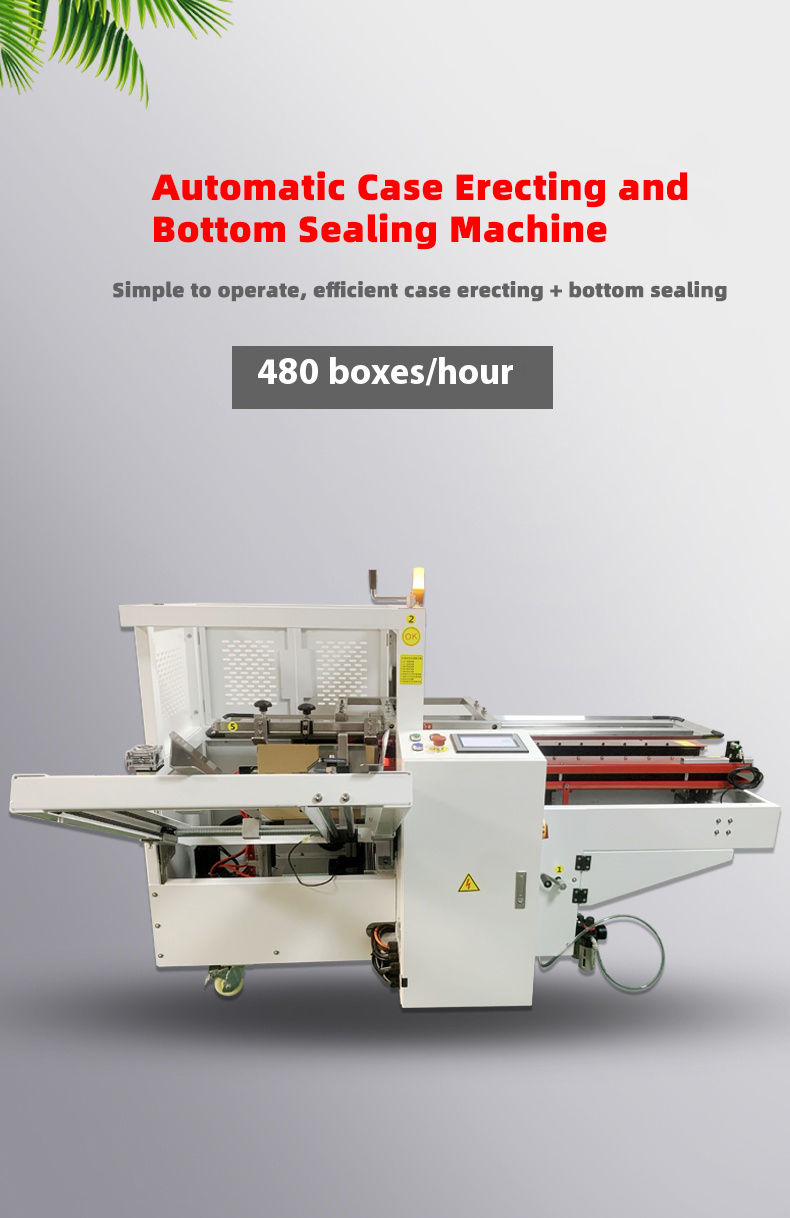

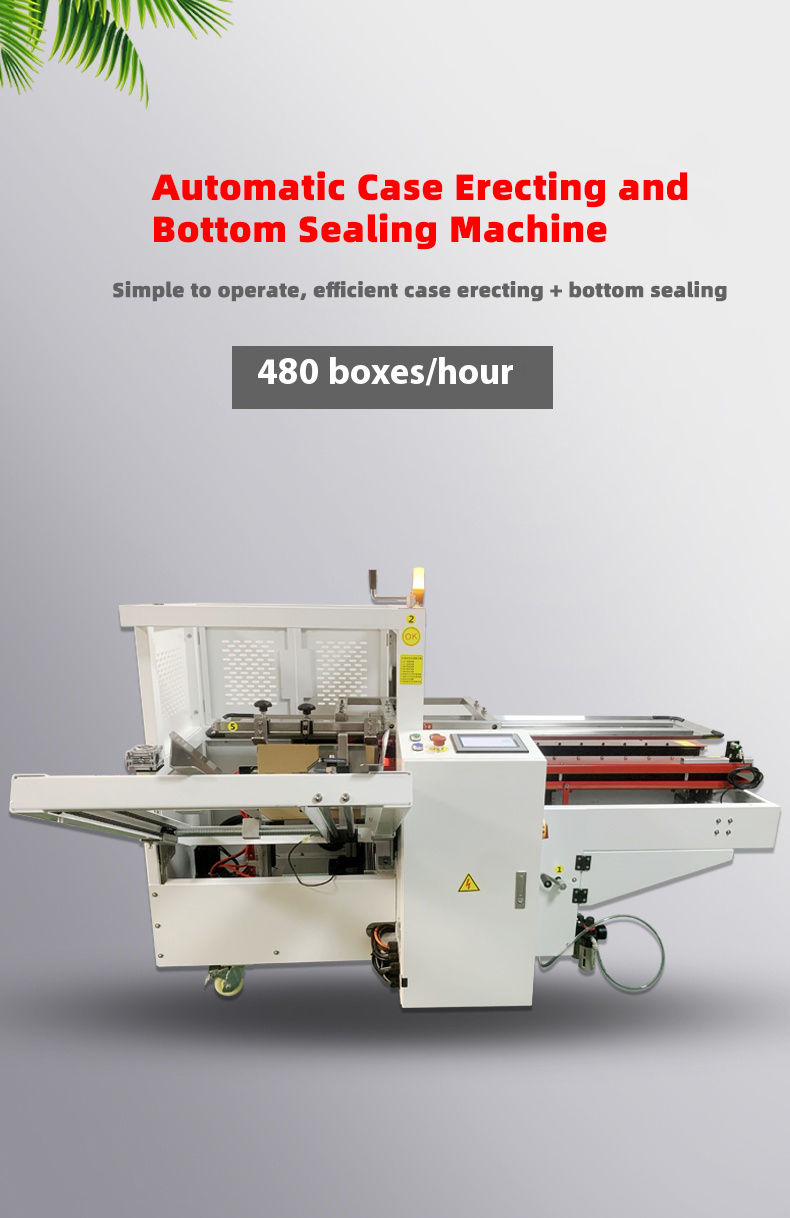

The working efficiency of automatic carton forming and bottom-sealing machines is usually measured by the number of cartons processed per minute as the core indicator. Its specific efficiency varies significantly depending on factors such as equipment model, degree of automation, structural type (vertical/horizontal), and actual working conditions (e.g., stability of carton specifications, operation and maintenance). Overall, it is "highly efficient and controllable," which can be analyzed in the following aspects:

Based on the speed level of the equipment, its efficiency can be roughly divided into:

- Low-speed type: Suitable for small to medium production capacity needs, such as vertical carton erecting machines (e.g., Model GPK-40), with a speed of approximately 12-15 cartons per minute;

- Medium-speed type: Balancing efficiency and stability, such as medium-speed vertical (18 cartons per minute) or medium-speed horizontal (25 cartons per minute) machines, which can meet the mass production needs of most small and medium-sized enterprises;

- High-speed type: Targeting high-capacity scenarios, such as high-speed horizontal carton erecting machines (e.g., Model GPK-40H40), with a speed of over 40 cartons per minute. Some high-end models can even exceed 60 cartons per minute, adapting to the continuous operation of large-scale production lines.

Compared with manual carton erecting and bottom-sealing, the efficiency advantage of machines is significant:

- Manual operation is limited by physical strength and proficiency, usually processing only 2-5 cartons per minute, and efficiency is prone to decline due to fatigue, with increased errors;

- Machines can achieve 24-hour continuous and stable operation (when equipped with auxiliary equipment such as automatic feeding systems). The daily processing capacity (based on 8 hours) can reach 4,000-20,000 cartons (calculated with medium to high-speed models), which can efficiently match the rhythm of mass production in assembly lines.

In practical applications, efficiency is affected by the following factors:

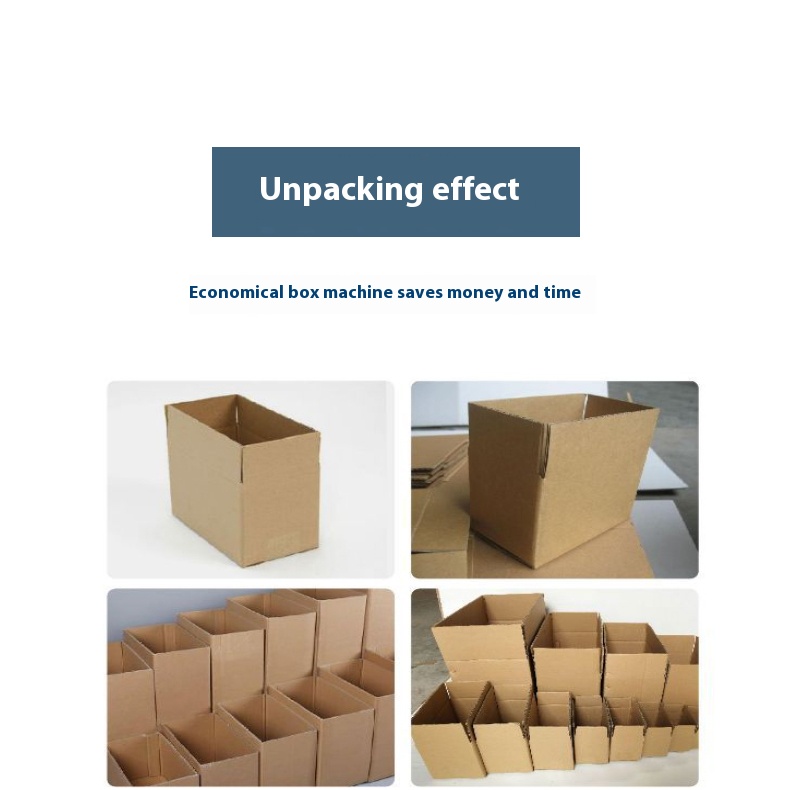

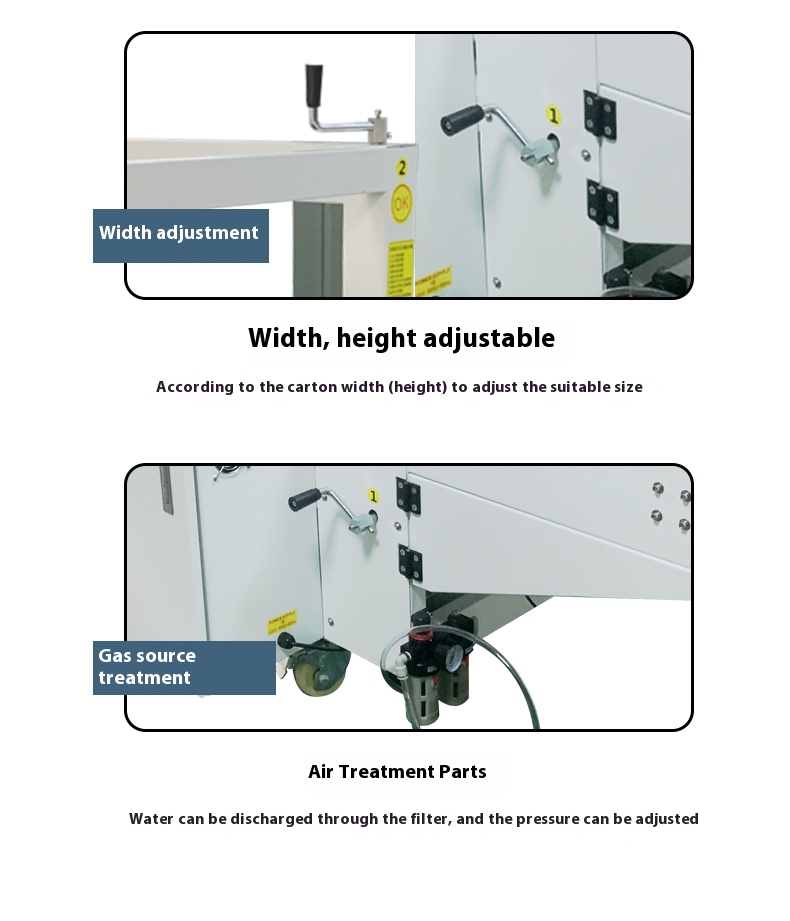

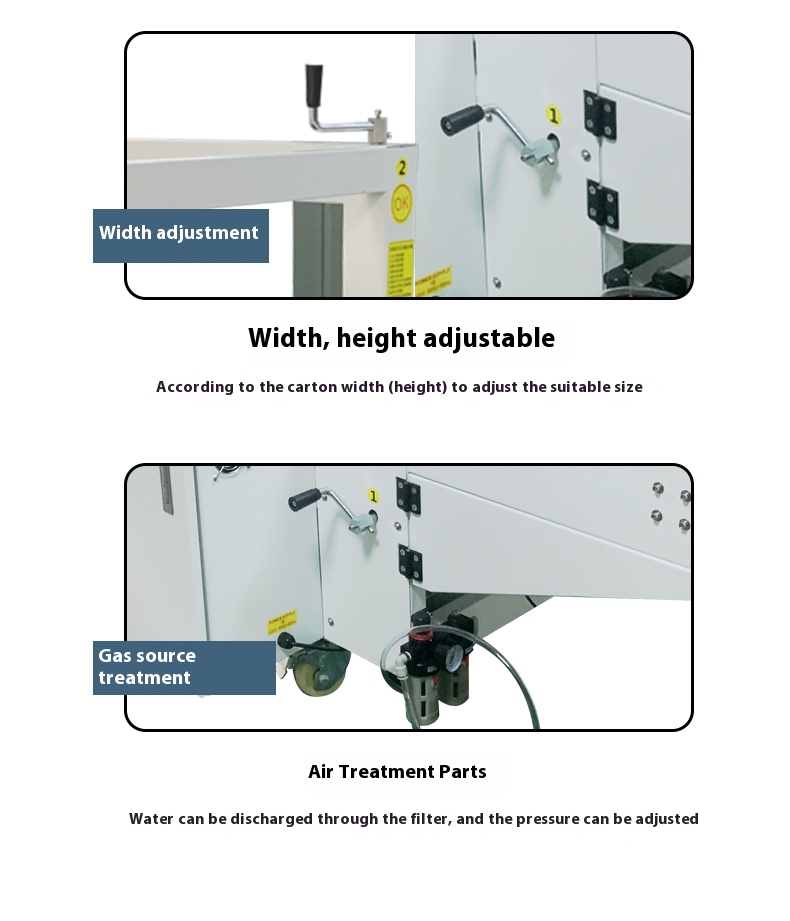

- Stability of carton specifications: If carton sizes need to be changed frequently, manual adjustment of the equipment (taking about 2-3 minutes each time) will temporarily reduce efficiency; fully automatic models (with automatic size adjustment function) can shorten the adjustment time and reduce efficiency losses.

- Degree of equipment automation: Fully automatic models (equipped with functions such as automatic feeding, material shortage alarm, automatic shutdown in case of failure, etc.) require no manual intervention, resulting in more stable efficiency; semi-automatic models (needing manual auxiliary feeding) will have their efficiency limited by the rhythm of manual cooperation.

- Maintenance: Regular cleaning and lubrication of key components (such as transmission systems, carton suction mechanisms) can avoid carton jams and shutdowns due to faults, maintaining the rated efficiency of the equipment; conversely, improper maintenance may lead to reduced efficiency or frequent shutdowns.

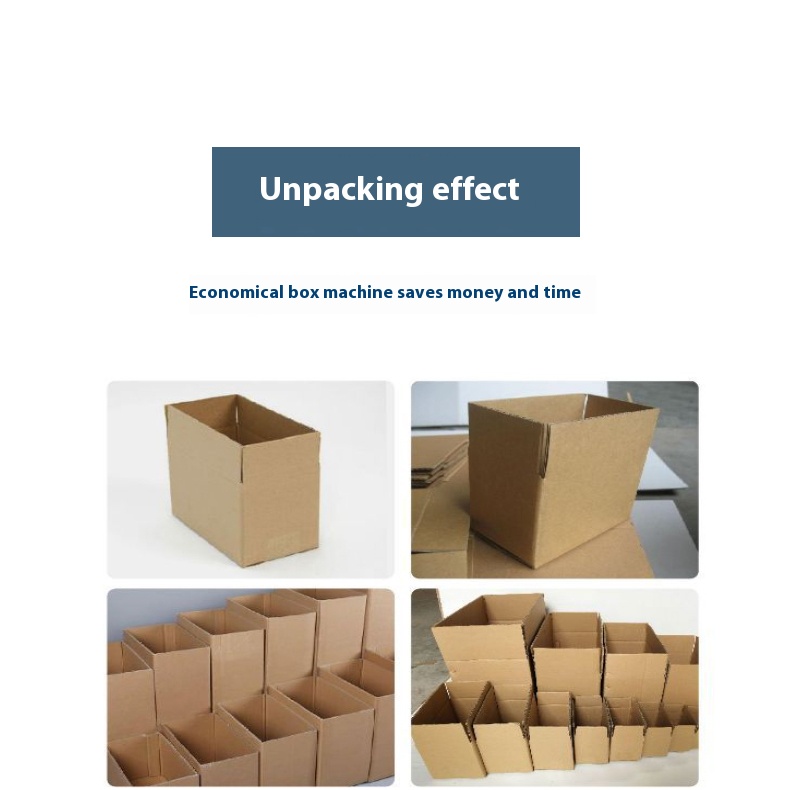

- Carton quality: If the carton material is too soft, creases are unclear, or there is excessive dimensional deviation, it may increase the difficulty of equipment adjustment or cause poor forming, indirectly affecting efficiency.