The core of fault prevention for vertical sealing, cutting and heat shrinking packaging machines lies in standardized operation, regular maintenance and potential hazard troubleshooting in advance, so as to fundamentally reduce common faults such as film jamming, poor sealing and cutting, and uneven shrinking. The specific measures can be divided into the following 5 categories:

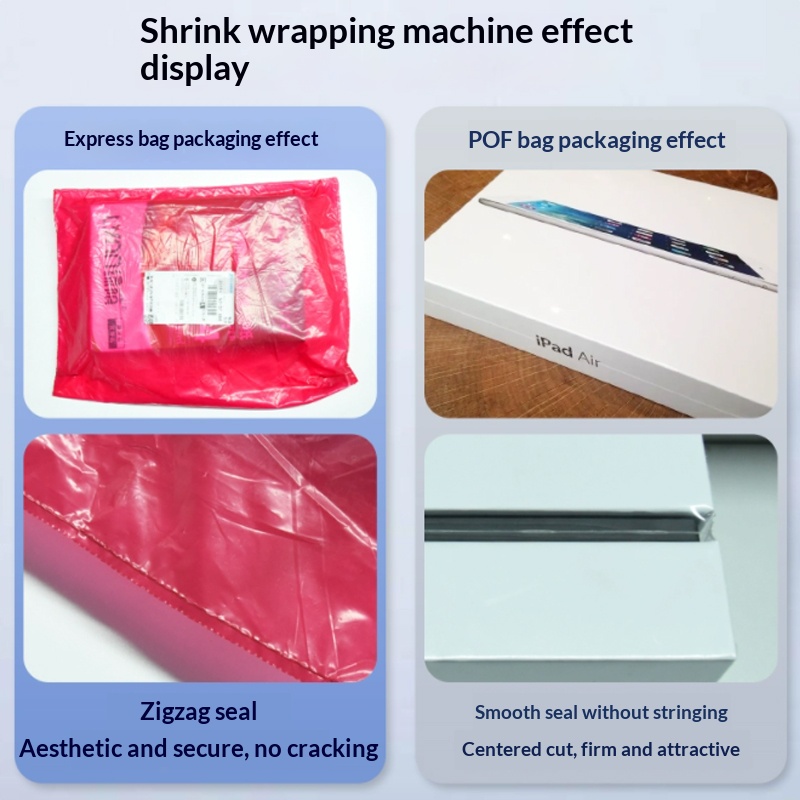

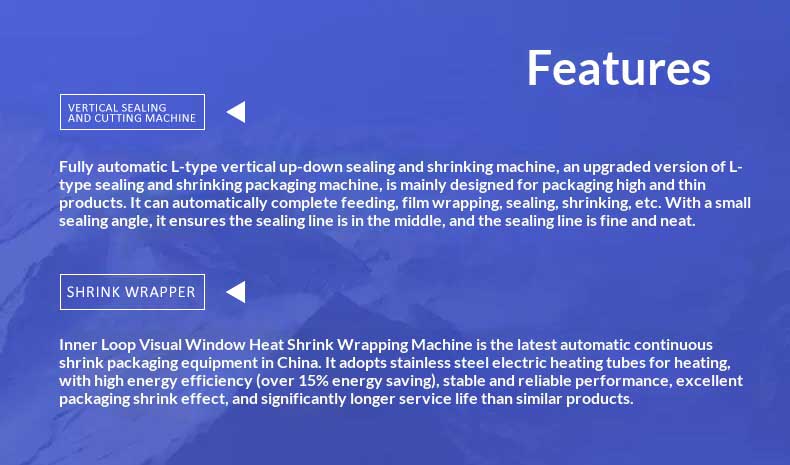

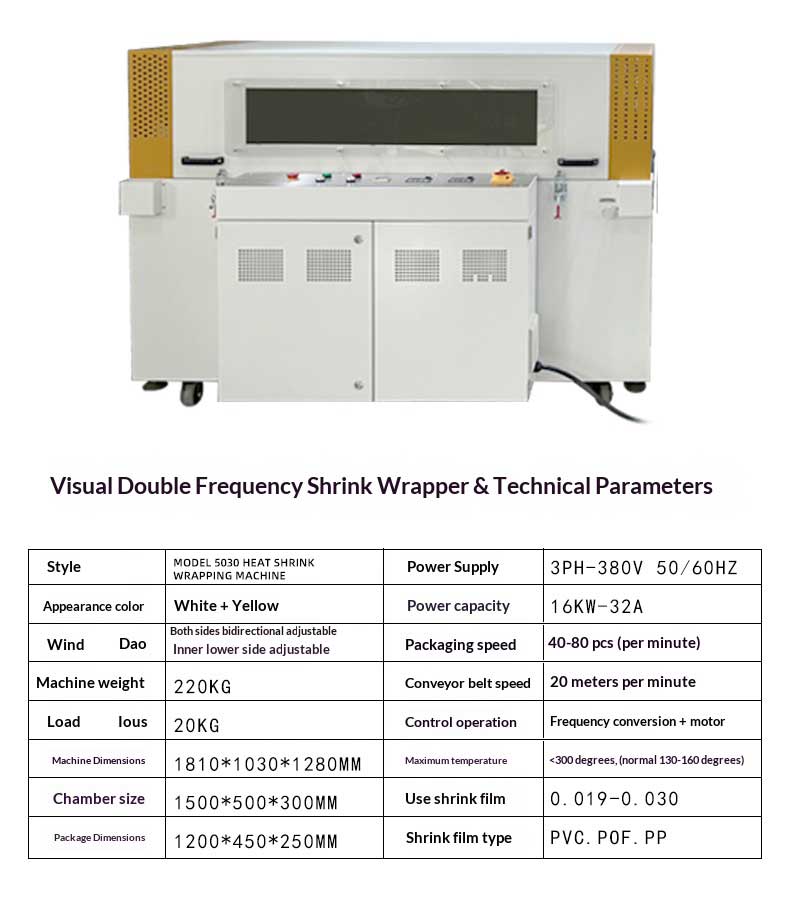

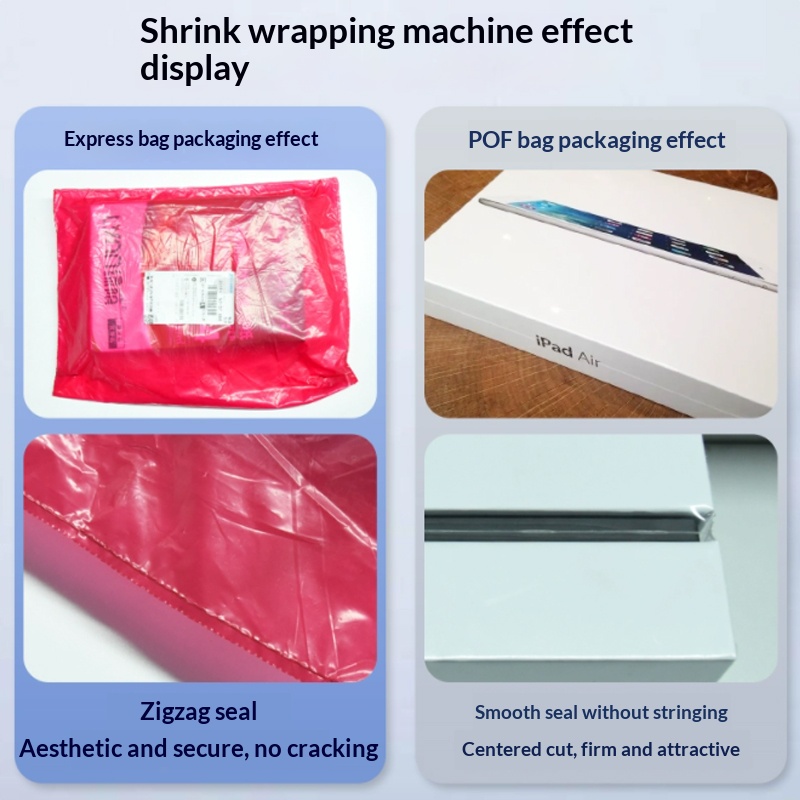

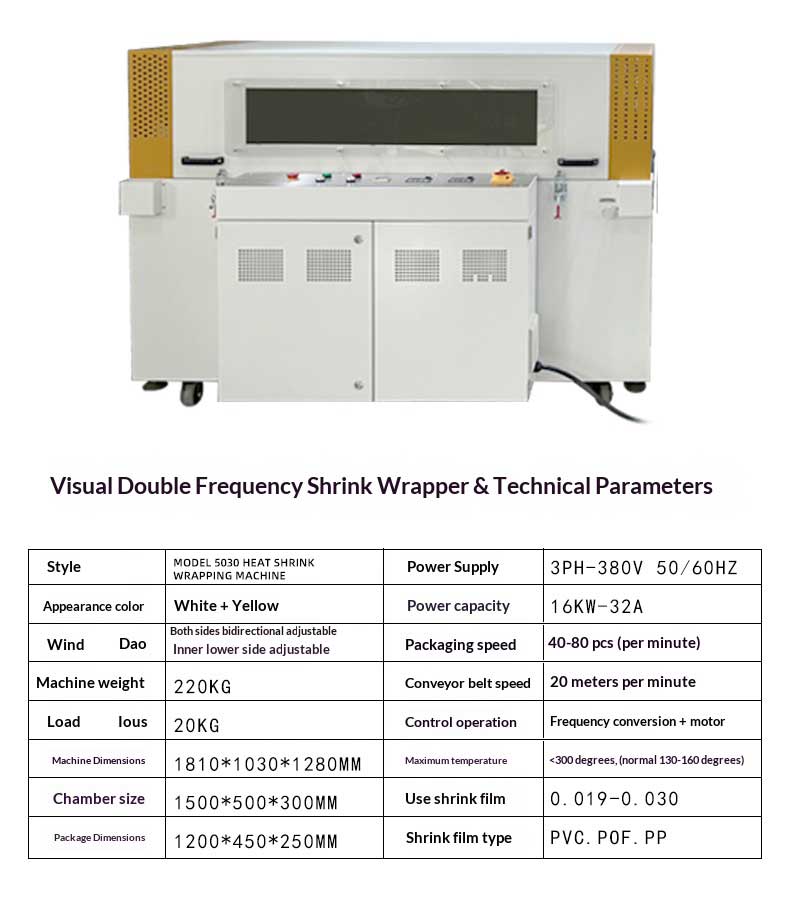

- Strictly use the film type and thickness calibrated for the equipment: For example, machines marked to be compatible with POF film (0.015-0.03mm) should not be mixed with thick PE film or inferior PVC film, so as to prevent film jamming and sealing cracking caused by excessive film feeding resistance and mismatched sealing and cutting temperatures.

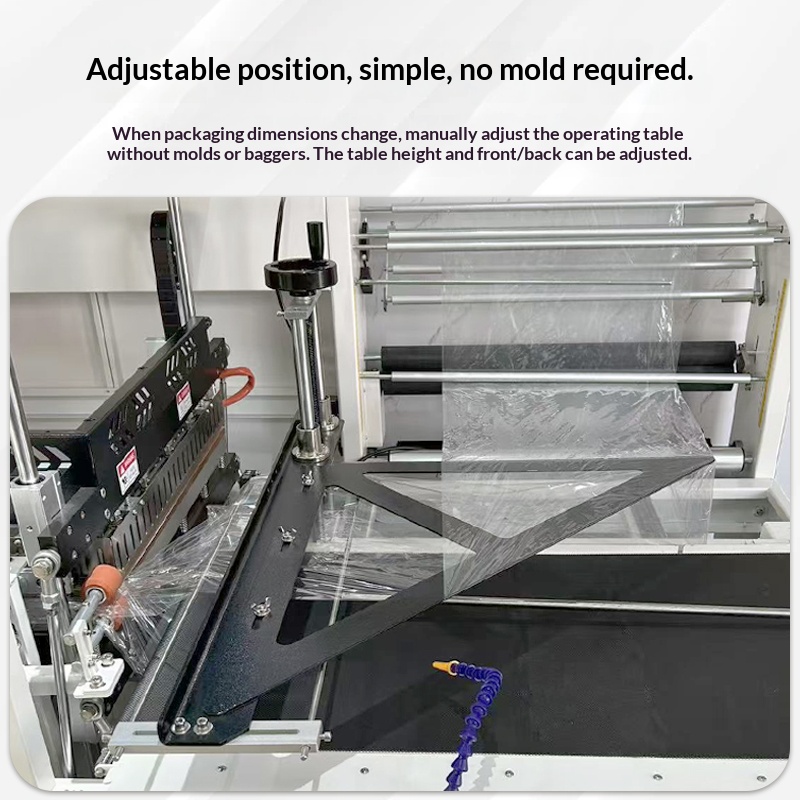

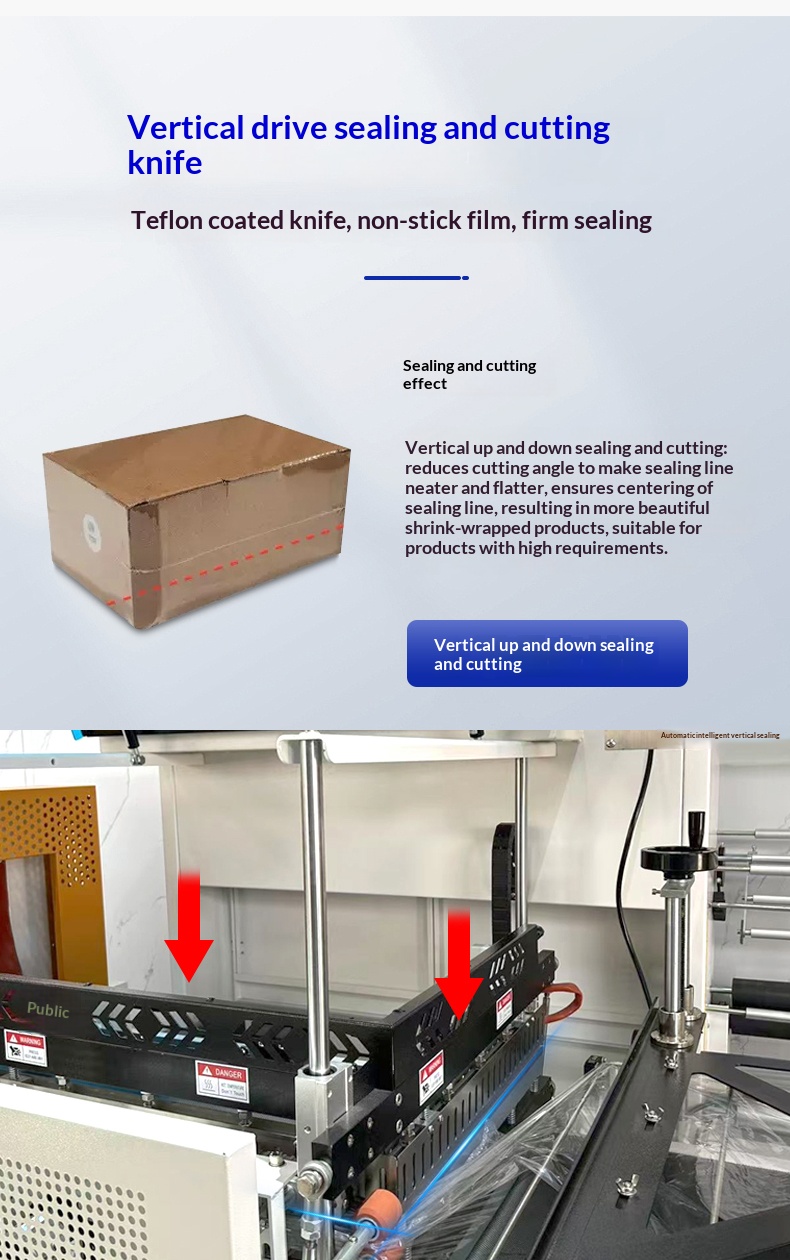

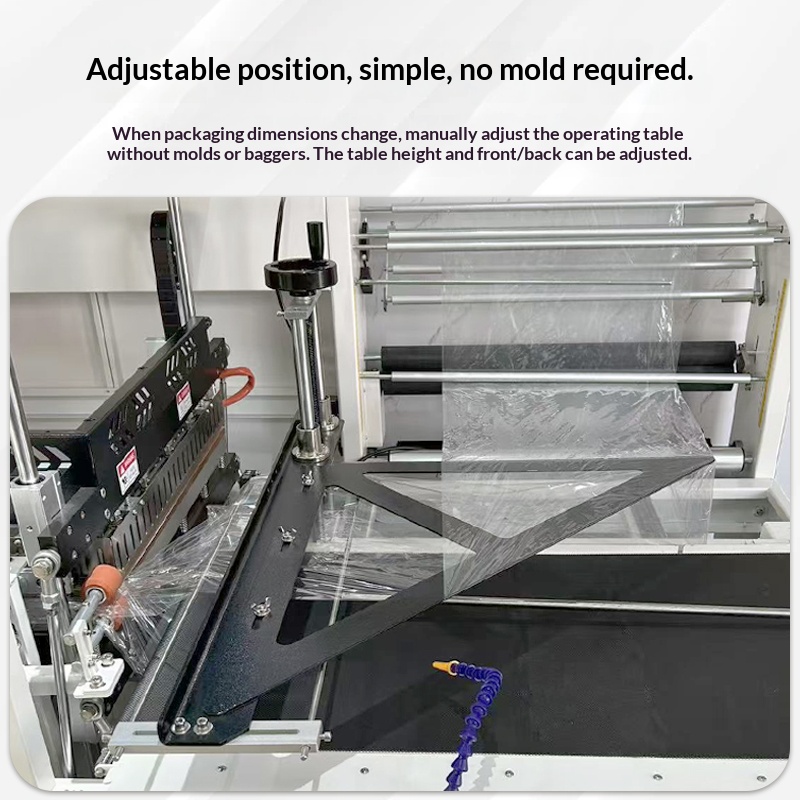

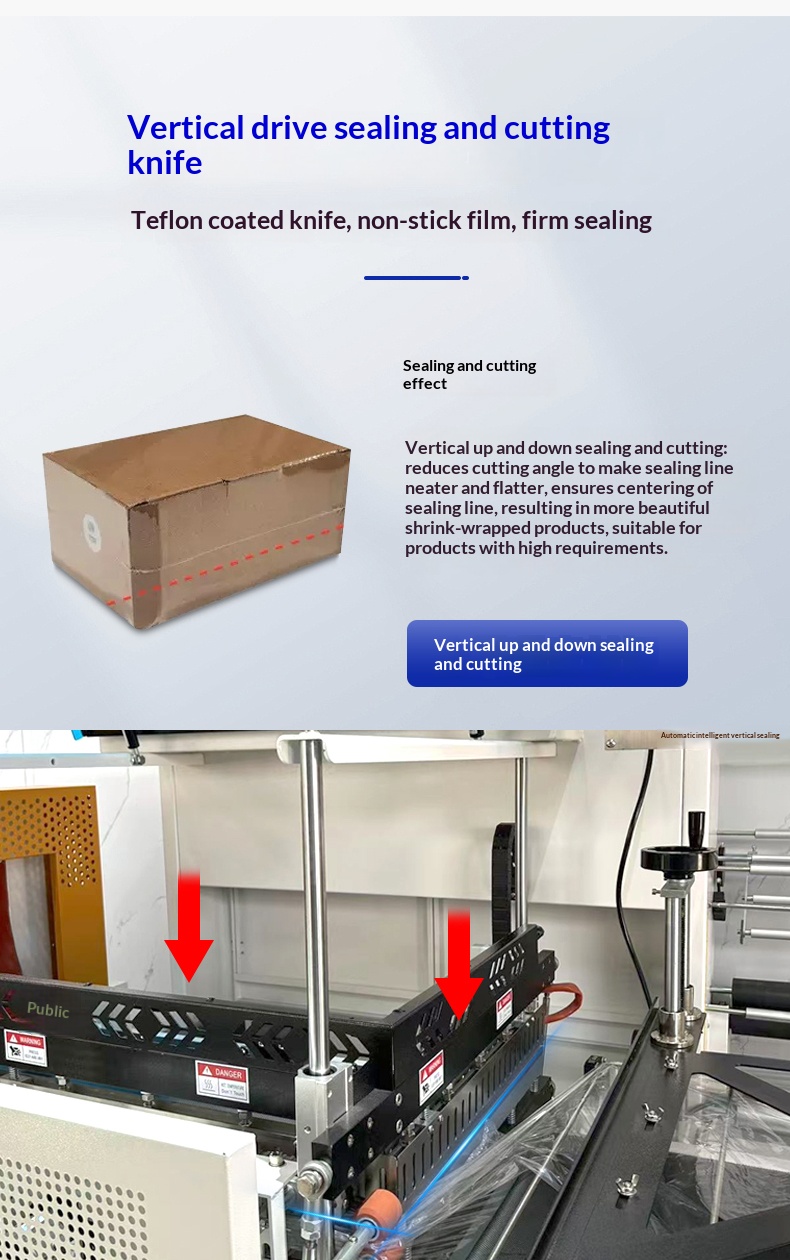

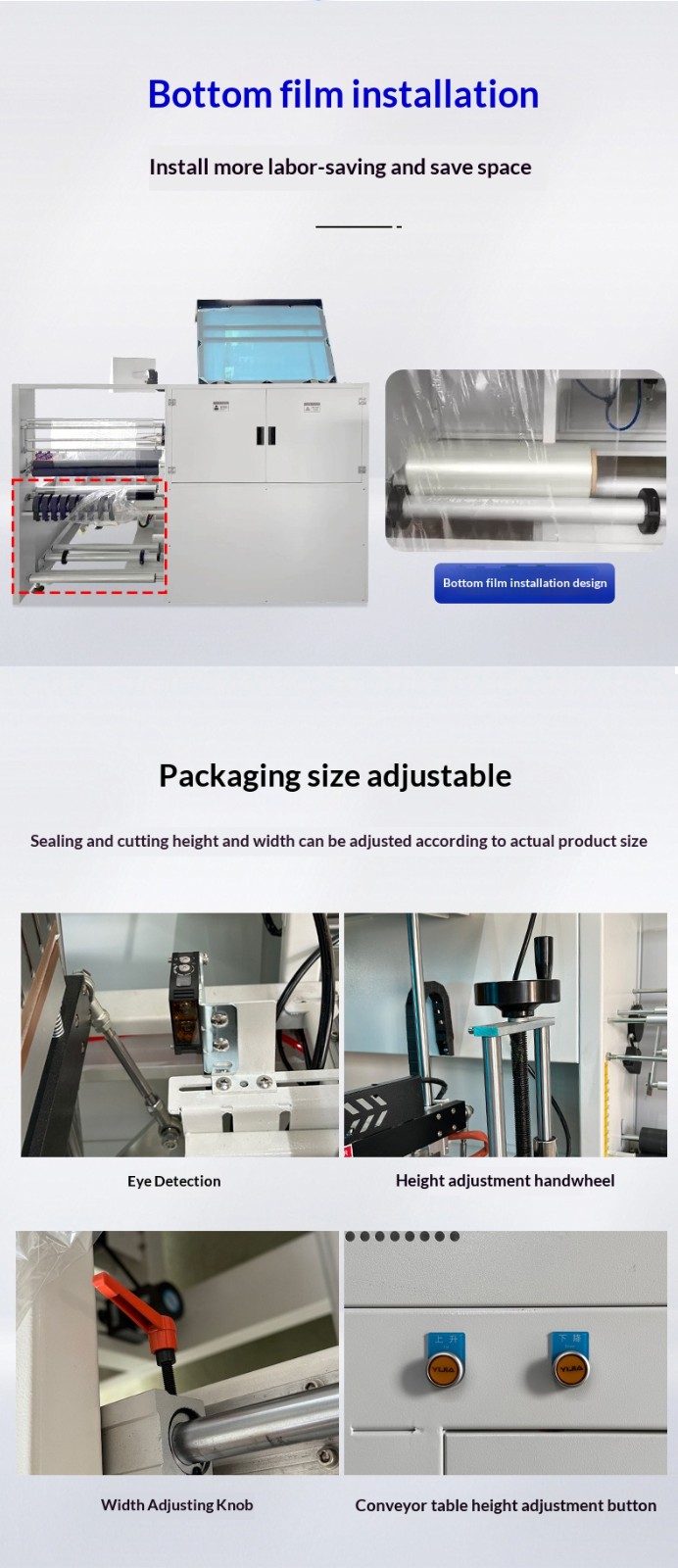

- Ensure product dimensions do not exceed limits: Do not package products that exceed the maximum length, width and height of the equipment, to avoid conveying jams and collision damage to the sealing and cutting knife; positioning fixtures should be installed for special-shaped products to prevent sealing and cutting misalignment caused by conveying deviation.

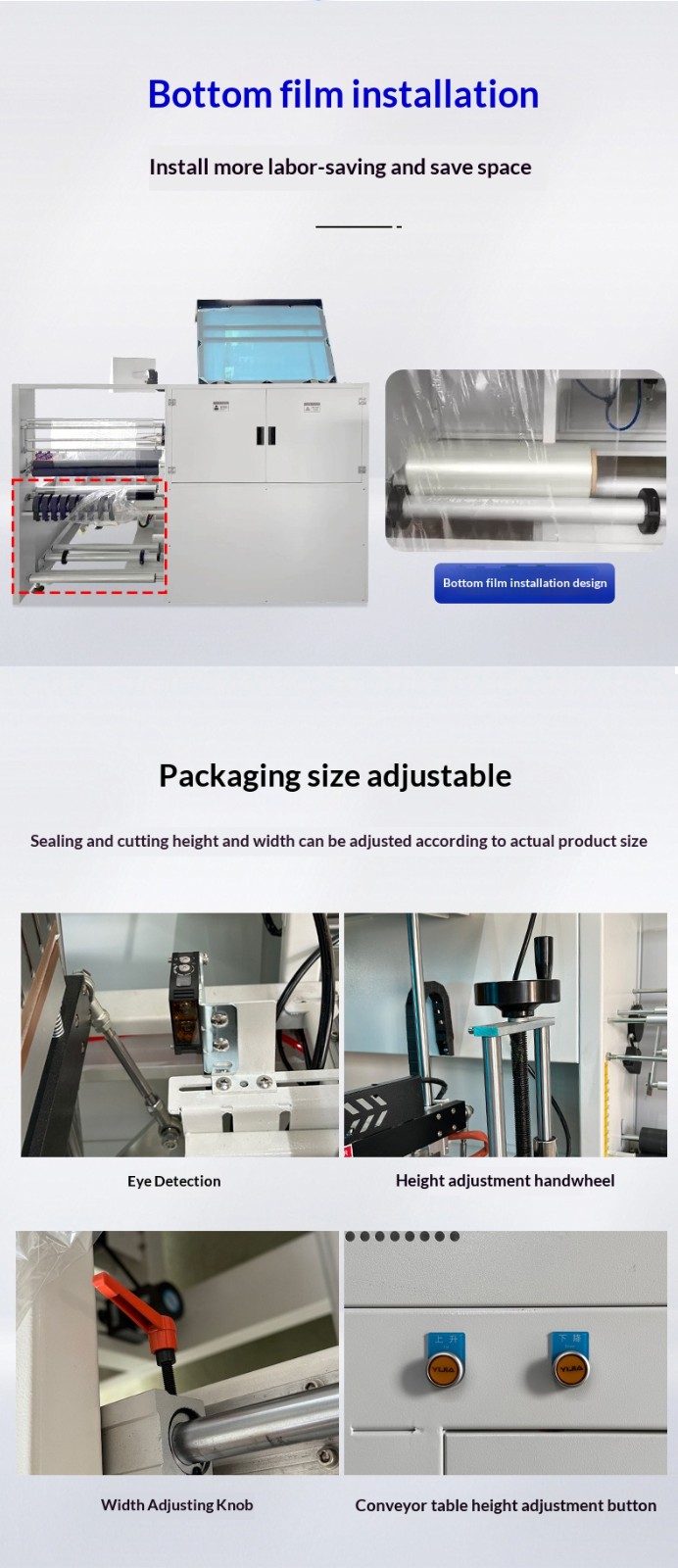

- Install film rolls smoothly: Align film rolls with guide rollers during installation to avoid edge wrinkling; meanwhile, clean dust and impurities on the surface of film rolls to prevent impurities from being caught in the sealing and cutting knife and affecting sealing quality.

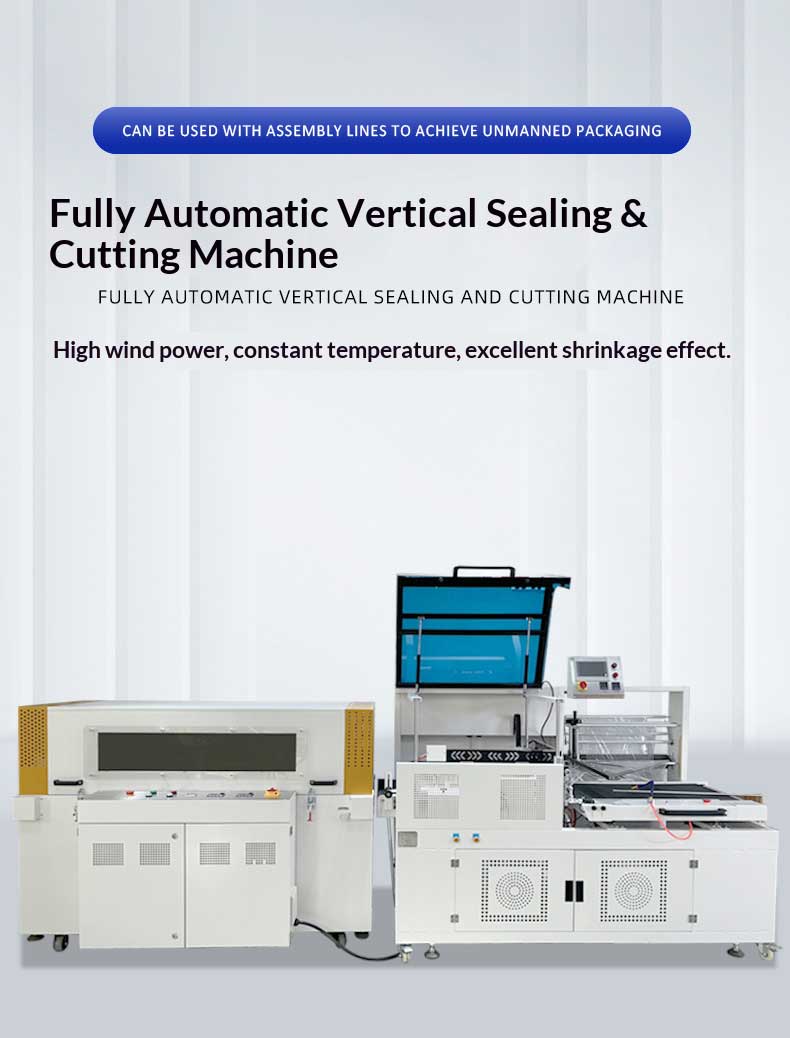

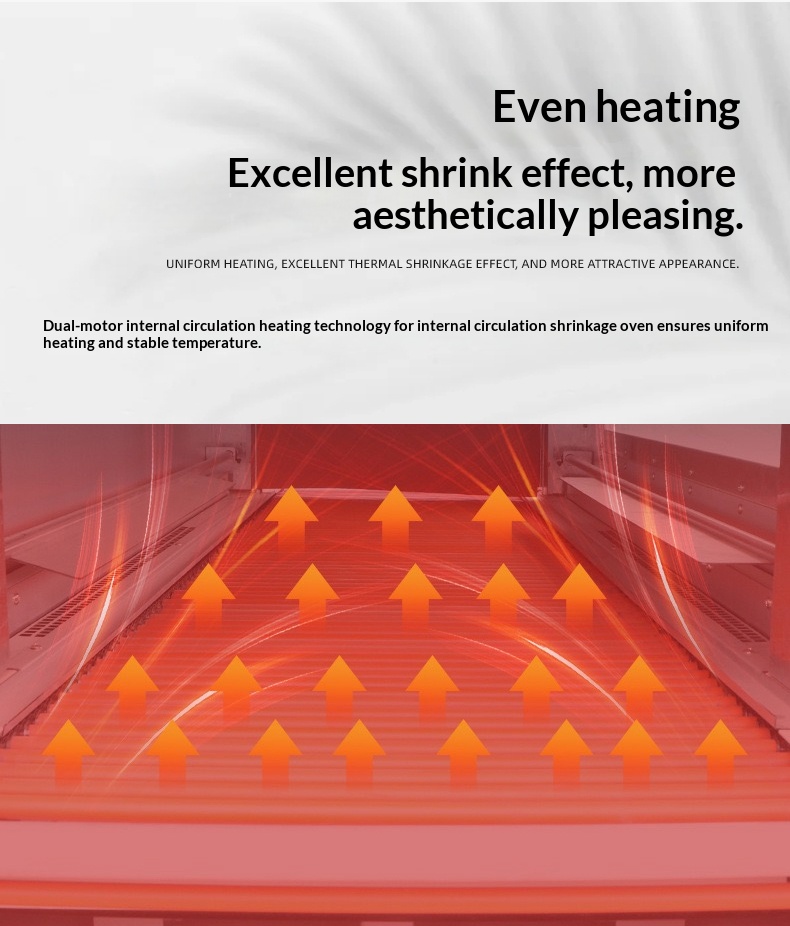

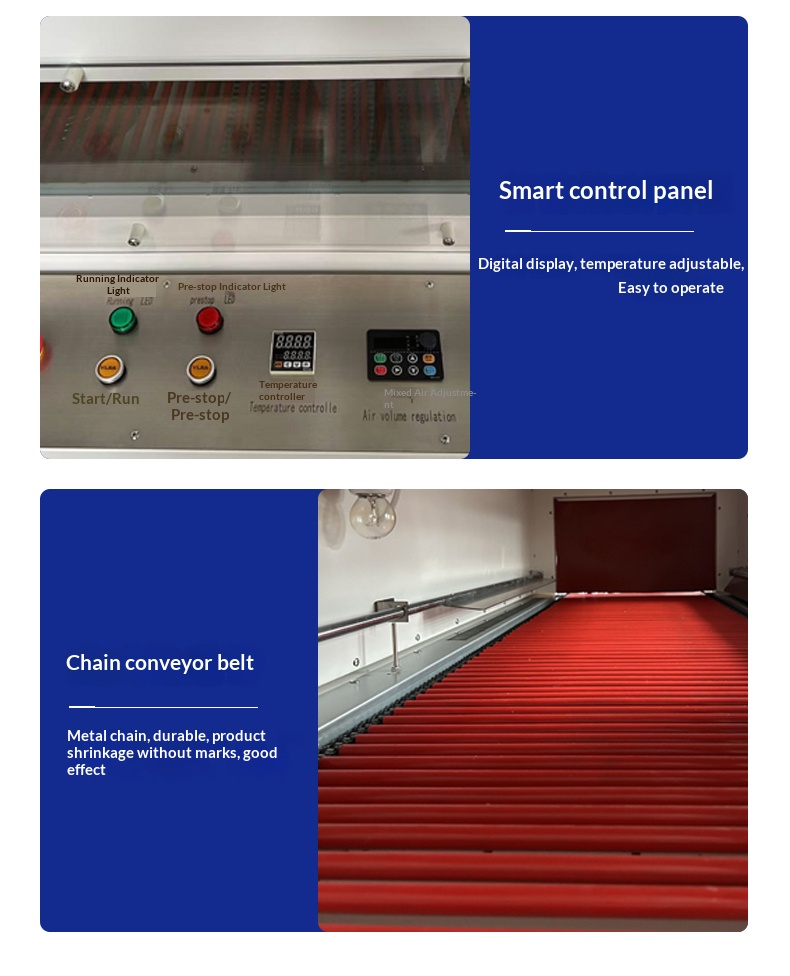

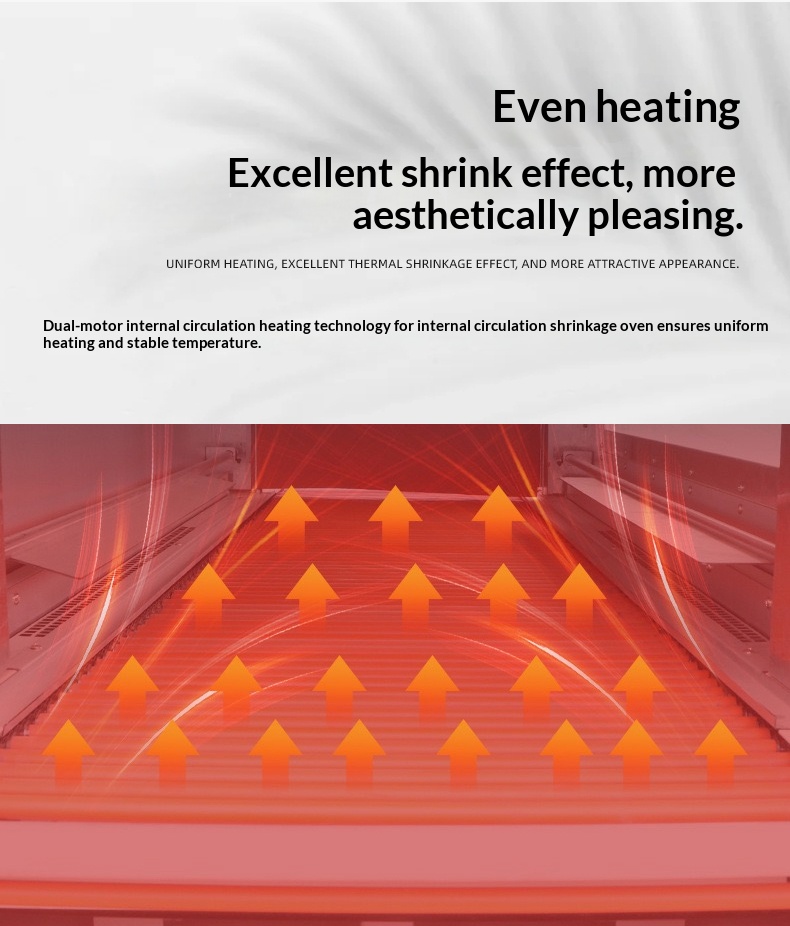

- Perform preheating checks before startup: Preheat the sealing and cutting knife and heat shrinking oven to the set temperatures in accordance with the instruction manual (usually 180-220℃ for the sealing and cutting knife and 120-160℃ for the heat shrinking oven); do not start operation before reaching the required temperatures to prevent weak sealing due to low-temperature processing.

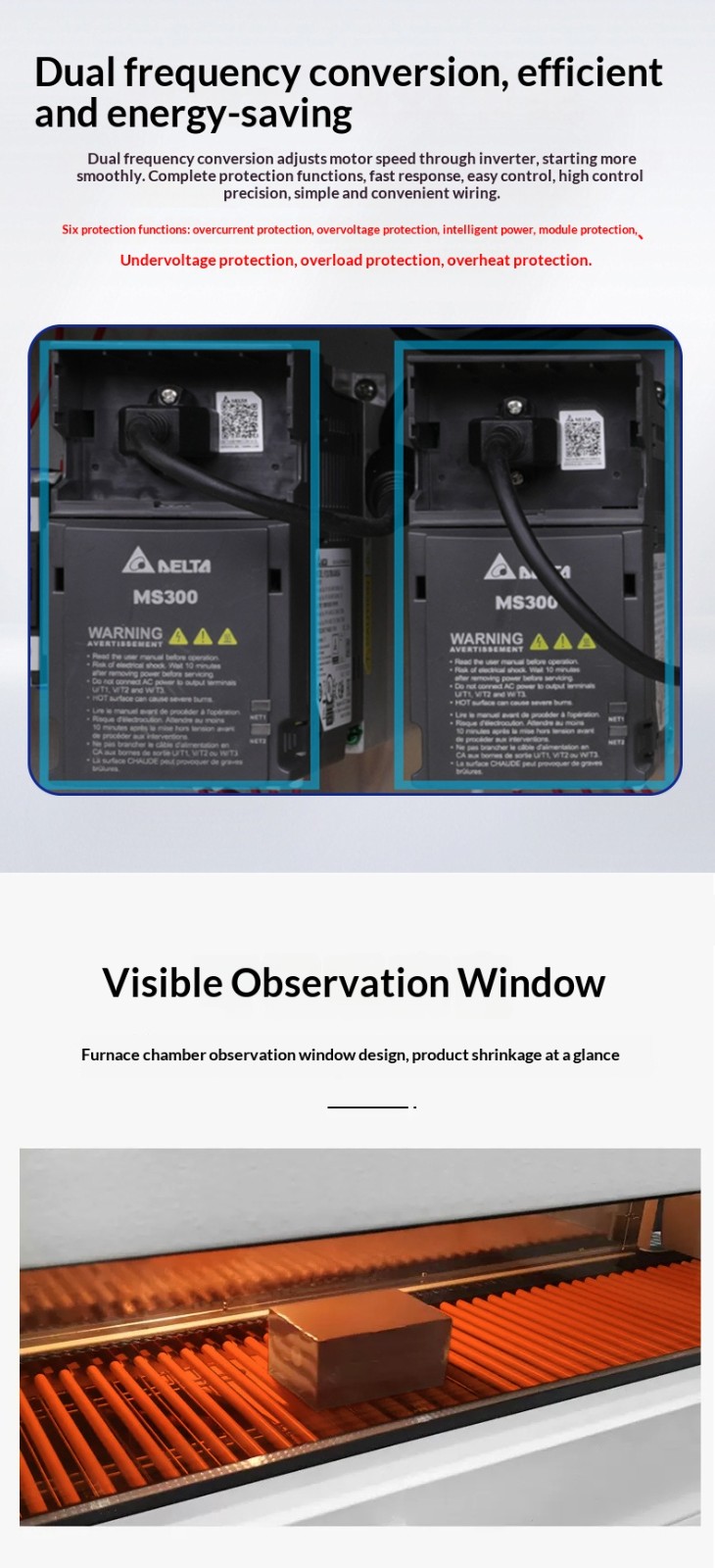

- Prohibit frequent start-stop or emergency stop operations: Repeated switching on and off within a short period can easily damage the motor and temperature control system; do not press the emergency stop button unless under emergency circumstances, to avoid failures of transmission mechanisms and electrical components caused by instantaneous impact.

- Recalibrate parameters during product changeover: When switching to products of different sizes, adjust the conveyor belt speed, sealing and cutting knife position and heat shrinking oven temperature, and save the settings to the parameter memory bank, to prevent uneven shrinking and sealing deviation caused by using old parameters for new products.

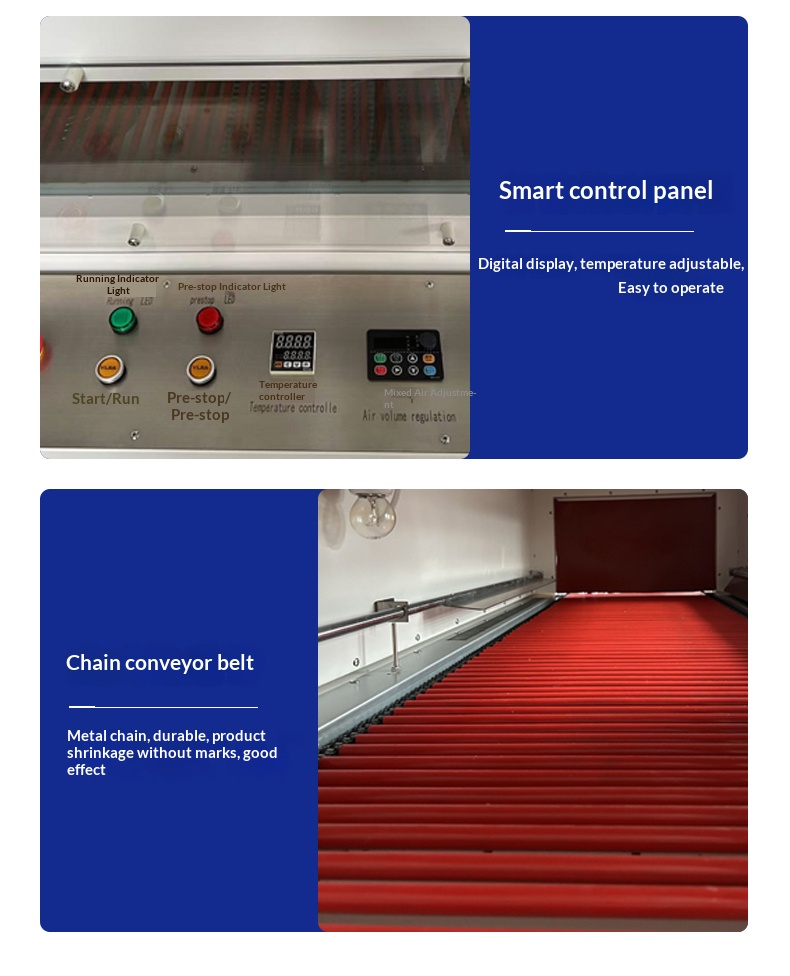

- Regularly lubricate transmission components: Add special lubricating oil/grease to chains, gears and rollers weekly to avoid abnormal noise and unstable rotation speed caused by dry friction; note that lubricating oil should not drip onto the conveyor belt and sealing and cutting knife.

- Replace vulnerable parts in advance: Check monthly whether the edge of the sealing and cutting knife is blunt, whether the silicone pressure strip is deformed, and whether the conveyor belt is aged or cracked; replace worn parts in a timely manner to prevent problems such as uneven sealing and conveyor slippage.

- Conduct regular inspections of the electrical system: Check monthly whether the wiring terminals are loose, whether the heating tubes generate heat normally, and whether the temperature control probes are sensitive, to prevent local heating failure and temperature control malfunction caused by poor contact.

- Place the equipment in a dry, well-ventilated and dust-free workshop environment: Humid conditions can easily cause short circuits of electrical components; excessive dust will block the air outlet of the heat shrinking oven and adhere to the surface of heating tubes, reducing efficiency—dust covers can be installed for protection.

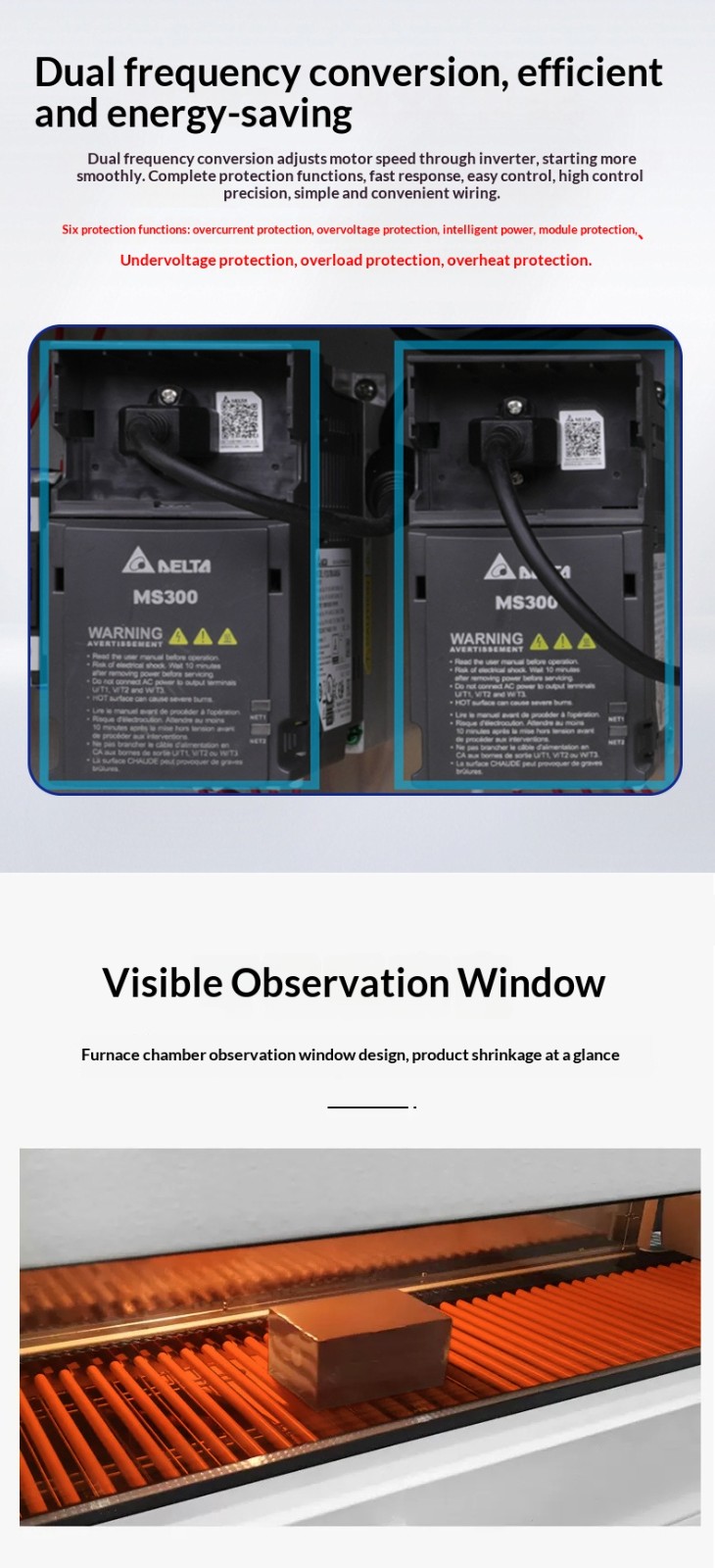

- Avoid the impact of voltage fluctuations: Connect the equipment to an independent stabilized power supply to prevent voltage instability caused by the startup and shutdown of high-power equipment in the workshop, which may damage core components such as frequency converters and motors.

- Implement proper protection during long-term shutdown: Cut off the main power supply if the equipment is out of service for more than 3 days, clean residues inside the equipment, and cover the entire machine with a dust cover to prevent dust from entering the transmission and electrical systems.