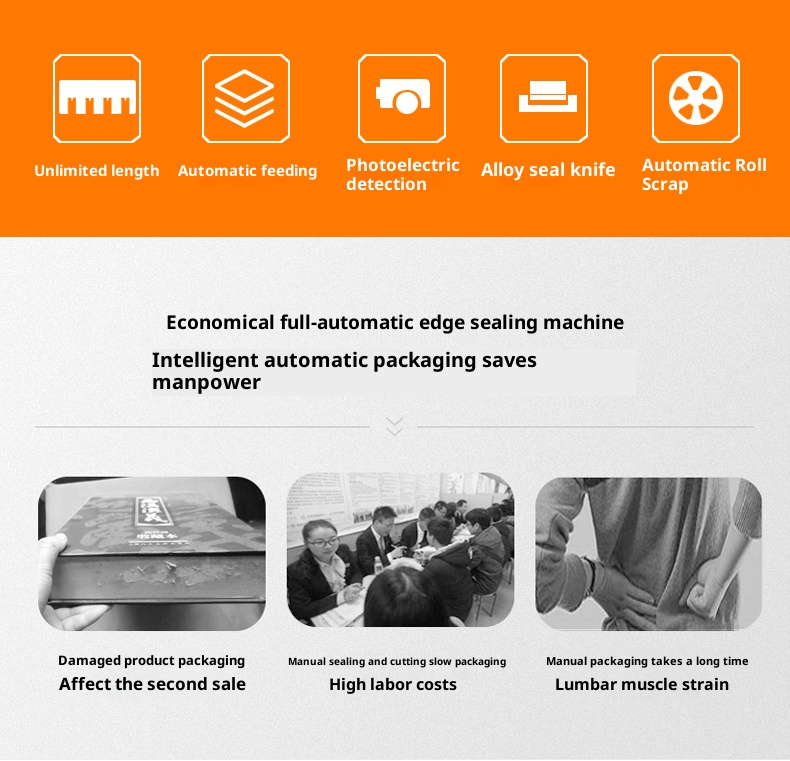

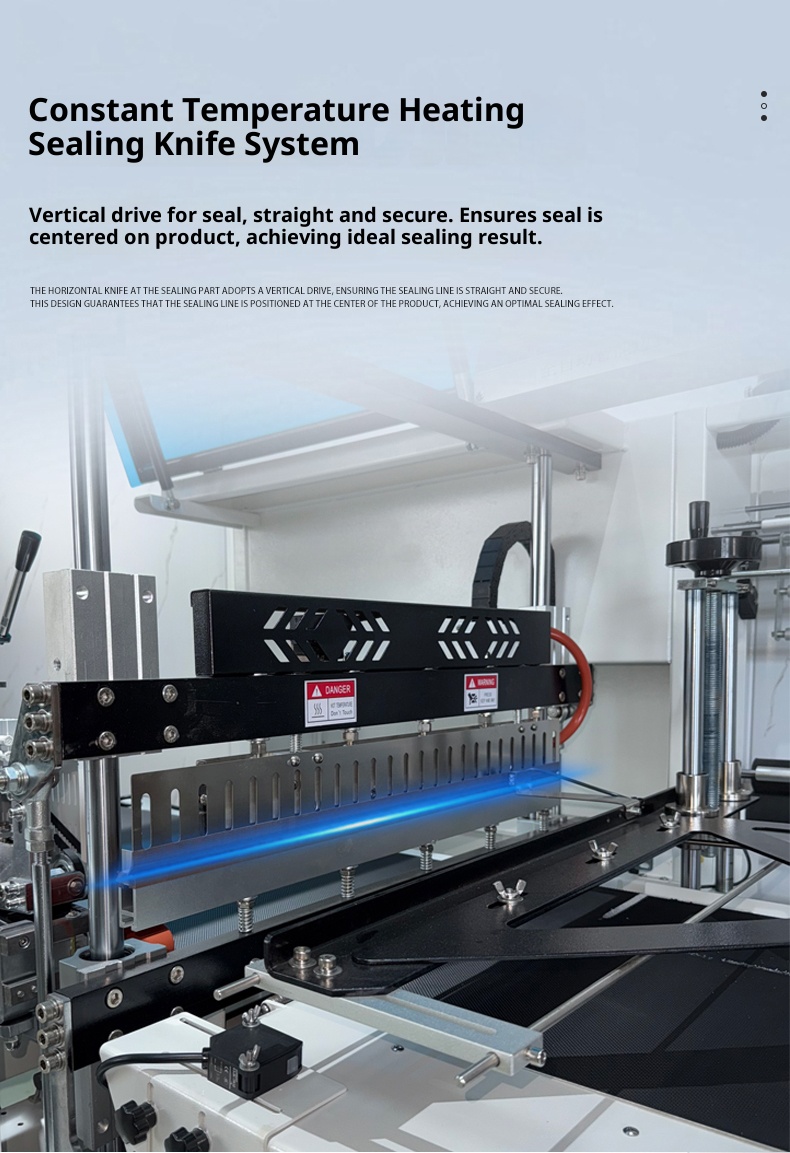

- Strong continuous working capability: Adopting durable sealing knives and heating systems, it supports 24-hour continuous operation. Only regular film replenishment is needed, reducing downtime.

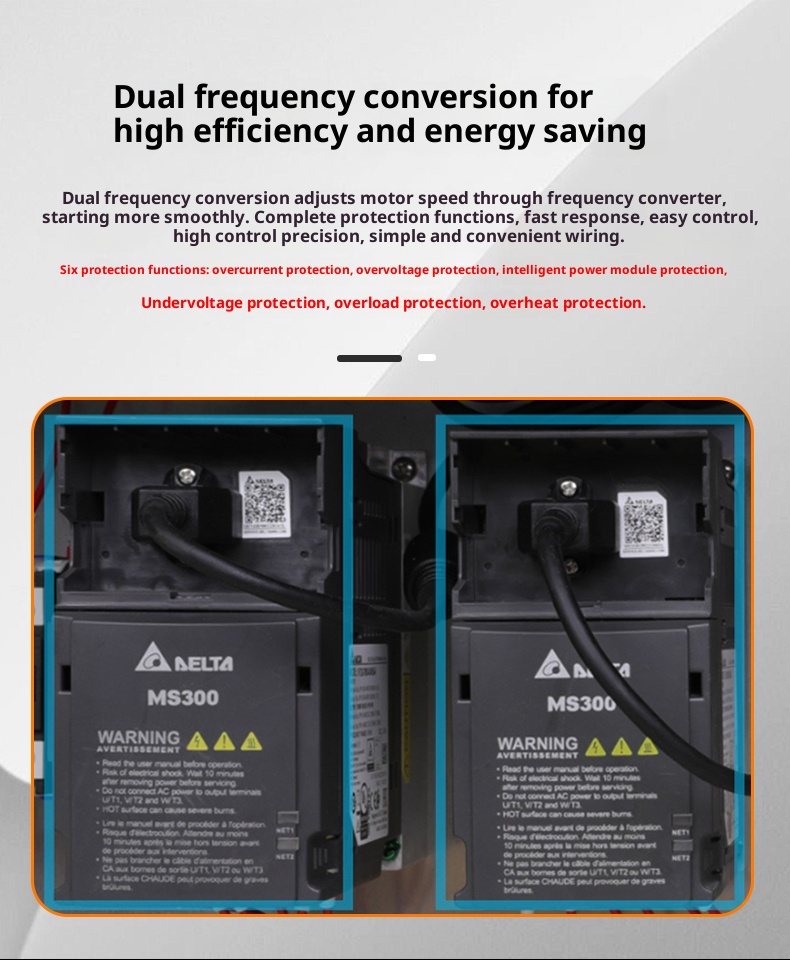

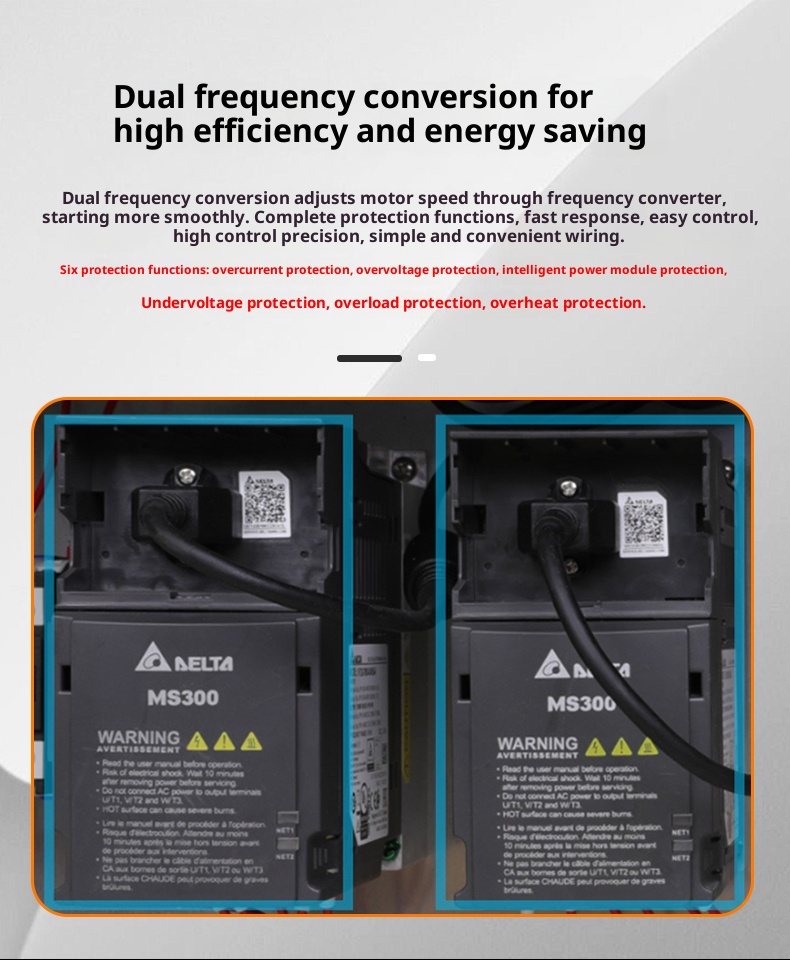

- Low failure rate: Key components (such as constant-temperature sealing knives, conveying motors) are mostly industrial-grade configurations. It is also equipped with overload protection, abnormal temperature alarm and other functions to reduce efficiency loss caused by failures.

The machine's adaptability to different products also indirectly affects the overall production efficiency.

- Quick model change: When changing packaging specifications, most models can adjust the conveying width and sealing knife position through handwheels or motors. The adjustment time only takes 5-15 minutes, without major modifications to the machine.

- Production line compatibility: It can be connected with front-end feeding machines, back-end sorting machines and cartoning machines to form a fully automatic packaging line, eliminating efficiency waste in manual transfer links.