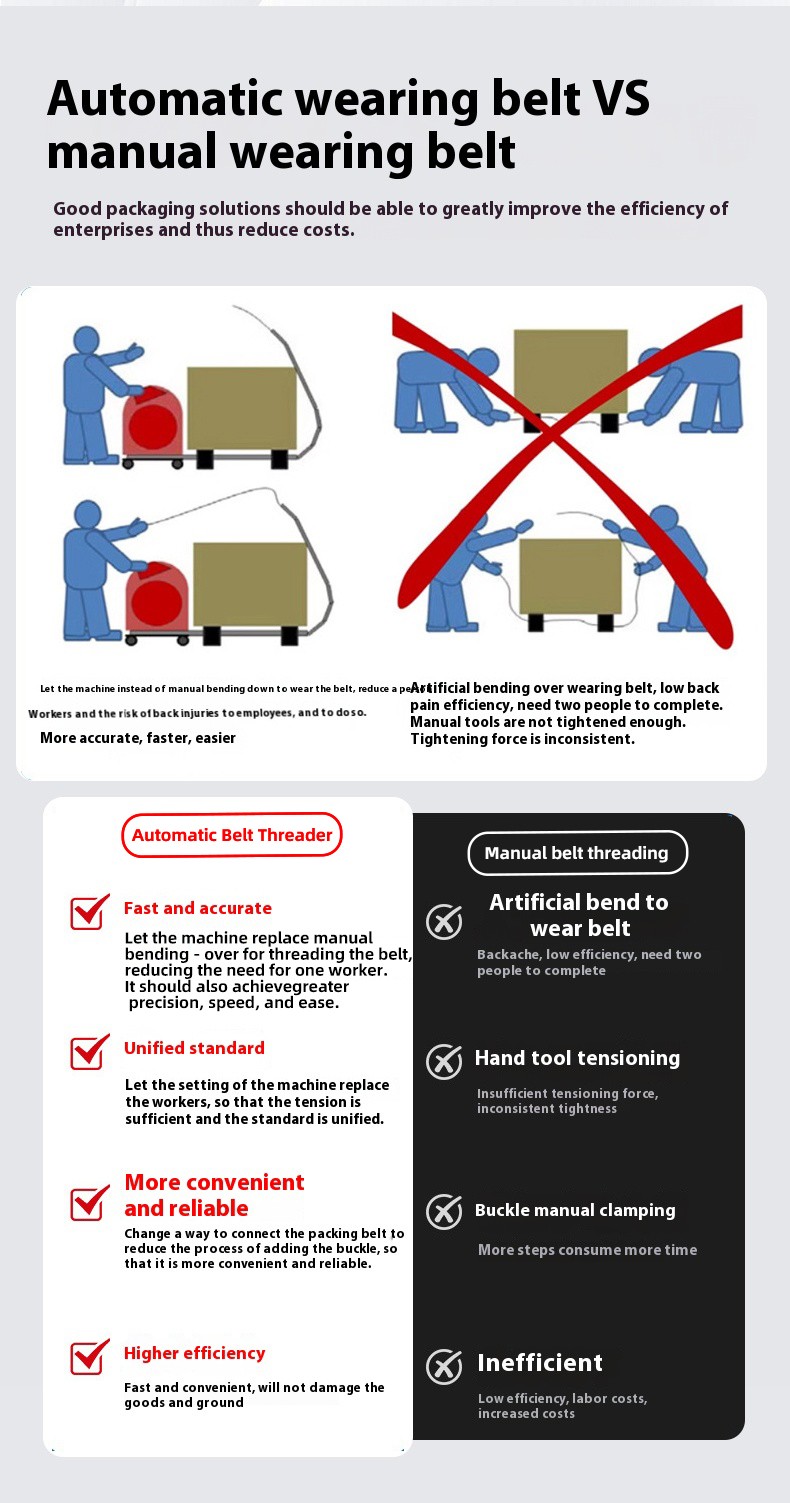

The application scenarios of automatic pallet strapping machines mainly revolve around the needs of "firmly strapping goods to pallets, pursuing efficient automated strapping, and adapting to bulk or heavy cargo handling". Specifically, they include the following categories:

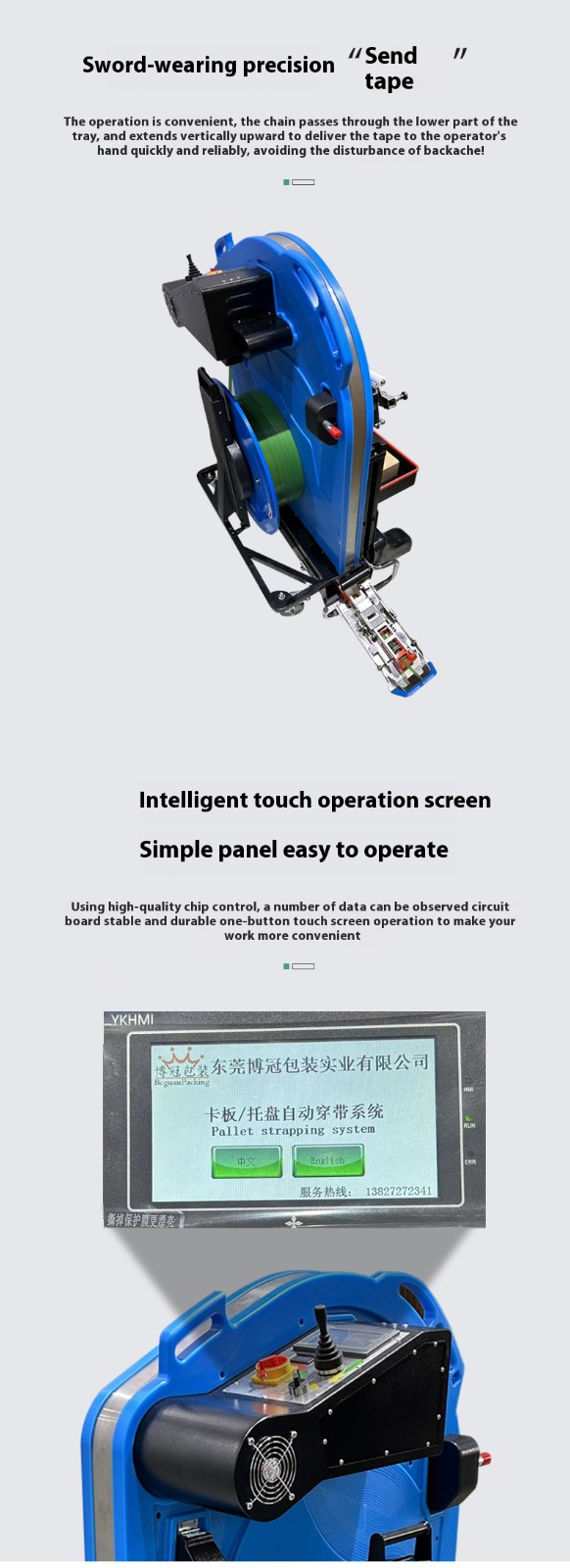

It targets goods with large weight that tend to shake during transportation, such as steel products (steel pipes, steel plates), stone materials (marble slabs, granite), large industrial parts (engines, machine tool accessories), and heavy household appliances (refrigerators, washing machines, air conditioner outdoor units). For such goods, sword-piercing strapping allows the strapping tape to penetrate the bottom of the pallet, fixing the goods to the pallet from the base. This prevents goods from falling off or being damaged due to shaking during transportation or hoisting.

It is suitable for various piece goods stacked on pallets, which need to be fixed through strapping to achieve "goods-pallet integration". Examples include:

- Products packaged in cartons/wooden boxes (food boxes, electronic component boxes, daily necessities boxes);

- Bagged goods (fertilizers, feed, cement, grain, etc. packaged in woven bags);

- Barrel/bottle collections (chemical raw material barrels, beverage bottle turnover boxes), etc.

In such scenarios, the strapping machine ensures that goods do not shift or collapse during warehousing stacking, forklift handling, or long-distance transportation, thus guaranteeing the stability of logistics links.

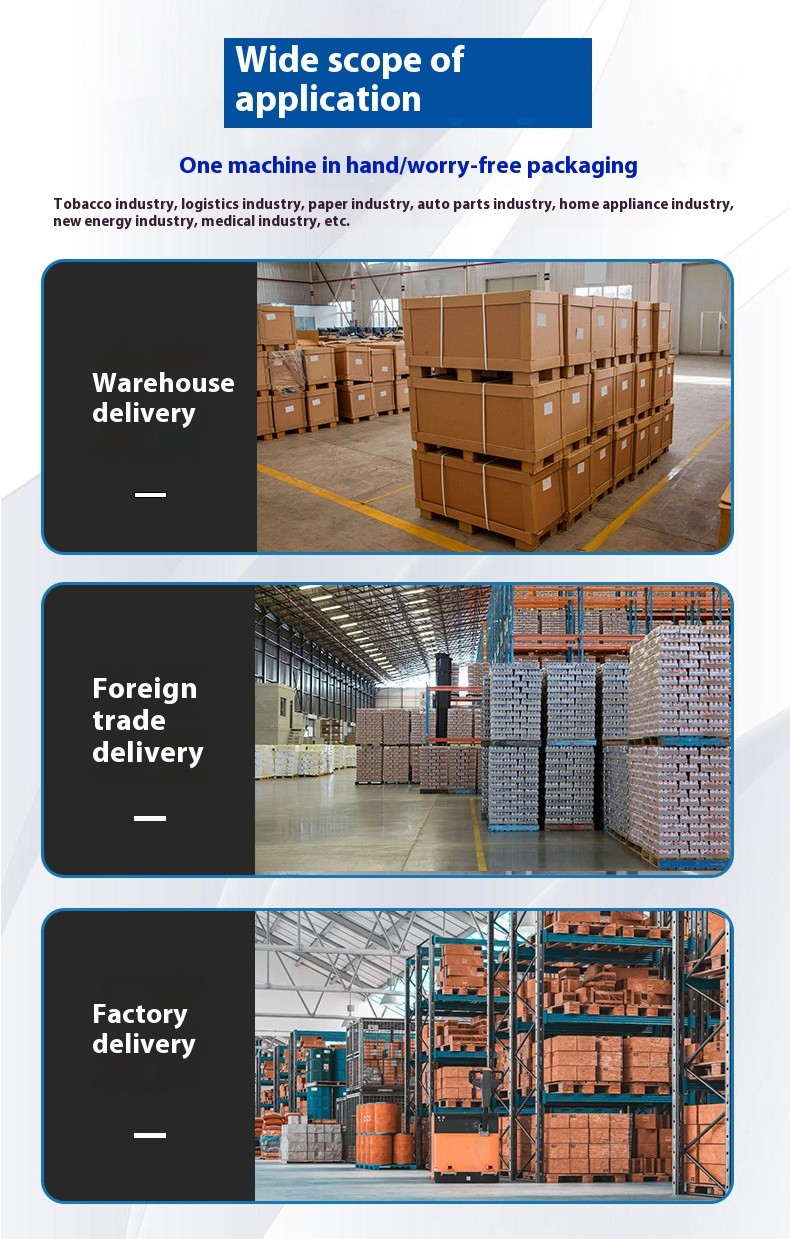

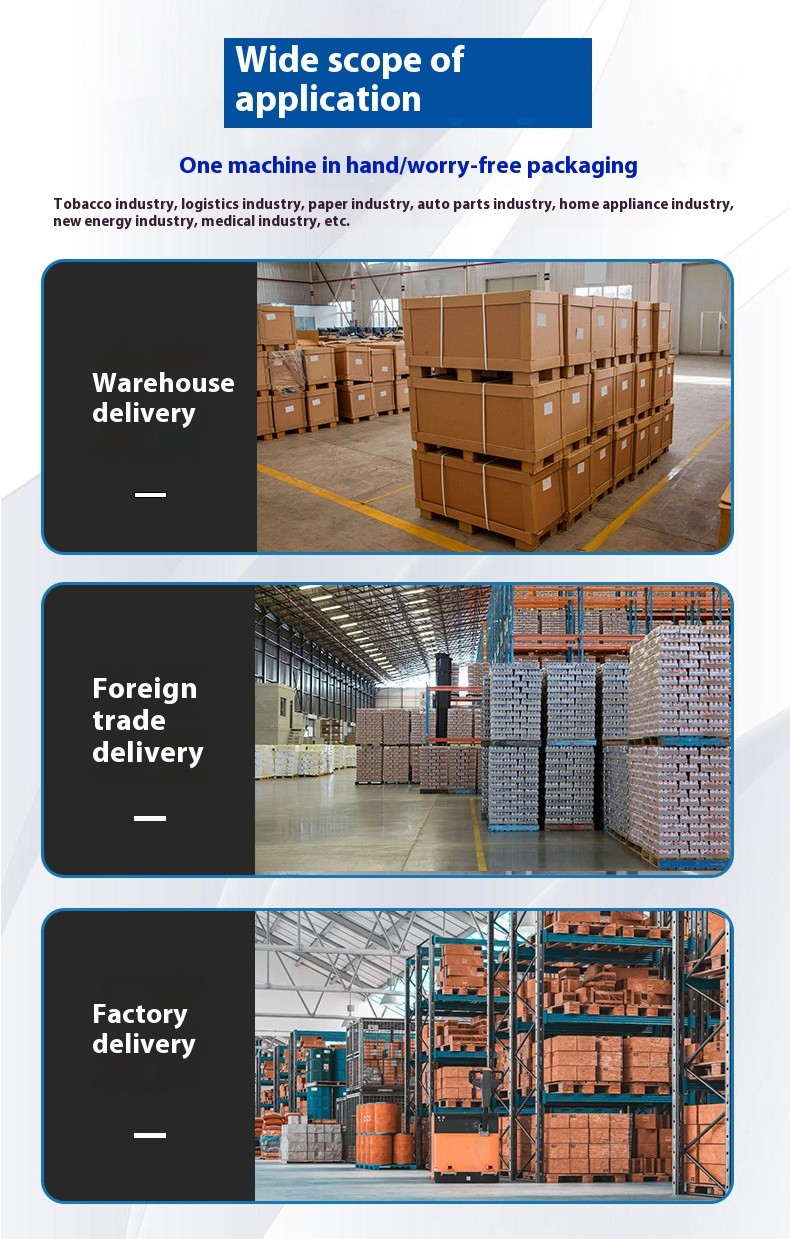

Enterprises that need to adapt to the rhythm of assembly lines and efficiently complete bulk strapping, such as:

- Manufacturing factories (building material factories, home appliance assembly plants, auto parts factories): At the end of the production line, finished products need to be quickly strapped to pallets to match the continuous output efficiency of the assembly line;

- Logistics and warehousing centers: Handling a large number of inbound and outbound goods, requiring standardized strapping to improve loading/unloading and storage efficiency and reduce labor costs;

- E-commerce/retail warehouses: For centralized delivery of large commodities (furniture, home appliances), automated strapping ensures the safety of goods during delivery.

Industries such as the chemical industry, dangerous goods (non-flammable and non-explosive), and precision instruments require goods to be strictly fixed to avoid leakage or damage caused by collisions during transportation. The "full wrapping and strong tightening" characteristics of sword-piercing strapping can meet the safety standards of such scenarios.