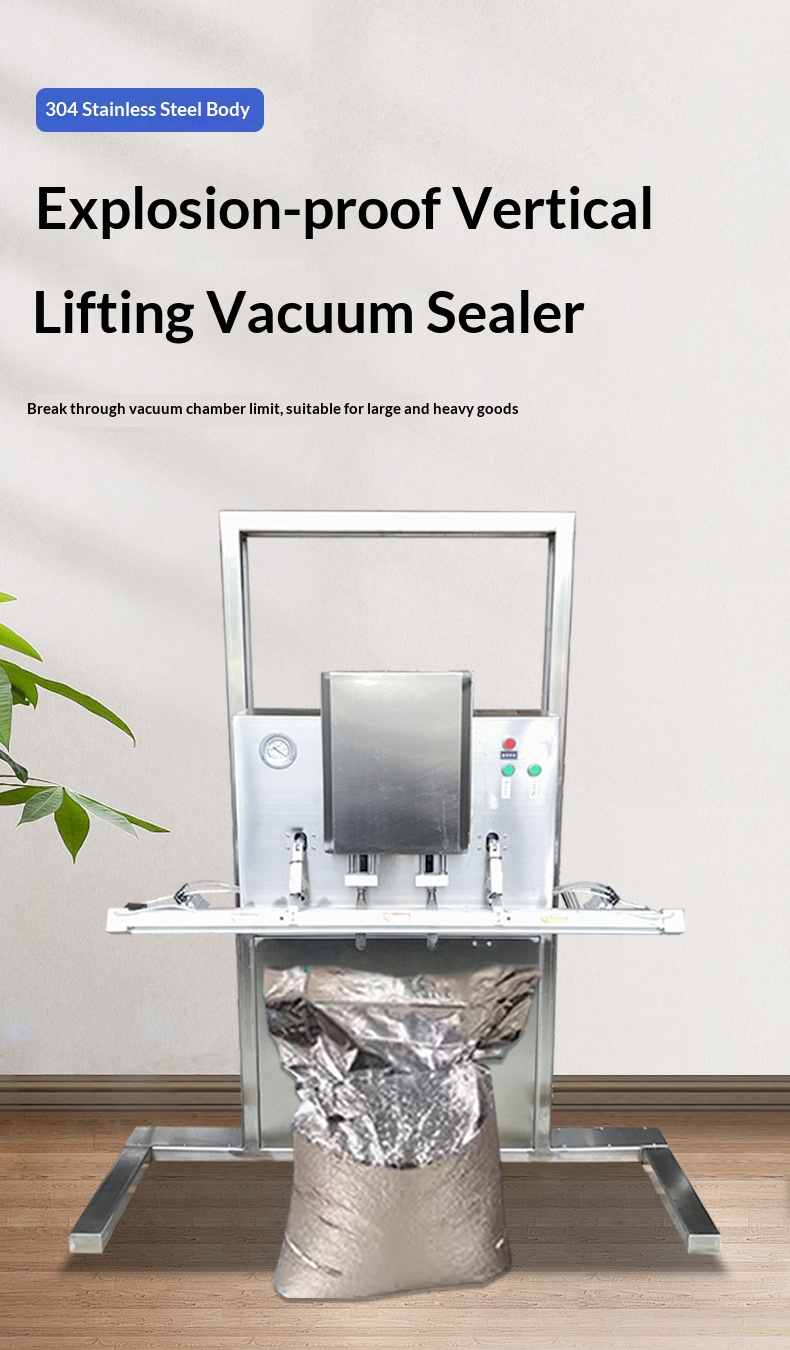

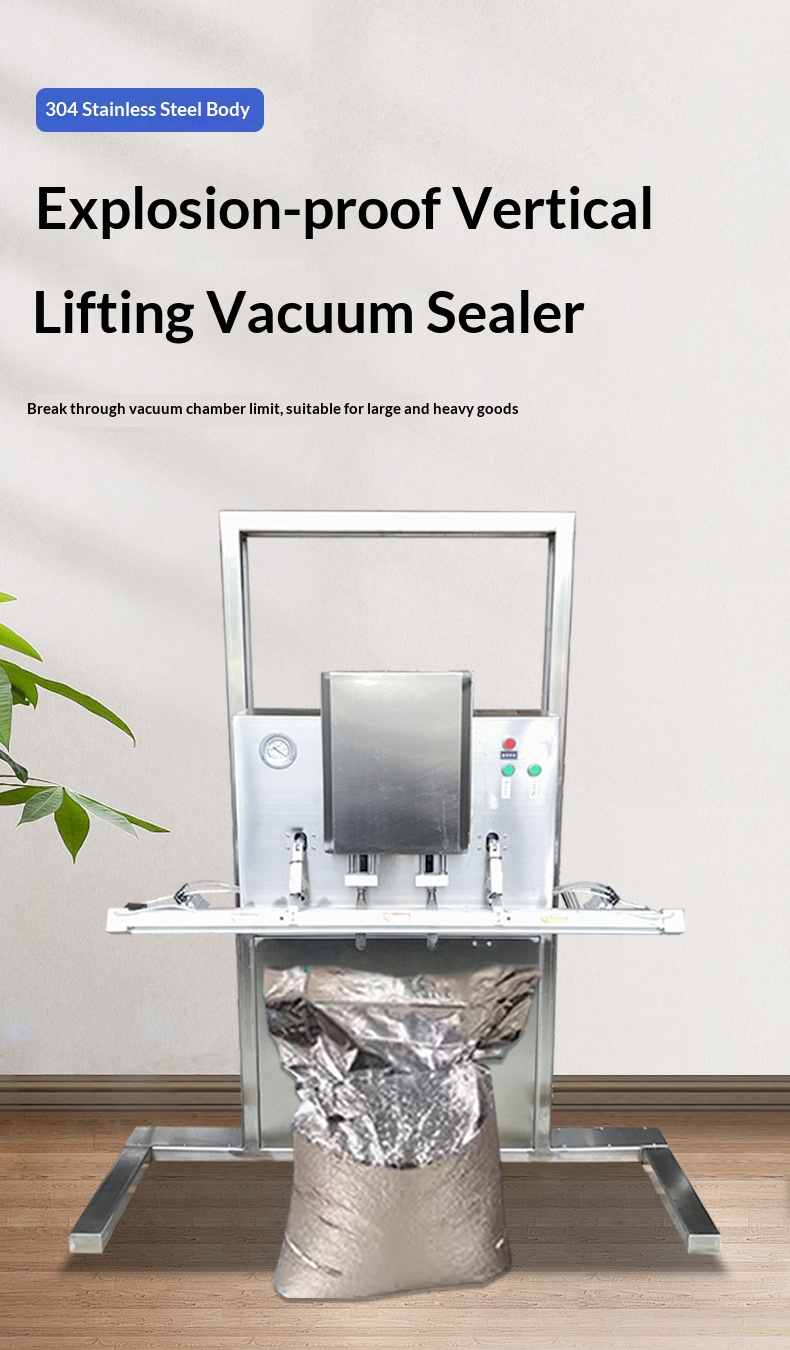

The explosion-proof configurations of the Vertical Explosion-Proof Vacuum Packaging Machine are concentrated in key components such as electrical systems, power units, and sealing & filtration assemblies, enabling it to adapt to special operating conditions involving flammable and explosive substances

Release date:2025-11-26

The explosion-proof configurations of the Vertical Explosion-Proof Vacuum Packaging Machine are concentrated in key components such as electrical systems, power units, and sealing & filtration assemblies, enabling adaptation to special operating conditions involving flammable and explosive substances. It is primarily suitable for factories with explosion hazards in sectors like chemical engineering, pharmaceuticals, etc. Details are as follows:

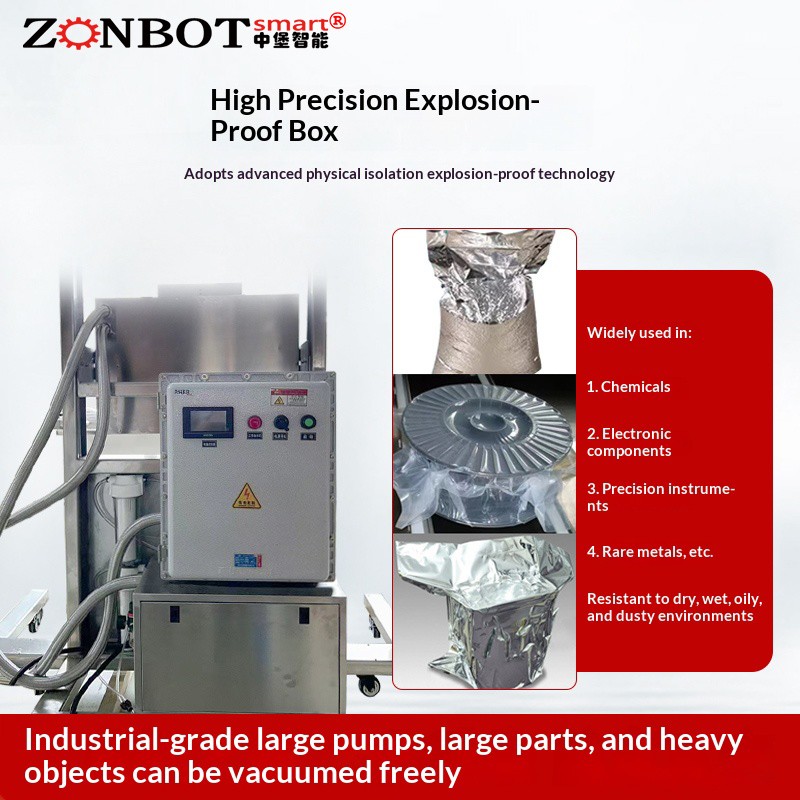

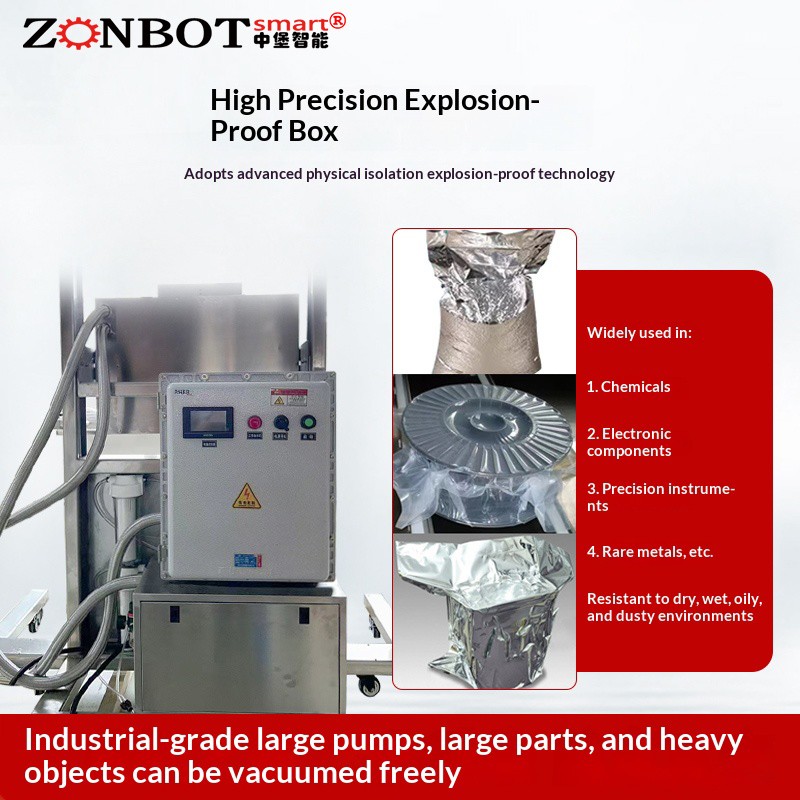

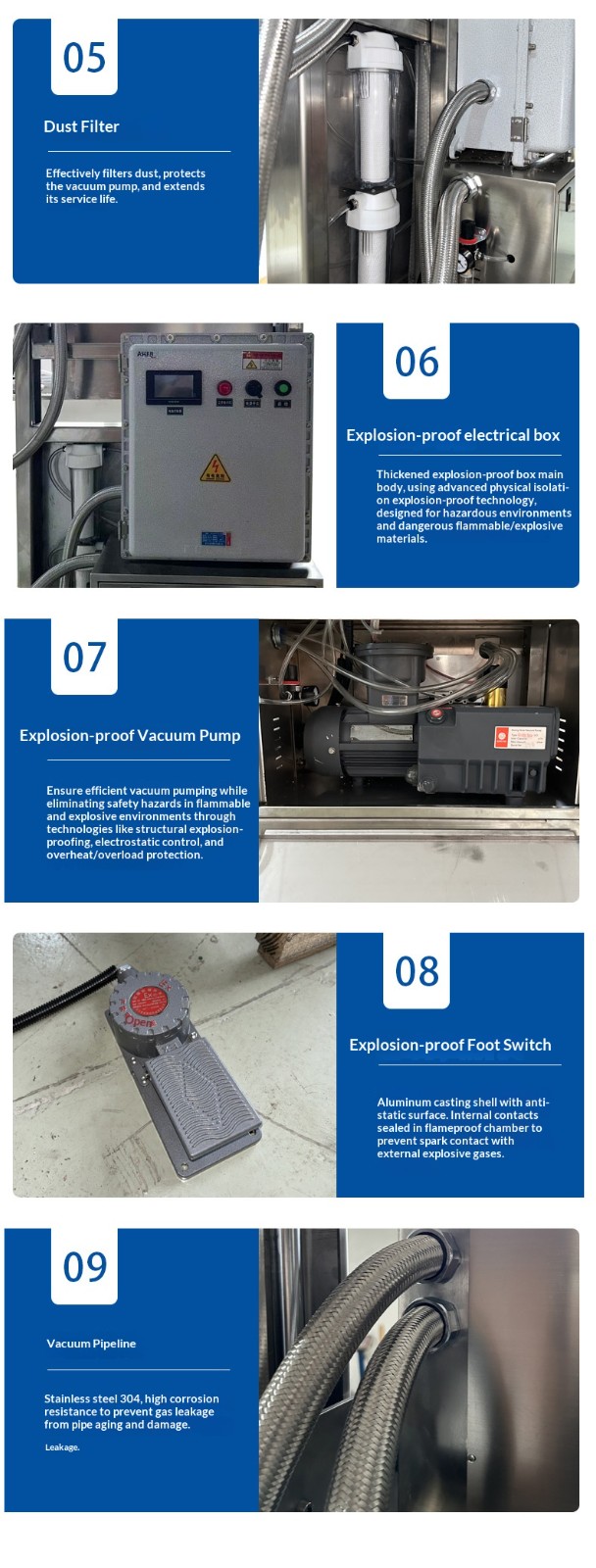

- The entire machine adopts explosion-proof electrical elements, including explosion-proof control cabinets, explosion-proof switches/buttons, and explosion-proof indicator lights.

- Core control components such as PLCs and temperature transmitters are all installed in explosion-proof enclosures to prevent electric sparks generated during operation from causing hazards.

- Circuit connections use explosion-proof conduits and joints to avoid electric leakage or spark leakage at line interfaces.

- Additionally, some models are controlled by 24V DC contactless solid-state relays, further reducing the risk of contact sparks.

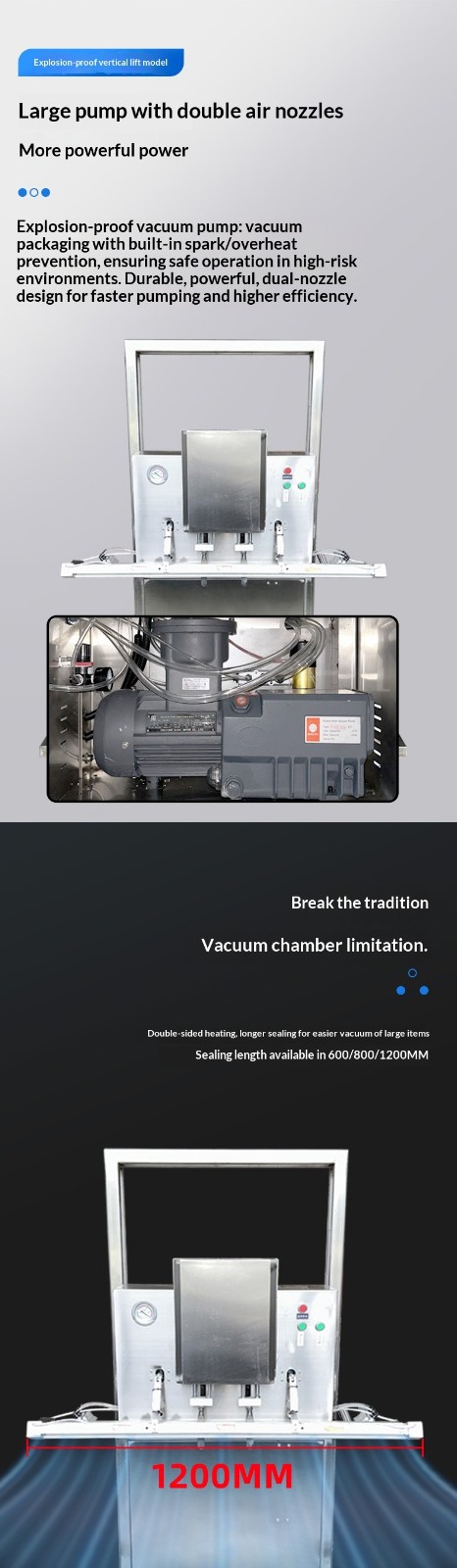

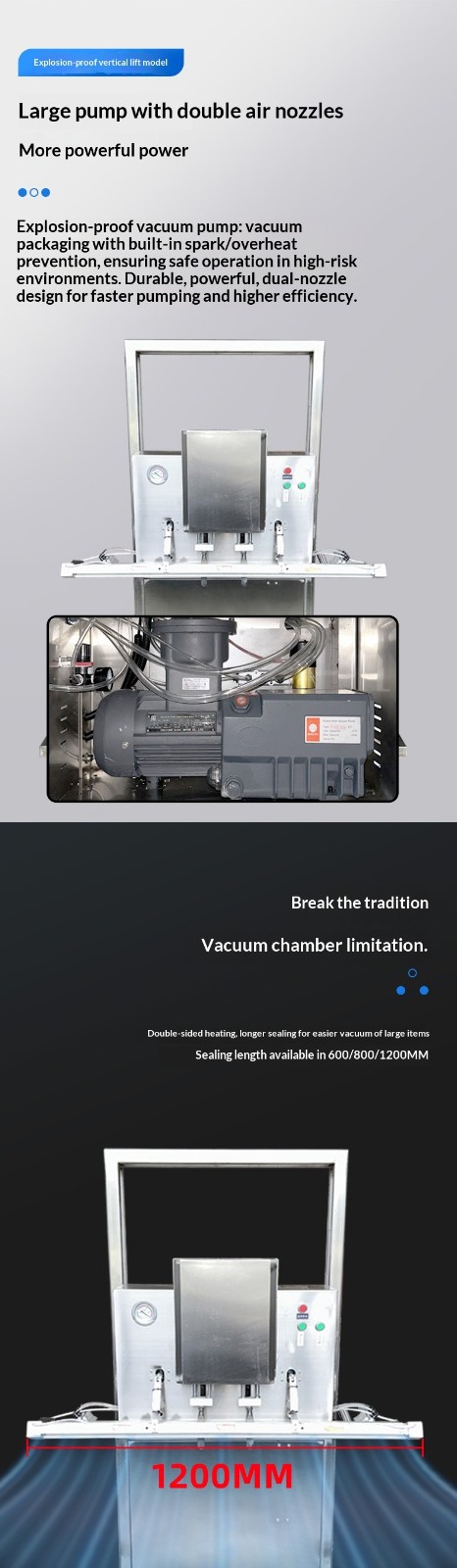

- Equipped with explosion-proof vacuum pumps and explosion-proof motors:

- The external-mounted design of the vacuum pump prevents heat and sparks generated during its operation from contacting flammable and explosive media in the workplace.

- The explosion-proof motor eliminates potential safety hazards caused by electrical failures during operation, ensuring safe power output.

- In addition, explosion-proof solenoid valves are used for the pneumatic components that drive nozzle and sealing actions, ensuring stable explosion-proof performance of the pneumatic system.

- Both the head cabinet and electrical cabinet adopt fully sealed designs with added sealing gaskets to prevent flammable and explosive gases/dust from entering the interior, which could damage components or cause short circuits.

- Key parts such as air suction nozzles and vacuum chambers are made of 304 stainless steel. Some models are also equipped with 40mm-thick transparent acrylic observation windows, which not only guarantee explosion-proof performance but also facilitate real-time monitoring of the packaging process.

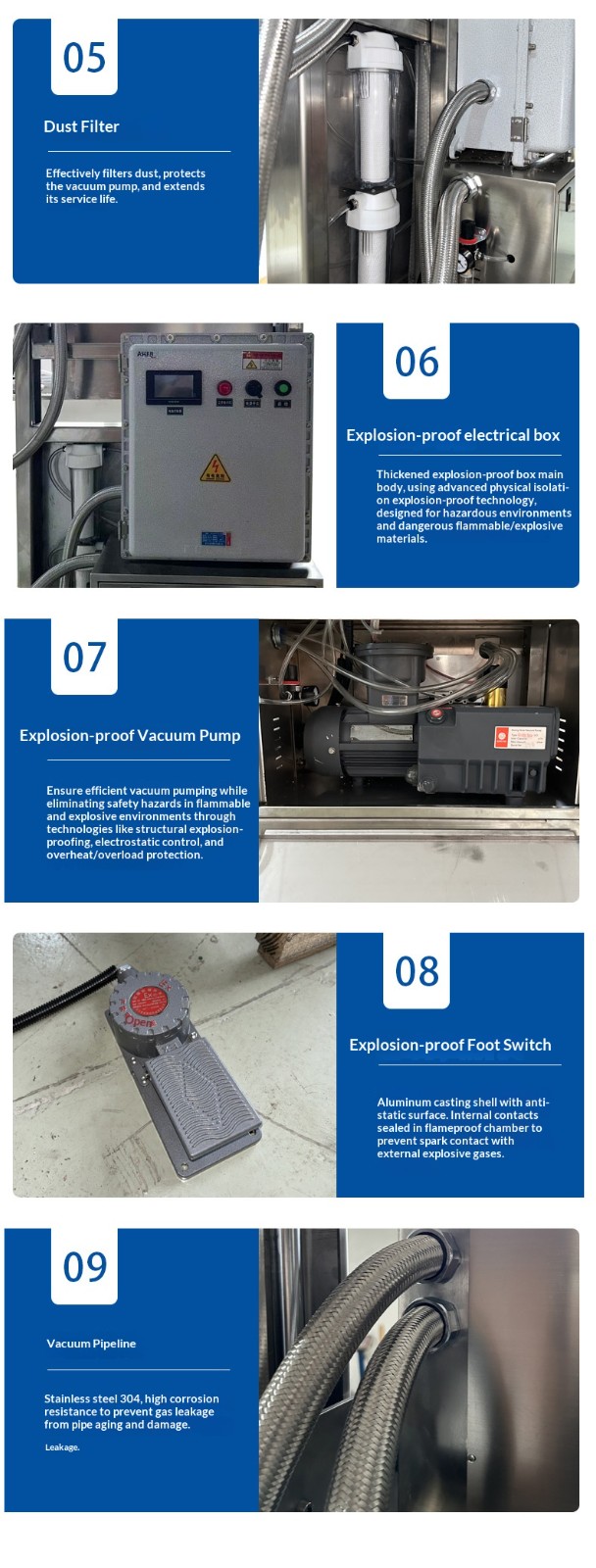

- A powder isolation and filtration device is installed to prevent dust from packaging materials from clogging the vacuum pump, avoiding safety issues caused by equipment malfunctions.

Including organic chemical plants, fine chemical plants, chemical fertilizer factories, etc. Examples include factories producing chemical solvents such as acetone and ethanol, as well as plants processing chemical fertilizer raw materials and chemical powder additives. The raw materials or semi-finished products in these factories are mostly flammable and explosive media. This equipment can ensure the safety of the packaging process and extend the storage life of materials.

Including chemical pharmaceutical plants and bulk drug processing factories. When producing pharmaceutical intermediates and bulk drugs, these factories often involve flammable and explosive chemical reagents or reaction products. The equipment not only meets explosion-proof requirements but also uses materials such as 304 stainless steel that comply with hygiene standards, which can adapt to the cleanliness requirements of pharmaceutical packaging and avoid drug contamination.

Such as auxiliary material production or finished product packaging factories for civil explosives and fireworks. The products or raw materials in these factories are highly sensitive, and even minor sparks may trigger explosions. The comprehensive explosion-proof design of the Vertical Explosion-Proof Vacuum Packaging Machine can reduce risks in the packaging process and ensure production safety.

- Supporting material processing factories in the aerospace field: The special materials they produce may involve flammable and explosive reagents or components, requiring this equipment for safe packaging.

- Some feed additive factories and special powder material factories involving flammable and explosive dust: These factories can use dedicated dust explosion-proof models to meet the explosion-proof packaging needs of powder materials.