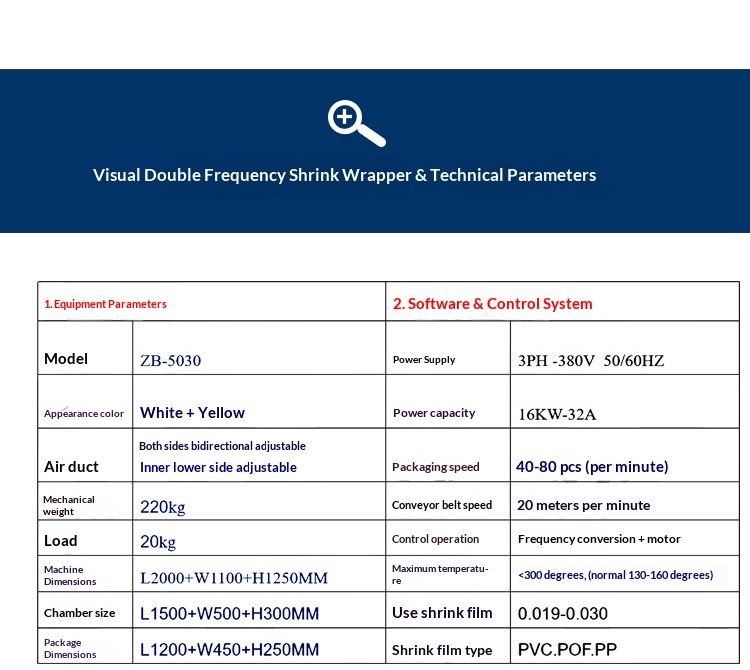

Featuring the core design of dual independent frequency conversion control systems, the dual-frequency conversion heat shrink wrapping machine has formed significant advantages in operational stability, regulation precision and safety protection compared with traditional single-frequency conversion and non-frequency conversion heat shrink models.

Release date:2025-12-29

The dual-frequency conversion heat shrink wrapping machine, featuring the core design of dual independent frequency conversion control systems, has formed significant advantages in operational stability, regulation precision, and safety protection compared with traditional single-frequency conversion and non-frequency conversion heat shrink models. Meanwhile, it directly drives the efficiency leap of the packaging process, becoming the preferred equipment for high-efficiency packaging across multiple industries.

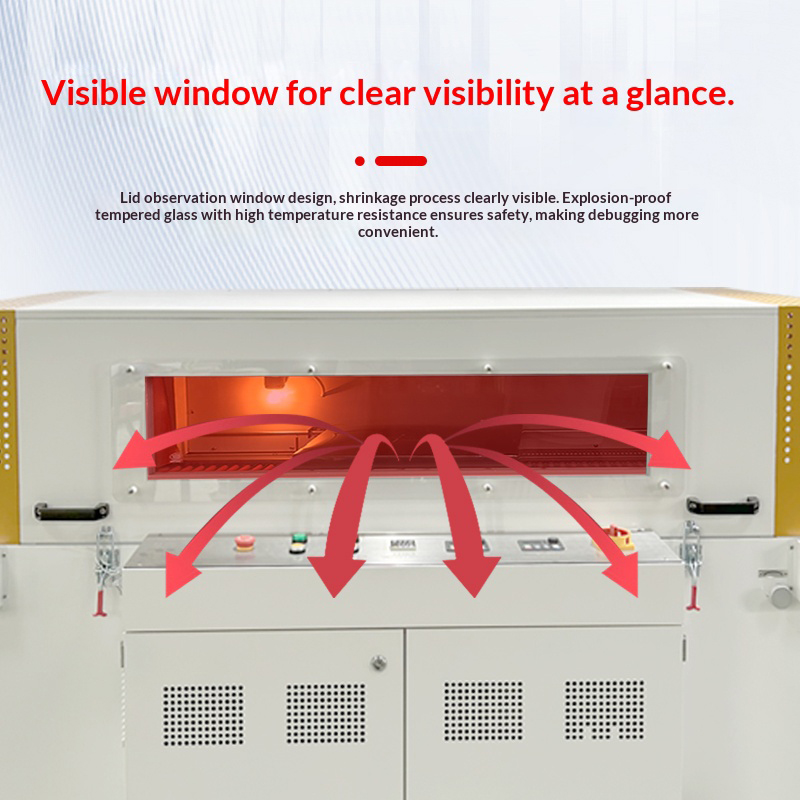

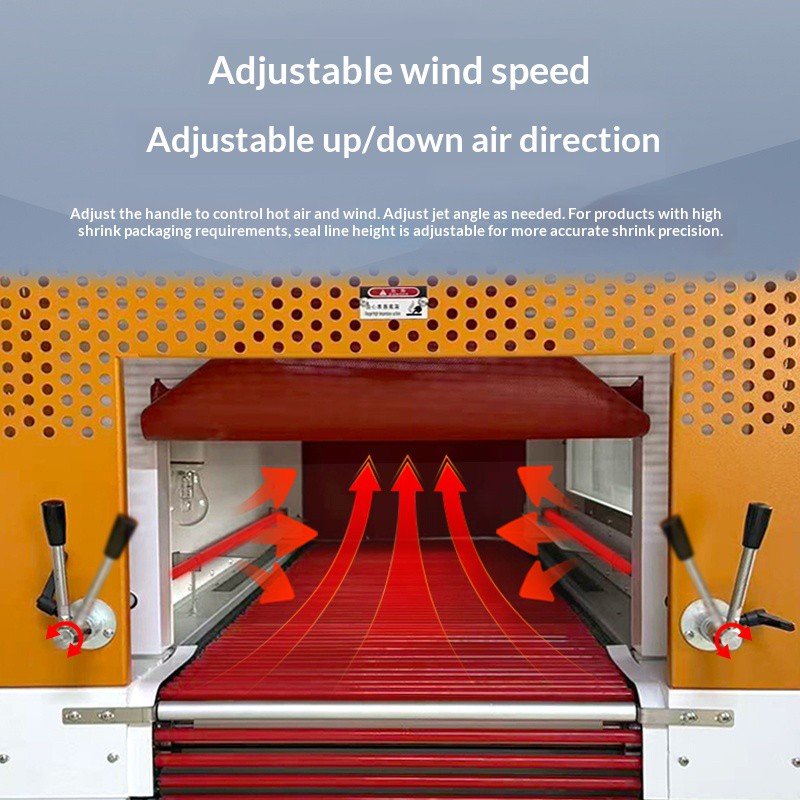

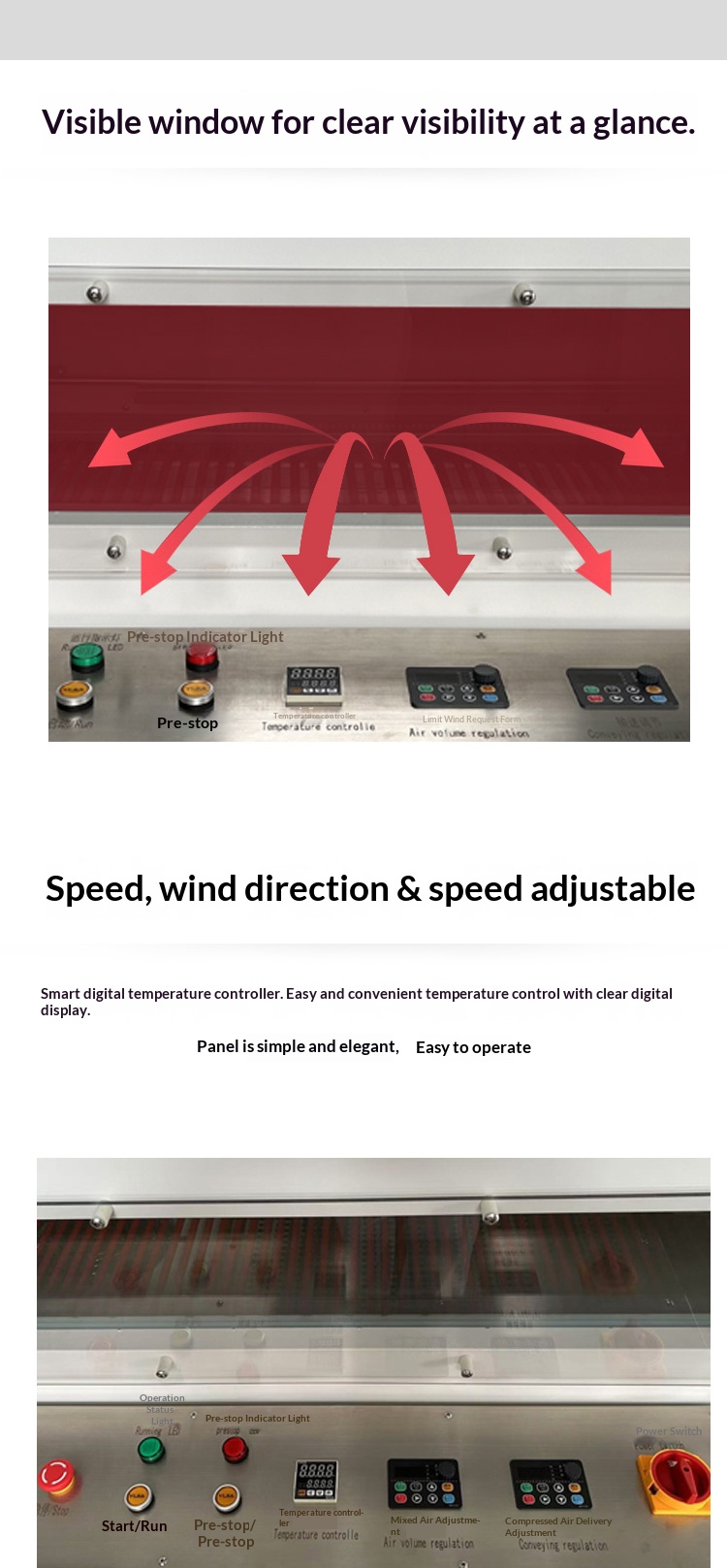

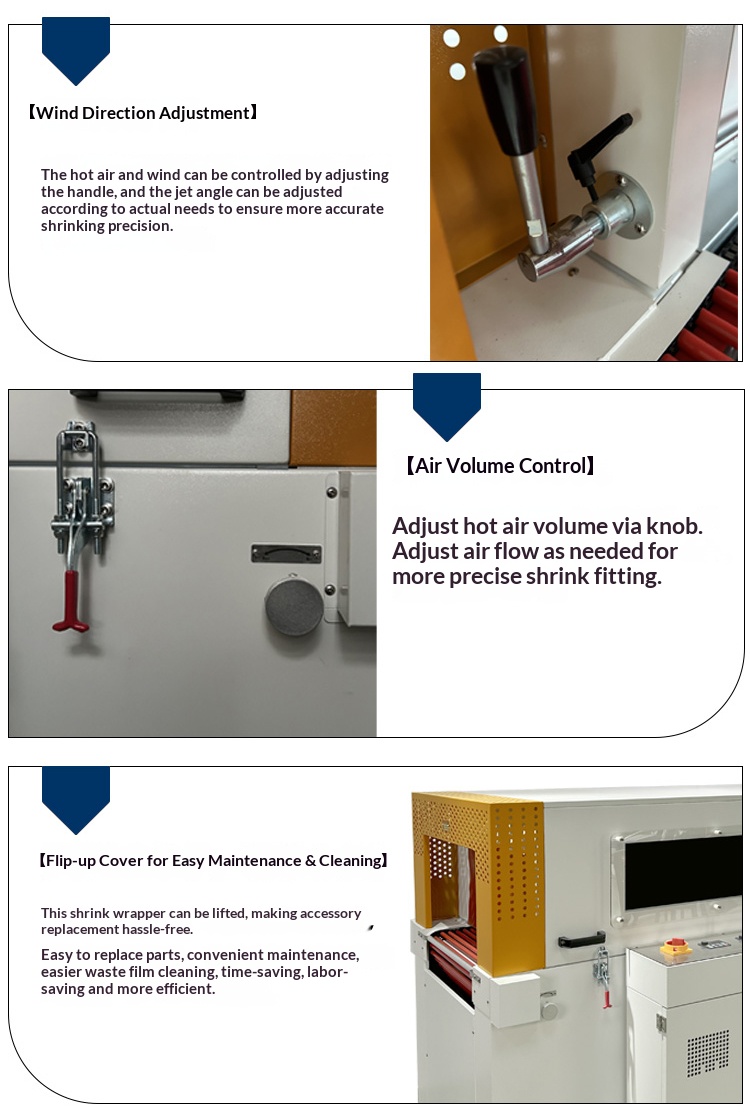

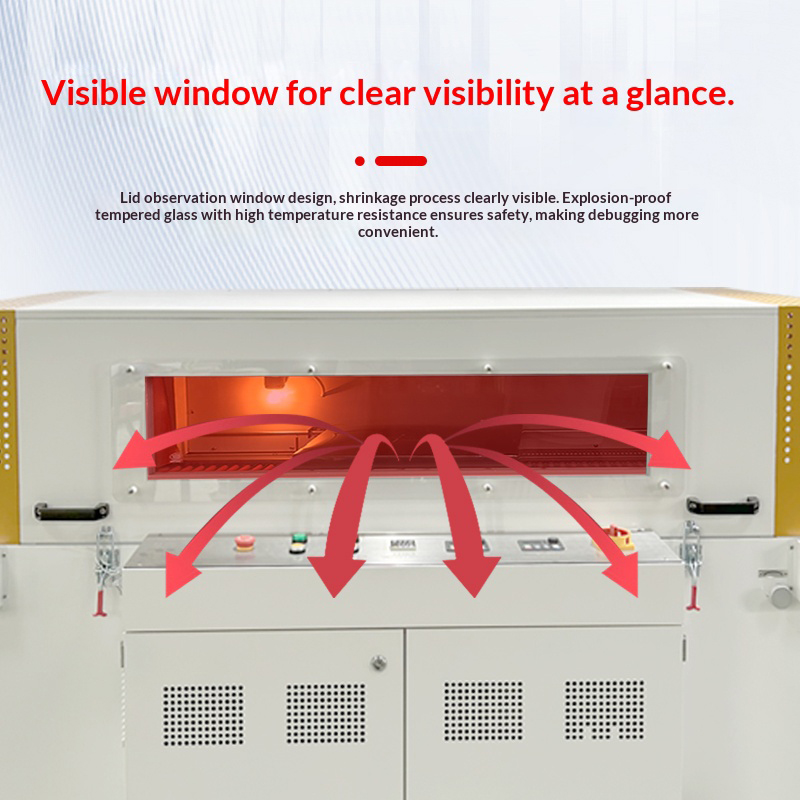

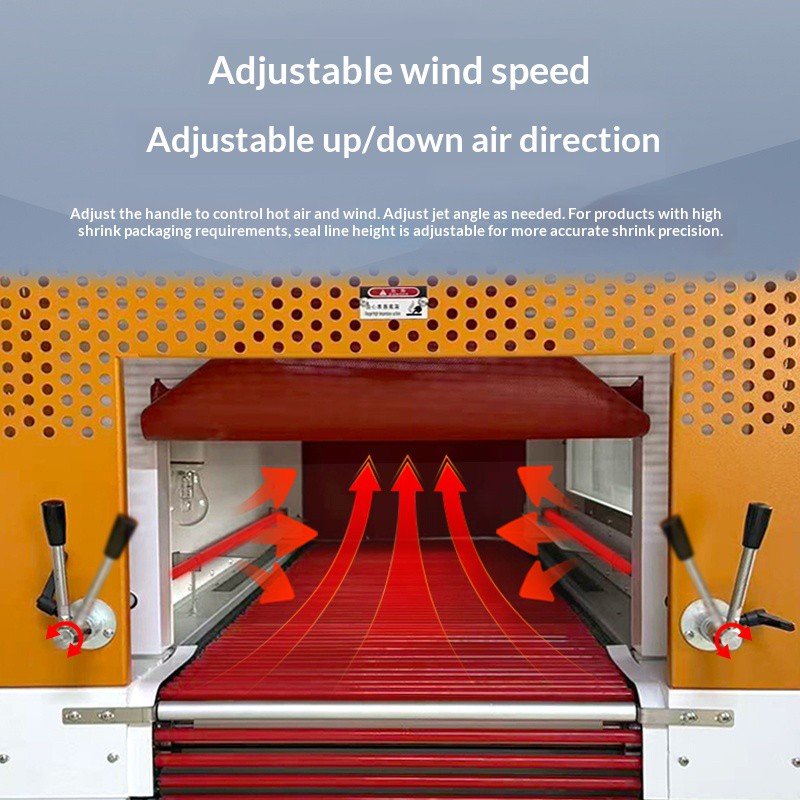

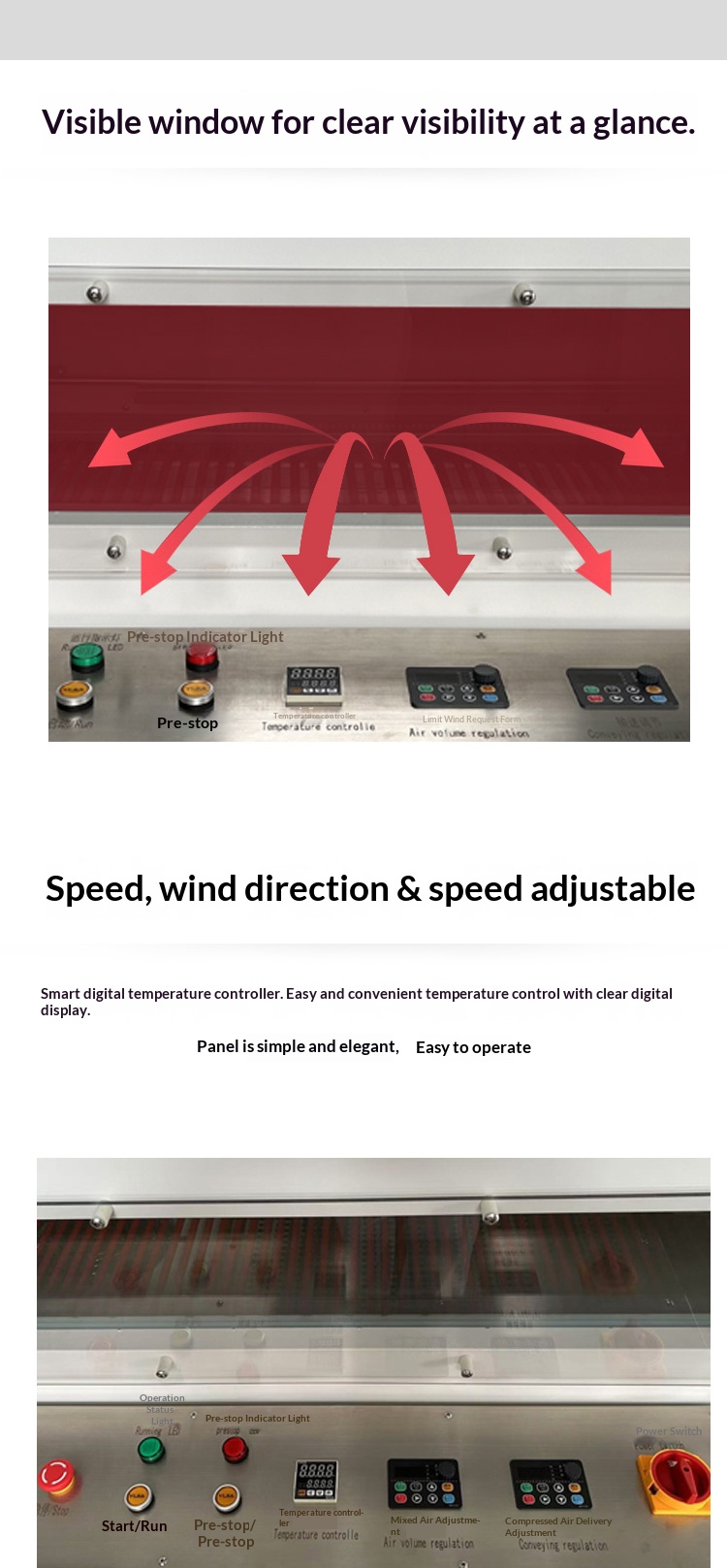

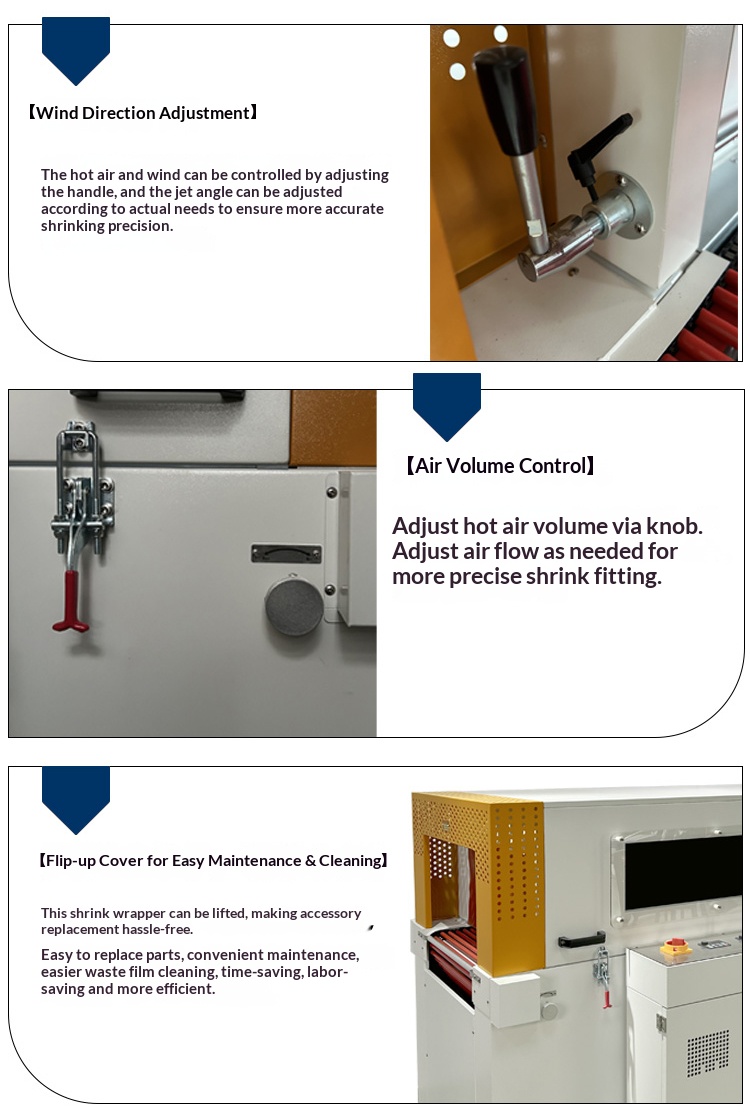

Dual Independent Frequency Conversion Regulation for High Adaptability and PrecisionThe equipment is equipped with two independent frequency converters to precisely adjust the rotational speeds of the conveying motor and heating blower motor respectively, completely solving the core pain point of traditional models under "single-frequency conversion linkage control" where "speed adjustment must lead to temperature adjustment and temperature adjustment affects speed adjustment". On the one hand, stepless independent adjustment of conveying speed is achievable, and the heating power dynamically adapts based on real-time feedback data from temperature sensors, enabling flexible parameter matching for products of different sizes (ranging from small electronic components to full-box gift sets) and different film materials (POF, PE, PVC, etc.). For instance, small hardware parts can be conveyed at high speed with low-temperature shrinking to avoid film carbonization, while large cartons can pass at low speed with high-temperature uniform shrinking to eliminate substandard edge and corner shrinking. On the other hand, the temperature control precision can reach ±1℃, and the air blowing direction supports multi-dimensional directional adjustment. The synergy of the three ensures that the film shrinks synchronously from edges and corners to flat surfaces, resulting in packaged products with smooth, wrinkle-free and bubble-free adhesion.

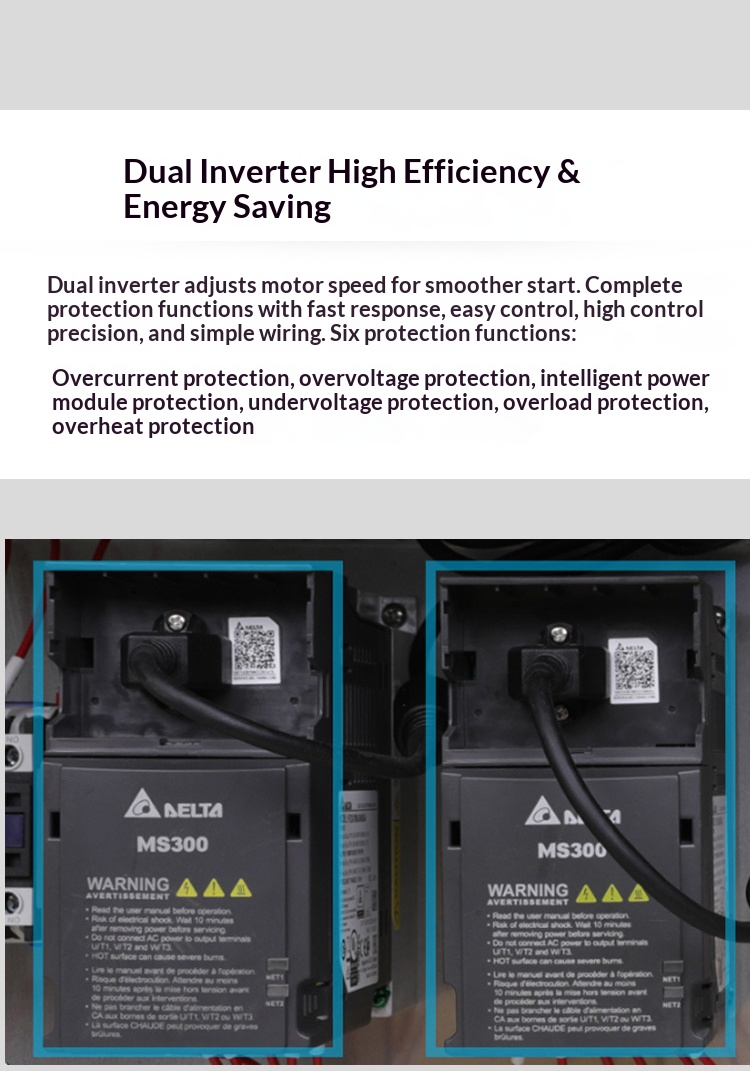

Smoother Operation and Significantly Reduced Failure RateThe soft start and soft stop functions of the frequency converter eliminate current impact during equipment startup and maintain stable motor speed without fluctuations during operation, effectively avoiding shutdown failures of traditional models caused by frequent start-stop cycles, unstable voltage and load changes. Meanwhile, dual-frequency conversion regulation reduces overload operation of the motor and heating system, significantly lowering the wear rate of core equipment components. The equipment remains stable and reliable even under long-term continuous operation, with the failure rate reduced by more than 25% compared with traditional models, thus greatly cutting down equipment maintenance downtime.

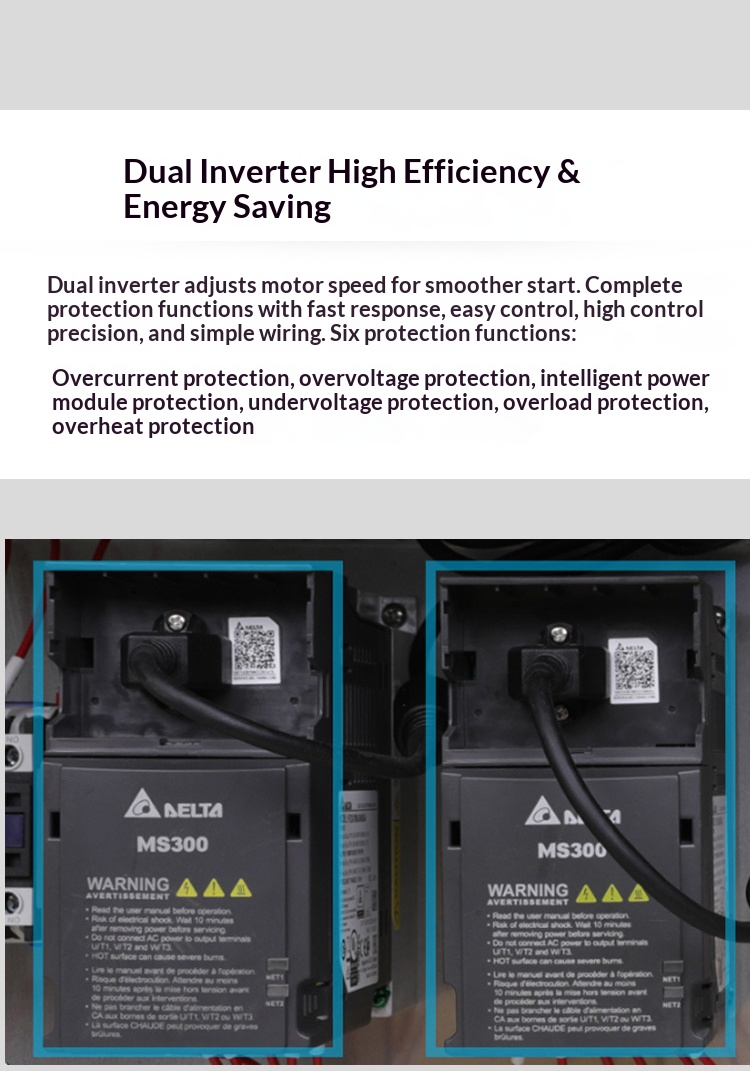

Comprehensive Six Major Intelligent Protection Functions for Rapid Safety ResponseThe equipment is equipped with six core protection functions: overcurrent protection, overvoltage protection, intelligent power module protection, undervoltage protection, overload protection and overheating protection. It features fast response speed, high control precision and simple wiring, greatly lowering the threshold for operation and maintenance. The six protection functions fully cover operational risk points: overcurrent/overload protection monitors circuit current and motor load in real time to prevent component burnout and mechanical wear; overvoltage/undervoltage protection accurately senses voltage fluctuations to avoid damage to frequency converters and motors caused by abnormal voltage; intelligent power module protection specifically safeguards core frequency conversion components to extend equipment service life; overheating protection monitors equipment temperature in real time via temperature sensors and automatically shuts down when the temperature exceeds the limit, eliminating potential safety hazards.

Energy Conservation and Consumption Reduction for Optimal Long-term Operation CostThe frequency conversion system can adjust the power output of the motor and heating elements according to production demand, avoiding the high no-load power loss of traditional models. For example, during intermittent production, the conveying motor can stand by at low speed and the heating system can maintain heat preservation power, saving 20%-30% of electrical energy compared with traditional models. At the same time, the precise temperature control of ±1℃ reduces film waste caused by poor shrinking, cutting the film loss rate by about 15%. Long-term use can significantly reduce labor, material and energy consumption costs.

The advantages of the dual-frequency conversion heat shrink wrapping machine are directly translated into packaging efficiency improvement, and it can precisely address the packaging pain points of different industries to achieve the dual breakthrough of "quality improvement + speed acceleration", with specific performance as follows:

High Adaptation Efficiency for Multiple Product Categories and Greatly Improved Production Line FlexibilityWithout replacing a large number of equipment accessories, rapid switching from individual small-package products (stationery, electronic components) to full-box collective packaging (beverages, food gift boxes) can be achieved simply by adjusting frequency converter parameters. For production scenarios with multiple product categories and small batches, the equipment commissioning time is shortened from 30-60 minutes of traditional models to 5-10 minutes, greatly improving production line flexibility and avoiding production capacity waste caused by equipment adaptation issues.

Targeted Efficiency Improvement Performance Across Various Industries

- Hardware and Building Materials Industry: For irregular-shaped and heavy-duty products, adjusting conveying speed and air blowing direction ensures tight shrinking of edges and corners, avoiding rework. The frequency conversion conveying motor provides stable power to support continuous operation of heavy-duty products, extending the daily effective production duration by 2-3 hours, and reduced failure rate cuts down shutdown losses.

- Daily Chemical and Pharmaceutical Industry: Rapid switching of packaging parameters for products of different specifications adapts to diverse packaging forms such as bottled and boxed products. Stable conveying reduces product collision and wear, improving the qualification rate of packaging appearance. The closed tunnel combined with precise temperature control meets the GMP clean production requirements of the pharmaceutical industry, eliminating the need for additional clean protection costs.

- Electronic and Electrical Industry: Precise regulation of low speed and low temperature avoids static electricity generation and heat damage to electronic components, and tight film adhesion enhances dustproof and moisture-proof effects. It reduces rework caused by poor packaging, improves production continuity, and high-quality packaging helps achieve brand premium.

Improved Operation and Maintenance Efficiency with Reduced Hidden CostsThe equipment features simple wiring and easy operation, allowing basic commissioning and daily operation to be completed without professional technicians. The comprehensive protection functions and stable operational status reduce equipment maintenance frequency and costs, while lowering labor costs of rework caused by poor packaging, further improving overall production efficiency.

In summary, through the core advantages of precision regulation, stable operation and safety protection, the dual-frequency conversion heat shrink wrapping machine not only solves many pain points of traditional heat shrink wrapping machines, but also achieves efficiency leap from multiple dimensions such as production capacity improvement, cost reduction and flexible adaptation, becoming a high-efficiency packaging equipment suitable for multiple industries and scenarios.