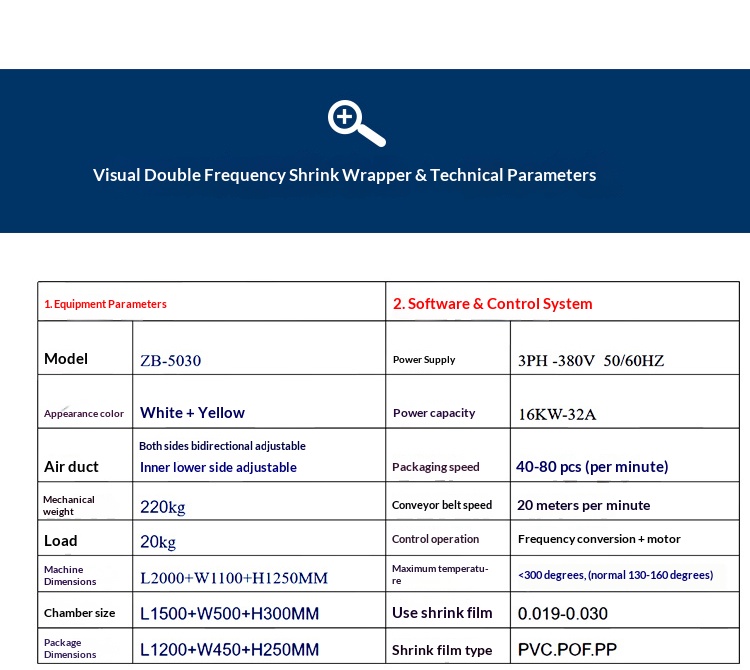

The visual dual-inverter heat shrink machine achieves precise temperature control and uniform shrinkage through the synergy of multiple core technologies. It not only solves problems such as large temperature fluctuations and shrinkage dead zones of traditional heat shrink machines but also adapts to the packaging needs of different products and films. The specific technical implementations and advantages are as follows:

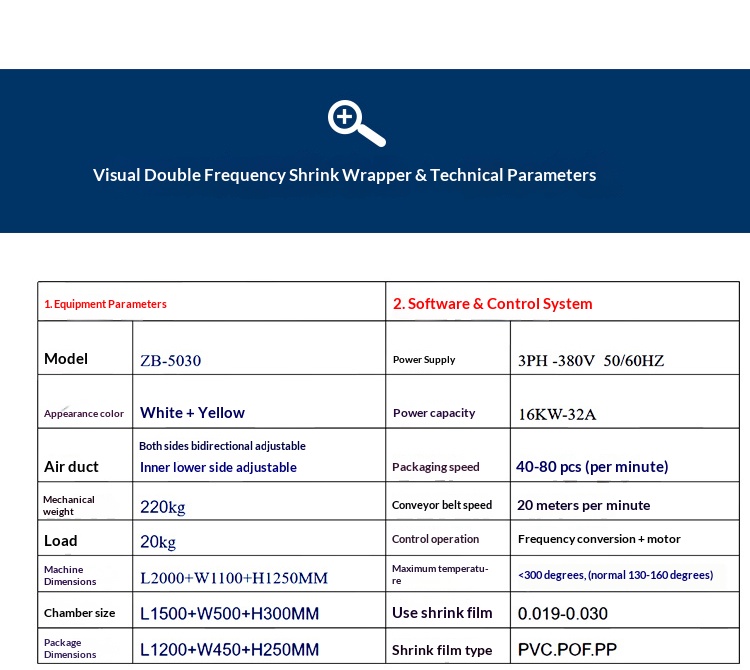

Equipment is generally equipped with a PID intelligent temperature control module combined with solid-state relays, which can accurately capture temperature changes in the furnace and adjust quickly, controlling temperature fluctuations within ±1℃. Meanwhile, multiple distributed temperature sensors are arranged in the furnace chamber to monitor temperatures in different areas (upper, middle, lower, etc.) in real time. Data is then integrated through a PLC programmable logic controller to avoid local temperature abnormalities. For example, it can accurately match temperature curves for different requirements: 100-140℃ for POF film and 130-180℃ for PP film.

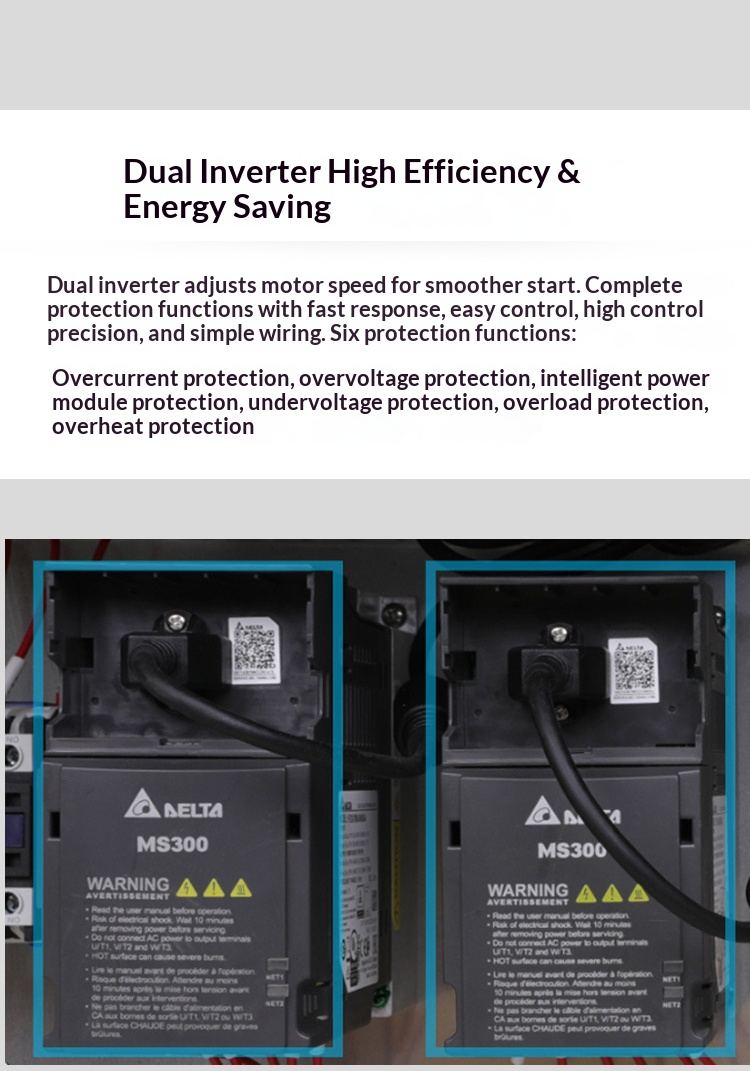

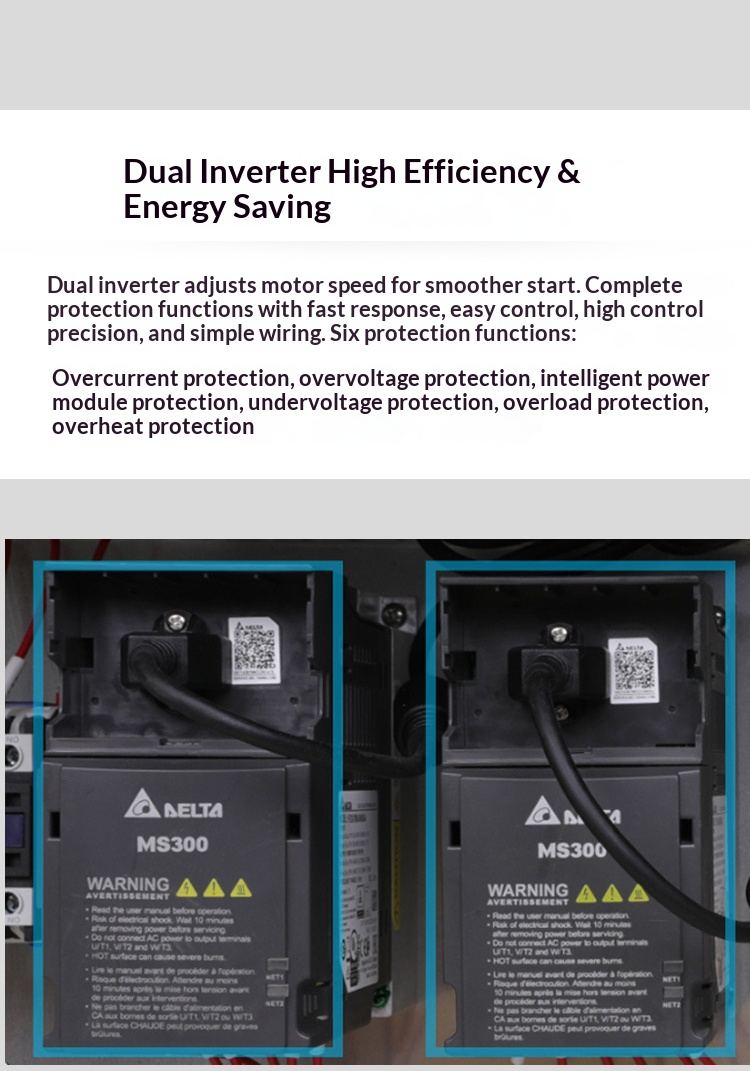

The dual inverters not only regulate the conveying speed but also synchronously adjust the power of the heating system. When the conveying speed increases, the system automatically raises the heating power; when the speed decreases, it reduces the power. This avoids excessive or insufficient heating caused by changes in the product's residence time in the furnace, ensuring the adaptability between temperature control and conveying rhythm.

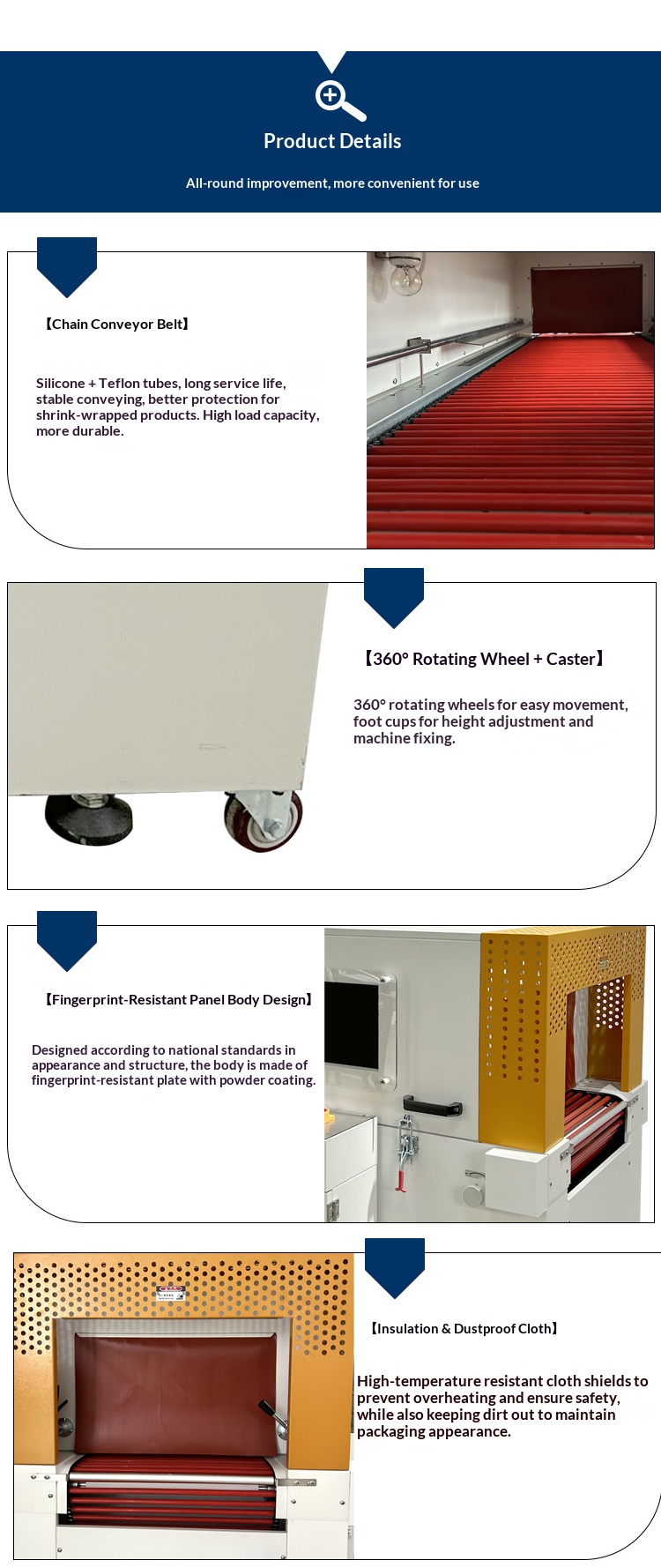

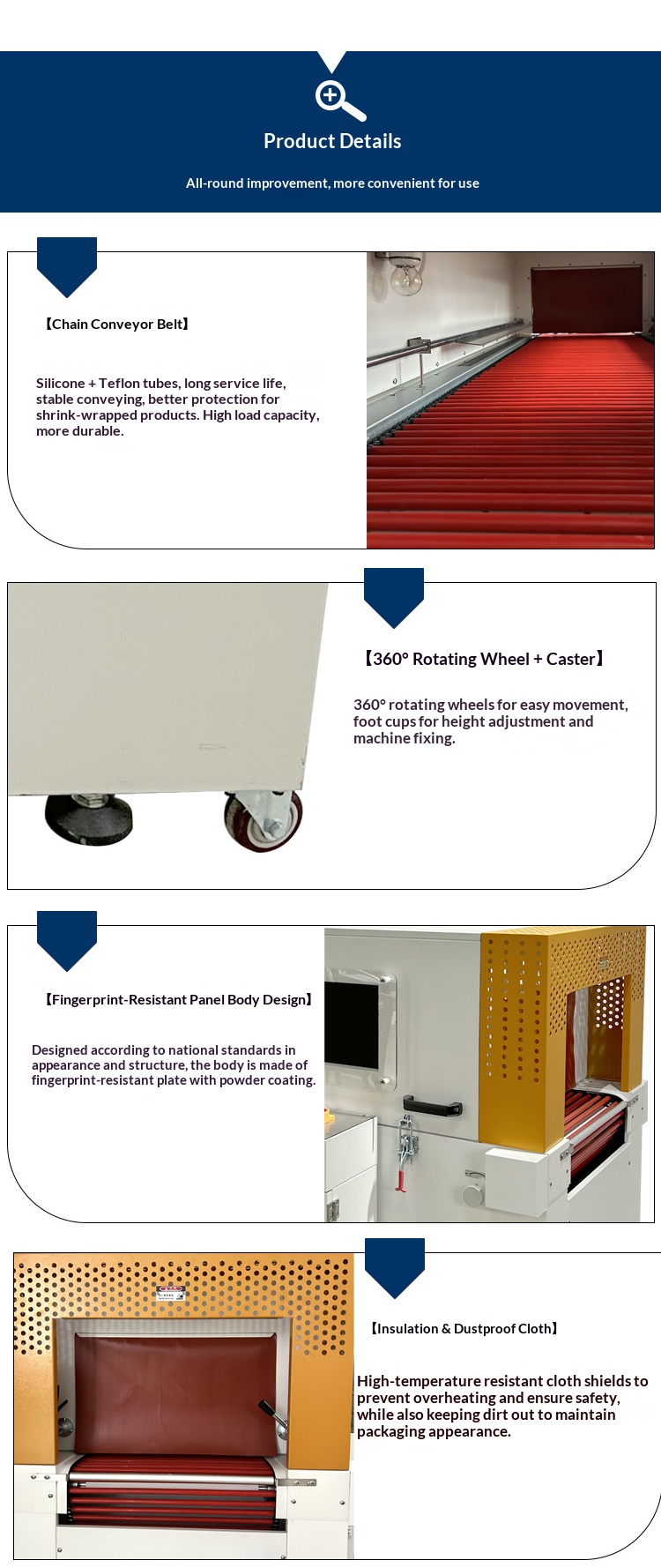

Equipment often adopts imported heat-insulating curtains and thickened heat-insulating inner liners to reduce heat leakage from the furnace. The design of high-quality stainless steel heating tubes not only improves heating efficiency but also reduces heat loss, maintaining a constant temperature inside the furnace and further enhancing the effect of precise temperature control.

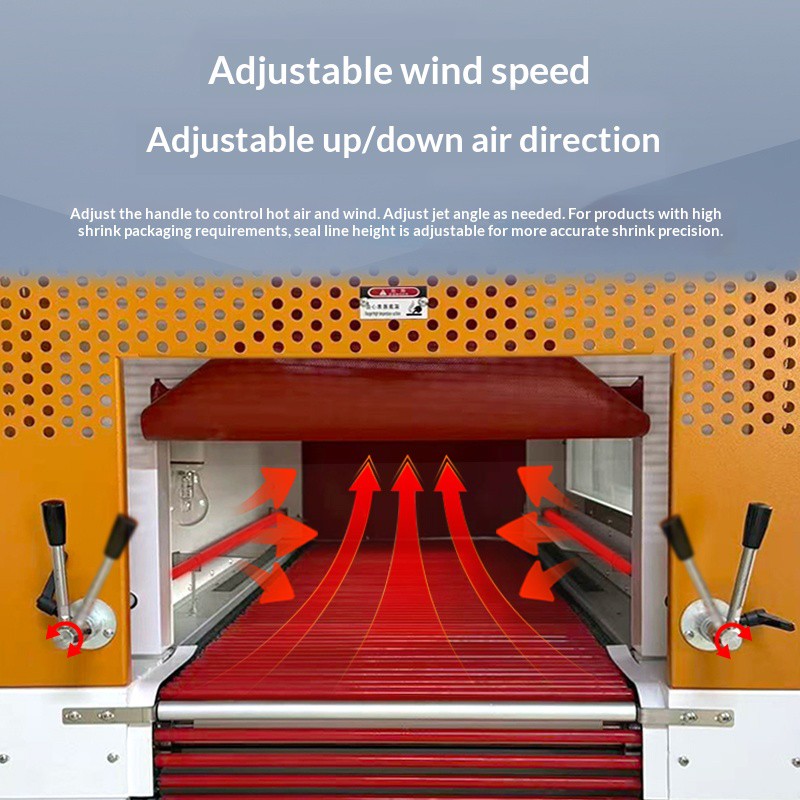

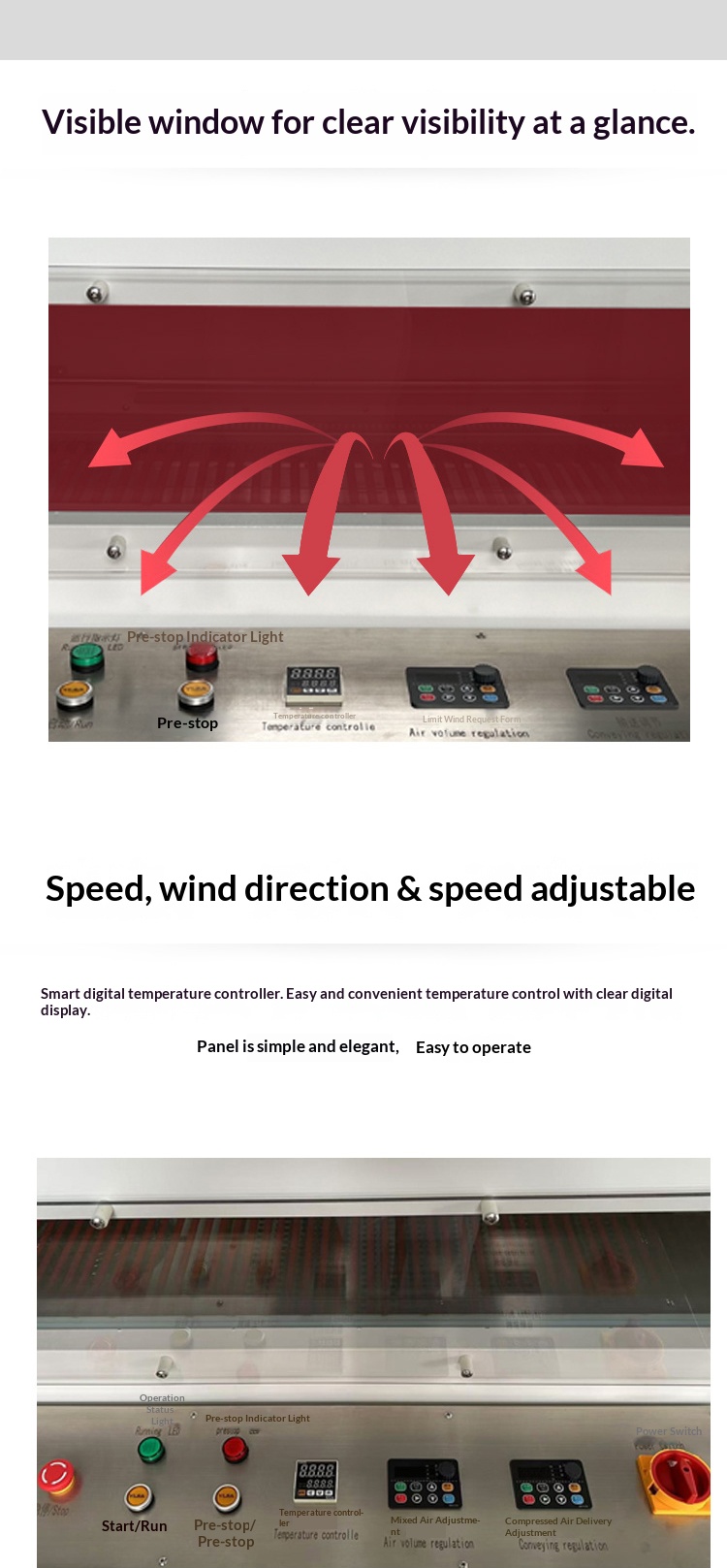

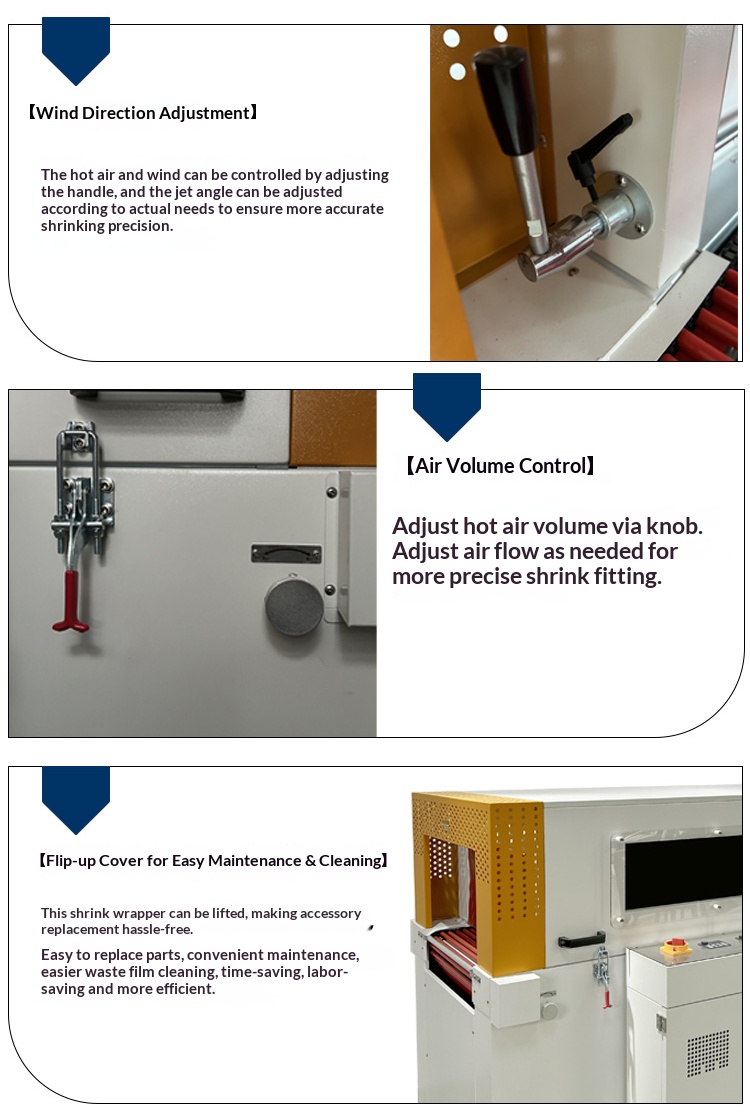

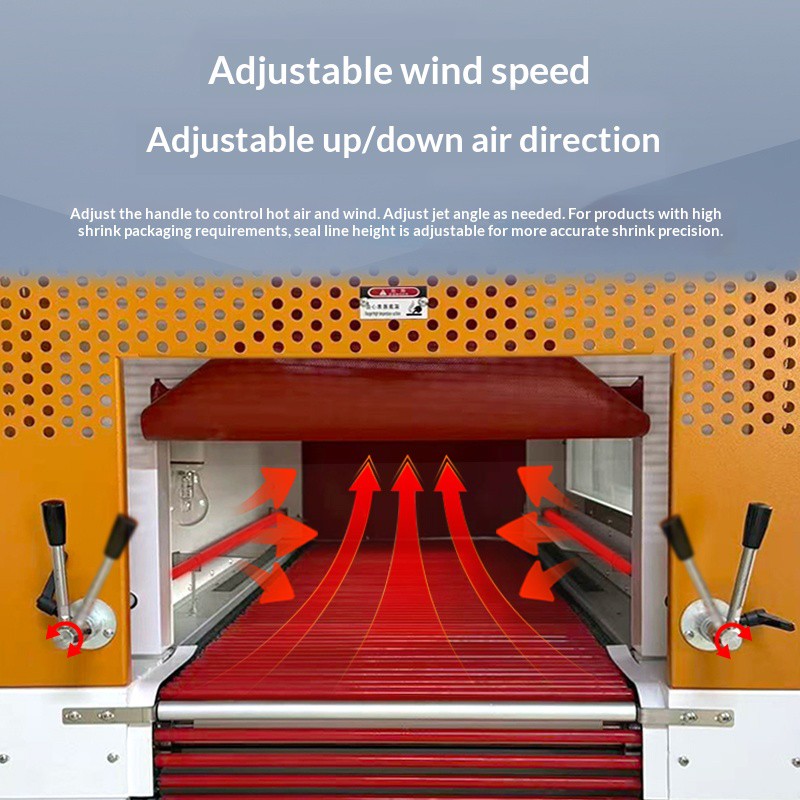

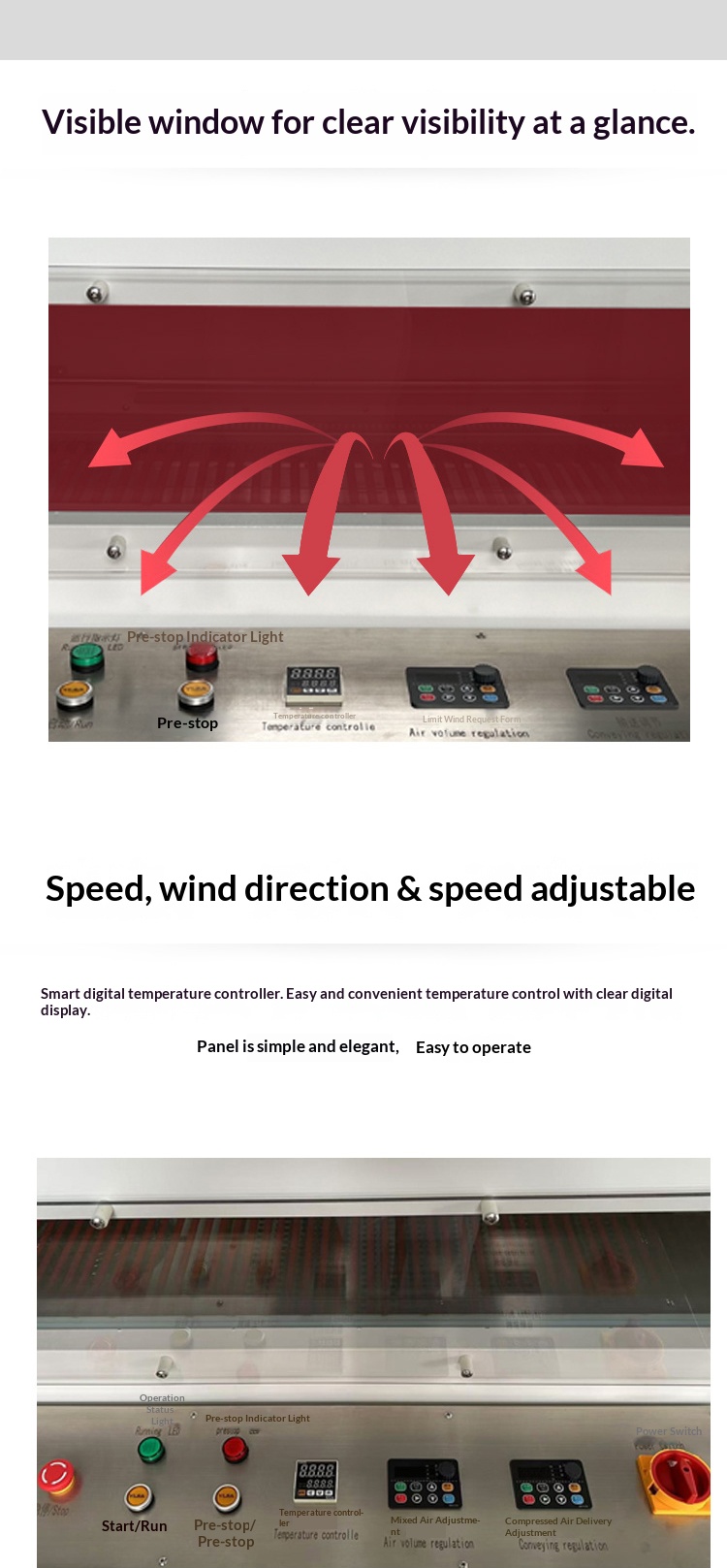

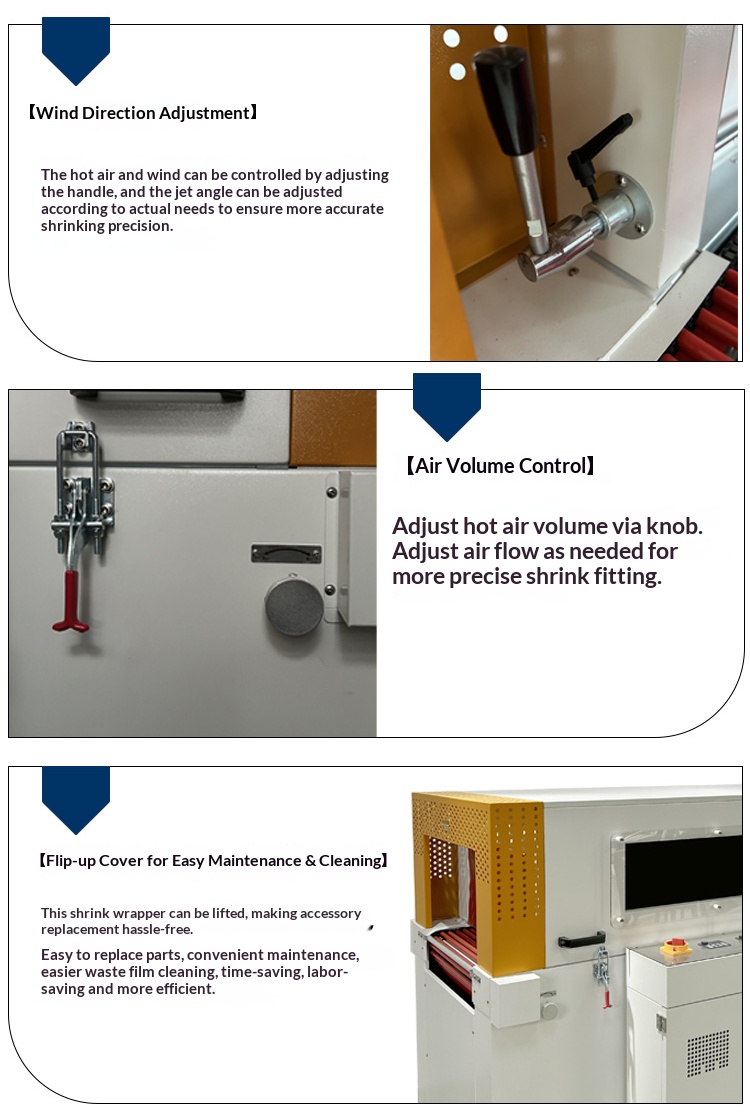

Most models are equipped with dual air circulation motors or high-performance centrifugal fans, combined with scientifically designed air duct layouts, enabling hot air to form a dead-angle-free bidirectional or multi-directional circulation in the furnace and eliminating temperature blind spots. For example, some equipment supports air direction adjustment, allowing users to adjust the hot air flow according to product shape and size, ensuring uniform heating of all parts of the product (such as edges, corners, and sides).

The conveying system uses new-type rollers covered with imported fiber sleeves or Teflon mesh belts, which are not only high-temperature resistant and non-stick to film but also ensure stable product conveying, avoiding excessive local heating time caused by conveying jams. Meanwhile, the rollers can be selected to rotate or not to adapt to different products. Combined with the stepless speed regulation realized by dual inverters, products pass through the heating tunnel at a constant speed, achieving consistent shrinkage results.

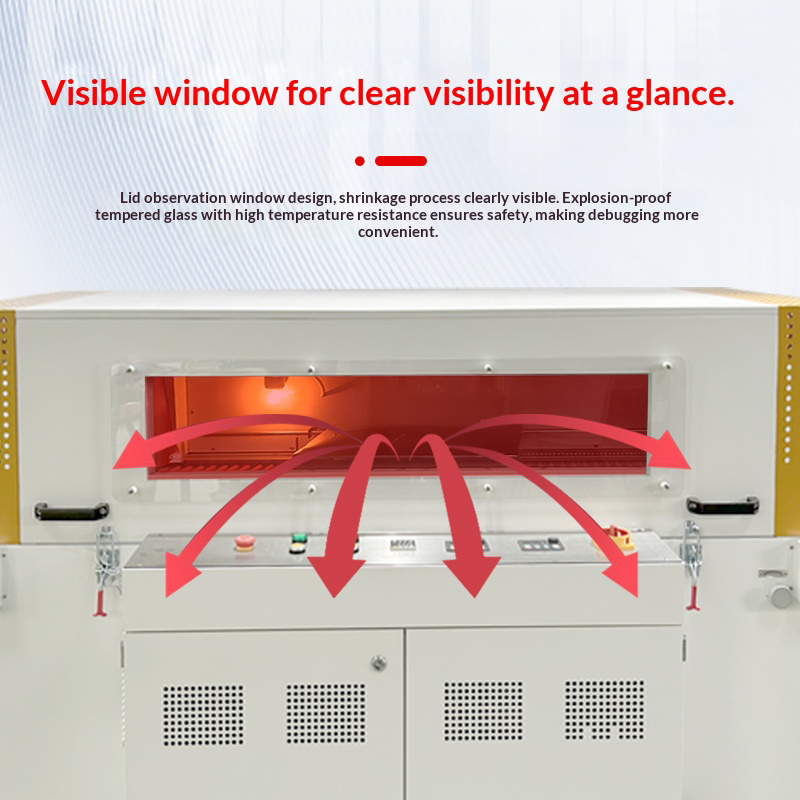

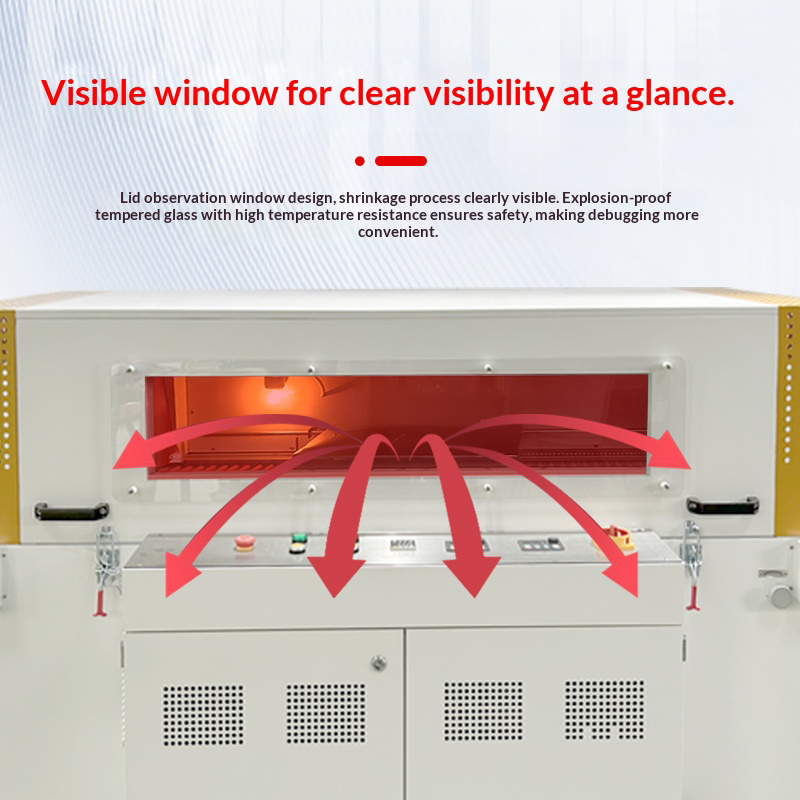

The observation window of the equipment allows operators to monitor the shrinkage process in real time. If problems such as local uneven shrinkage are found, parameters such as temperature, air volume, or conveying speed can be fine-tuned in a timely manner, avoiding batch packaging defects and further ensuring the overall uniformity of shrinkage.