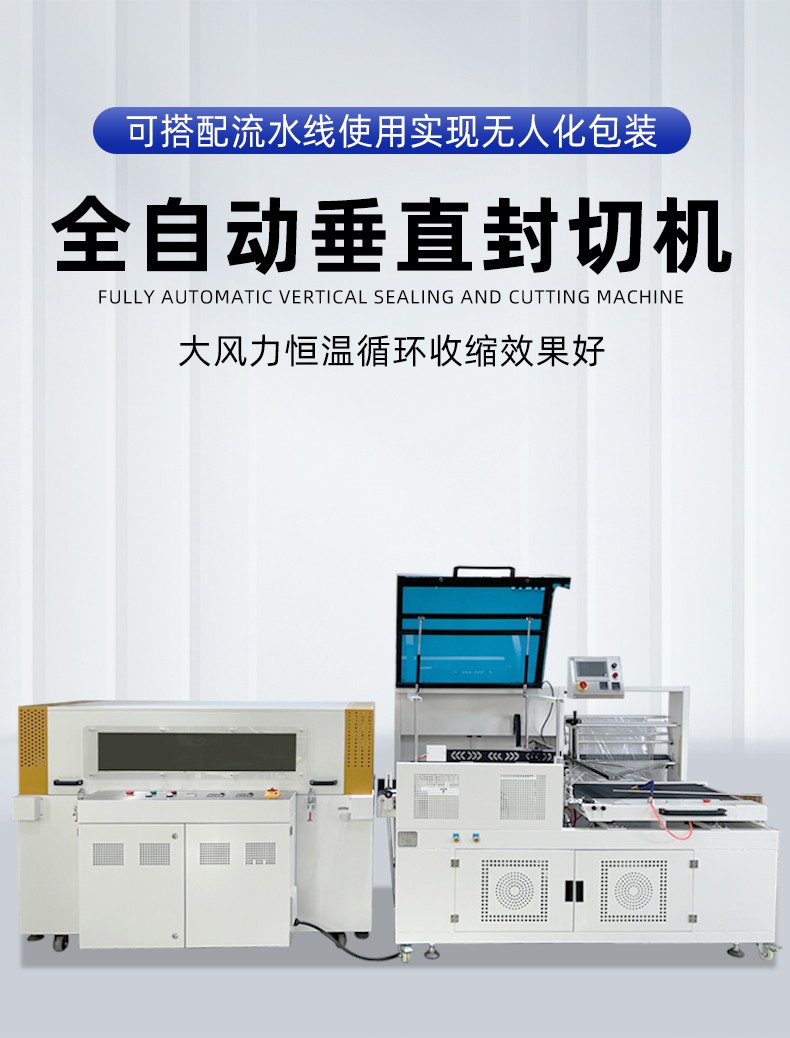

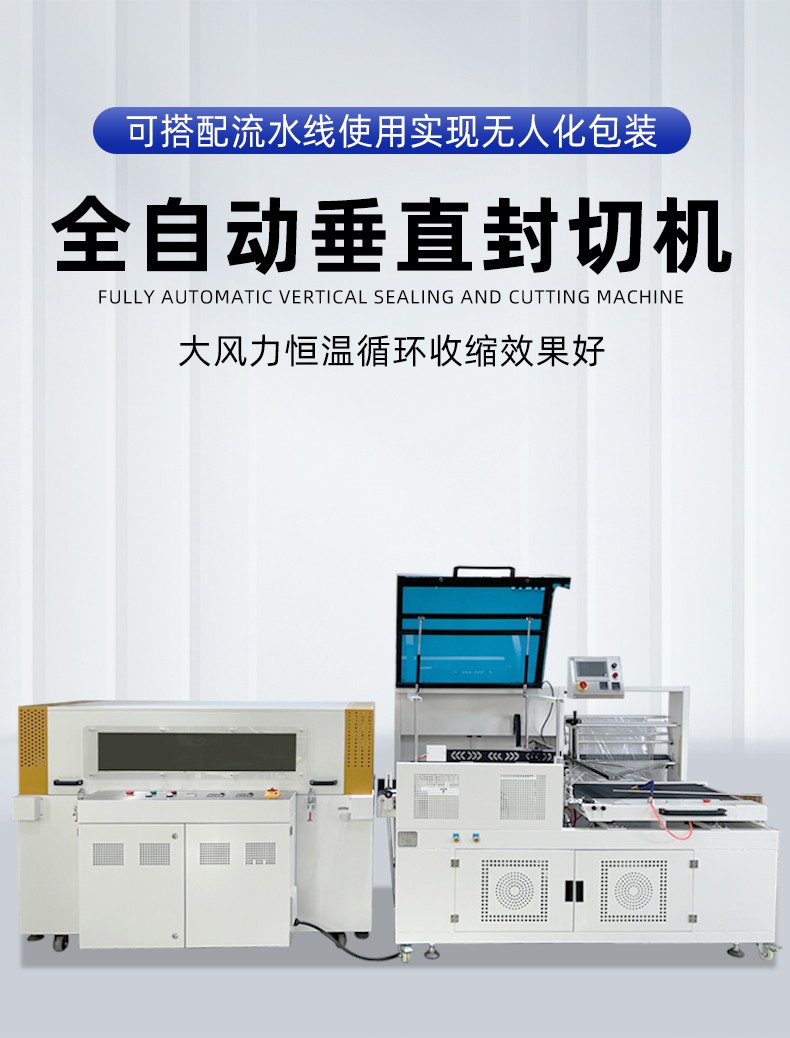

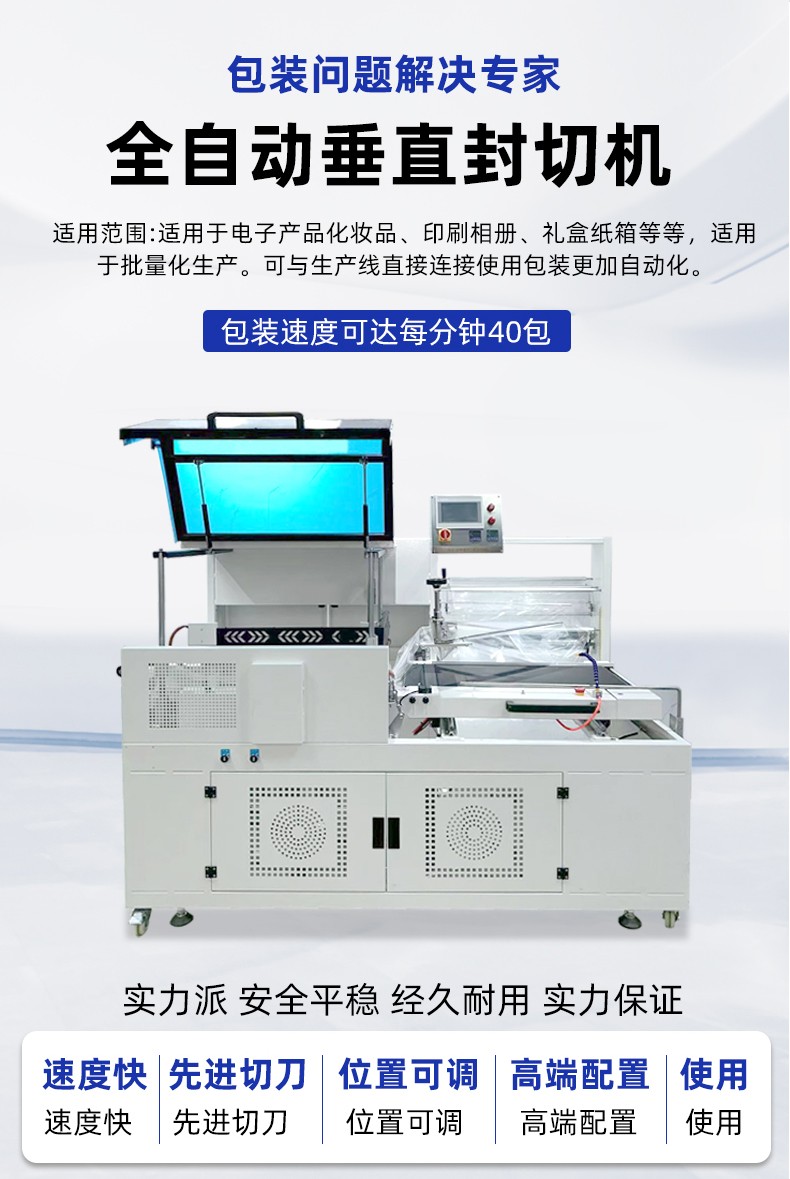

The advantages of the automatic vertical sealing, cutting and heat shrink packaging machine are mainly reflected in multiple dimensions such as efficiency, stability and adaptability, and it is especially suitable for large-scale and refined packaging needs. The details are as follows:

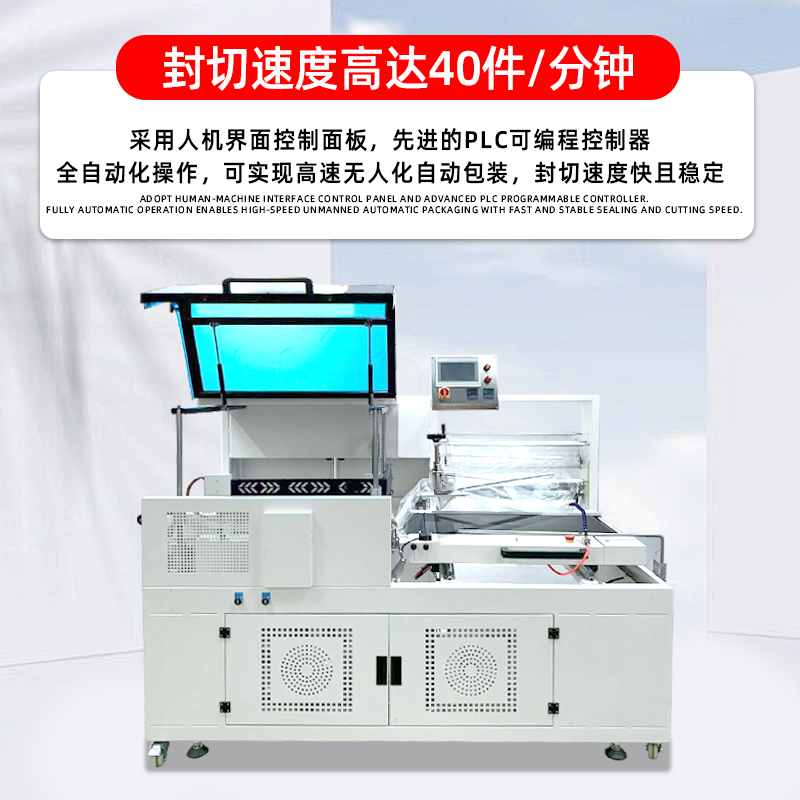

Efficient automation, significantly improving production capacity

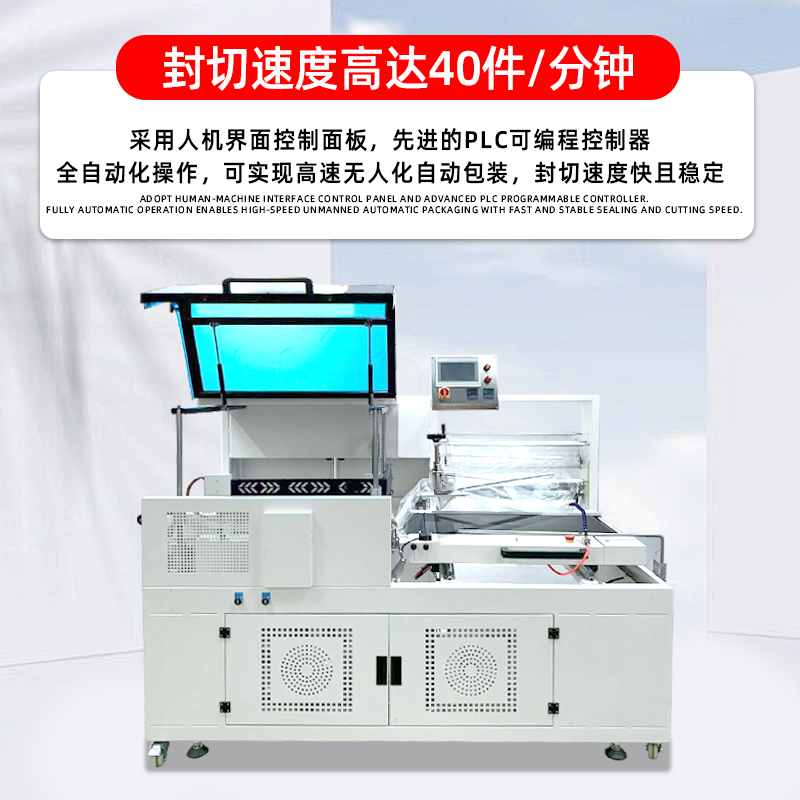

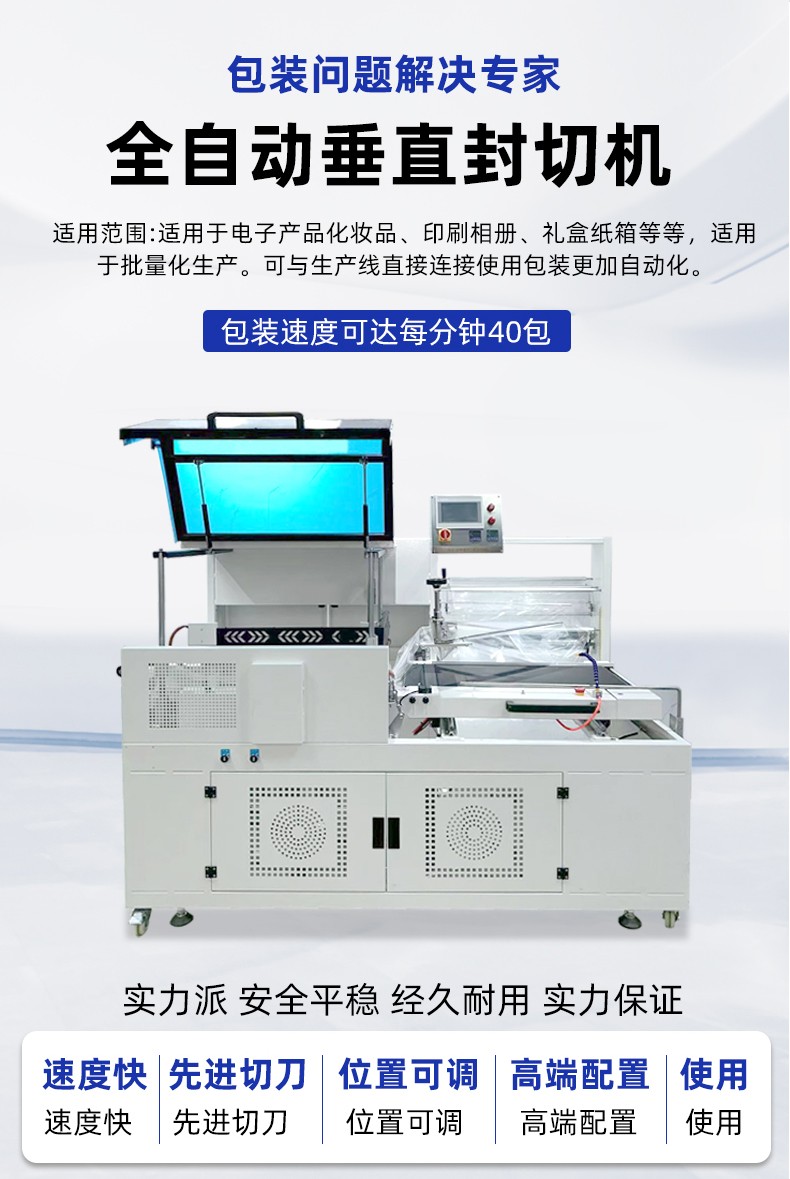

It requires no manual intervention throughout the process and can automatically complete the entire process of feeding, film covering, sealing and cutting, and heat shrinking, avoiding the efficiency bottleneck of manual operation. Compared with semi-automatic or horizontal equipment, it has stronger continuous operation capability, capable of packaging 20-60 pieces per minute (depending on product size). Its daily production capacity can easily meet the needs of mass production, significantly reducing labor and management costs.

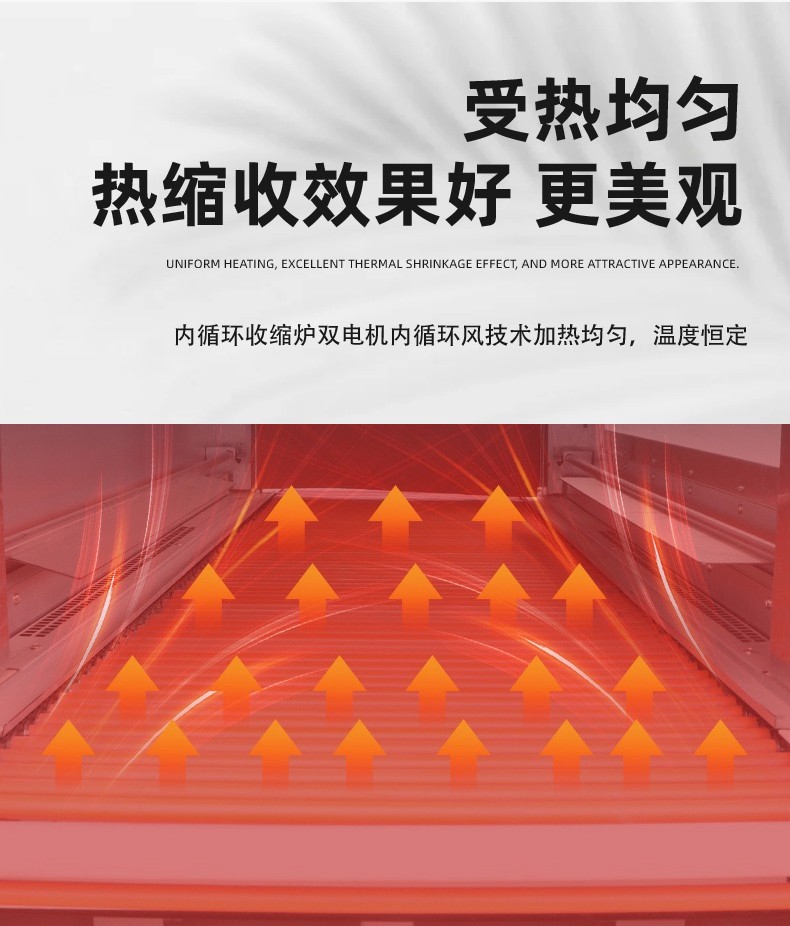

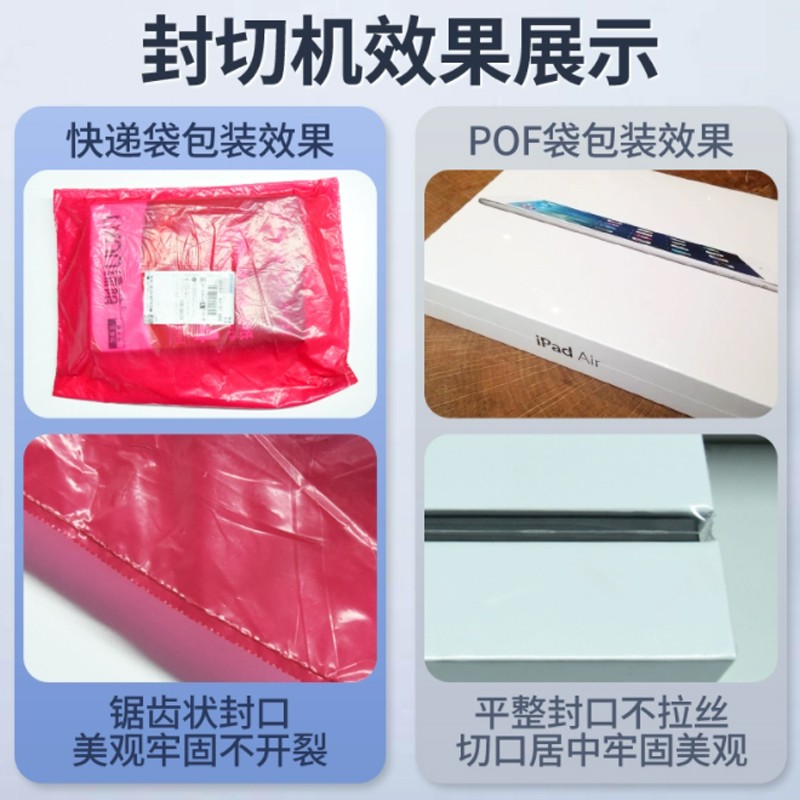

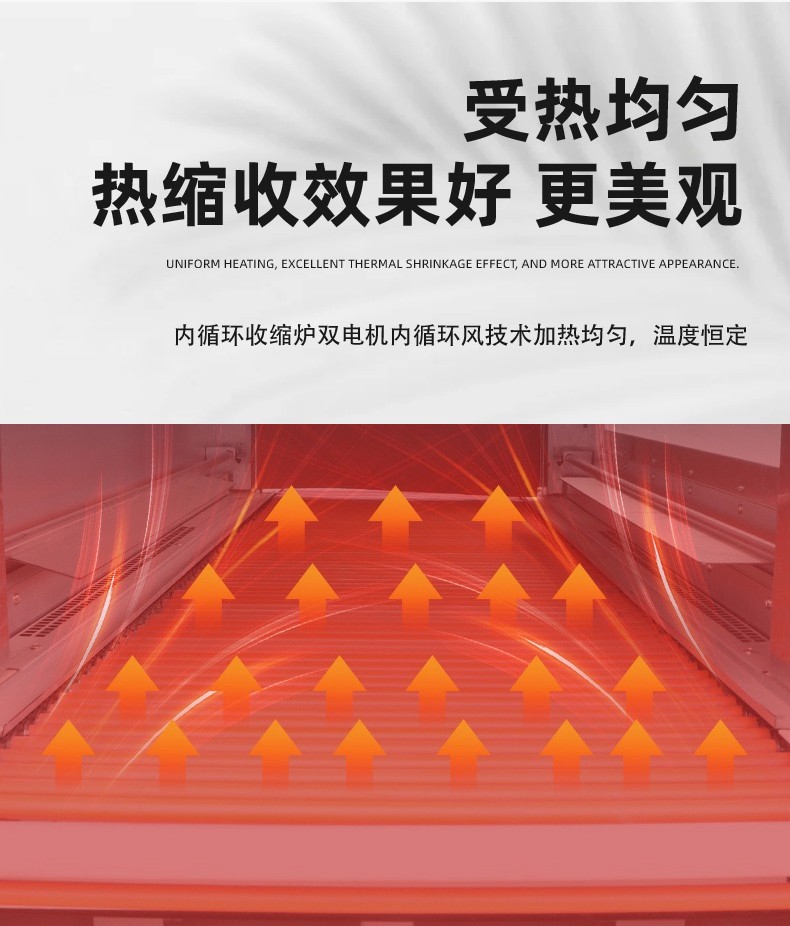

High packaging precision and better appearance quality

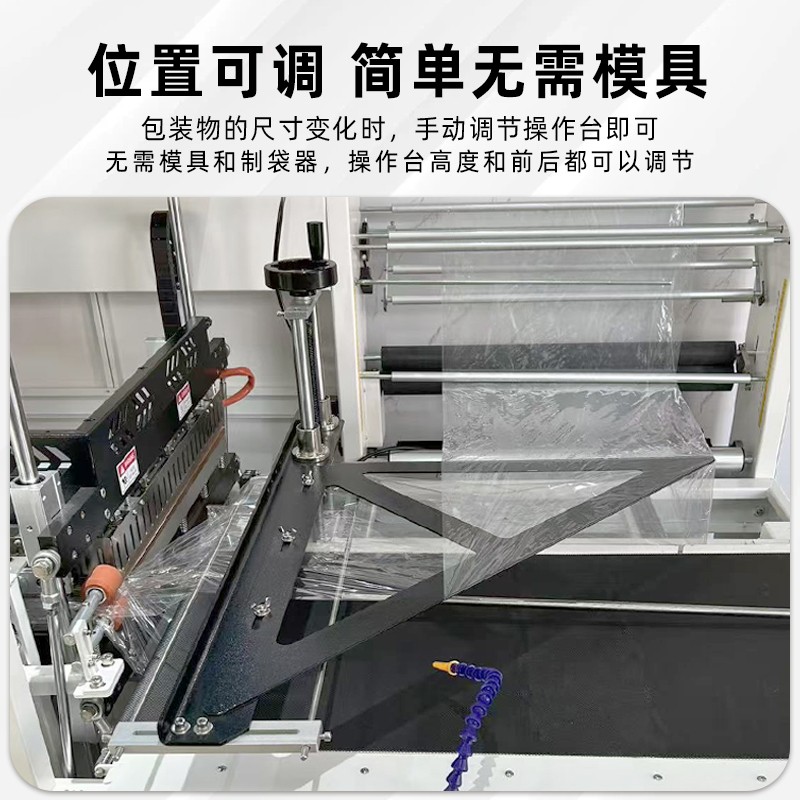

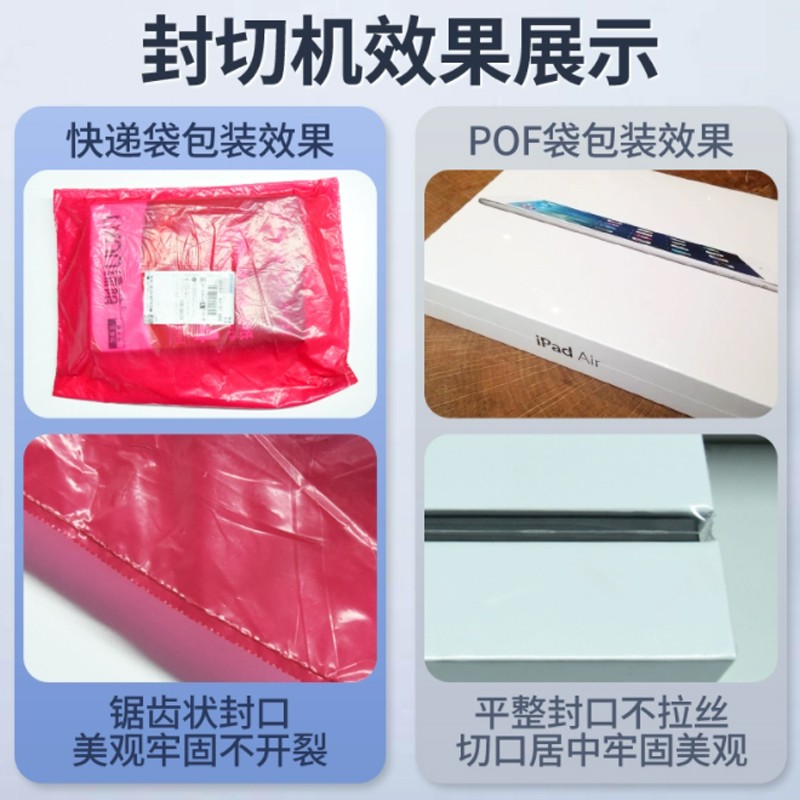

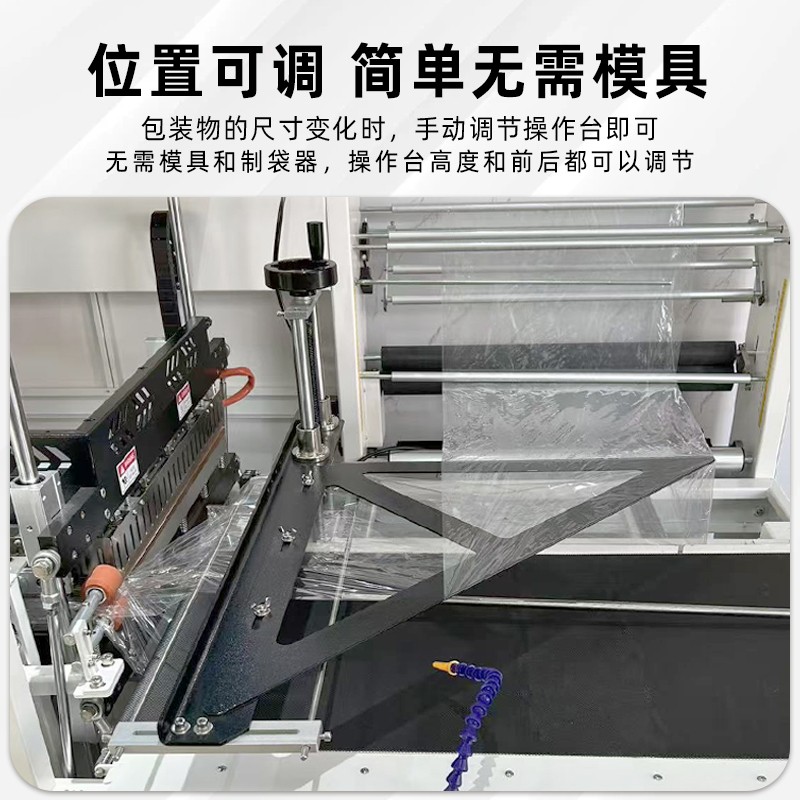

- Vertical sealing and cutting design: The sealing action is vertically downward with uniform force, making the sealing line flat and firm, less prone to cracking, coking or incomplete sealing. Moreover, the sealing position is closer to the product, reducing film waste, making the edges and corners more invisible, and enhancing the packaging aesthetics.

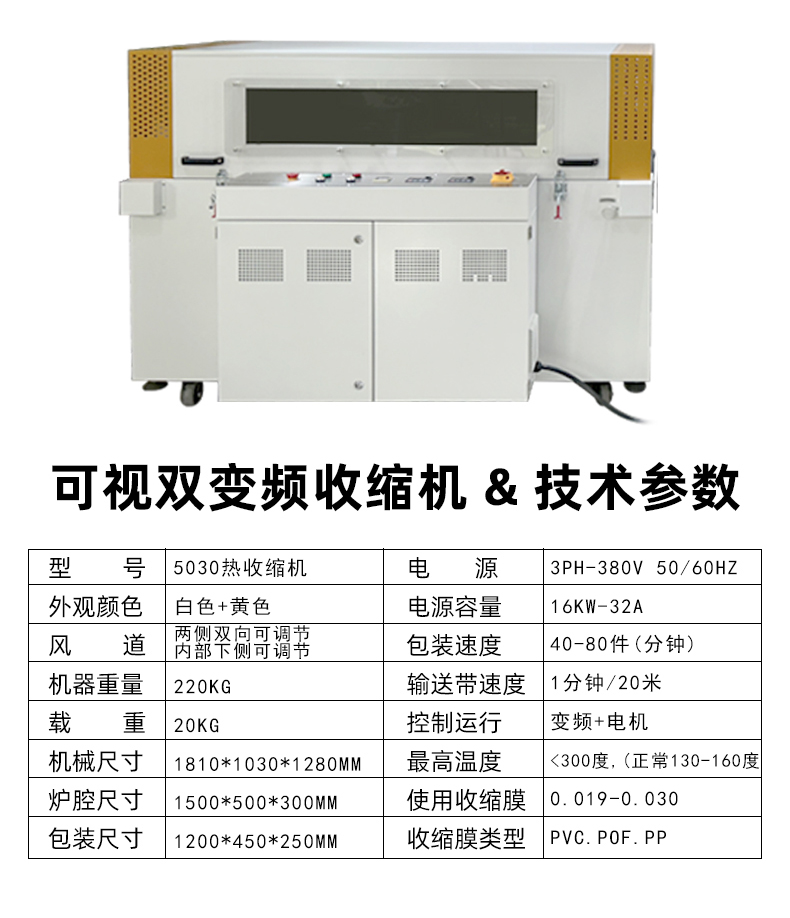

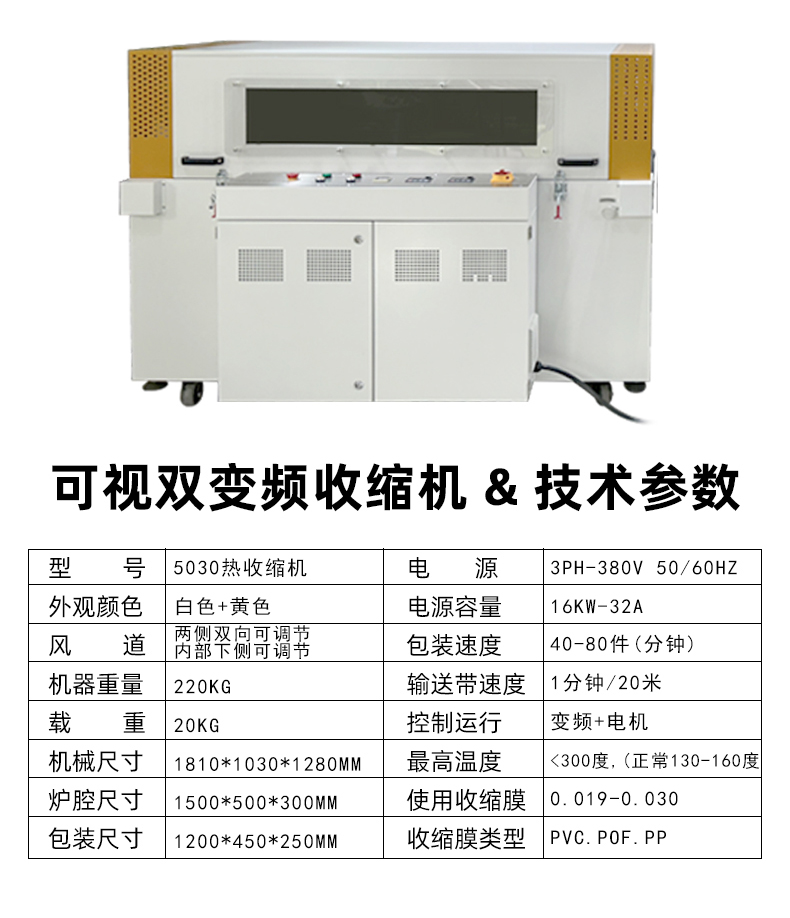

- Uniform heat shrinkage: The shrink oven is equipped with a circulating fan and a precision temperature control system (such as quartz far-infrared heating), ensuring uniform distribution of hot air. After shrinking, the film fits tightly to the product without wrinkles or bubbles. It is especially suitable for special-shaped and irregular products (such as bottled, boxed, and multi-piece combined products), enhancing the product display texture.

- Wide application range and strong compatibility

- Product compatibility: It can package products of different shapes (circular, square, special-shaped) and sizes (from small individual parts to large combined gift boxes), covering multiple industries such as food, daily chemicals, pharmaceuticals, electronics, and hardware.

- Film compatibility: It is compatible with various heat shrink films (POF, PVC, PE, etc.) without frequent replacement of equipment components, flexibly meeting the needs of different packaging materials.

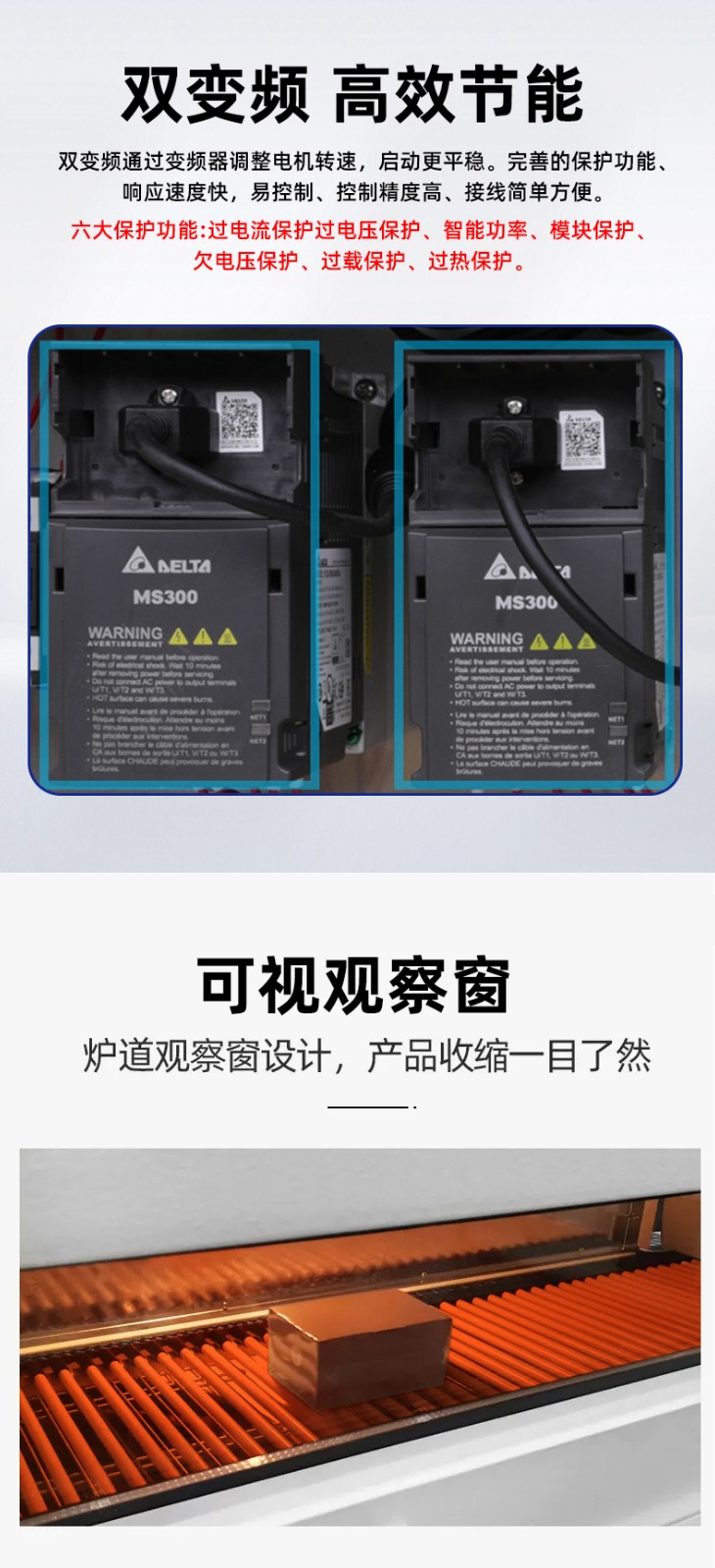

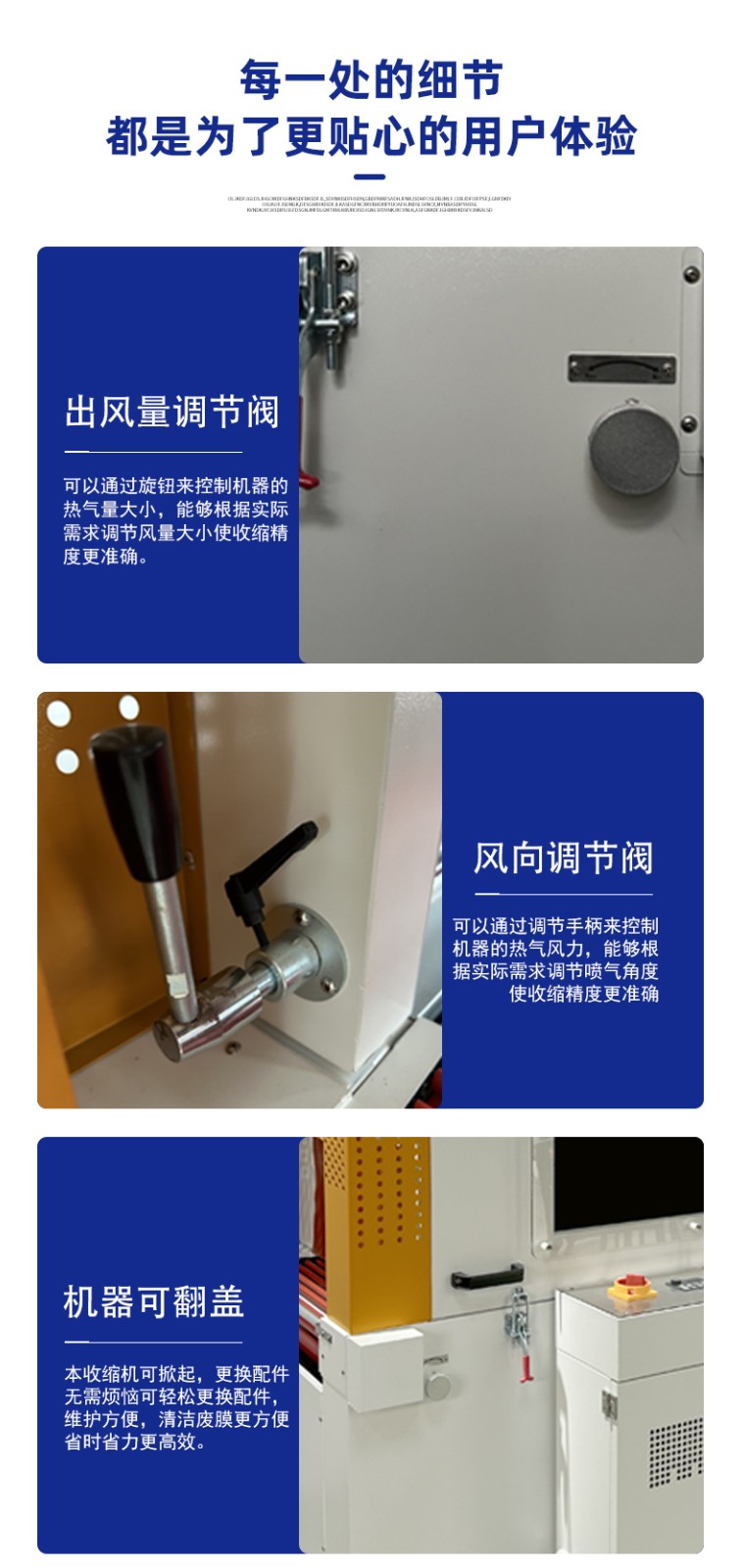

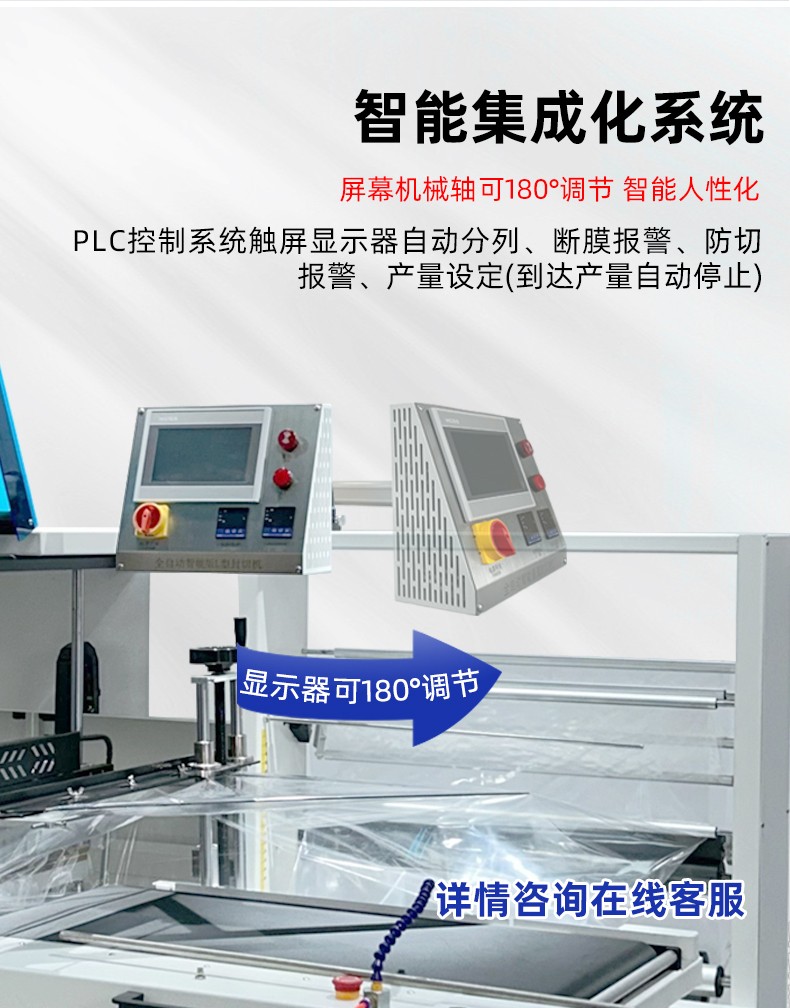

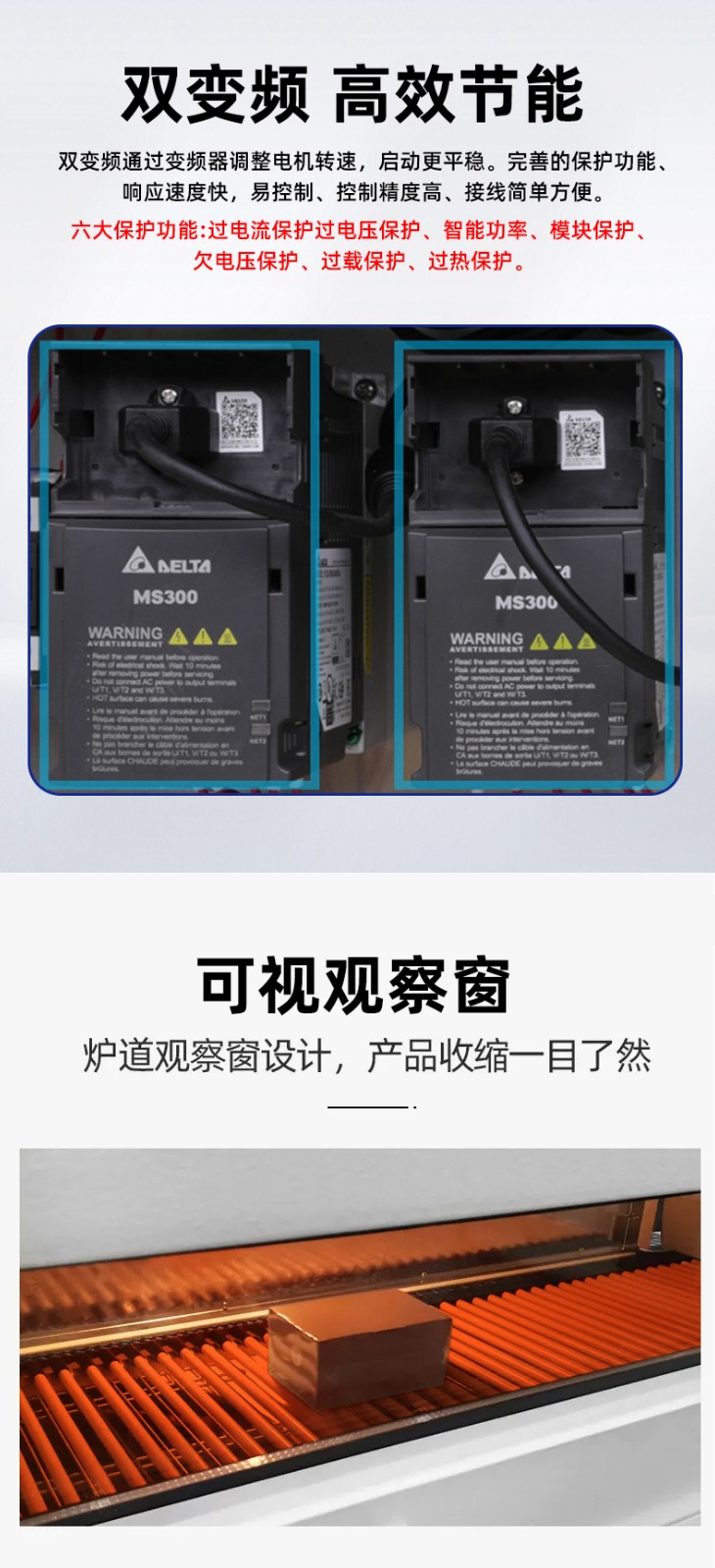

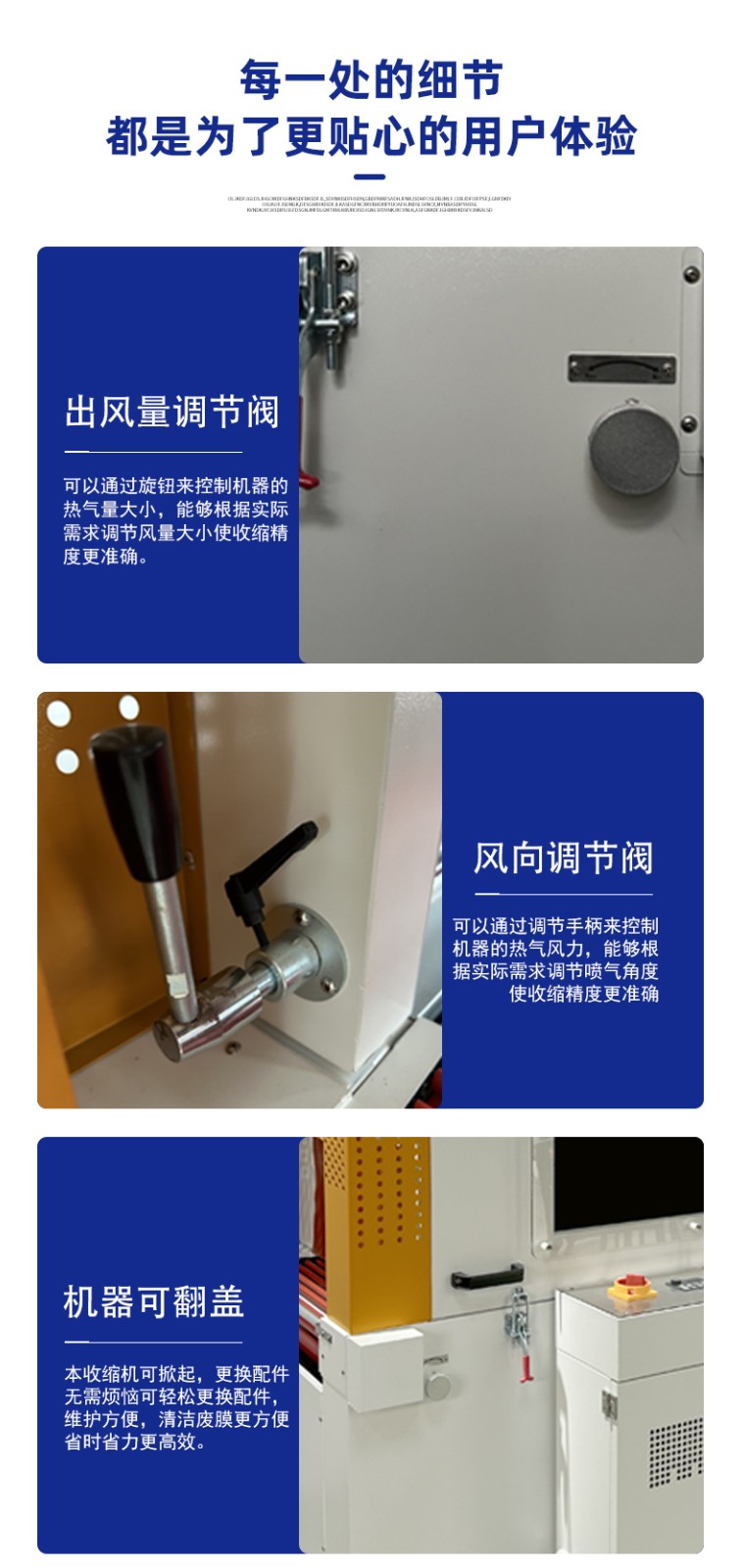

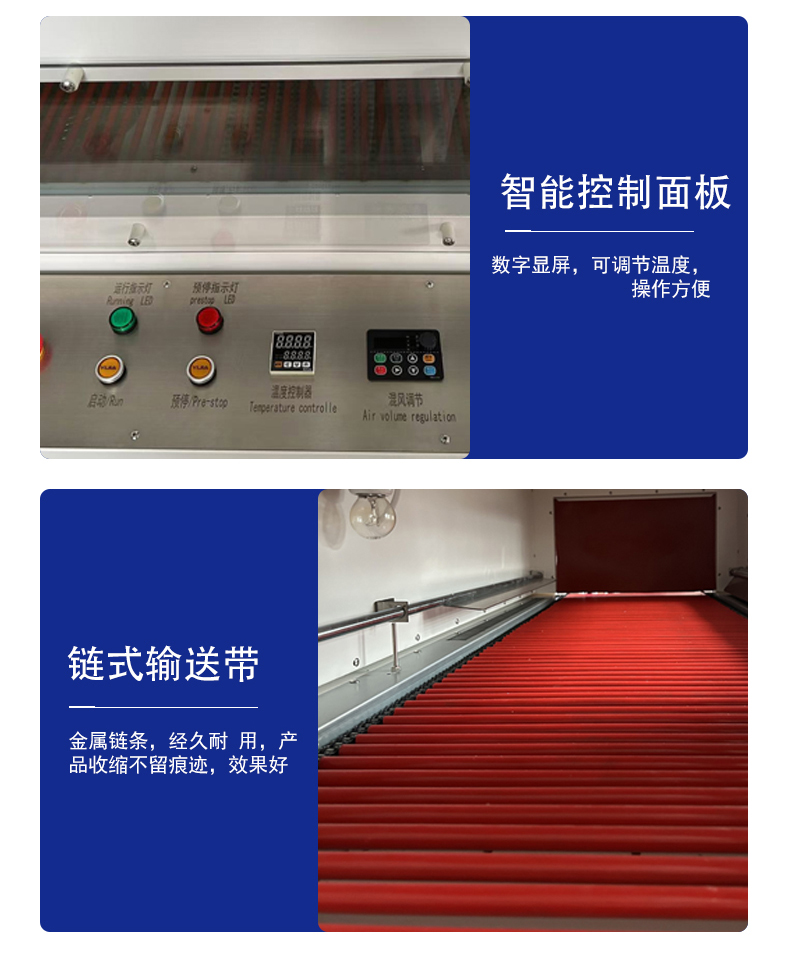

- Convenient operation and high stability

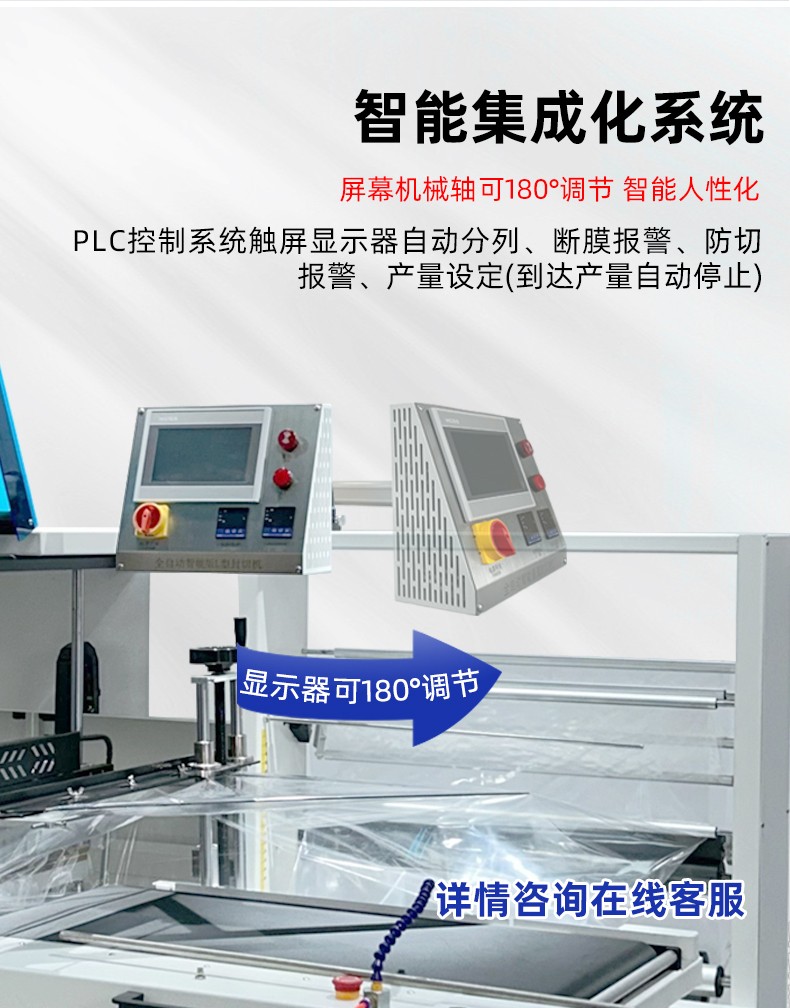

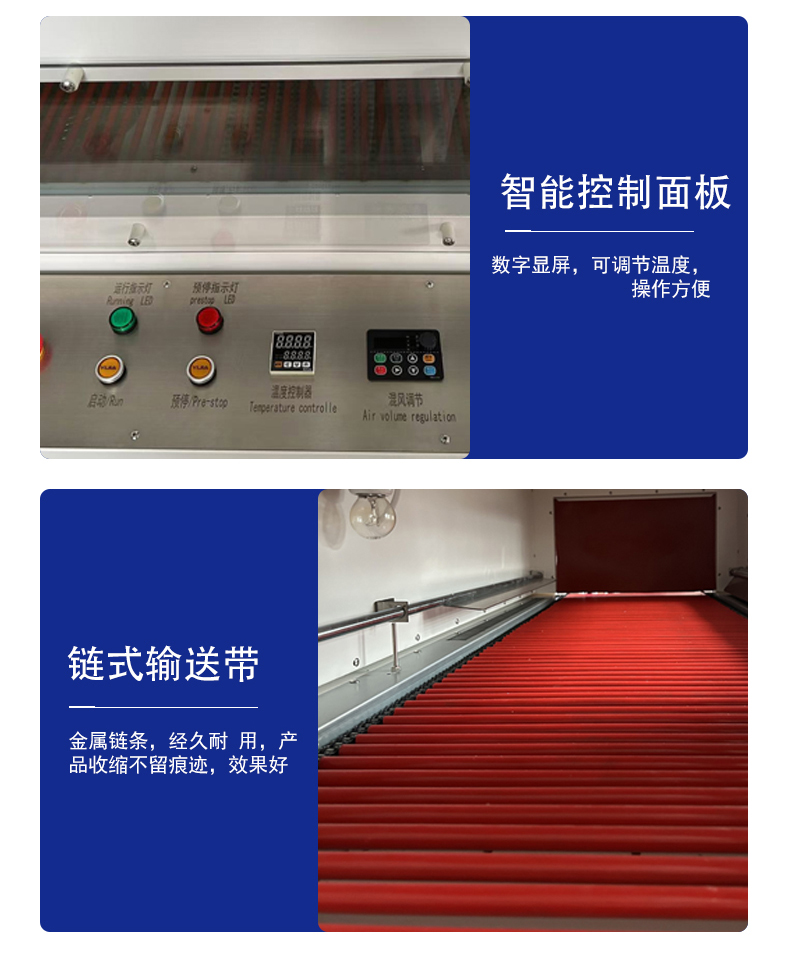

- Intelligent control system: Adopting PLC programming + touch screen operation, it allows one-key setting of parameters such as sealing and cutting temperature, shrinking time, and feeding speed. It also supports parameter memory function, eliminating the need for repeated debugging during product changeover and lowering the operation threshold.

- Fault self-diagnosis: Equipped with sensors and alarm systems, it can monitor the equipment operation status in real-time (such as insufficient film material, abnormal temperature, material jamming, etc.), and timely shut down and alarm, reducing fault downtime and ensuring production continuity.

Safe and reliable, reducing production risks

The equipment is equipped with multiple safety protections: such as a transparent protective cover (preventing operators from touching high-temperature components), sealing and cutting knife induction protection (automatic shutdown when touching foreign objects), overload protection, etc., to avoid safety accidents caused by misoperation.

Core components (such as sealing and cutting knives, motors, heating tubes) are mostly made of wear-resistant and high-temperature-resistant materials, with a long service life, reducing equipment maintenance frequency and costs.

Saving consumables and reducing comprehensive costs

The vertical sealing and cutting design reduces the invalid consumption of film (with less scrap compared to the "L-shaped" sealing of horizontal cutting). At the same time, automatic film feeding and tension control ensure stable film transportation, avoiding film waste caused by manual pulling. Long-term use can significantly reduce packaging material costs.