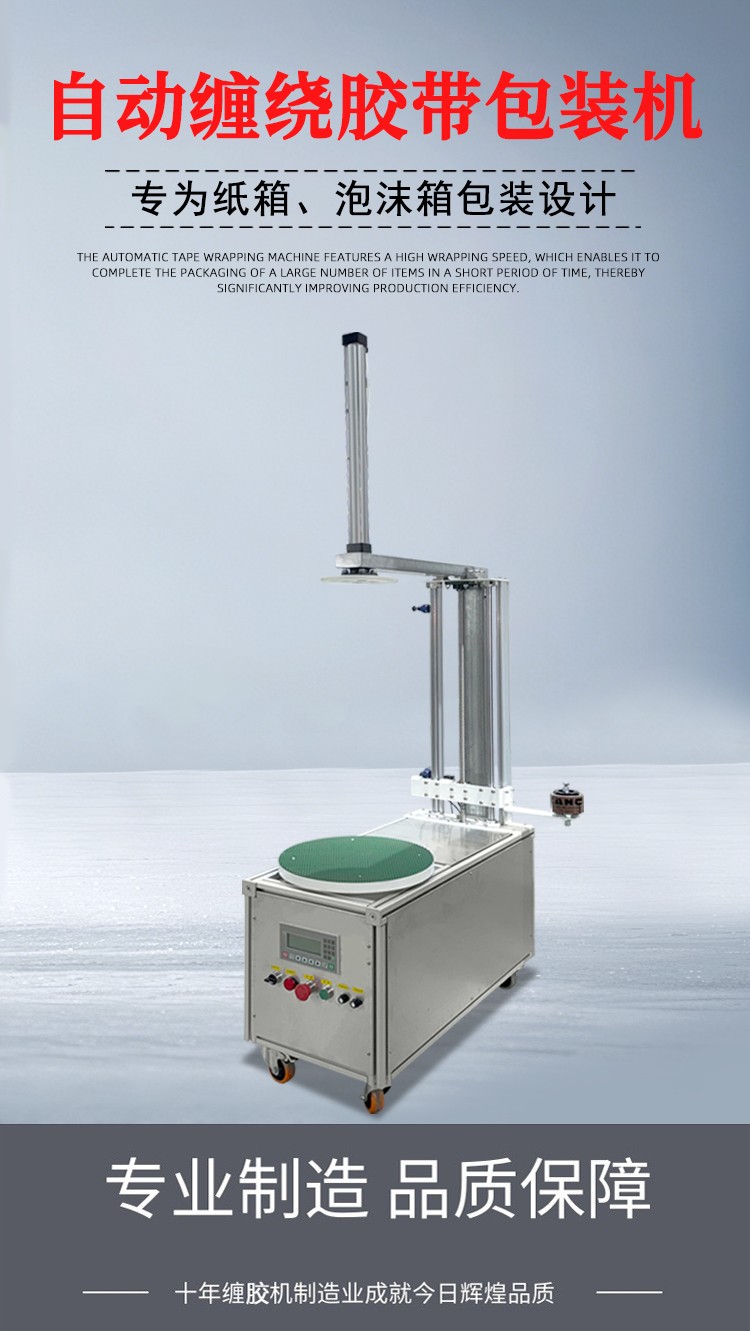

With advantages such as automation, high precision, and adjustability, automatic tape wrapping machines are widely used in various industries that require object fixing, protection, and containerization. Their core application scenarios revolve around three key needs: packaging and fixing, protective safeguarding, and efficiency improvement. Specifically, they can be categorized into the following types:

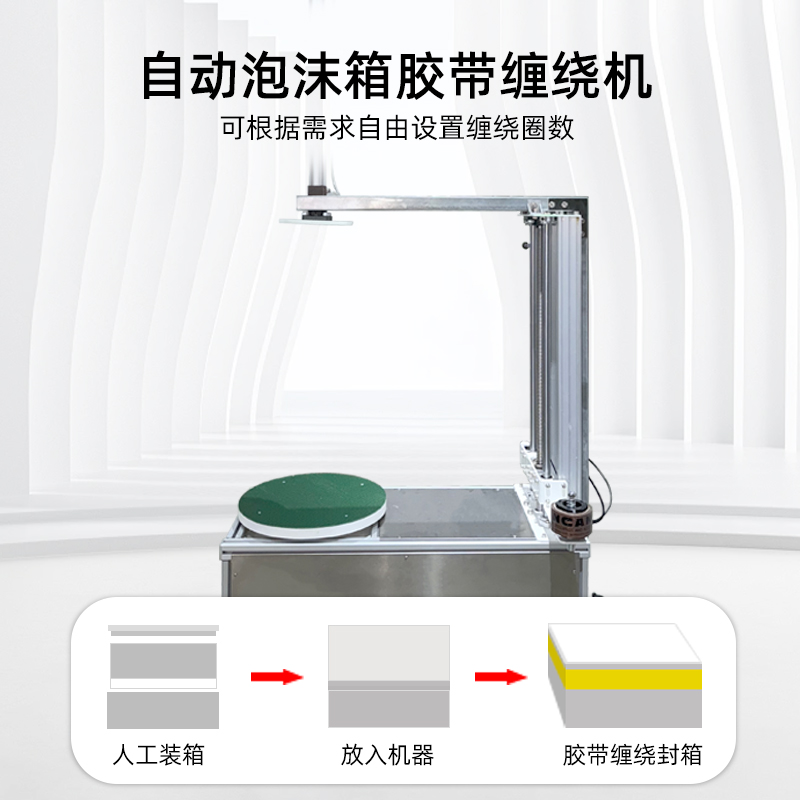

This is the most mainstream application scenario for automatic tape wrapping machines, primarily targeting the intensive packaging of bulk goods to address issues of scattering and damage during transportation and storage.

- Palletized Goods Containerization: Wrap and package cartons, turnover boxes, and bagged goods (such as rice, flour, and chemical raw material bags) stacked on pallets. The tape tightly secures multiple layers of goods to the pallets, preventing tilting and scattering during handling (by forklifts, conveyors) or transportation (by trucks, containers).

- Large Goods Protection: Wrap tape around large-volume goods such as furniture, home appliances (refrigerators, washing machines), and large equipment accessories to form an outer protective layer. This layer provides dustproof, moisture-proof, and scratch-resistant effects, making it particularly suitable for long-term warehousing or cross-regional logistics and transportation.

Electronic and electrical products and components are sensitive to the environment (humidity, dust) and physical contact (static electricity, scratches). Tape wrapping machines need to work with special tapes to achieve functional protection.

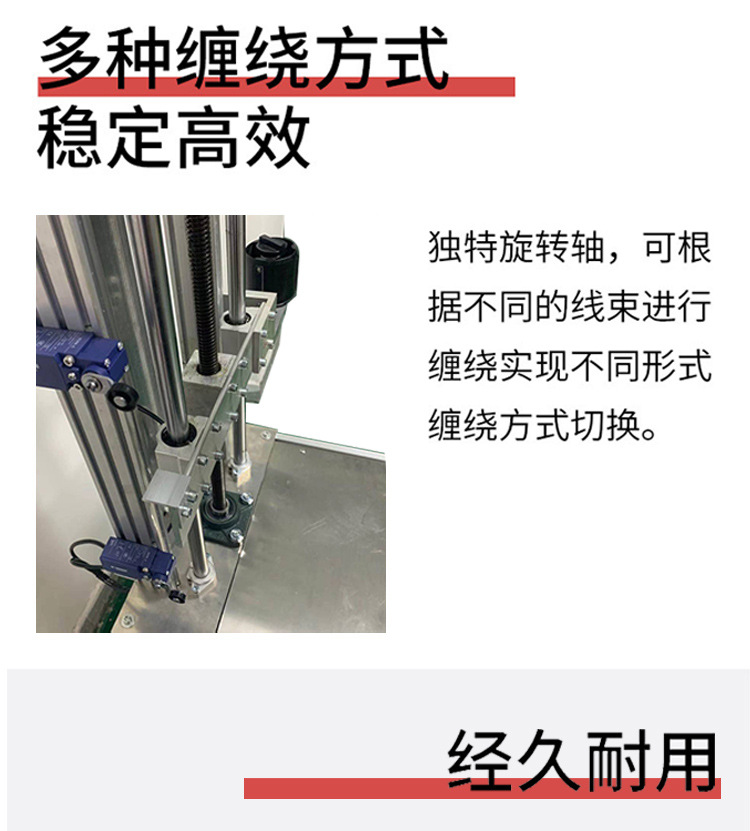

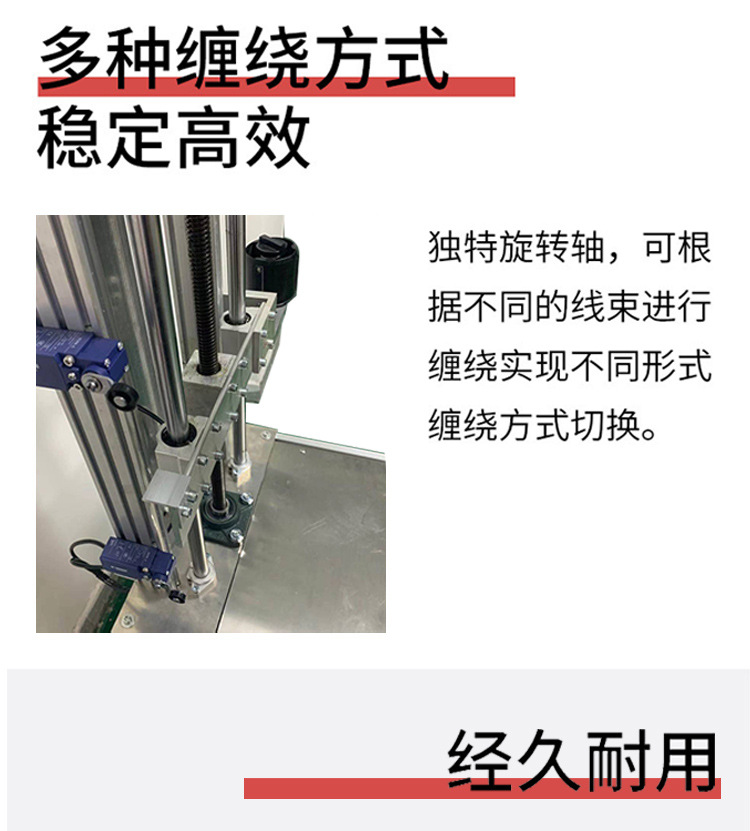

- Component and Cable Processing:

- Wrap wires and cables (such as engineering cables and internal wire harnesses of home appliances) using PVC tapes or insulating tapes to achieve insulation and fixation, avoiding tangled cables or damaged outer sheaths caused by friction.

- Wrap and enclose electronic components (resistors, capacitors) and semi-finished circuit boards to prevent dust accumulation, electrostatic interference during transportation and processing, and damage to pins.

- Finished Equipment Packaging: Reinforce the outer packaging boxes of small electronic devices (routers, chargers, sensors) by wrapping tape, or wrap protective tape around device casings (such as metal sensor casings) to avoid surface scratches before assembly.

This industry has strict requirements for the hygiene and sealing of packaging. Wrapping machines must be compatible with food-grade tapes, and the equipment should be easy to clean and non-polluting.

- Fixation of Bottled/Canned Products: Use tape to wrap groups of beverage bottles (mineral water, cola) and food cans (canned fish, fruit cans) into "carrier packs" or "carton-matched sets". This facilitates terminal sales (such as supermarket shelf display) and consumer carrying, while preventing individual packages from falling off.

- Semi-Finished Product Protection: After sealing the packaging of baked food boxes (cake boxes, bread gift boxes) and quick-frozen food outer packaging (dumpling bags, glutinous rice ball bags), wrap tape to enhance sealing, reduce air entry, and help extend the freshness period. For turnover barrels used in food processing (such as sauce barrels, edible oil barrels), wrap tape to fix the barrel lids and prevent leakage during transportation.

Building materials and home furnishing products are mostly irregular, long-strip-shaped, or made of surface-vulnerable materials (such as wood, glass, and metal). Wrapping is required to achieve the dual effects of "shape setting + protection".

- Packaging of Long-Strip Building Materials: Tightly wrap single or multiple pieces of materials such as pipes (PVC pipes, steel pipes, aluminum alloy pipes), profiles (door and window frames, ceiling keels), and plates (gypsum boards, wood boards, glass panels) using wrapping machines. This fixes their shapes and prevents surface scratches and edge damage caused by collisions during handling and stacking.

- Finished Home Furnishings and Accessories: Wrap protective film tapes (in conjunction with wrapping machines) around assembled furniture (tables, chairs, wardrobes) and furniture accessories (cabinet doors, drawer panels). This prevents stains and scratches from hard objects during transportation to terminal stores, especially suitable for vulnerable surfaces such as solid wood and baking varnish.

Chemical raw materials are mostly corrosive and volatile substances, while pharmaceutical products have extremely high requirements for hygiene and stability. Wrapping machines must be compatible with corrosion-resistant and impermeable special tapes and meet industry compliance standards.

- Chemical Raw Material Packaging: Wrap tape around the joints between the bodies and lids of chemical raw material packaging containers (plastic barrels, iron barrels, such as paint barrels, solvent barrels, and reagent barrels) to reinforce them and prevent material leakage. For bagged chemical products (such as chemical fertilizer bags, industrial salt bags), wrap tape to enhance the sealing of bag mouths and avoid powder or liquid leakage that pollutes the environment.

- Pharmaceutical Products and Consumables: Reinforce the packaging of medicine boxes (capsule boxes, tablet boxes) and medical consumables (syringe outer packaging, infusion set outer packaging) by wrapping tape to ensure packaging integrity and prevent drug contamination due to packaging damage during transportation. For medical equipment accessories (such as disinfection equipment parts), wrap sterile tape to achieve temporary protection, complying with the hygiene standards of the pharmaceutical industry.

In the production processes of various manufacturing industries, automatic tape wrapping machines are often used for temporary packaging during "inter-process transfer" to solve the problems of semi-finished product fixing and protection.

- Automotive Components: Wrap tape around automotive interior parts (instrument panel casings, door panels) and metal accessories (screws, bearings) to fix them on turnover racks after production and before final assembly. This prevents collision deformation and surface wear during transfer.

- Machined Parts: Wrap anti-rust tape or protective tape around metal workpieces (shafts, gears) processed by machine tools. This avoids rusting and iron chip contamination during temporary storage and transfer to the next process (such as painting, assembly).