Leveraging steam as its core heating medium, the steam shrink machine offers significant advantages in the heat shrink packaging field, particularly excelling in packaging effectiveness, product protection, material compatibility, energy consumption, and cost efficiency. Specifically, its advantages can be summarized into the following five core aspects:

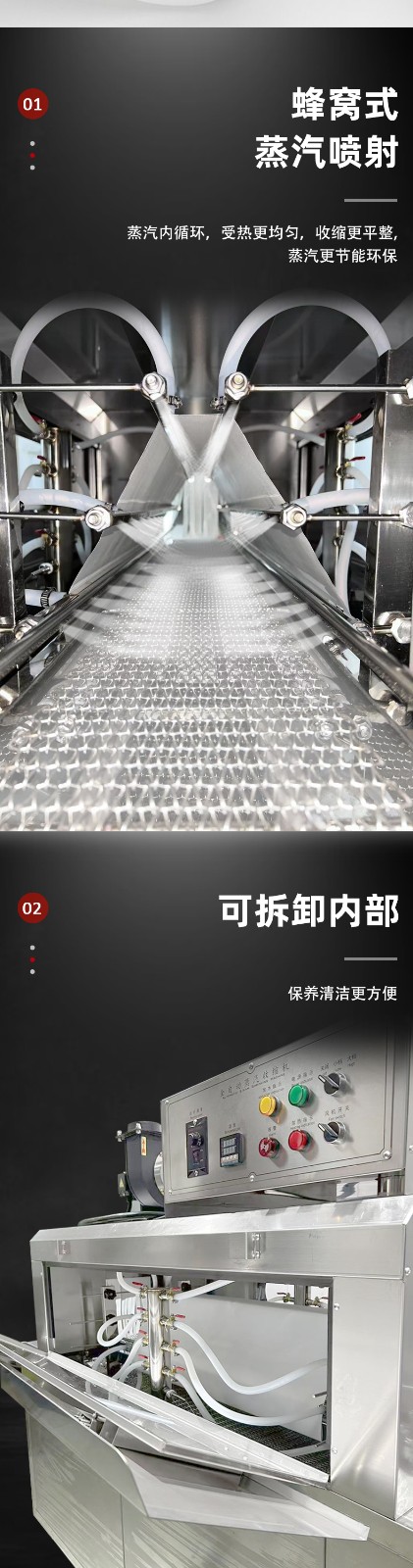

This stands as the most core advantage of steam shrink machines, derived from the "all-around surrounding" heating characteristic of steam:

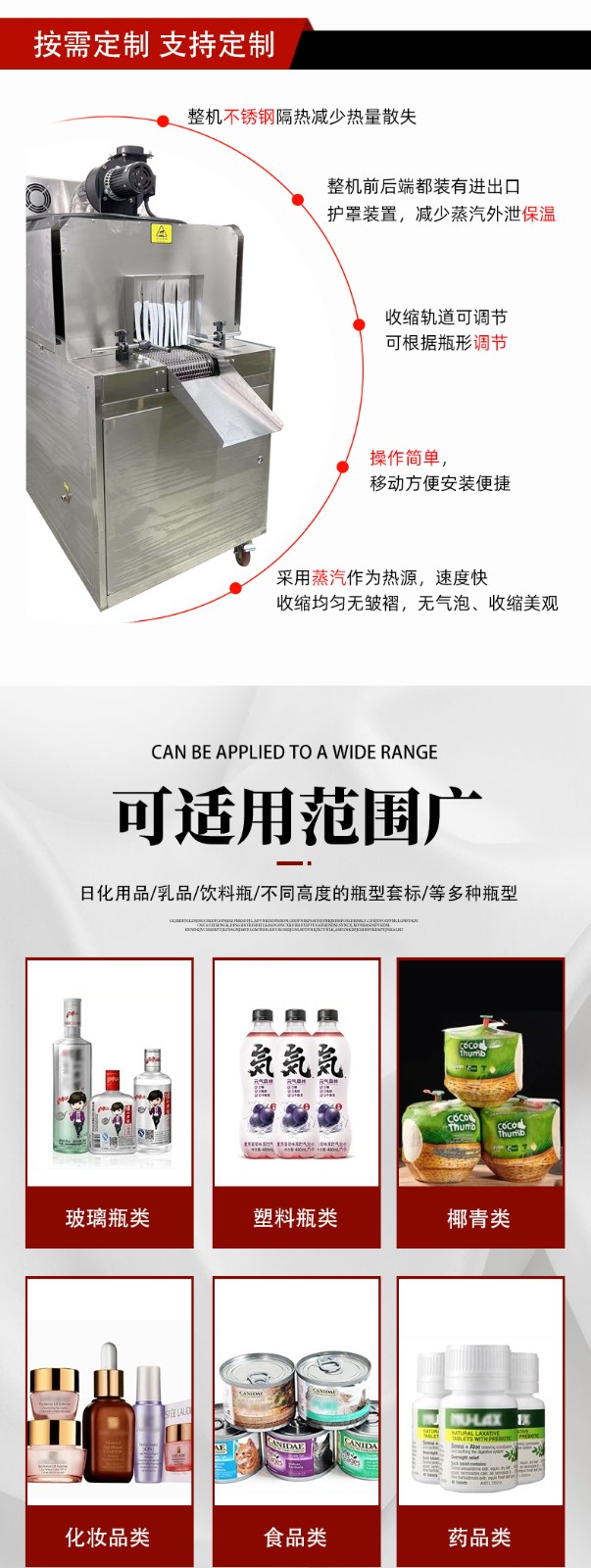

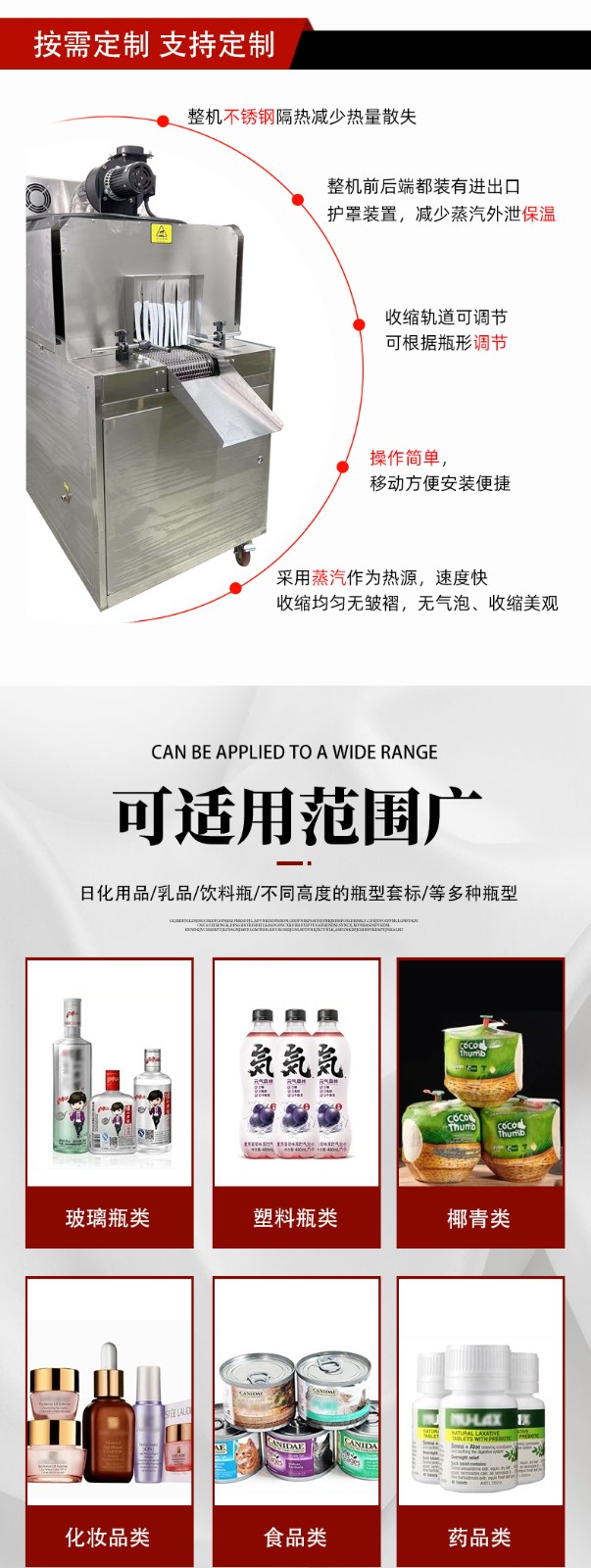

- No Shrinkage Dead Ends, High Adhesion: Steam can fully envelop both the product and the film. Whether the product is a regular bottle/can or an irregular item with protrusions or depressions (e.g., gift boxes with handles, multi-bottle combination packages), the film shrinks uniformly and adheres tightly to gaps. This avoids issues commonly seen in hot air shrink machines, such as "wrinkles, stubborn folds, and hollow bulges."

- Better Transparency and Gloss: Steam heating is gentle and uniform, preventing films (especially transparent ones like POF and PVC) from "fogging, whitening, or deforming" due to localized overheating. It maximizes the film’s transparency and gloss, making the packaged product appear more high-end. This is especially suitable for scenarios where appearance enhances product grade, such as cosmetics, health products, and premium food.

The "low-temperature moist heat" characteristic of steam heating makes it far more protective of products than hot air shrink machines:

- Suitable for Heat-Sensitive Products: The operating temperature of steam typically ranges from 80°C to 120°C, much lower than the 150°C to 200°C of hot air shrink machines. Moreover, heat is transferred via moist heat, which does not directly scorch the product. Thus, it can be safely used for heat-sensitive and high-value products such as chocolate (to prevent melting), lipstick (to avoid deformation of the waxy casing), pharmaceuticals (to maintain stable efficacy), and electronic components (to prevent circuit damage from high temperatures).

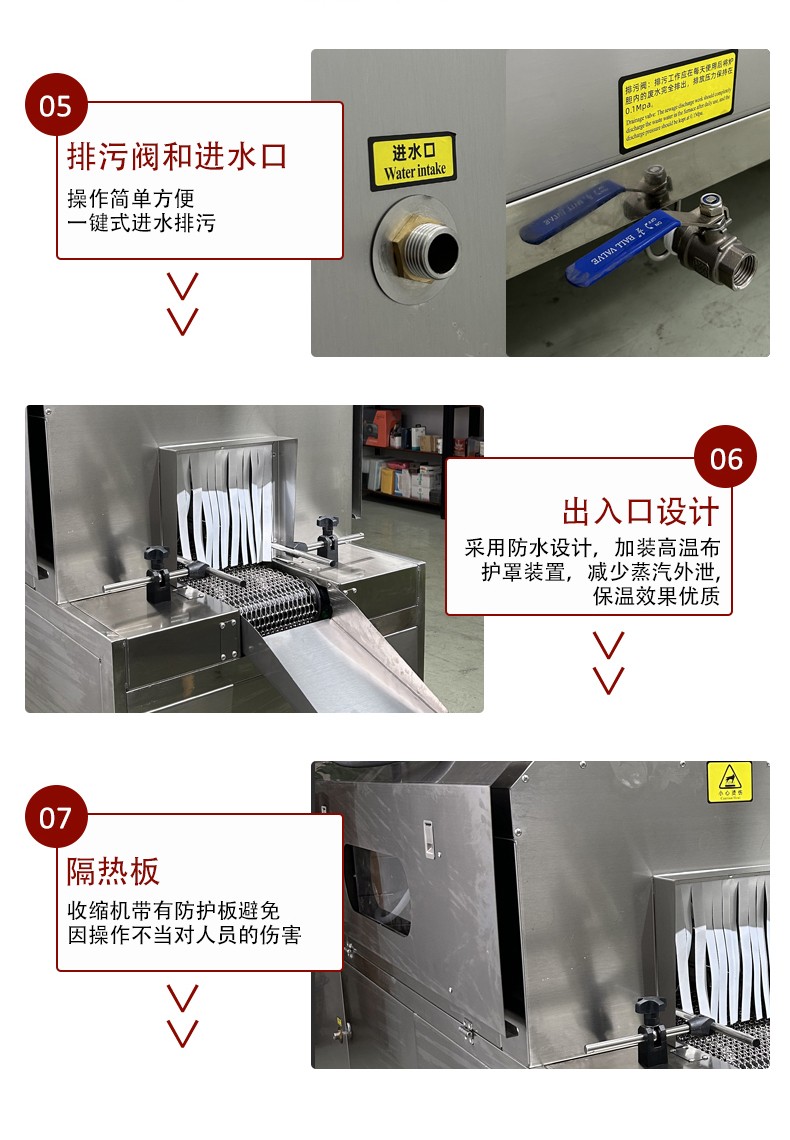

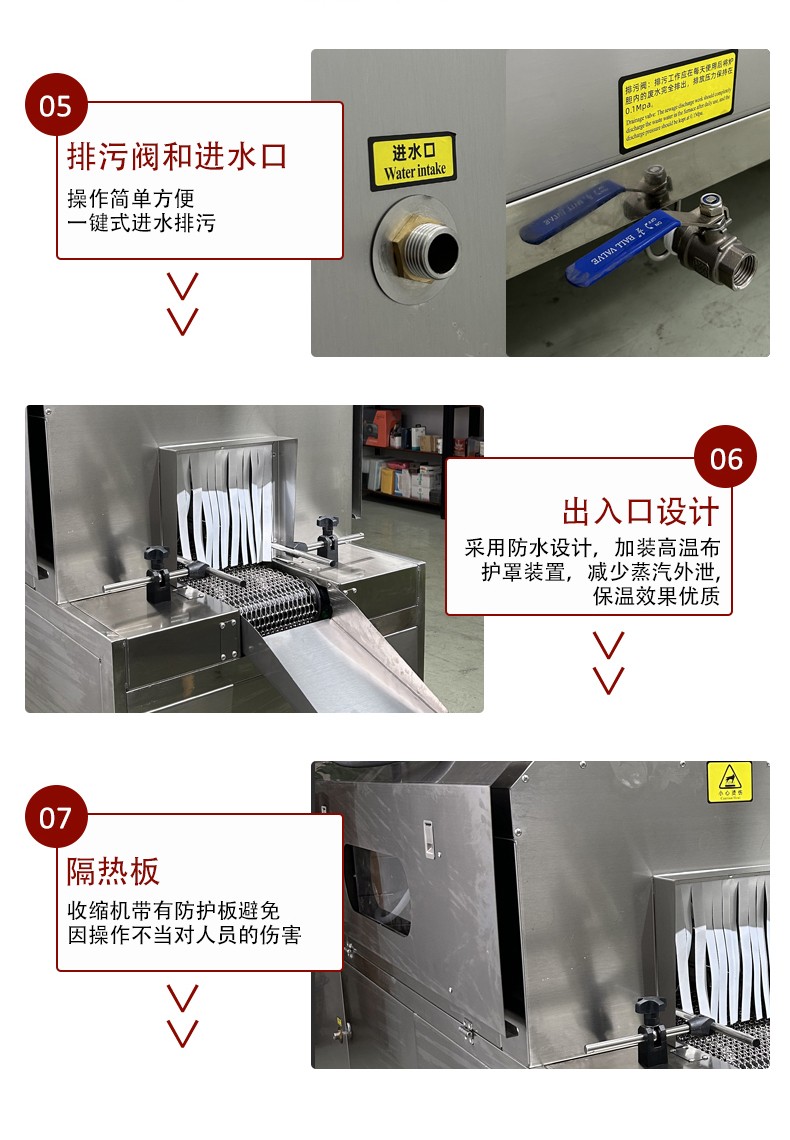

- Superior Sealing and Moisture Resistance: Some steam shrink machine models can be designed with sealed shrink tunnels. After shrinkage, the film edges have stronger sealing performance, effectively blocking dust and moisture. This is particularly suitable for food products (e.g., dried goods, snacks) and pharmaceuticals that have high requirements for storage environments.

The heating method of steam offers greater flexibility in adapting to different film thicknesses and materials:

- Compatible with Mainstream Film Types: Whether it is a thick film (e.g., PE film, commonly used for heavy-duty packaging and outer films of bottled water), a thin film (e.g., environmentally friendly POF film, used for small/large items and gift box packaging), or PVC cling film, the steam shrink machine can achieve precise shrinkage by adjusting steam pressure and conveyor speed. Unlike hot air shrink machines, it eliminates the need for frequent replacement of heating components or complicated debugging.

- Reduced Film Waste: Uniform heating prevents issues like localized overheating damage or insufficient shrinkage of the film, reducing material waste during the packaging process and saving consumable costs in the long run.

In terms of energy efficiency and operating costs, steam shrink machines have obvious advantages:

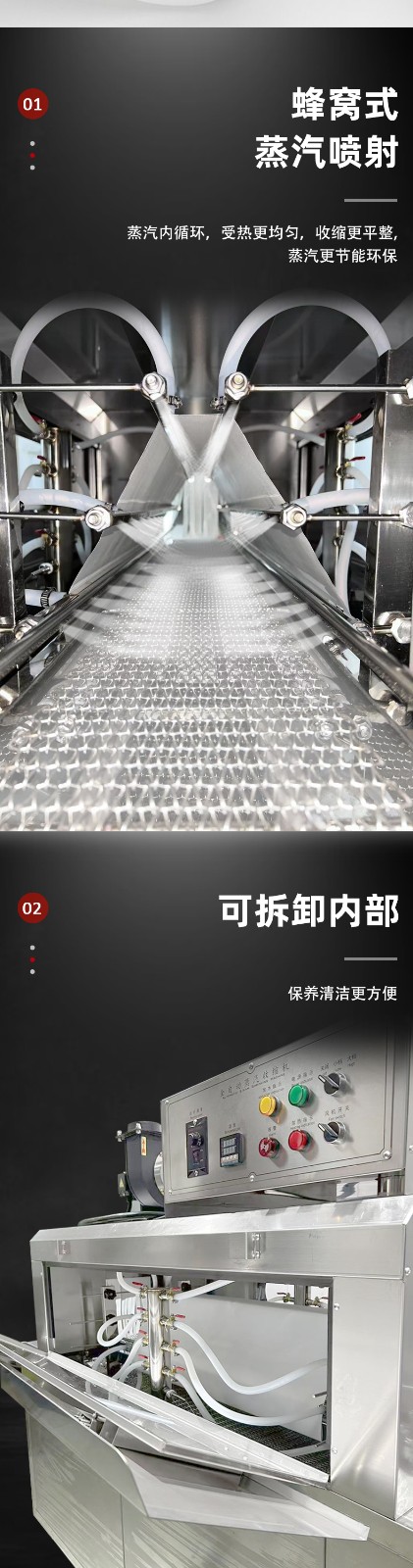

- High Heat Transfer Efficiency: The heat transfer efficiency of steam is approximately 90%, far higher than the 50%-60% of hot air (hot air machines first heat the air, then transfer heat through the air, resulting in significant heat loss). Under the same production capacity, steam shrink machines consume less electricity.

- Recyclable Resources: Some models are equipped with condensed water recovery devices. The condensed water generated can flow back into the steam generator, reducing water waste and further lowering long-term operating costs.

Compared with hot air shrink machines, steam shrink machines have lower thresholds for operation and maintenance:

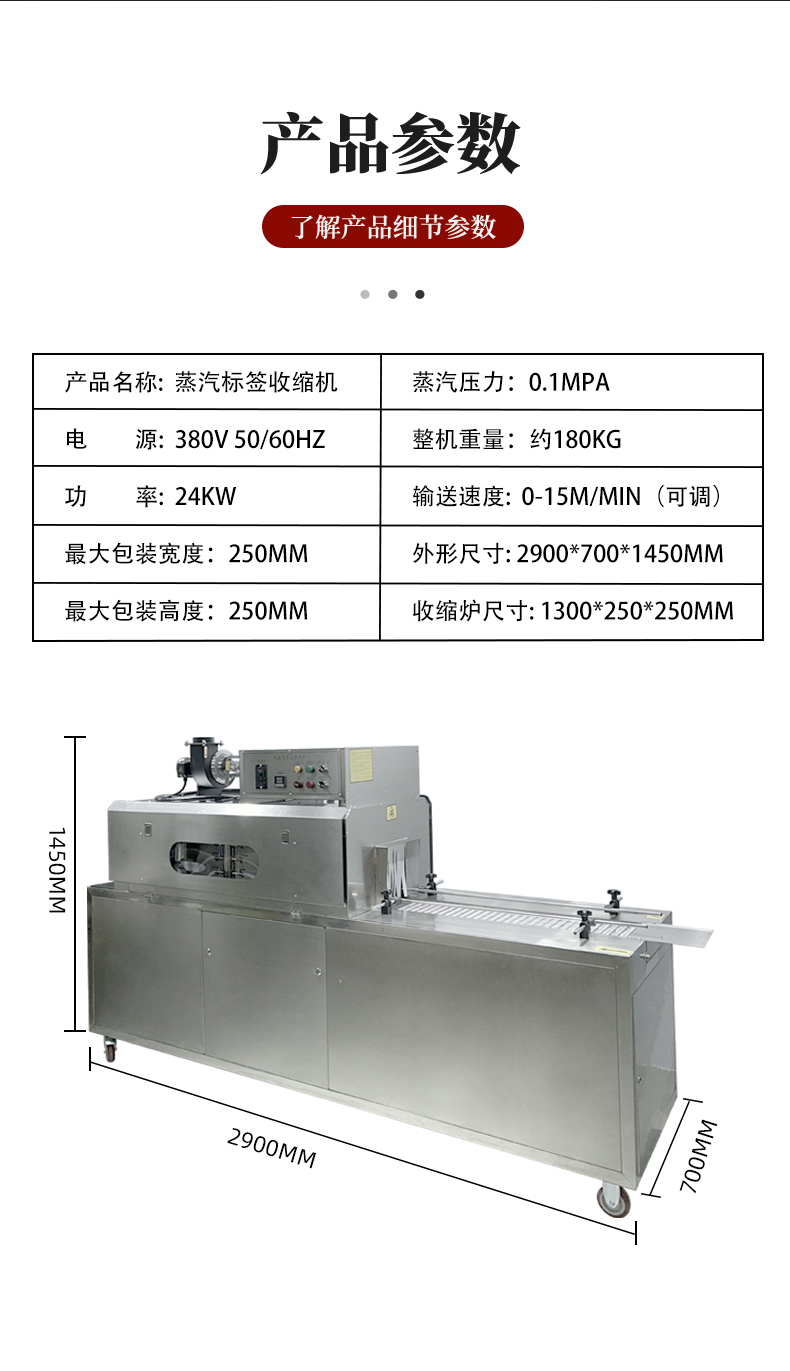

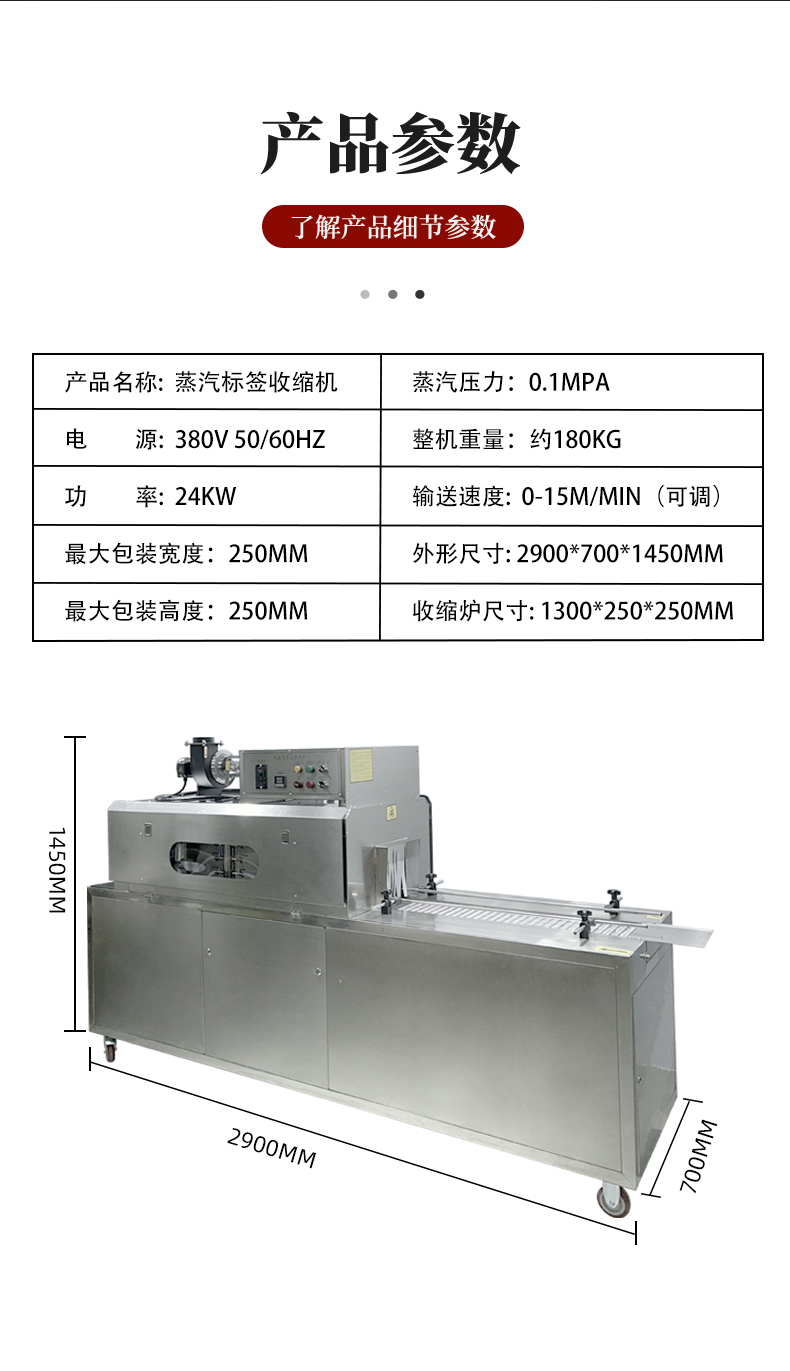

- Simple Parameter Adjustment: The core control parameters are only "steam pressure" (usually 0.2-0.5MPa) and "conveyor speed." Through a PLC control system, multiple sets of parameters can be preset. When switching between different products, there is no need for repeated testing, and the skill requirements for operators are low.

- Low Maintenance Costs: Core components (steam generator, nozzles) have a simple structure and are not prone to dust accumulation (unlike hot air machines, which suffer from dust buildup clogging air ducts due to fan circulation). Routine maintenance only requires regular descaling of the steam generator, reducing the frequency of component replacement and maintenance man-hours.