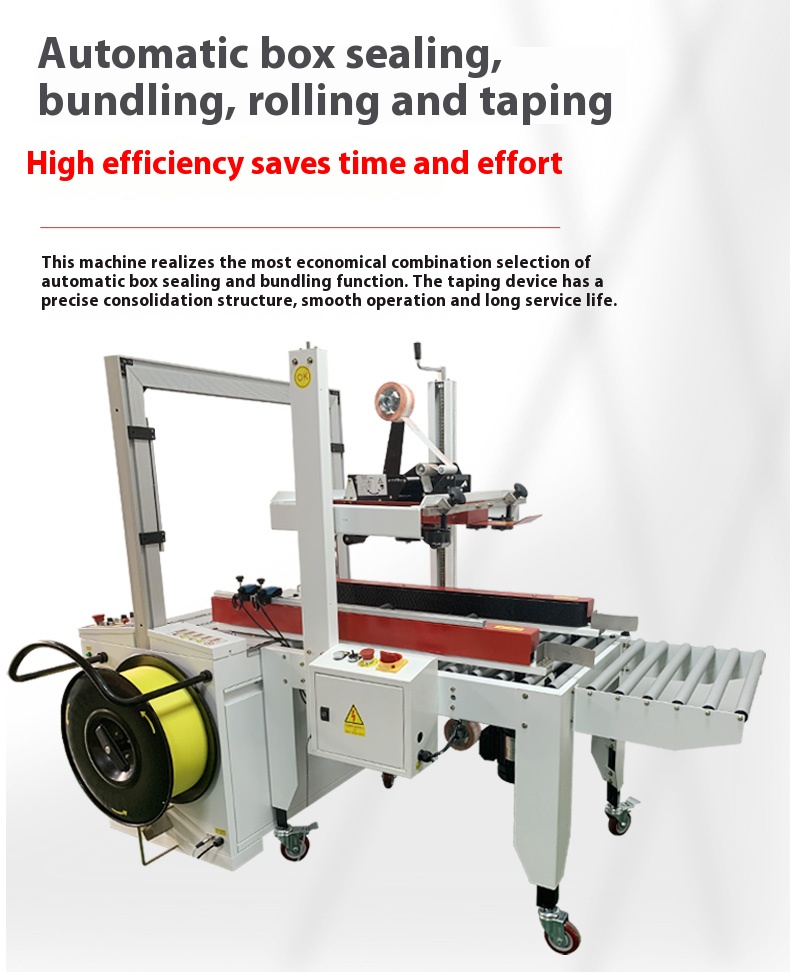

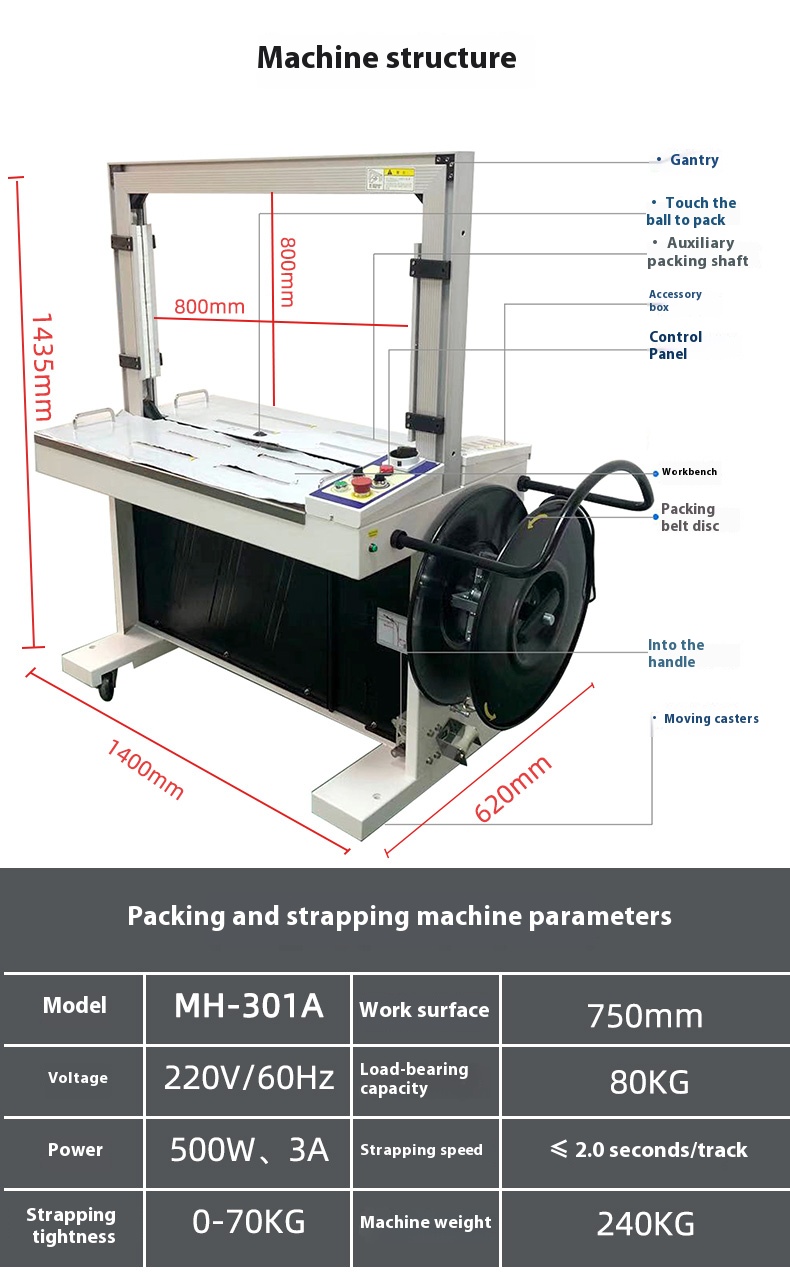

The daily maintenance of the carton sealing and strapping integrated machine requires attention to the following aspects:

Cleaning

Regularly clean the dust, debris, and adhesive tape scraps on the surface of the equipment to keep the appearance of the equipment tidy. You can wipe the body of the equipment with a clean cloth. For some stubborn stains, you can wipe them with a mild cleaning agent, but be careful to avoid the cleaning agent coming into contact with the electrical components of the equipment.

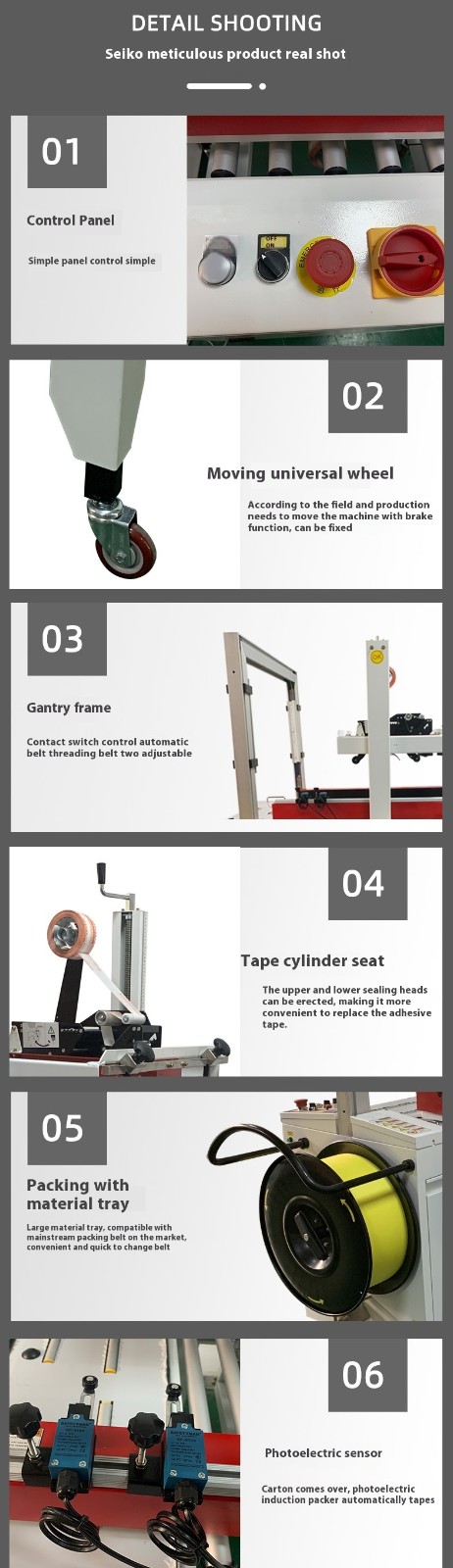

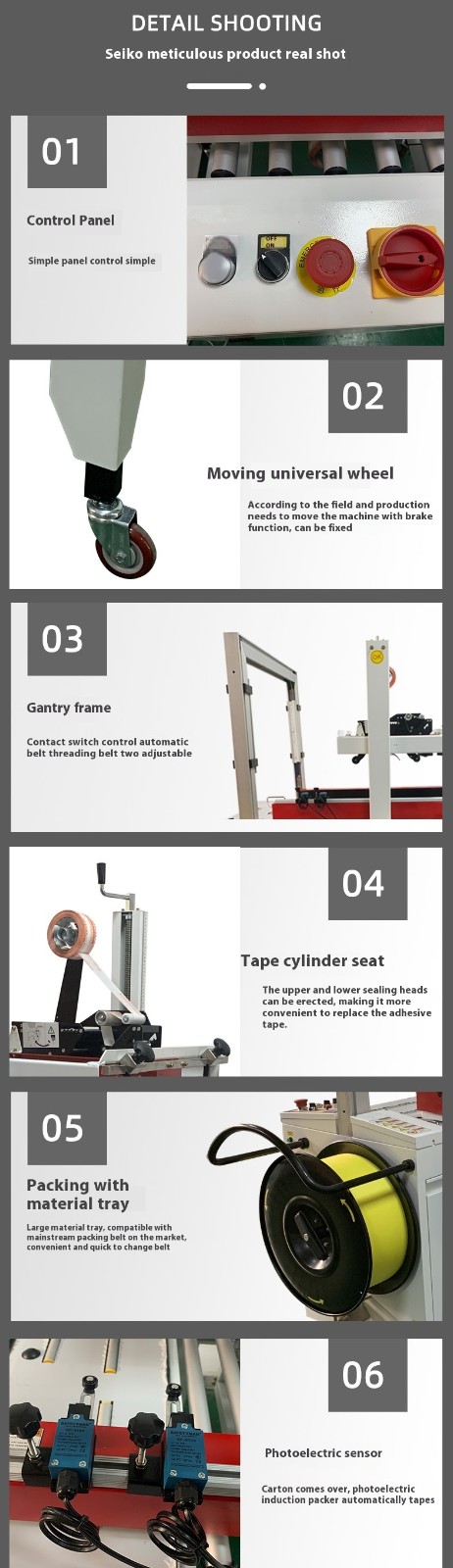

Clean the residual paper scraps and dust in parts such as the paper supply mechanism, carton sealing mechanism, and strapping mechanism to prevent their accumulation from affecting the normal operation of the equipment. Pay particular attention to cleaning the debris around the adhesive tape cutting part and the strapping belt transmission components to avoid problems such as poor adhesive tape sticking or strapping belt jams.

Component Inspection

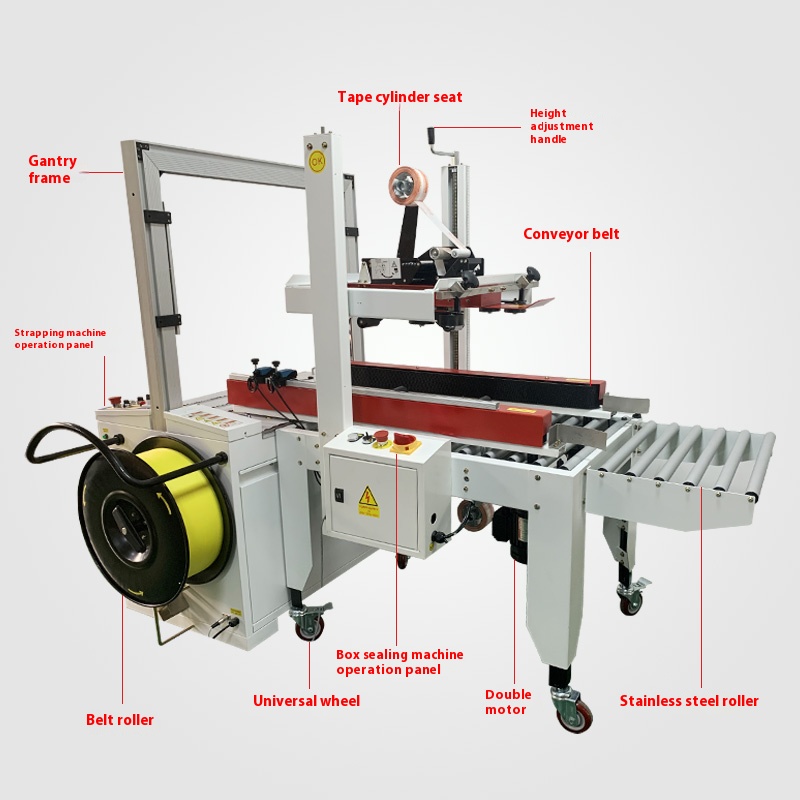

Check whether there are any looseness or wear phenomena at the joints and connections of the robotic arm. Tighten the loose screws and nuts in a timely manner, and replace the severely worn components. At the same time, check whether the movements of the robotic arm are flexible. If there is any 卡顿 (stuck) or abnormality, promptly investigate the cause and carry out repairs.

Check whether components such as the adhesive tape rollers and pressure wheels of the carton sealing mechanism rotate flexibly. If there is any sticking, clean or replace the bearings in a timely manner. Check whether the cutting blade of the carton sealing adhesive tape is sharp. If the blade is severely worn, replace it promptly to ensure that the adhesive tape is cut neatly during carton sealing.

Check the wear condition of components such as the strapping belt feeding wheels, tightening wheels, and cutting knives of the strapping mechanism to ensure that the strapping belt can be smoothly fed, tightened, and cut. If the strapping belt slips during the feeding process, adjust the pressure of the feeding wheels in a timely manner or replace the worn wheel grooves.

Check whether the surface of the sensor is covered with dust or stains. If so, clean it in a timely manner to ensure that the sensor can accurately detect parameters such as the position and size of the carton. At the same time, check whether the installation position of the sensor is loose. If it is loose, fix it in a timely manner to ensure its detection accuracy.

Lubrication and Maintenance

Regularly lubricate all transmission components of the equipment, such as the joints of the robotic arm, belt transmission devices, chain transmission devices, etc. Apply an appropriate amount of lubricating oil or grease to the corresponding parts, which can reduce the friction between components, decrease wear, and extend the service life of the equipment.

For some moving components in the carton sealing mechanism and strapping mechanism, such as rollers and bearings, also lubricate them regularly to ensure their flexible rotation. However, be careful to avoid the lubricating oil dripping onto the packaging materials or products to prevent contamination.

Electrical System Inspection

Check whether the power cord of the equipment has any damage, aging, or other phenomena. If so, replace it in a timely manner to prevent electric leakage accidents. At the same time, check whether the power plug and socket are in good contact to avoid equipment failures caused by poor contact.

Regularly check whether there are any signs of overheating or burning of the electrical components in the electrical control box of the equipment. If there is any abnormality, promptly investigate the cause and carry out repairs or replacements. Check whether the connection wires of each electrical component are firm. If they are loose, tighten them in a timely manner to prevent electrical failures caused by poor contact.

Clean the dust in the electrical control box to prevent excessive dust accumulation from affecting heat dissipation and causing electrical short circuits. You can use tools such as a hair dryer or a vacuum cleaner for cleaning, but be careful not to touch the electrical components during the cleaning process.

Control System Maintenance

Regularly back up the control system programs and parameters of the equipment to prevent data loss due to unexpected situations. At the same time, check whether the software version of the control system is the latest version. If there is an update, you can upgrade it according to the recommendations of the equipment manufacturer to improve the performance and stability of the equipment.

Check whether the touch screen of the operation interface is sensitive. If there are problems such as unresponsive touch or mis-touch, carry out calibration or repairs in a timely manner. Keep the operation interface clean and avoid placing sharp objects or heavy objects on it to prevent damage.

Consumables Inspection

Regularly check the quantity of cartons stored in the paper supply mechanism and replenish the cartons in a timely manner to avoid equipment shutdown due to running out of cartons. At the same time, check the quality of the cartons. If there are situations such as deformation or damage to the cartons, replace them in a timely manner to avoid affecting the carton sealing effect.

Check the remaining quantity of the adhesive tape and strapping belt, and replace the used adhesive tape rolls and strapping belt rolls in a timely manner. Select adhesive tapes and strapping belts with good quality and that meet the requirements of the equipment to ensure the packaging quality and the normal operation of the equipment.

By implementing the above daily maintenance precautions, it is possible to effectively ensure the stable performance of the carton sealing and strapping integrated machine, extend the service life of the equipment, improve work efficiency, and reduce production delays and cost increases caused by equipment failures