Turn off the machine’s main power switch and unplug the power cord. For pneumatic models, close the air supply valve and release residual air pressure in the air pipes (to prevent accidental actuation of the air cylinder).

- Crosshead/flathead screwdriver, hex key wrench (selected based on the type of fixing screws on the equipment);

- New heat-sealing strip (must match the original model’s length, width, and material. Common materials include Teflon-coated heat-sealing strips and pure copper heat-sealing strips; prioritize accessories consistent with the original specifications);

- High-temperature resistant silicone strip (if the buffer silicone strip under the heat-sealing strip is aged, simultaneous replacement is recommended);

- Cleaning cloth (for surface cleaning).

Ensure the heat-sealing unit is fully cooled (to avoid high-temperature burns) and wait 10–15 minutes before proceeding.

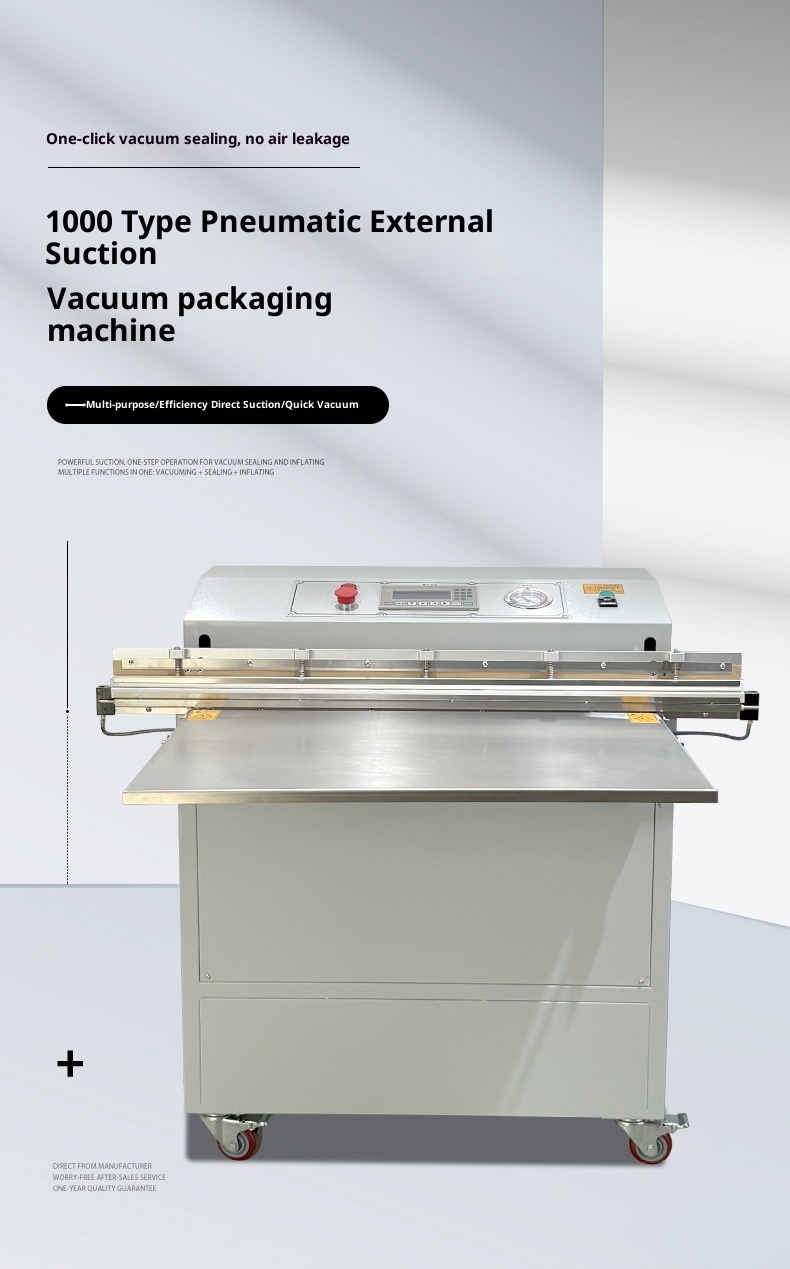

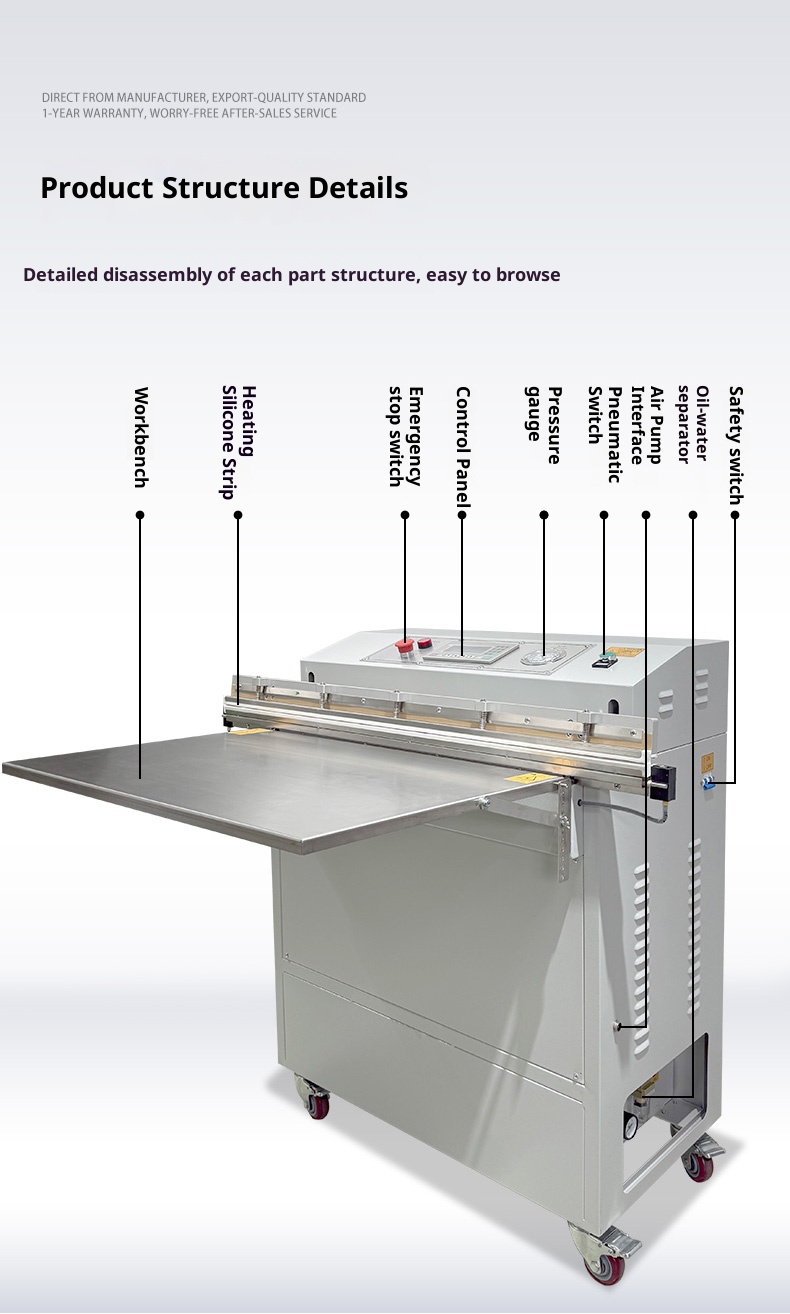

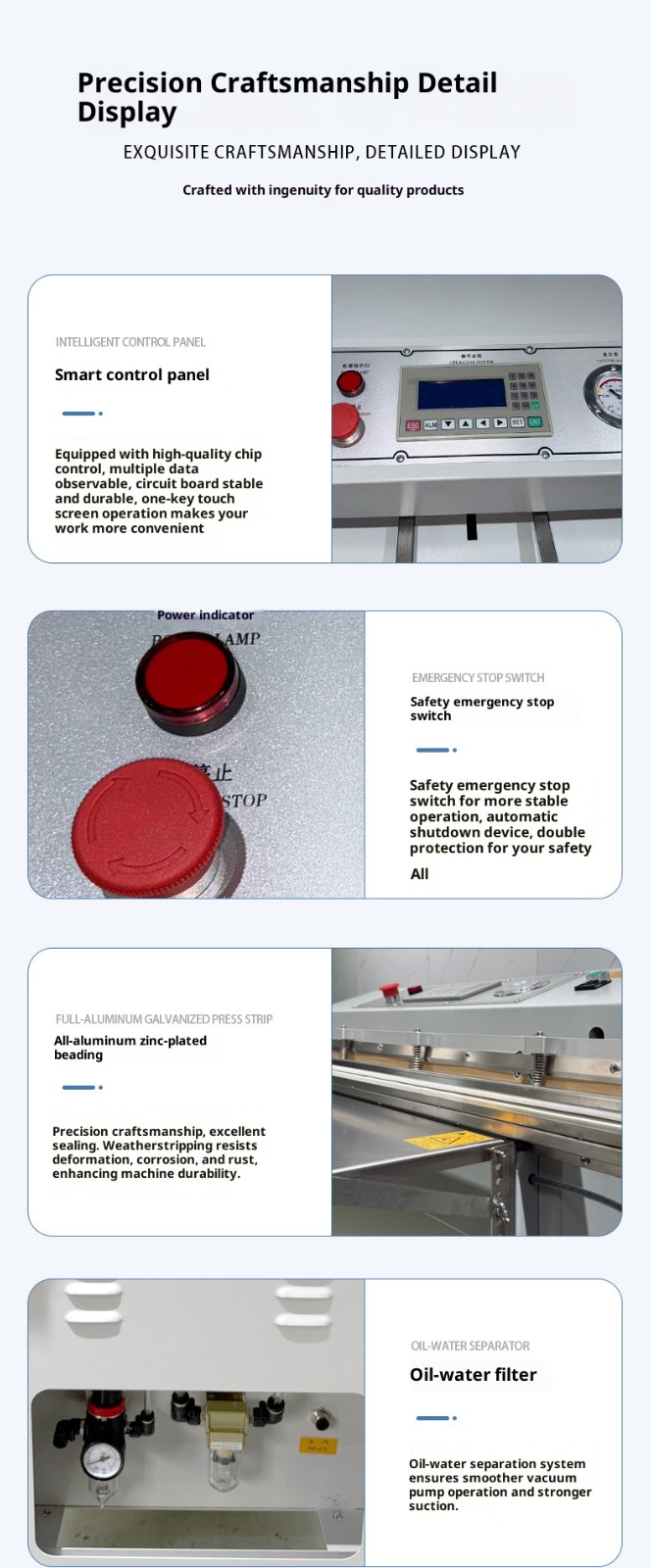

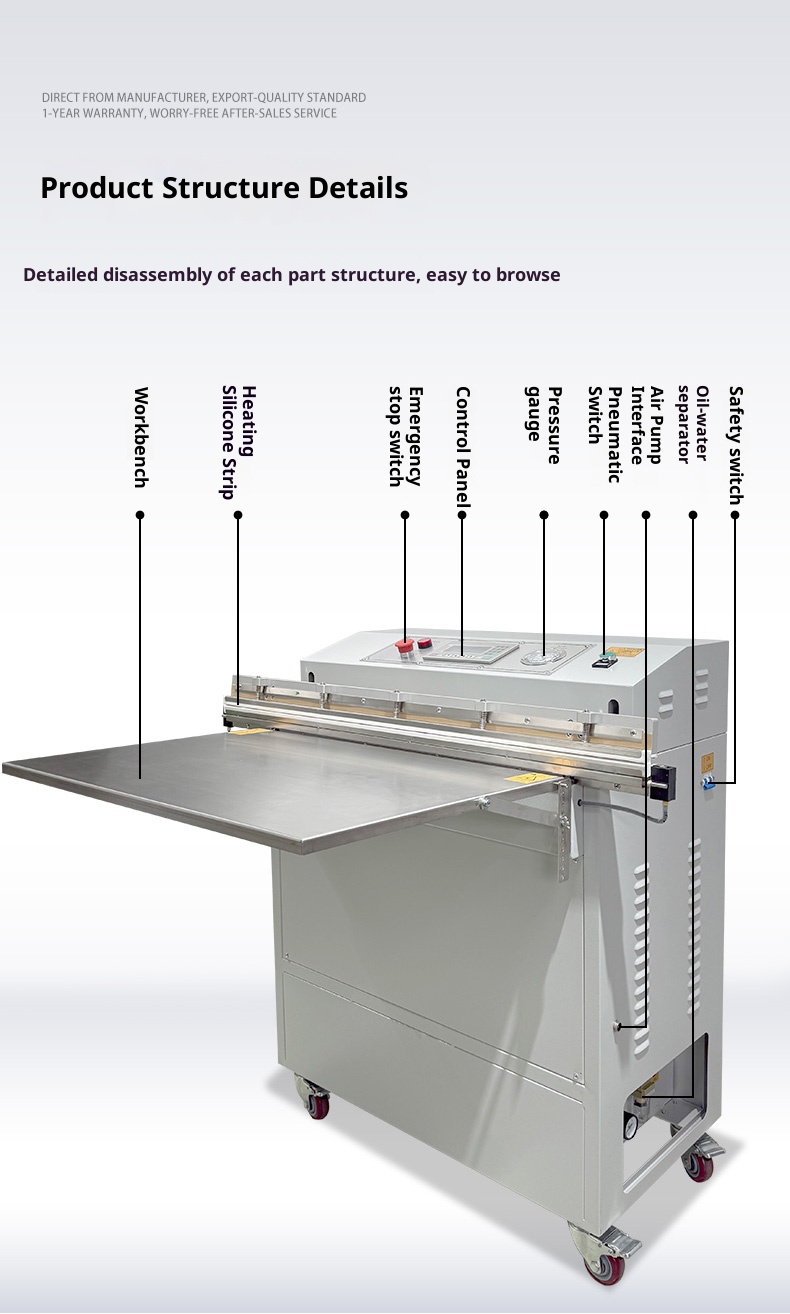

The heat-sealing strip of an external vacuum packaging machine is typically located beneath the air suction nozzle or at the sealing mechanism, with a metal protective shield on the exterior (to prevent accidental contact with high temperatures).

Use a screwdriver to remove the protective shield’s fixing screws (usually 2–4 screws), take off the shield, and expose the heat-sealing strip and connecting wires.

The two ends of the heat-sealing strip are generally connected to the heating circuit via wiring terminals (some models use screw-compressed wiring; others use plug-in connections).

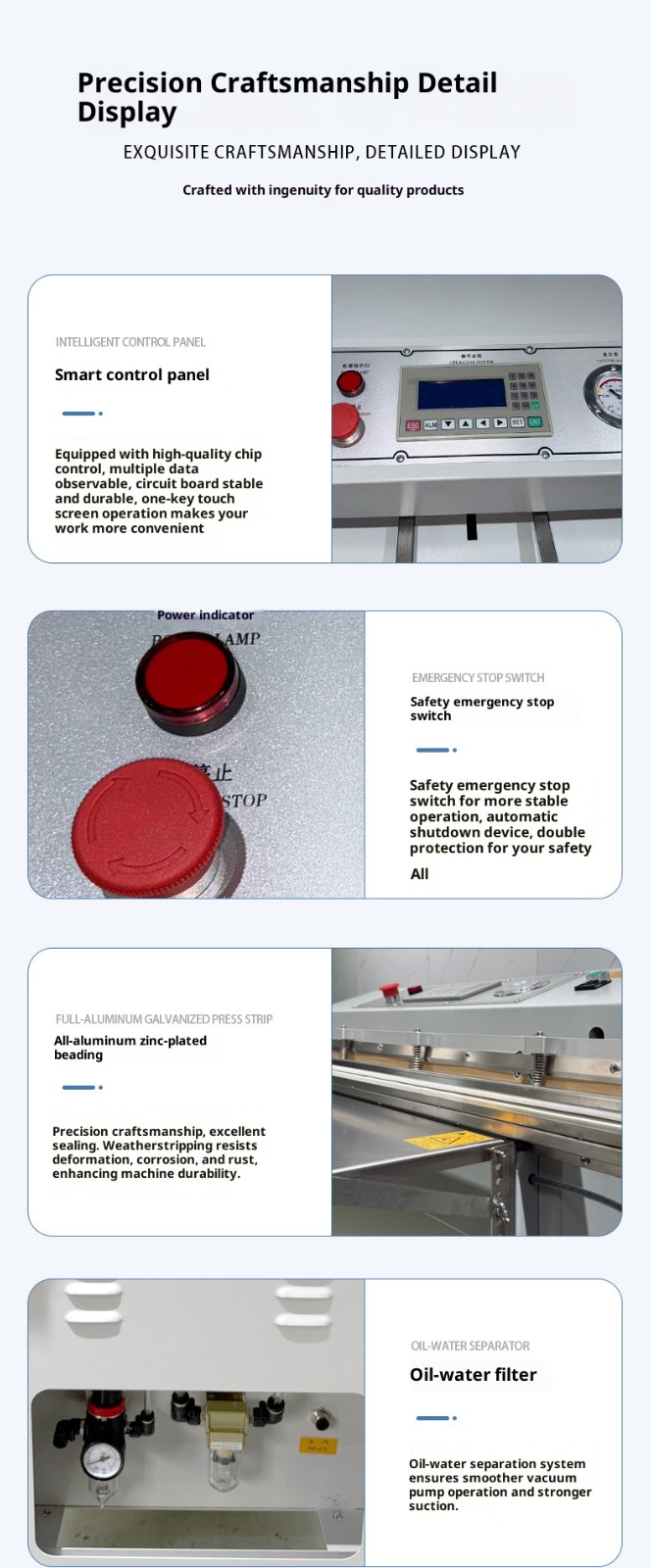

First, record the wiring configuration (take photos for reference to avoid reverse connection), then use a screwdriver to loosen the terminal fixing screws or gently pull out the plugs to separate the heat-sealing strip’s wires from the circuit.

Caution: The wires are thin—avoid excessive pulling to prevent breakage.

The heat-sealing strip is secured to the heat-sealing base by a pressure bar (metal or high-temperature resistant plastic) and screws. The pressure bar ensures the heat-sealing strip fits flat and tightly.

Use a screwdriver to sequentially remove the pressure bar’s fixing screws (evenly spaced along the length of the heat-sealing strip, usually 3–6 screws) and take off the pressure bar.

Gently extract the old heat-sealing strip (if adhered to the base, wipe the contact area with a cloth dampened with a small amount of alcohol to separate—do not pry forcefully).

Wipe the surface of the heat-sealing base with a dry cloth or an alcohol-dampened cloth (to remove oil stains, plastic residues, etc., which may affect the new strip’s fit).

Inspect the

buffer silicone strip under the heat-sealing strip (functions to cushion pressure during sealing and ensure uniform sealing): If the silicone strip is cracked, deformed, or hardened, replace it immediately (the new silicone strip must match the base size and can be directly inserted into the slot).

Take out the new heat-sealing strip, confirm its length and wiring terminals match the old one, and place it flat into the heat-sealing base’s slot (ensure both ends are aligned without deviation).

Cover with the pressure bar and sequentially tighten the fixing screws (apply even force to avoid pressure bar tilting, which may cause uneven stress on the heat-sealing strip and compromise sealing performance).

Caution: The heat-sealing strip’s heating surface (usually the smooth side) must face upward to contact the packaging bag; if Teflon-coated, the coated side should face the bag to prevent coating wear.

Following the recorded wiring configuration, connect the new heat-sealing strip’s wires to the terminals, tighten the fixing screws (or secure the plugs firmly) to ensure stable connections (avoid poor contact leading to uneven heating).

Check for wire tangling or pressure to eliminate short-circuit risks.

Replace the heat-sealing unit’s protective shield and tighten the fixing screws.

Connect the power and air supply, start the machine, set a low heat-sealing temperature (e.g., 120℃) and short sealing time (e.g., 1 second), and perform an idle test:

- Verify uniform heating of the heat-sealing strip (check by touching the shield’s exterior or using temperature test paper).

- Insert an empty packaging bag and conduct a vacuum sealing test. Inspect the seal for flatness, no leakage, and no scorching (if the seal is loose, adjust the temperature appropriately; if scorching occurs, reduce the temperature or time).

After replacement, perform 5–10 consecutive sealing tests to confirm seal integrity and flatness. Only put the machine into formal use if no abnormalities are detected.

For the first use of the new heat-sealing strip, gradually adjust from low temperature/short time to normal parameters to prevent coating damage from sudden high temperatures.

After 1–2 days of use, recheck the pressure bar screws for loosening (vibration during operation may cause loosening) and retighten as needed.

- Heat-sealing strip not installed flat (readjust the strip position and retighten pressure bar screws);

- Poor wiring contact (retighten wiring terminals);

- Aged buffer silicone strip (replace with a new one if not previously replaced).

- Excessively high heat-sealing temperature (lower the temperature);

- Worn heat-sealing strip coating (replace with a Teflon-coated strip).

- Reverse wiring (adjust according to previously taken photos);

- Blown fuse (inspect the heating circuit fuse in the machine’s power box and replace if damaged).

- When replacing accessories, use only heat-sealing strips compatible with the original model (strips of different power or size may cause circuit malfunctions or sealing failure). Purchase from the equipment manufacturer or authorized suppliers.

- Avoid direct contact with the heat-sealing strip’s heating surface during operation, and exercise caution to prevent burns during post-installation testing.